Abstract

Electrochemical experiments have an increasing demand for determining the concentration of biological and environmental samples as simple, inexpensive, and rapid analytical methods. Most developments in electroanalytical chemistry in recent years have originated from advances in sensor design, chemical modification, and functionalization of electrodes for enhanced sensitivity and selectivity of electroanalysis. In this work, a novel method for the fast monitoring of a thiol compound in flow injection systems has been developed. The fast Fourier transform continuous cyclic voltammetry at carbon paste electrode in flowing solution system was used for the determination of a thiol compound. The suggested technique demonstrated some advantages over other reported methods. Picomolar detection limit that is fast enough for the determination of any thiol compound was achieved. The linearization equation was current = 24.601x + 3.7068, with the correlation coefficients of 0.9812. The obtained detection limit was calculated to be 14.80 × 10−14 mol thiocholine (thiol compound sample). This system offers the necessary accuracy, sensitivity, and selectivity to assay a thiol compound in various sensors.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Most developments in electroanalytical chemistry in recent years have originated from advances in sensor design, chemical modification, and functionalization of electrodes for enhanced sensitivity and selectivity of electroanalysis. Organophosphorous (OP) compounds are highly toxic that often causes respiratory paralysis and death and can irreversibly inhibit acetylcholinesterase (AChE) which is essential for the central nervous system. Therefore, the rapid, sensitive, selective, and reliable quantification of these compounds is highly essential at a lower cost. Chromatographical techniques have been extensively used for the sensitive detection of OP insecticides, but they require trained staff, complicated sample pretreatments, and are often not suitable for field conditions. In recent years, biosensors show remarkable advances for the detection of toxic compounds based on enzymatic reactions. A variety of enzymes such as organophosphorous hydrolase, alkaline phosphatase, ascorbate oxidase, tyrosinase, and acid phosphatase have been employed in the preparation of pesticide biosensors [1]. Based on the inhibition action of pesticides and insecticides on cholinesterases, AChE and butyrylcholinesterase have been widely used due to the stability and sensitivity of the enzymes [2]. This method generally uses either single enzyme [3] or bienzyme (AChE and choline oxidase) [4] systems by monitoring the electrochemical oxidation of thiocholine or p-aminophenol and hydrogen peroxide, respectively. Some of the reports on immobilized AChE-based single enzyme system apply voltages of +400 to +700 mV for the oxidation of thiocholine [5].

Traditional methods to detect thiocholine involve spectrophotometric techniques [6]. The Ellman reaction involves the reaction of 5,5′-Dithiobis(2-nitrobenzoic acid) and 5-thio-2-nitrobenzoate (DTNB) with thiocholine liberated from its esters by enzymatic hydrolysis so the yellow 5-thio-2-nitro-benzoate product is measured spectrophotometrically at 412 nm. The thiocholine also generates a highly fluorescent product with 7-diethylamino-3-(40-maleimidylphenyl)-4-methylcoumarin, which is monitored by microfluorometric assay to detect nanomoles of released thiocholine as thiol compound. In AChE-based biosensors, acetylthiocholine is commonly used as a substrate. The thiocholine produced during the catalytic reaction can be monitored using spectrometric, amperometric, or potentiometric methods. The enzyme activity is indirectly proportional to the pesticide concentration.

AChE can be immobilized on electrode surface using a variety of matrices such as cross-linked polymers, cross-linked bovine serum albumin [7], chitosan and cellulose [8], different support matrices such as nylon [9], controlled pore glass [10], magnetic particles [11], or the strong affinity linking with concanavalin A and metal ions [12].

Carbon paste electrode (CPE) is a special kind of heterogeneous carbon electrode consisting of mixture prepared from carbon powder and a suitable water-immiscible or nonconducting binder [13, 14]. CPEs are widely applicable in both electrochemical studies and electroanalysis, thanks to their advantages such as ease and speed of preparation and of obtaining a new reproducible surface, very low background current (compared to solid graphite or noble metal electrodes), low cost, large potential window, and simple surface renewal process. The level of background currents cannot be exactly defined; it strongly depends on the composition of carbon paste as well as upon the type of measurement. For instance, in stripping voltammetry, carbon pastes containing Nujol or silicone oil exhibit background currents of about 10 to 500 nA. Whereas the background of tricresyl phosphate-based CPE may exceed the level of microampere due to unique interactions of the binder [15]. Besides the advantageous properties and characteristics listed before, the feasibility of incorporation of different substances during the paste preparation (which results in the so-called modified carbon paste electrode) allows the fabrication of electrodes with desired composition and, hence, with predetermined properties [16, 17].

The modification of electrodes using redox modifiers is an interesting field in analytical chemistry. Redox modifiers are electroactive compounds that effectively shuttle electrons between the analyte and the electrode. One of the most important effects of any modifier is a reduction of the overpotential required for electrochemical reaction, which enhances the sensitivity and selectivity of the method. Carbon nanotubes (CNTs) are new kinds of carbon nanostructure materials possessing properties such as high electrical conductivity, high surface area, chemical stability, and significant mechanical strength. CNTs have demonstrated to be extremely useful for the development of new electrode materials. Their electrocatalytic properties have been widely demonstrated in connection with several compounds of clinical, biological, and environmental interest [18]. Also, the application of chemically modified electrodes in electroanalysis offers several advantages. They can lower the overpotential, increase the reaction rate and sensitivity, and improve selectivity [19].

Recently, stripping voltammetric methods were used in the determination of heavy metal ions and some organic compounds in flowing solutions with a parts-per-billion sensitivity range. Indeed, application of such techniques needs fast analyte accumulation and fast potential sweeping, which is not appropriate for large electrodes [20]. Nonetheless, this study aims to present a novel method for the rapid determination of thiocholine in ultratrace amounts.

Stripping voltammetric techniques have the advantages of being both rapid and economical in the determination of thiols in aqueous systems, with sensitivity for trace amounts. In fact, because of the passage of an analyte through the zone in front of the electrode in an electrochemical flow cell, the application of such techniques in flowing solutions requires fast accumulation of the analyte and fast potential sweeping, which is not appropriate in traditional voltammetry but is applicable in fast Fourier transform (FFT) voltammetry.

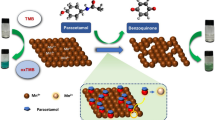

In this work, the proposed biosensor based on the immobilization of AChE on MWCNT-silicate sol composite showed high sensitivity for thiocholine which could be employed for flow injection analysis of OPs. The objective of this paper is the presentation of the Fourier transform continuous cyclic voltammetry (FFTCCV) technique for the determination of thiocholine through a flow injection system. The combination of biosensors with flow injection analysis makes it possible to control all the stages of the reagent additions, measure the enzyme activity, improve the sample throughput, and achieve the completely automated determination.

Results and discussion

Electrochemical behavior of system

The cyclic voltammograms of 1.0 mM acetylthiocholine (ATCh) are shown in Figure 1. Thiocoline (TCh) was injected to the flow system and showed an oxidation peak at +310 mV, while no detectable signals were observed at phosphate buffer saline (PBS) solution contain enzyme. In Figure 1A, it did not show any detectable response in the absence of TCh. Obviously, the peak came from the oxidation of thiocholine.

In this system, the stability of the background was the most essential problem. This was mainly due to the changes that occurred in the electrode surface during the oxidation and reduction of the thiocholine in each potential cycle. The best potential waveform, producing a stable background and an unchanged electrode surface, was the waveform displayed in Figure 2. Figure 3 presents an example of this waveform. Figure 3b shows the cyclic voltammetry (CV) sequences recorded during the flow analysis of 50 μL 1 mM thiocholine into the eluent solution, containing phosphate buffer (0.1 M and pH 7.4). The potential axis of this graph represents the potential applied to the working electrode during each sweep. The time axis represents the time passing between the beginning of the flow injection experiment and the beginning of a particular sweep. As can be observed, in the absence of thiocholine, the shape of the CV curves is typical for phosphate buffer (0.1 M and pH 7.4).

Cyclic voltammograms and Curves result (A) Cyclic voltammograms at carbon nanotube paste electrode recorded during a flow injection experiment. The eluent was phosphate buffer (0.1 M and pH 7.4), the flow rate was 3mL/min, and the sweep rate was 10 V.s-1. Each scan was preceded by 100 ms (at 1600 mV) and 200 ms (at 300 mV) conditioning, respectively. The injected solution (50 µL) contained 1 mM thiocholine. (B) Curves result from the subtraction of a CVs average (in the absence of the analyte) from test of the CVs in (A).

Figure 3a,b illustrates the absolute current changes in the CV curves, after the subtraction of background current. As can be seen, this way of presentation of the electrode response gives more details about the effect of adsorbed ion on currents of the CV. The curves show that current changes mainly take place at the potential regions of the oxidation and reduction of thiocholine. While the electrode-solution interface is exposed to thiocholine, the oxidation of TCh will be occurring. For the achievement of the detector maximum performance, the effect of the experimental parameters (such as the pH of the supporting electrolyte, and the sweep rate) were examined and optimized.

Sweeping rate effect

An acetylthiocholine concentration of 750 μM was used for the investigation of the sweeping rate effect. The detector responses to the potential sweep rates were recorded at different sweep rates in the range of 4 to 20 V s−1. The result was shown in Figure 4, where it is clear that the detector exhibits the maximum sensitivity at the sweep rate value of 10 V s−1. It should be mentioned that the sweep rate effects influence the detection performance in two ways. The first influence concerns the speed in data acquisition. The second influence concerns the kinetic factors of the thiocholine redox behavior. Also, the use of this detection method in conjunction with fast separation techniques such as capillary electrophoresis requires the employment of high sweep rates. From this point of view, it is important to check how the sensitivity of the method is affected by the sweep rate. In fact, to detect analyte on the electrode surface, high sweep rates must be employed to sense the correct concentration zone without any influence on kinetic of electron transferring. Nonetheless, the potential sweep rate is the determining factor which defines the sensitivity of the detection system, basically because of the kinetic factors and the instrumental limitations. In line with the resulting data for the examined thiocholine on the electrode, the height of the electrode response is almost constant within the experimental error for the sweep rates of 4 to 20 V s−1.

Calibration curve and detection limit

Figure 5 presents the calibration graph for the thiocholine monitoring in phosphate buffer (0.1 M and pH 7.4). The experimental conditions were set at the optimum values to obtain the lowest detection limits. It should be noted that, similar to the classical stripping voltammetric method, in the calculation method, the analyte response is proportional to the redox current of TCh. The redox reaction of TCh in different concentration makes different currents.

The linearization equation was current = 24.601x + 3.7068, with the correlation coefficients of 0.9812 (Figure 5). Measurements carried out for small analyte concentrations allow the estimation of the detection limit CDL:

where S b is the standard deviation (2.43%) of the baseline around the flow injection peak and m is the slope of calibration curve [21]. To ensure the best S/N ratio, the measurements were carried out at high sweep rates. The obtained detection limit was calculated to be 2.96 × 10−9 M and based on 50 μL of thiocholine injection 14.80 × 10−14 mol thiocholine. The detection limit of the proposed method is about 100 times lower than that of the most sensitive reported (3 × 10−7 M) method [22].

Conclusions

In this work, it is demonstrated that the concentration of thiocholine in flowing solution can be measured indirectly via monitoring the current changes at oxidation and reduction of the carbon nanotube paste electrode surface. In this method, the S/N ratio is enhanced using the fast Fourier transform of the analyte and signal integration. Also, for improving the sensitivity, the method takes advantage of the adsorption of the analyte on the electrode, and the influence of adsorbed possible impurity in the eluent was removed by background subtraction. FFTCCV can be considered as a new sensitive, accurate, and fast method for the determination of drugs and some pesticides. However, in order to obtain better sensitivity for a specific target, experimental parameters should be optimized. Finally, such detection limit (in nanomolar level) makes the method suitable for bioanalysis. The obtained detection limit was calculated to be 2.96 × 10−9 M and based on 50 μL of thiocholine injection 14.80 × 10−14 mol thiocholine.

Methods

Reagents

Multiwall carbon nanotubes with 95% purity, length 1 to 10 μm, external diameter 37 nm, and wall no. 3 to15 were obtained from Research Institute of Petroleum Industry, Iran. DTNB with 99% purity was supplied from Merck Company, Darmstadt, Germany. Triton X-100 was obtained from Sigma-Aldrich Chemicals Co., St. Louis, MO, USA. Acetylthiocholine chloride with 99% purity was purchased from Fluka, Dorset, England, UK. Dimethylformamide was obtained from Sigma. Acetylcholinesterase (EC: 3.1.1.7, type V-S: electric eel source, 500 U/0.5 mg) was purchased from Sigma. Ceramic cylinders with average length 1.8 mm, external diameter 1.9 mm, and internal diameter 1 mm were obtained from Tailor China Shop, Iran. Phosphate buffers with various pH values were prepared according to manual.

Flow injection setup part

In the flow system (Figure 6A), a peristaltic pump to impel solutions was used. The various system elements were connected with a silicon tube. The equipment for flow injection analysis included a ten-roller peristaltic pump (UltrateckLabs Co., Iran) and a four-way injection valve (Supelco Rheodyne Model 5020, Sigma) with a 50-μL sample injection loop. The solutions were introduced into the sample loop by means of a plastic syringe. The electrochemical cell used in flow injection analysis is shown in Figure 6B. The volume of the cell was 100 μL. In all experiments described in this paper, the flow rate of eluent solution was 3 mL/min. Flow system feed was phosphate buffered (0.1 M and pH 7.4).

Electrode preparation

For the preparation of the carbon nanotube paste electrode, a sampler head tube (5 cm in length) with the hole at one end (2 mm in diameter) was served for filling with carbon nanotube paste as the electrode body. Electrical contact was provided by a copper piston within the center of the tube. Carbon nanotube paste was prepared by adding 4.5 g paraffin oil to 1.25 g carbon nanotube powder and mixed for 20 min until a uniformly wetted paste was obtained. The paste was then packed into the hole of the electrode holder. For every five to seven experiment runs, a small amount of carbon nanotube paste was cut, and the electrode surface was polished for 1 min using a fine paper. The electrode was washed with water before being placed in the cell. Additionally, an Ag(s)/ AgCl(s)/ KCl (aq, 1 M) reference electrode was used for all measurements, while the auxiliary electrode was made of a Pt wire (1 cm in length and 0.5 mm in diameter, Figure 6B).

Standard solutions for flow injection analysis

A TCh (as thiol compound) standard stock solution was prepared in the phosphate buffer (0.1 M and pH 7.4). This solution was prepared by the enzymatic reaction of the AChE and ATChCl solution for 30 min in the phosphate buffer. The final concentration of TCh was determined by spectrophotometry after reaction with DTNB, as described by Ellman [23, 24]. Standard solutions of TCh and ATCh for studies were prepared by dilution of their stock solution with 0.1 M phosphate buffer.

Data acquisition and processing

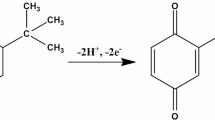

A setup of a PC PIII Pentium 300 MHz microcomputer, equipped with a data acquisition board (PCL-818HG, Advantech. Co., Milpitas, CA, USA), and a custom-made potentiostat comprised the equipment needed for the data acquisition and data processing. The corresponding programs were developed in Delphi 6 program environment. In Figure 2, the applied waveform potential diagram during the cyclic voltammetric measurements is shown. The waveform potential consists of two sections: first, the electrode conditioning and, second, the measurements (the section of accumulation of analyte was eliminated in this work and was not applied by instrument). The electrode conditioning starts with the cleaning process, in which the electrode potential is held at a positive potential, Ec1 (1,600 mV), at least for 100 ms. Then, for the reduction and desorption of any fouling component on the surface, it is held at the Ec2 potential (−400 mV) for 100 ms. Finally, the current measurements are performed during potential ramp. Signal calculation in this method is established based on the integration of net current changes over the scanned potential range. It must be noted that in this case, the current changes (result of injected analyte) at the voltammograms can be caused by redox processes of TCh, which take place at the electrode surface. Indeed, in order to see the influence of the change in the current of oxidation and reductions peaks of the electrode surface, the scan rate must be in optimum which is in correlation with redox kinetic and data acquisition. The starting point for the electrochemical oxidation process of the carbon nanotube paste electrode surface is as follows:

Abbreviations

- ATCh:

-

Acetylthiocholine

- CV:

-

Cyclic voltammetry

- FFTCCV:

-

Fourier transform continuous cyclic voltammetry

- TCh:

-

Thiocoline

- OP:

-

Organophosphorous compounds.

References

Trojanowicz M: Determination of pesticides using electrochemical enzymatic biosensors. Electroanalysis 2002, 14: 1311–1328.

Timur S, Telefoncu A: Acetylcholinesterase (AChE) electrodes based on gelatin and chitosan matrices for the pesticide detection. Artif. Cells Blood Substit. Immobil. Biotechnol. 2004, 32: 427–442.

Joshi KA, Tang J, Haddon R, Wang J, Chen W, Mulchandani A: A disposable biosensor for organophosphorus nerve agents based on carbon nanotubes modified thick film strip electrode. Electroanalysis 2005, 17: 54–58.

Lin Y, Lu F, Wang J: Disposable carbon nanotube modified screen-printed biosensor for amperometric detection of organophosphorus pesticides and nerve agents. Electroanalysis 2004, 16: 145–149.

Gogol EV, Evtugyn GA, Marty JL, Budnikov HC, Winter VG: Amperometric biosensors based on nafion coated screen-printed electrodes for the determination of cholinesterase inhibitors. Talanta 2000, 53: 379–389.

Cremisini C, Di Sario S, Mela J, Pilloton R, Palleschi G: Evaluation of the use of free and immobilised acetylcholinesterase for paraoxon detection with an amperometric choline oxidase based biosensor. Anal. Chim. Acta 1995, 311: 273–280.

Hendji AMN, Jaffrezic-Renault N, Martelet C, Clechet P, Shlu'ga AA, Strikha VI, Netchiporuk LI, Soldatkin AP, Wlodarski WB: Sensitive detection of pesticides using a differential ISFET-based system with immobilized cholinesterases. Anal. Chim. Acta 1993, 281: 3–11.

Bachmann TT, Schmid RD: A disposable multielectrode biosensor for rapid simultaneous detection of the insecticides paraoxon and carbofuran at high resolution. Anal. Chim. Acta 1999, 401: 95–103.

Pariente F, La Rosa C, Galan F, Hernández L, Lorenzo E: Enzyme support systems for biosensor applications based on gold-coated nylon meshes. Biosens. Bioelectron. 1996, 11: 1115–1128.

Lee H-S, Kim YA, Cho YA, Lee YT: Oxidation of organophosphorus pesticides for the sensitive detection by a cholinesterase-based biosensor. Chemosphere 2002, 46: 571–576.

Kindervater R, Künnecke W, Schmid RD: Exchangeable immobilized enzyme reactor for enzyme inhibition tests in flow-injection analysis using a magnetic device. Determination of pesticides in drinking water. Anal. Chim. Acta 1990, 234: 113–117.

Andreescu S, Barthelmebs L, Marty J-L: Immobilization of acetylcholinesterase on screen-printed electrodes: comparative study between three immobilization methods and applications to the detection of organophosphorus insecticides. Anal. Chim. Acta 2002, 464: 171–180.

Afkhami A, Madrakian T, Ghaedi H, Khanmohammadi H: Construction of a chemically modified electrode for the selective determination of nitrite and nitrate ions based on a new nanocomposite. Electrochim. Acta 2012, 66: 255–264.

Mazloum-Ardakani M, Sheikh-Mohseni MA, Abdollahi-Alibeik M, Benvidi A: Application of nanosized MCM-41 to fabrication of a nanostructured electrochemical sensor for the simultaneous determination of levodopa and carbidopa. Analyst 2012, 137: 1950–1955.

Švancara I, Schachl K: Testing of unmodified carbon paste electrodes. Chem Listy 1999, 93: 490–499.

Mazloum-Ardakani M, Beitollahi H, Amini MK, Mirjalili B-F, Mirkhalaf F: Simultaneous determination of epinephrine and uric acid at a gold electrode modified by a 2-(2,3-dihydroxy phenyl)-1, 3-dithiane self-assembled monolayer. J. Electroanal. Chem. 2011, 651: 243–249.

Mazloum-Ardakani M, Sheikh-Mohseni MA, Abdollahi-Alibeik M, Benvidi A: Electrochemical sensor for simultaneous determination of norepinephrine, paracetamol and folic acid by a nanostructured mesoporous material. Chem 2012, 171–172: 380–386.

Mazloum-Ardakani M, Beitollahi H, Ganjipour B, Naeimi H, Nejati M: Electrochemical and catalytic investigations of dopamine and uric acid by modified carbon nanotube paste electrode. Bioelectrochem 2009, 75: 1–8.

Goyal RN, Bishnoi S: A novel multi-walled carbon nanotube modified sensor for the selective determination of epinephrine in smokers. Electrochim. Acta 2011, 56: 2717–2724.

Kissinger PT, Heineman WR: Laboratory techniques in electroanalytical chemistry. New York: Marcel Dekker; 1996.

Norouzi P, Ganjali MR, Daneshgar P, Alizadeh T, Mohammadi A: Development of fast Fourier transformation continuous cyclic voltammetry as a highly sensitive detection system for ultra trace monitoring of penicillin V. Anal. Biochem. 2007, 360: 175–181.

Liu G, Riechers SL, Mellen MC, Lin Y: Sensitive electrochemical detection of enzymatically generated thiocholine at carbon nanotube modified glassy carbon electrode. Electrochem. Commun. 2005, 7: 1163–1169.

Ellman GL: A colorimetric method for determining low concentrations of mercaptans. Arch. Biochem. Biophys. 1958, 74: 443–450.

Ellman GL, Cotney KD, Andress V, Featherstone RM: A new and repid colorimetric determination of acetycholinesterase activity. Biochem. Pharmacol. 1961, 7: 88–95.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

All authors declare that they have no competing interests.

Authors' contributions

MBT and PD carried out the electrochemical studies. BEH and PN participated in the design of the study and performed the statistical analysis. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License ( https://creativecommons.org/licenses/by/2.0 ), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Barshan-Tashnizi, M., Ebrahimi-Hoseinzadeh, B., Daneshgar, P. et al. Trace detection of thiols with Fourier transforms cyclic voltammetry technique in flowing solutions. J Nanostruct Chem 3, 64 (2013). https://doi.org/10.1186/2193-8865-3-64

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2193-8865-3-64