Abstract

A method for the chemical synthesis of reduced graphene oxide has been developed. It is based on the chemical oxidation of multiwalled carbon nanotubes by means of heptavalent manganese with subsequent reduction. Sodium hypophosphite and sulfite were used as reductants. It has been confirmed by different methods that reduced graphene oxide is obtained. Current-potential curves for electrodes based on reduced graphene oxide in an oxygen fuel cell mock-up with alkaline electrolyte have been studied. It has been found that the characteristics of the electrode of graphene oxide reduced with sodium hypophosphite in oxygen reduction reaction are three to four times higher than those of the electrode of starting multiwalled carbon nanotubes. The electrodes based on reduced graphene oxide are superior to multiwalled carbon nanotube-MnO2 composite in characteristics. The characteristics of oxygen electrodes based on reduced graphene oxide were stable during 6-month tests. The reduced graphene oxide obtained promises much as a material for the oxygen electrodes of electrochemical power sources.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

The use of air or oxygen electrode in devices generating electrical energy is very promising since it does not give rise to environmental problems and makes it possible to save natural resources, such as oil and gas. Air and oxygen electrodes in current sources are a three-phase electrode-electrolyte-gas system, where the electric current generation processes are localized at the interface between these phases. The current magnitude generated at such a gas diffusion electrode depends on the size of the zone of the triple contact of these three phases. The electrode consists of a catalyst and a support; the interaction between them determines mainly the value of generated current. Platinum is at present the most efficient oxygen reduction catalyst, but it has a considerable demerit - high price. There are a large number of papers dealing with the investigation of other efficient catalysts [1]. Another important problem is catalytically active and stable support. The advantage of carbon nanotubes as a catalyst support is shown in [2–5]. At the present time, in view of the advent of a new carbon nanomaterial such as graphene, a number of papers have appeared which deal with its investigation as an electrode material for lithium-ion batteries [6] and as a support for catalysts in fuel cells [7–11]. Graphene is an atom-thick carbon layer, which consists of condensed six-membered rings.

The carbon atoms in graphene are bonded by sp2 bonds into a hexagonal two-dimensional lattice. Ideal graphene consists solely of six-membered rings; the appearance of defects leads to the formation of a number of five- or seven-membered rings in the graphene structure and hence to the curving of flat surface. At the same time, the extended π-system of conjugated aromatic rings makes graphene fairly stable in comparison with other nanosized objects. The structure peculiarities of graphene sheet are such that the charge carriers, having unlimited freedom to move in-plane, are confined in a narrow space between ‘walls’ (Figure 1), which are approximately 0.3 nm (the shortest atomic distance) apart, which gives rise to unique electrophysical characteristics and other extraordinary properties of graphene.

In view of this, the study of the dependence of electrochemical properties on the method for the preparation of reduced graphene oxide (RGO), which is used as a catalyst support for fuel cell oxygen electrodes, is of great interest.

Results and discussion

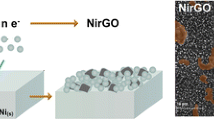

To synthesize oxidized graphene, a modified Hammers method [12, 13] using multiwalled carbon nanotubes (MCNTs) with a bulk density of 25 to 30 g/dm3, purified of catalyst impurities by treatment with a hydrofluoric acid solution, was employed. The outside diameter of nanotubes was approximately 10 to 30 nm, and the specific surface area was 126 m2/g (determined by the BET method).

One gram of MCNTs was dispersed for 1 h by stirring in 300 mL of concentrated sulfuric acid. Then 5 g of KMnO4 was added under stirring for 1 h at a temperature of not over 17°C. After that, the mixture was heated on a water bath to 55°C for 30 min and held for 1 h. Then the temperature of the solution was brought to 65°C, and it was left to cool to room temperature. To prevent the formation of manganese dioxide, the resulting mixture was diluted in 400 mL of bidistilled water with ice, which contained 5 mL of 30% H2O2. Then the diluted mixture was filtered on a fine paper filter. The filtered off precipitate was dispersed in bidistilled water.

A typical reductant for graphene oxide is hydrazine [12, 14–16], whose standard redox potential of electrochemical reaction in the alkaline solution (1) E = −1.16 V [17]. It follows that reductants with close redox potentials can be used for the reduction of graphene oxide. Such reductants can be hypophosphite (2) (E = −1.51 V) and sulfite (3) (E = −0.936 V) [17]. These reductants are nontoxic, which is their advantage.

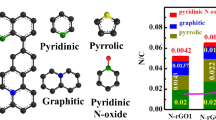

Two samples were selected for reduction. One sample of oxidized product was reduced with 0.14 mol of an alkaline solution of sodium hypophosphite (pH = 11) and the other with 0.14 mol of an alkaline solution of sodium sulfite (pH = 11). The reduced substance was filtered off on a fine paper filter, after which it was separated from the filter and dried in a desiccator at 140°C for 3 h. The solid filtrate has been investigated by electron microscopy and an X-ray phase analysis. The diluted solution of reduced graphene oxide has been investigated by spectral photometry. Figure 2 shows X-ray diagrams of products obtained by reduction with sodium hypophosphite (Figure 2a) and sodium sulfite (Figure 2b). In the X-ray diffraction (XRD) pattern of RGO (which is exfoliated into individual platelets and then agglomerated into a powder form), the major peak is observed at about 23° to 24° [14]. This gives an interlayer spacing of approximately 3.7 to 3.8 Å [14, 18, 19]. Figures 3 and 4 show micrographs of RGO, which was obtained using different reductants. Figure 5 shows an absorption spectrum (1-cm path length) of an alkaline dispersion (pH = 1) of RGO in the range 200 to 800 nm. As can be seen, the absorption peak of RGO dispersion is in the range of 231 to 270 nm [20–28]. One main peak at approximately 250 nm comes from the π-π* transition of C-C and C=C bonds in sp2 hybrid regions, and a shoulder peak at approximately 300 nm is due to the n-π* transition of the C=O bond in sp3 hybrid regions [25, 29, 30]. Figure 6 shows fluorescence emission spectra (1-cm path length) of a RGO dispersion in an alkaline medium (pH = 11) with the excitation wavelength λ = 285 to 400 nm. The fluorescence peaks lie in the short-wavelength region (λ = 430 to 450 nm), which corresponds to the aqueous dispersion of RGO [23–25, 31].

Thus, when studying absorption spectra and photoluminescence spectra of RGO dispersion, analyzing electron micrographs, and comparing peaks in X-ray diagrams with literature data, it may be concluded that RGO nanosheets can be fabricated by the above procedure.

Oxygen electrodes, where RGO was used as an active layer, have been made by pressing. The electrodes obtained were investigated on an oxygen fuel cell mock-up with alkaline electrolyte. Electrodes with an active layer of starting MCNTs have been made for comparison.

On the oxygen electrodes made, current-potential curves were measured. Figure 7 shows plots of potential against current density for oxygen electrodes based on graphene oxide reduced with sodium hypophosphite (RGO-SH; curve 1 in Figure 7) and graphene oxide obtained by reduction with sodium sulfite (curve 2 in Figure 7). In this figure, characteristics of electrodes with starting MCNTs are presented for comparison (curve 3). As is seen from Figure 7, RGO-SH-based electrodes give the best results.

It has been found that the characteristics of the RGO-SH electrode in oxygen reduction reaction are three to four times higher than those of the electrode of starting MCNTs. RGO-based electrodes are also superior to MCNT-MnO2 nanocomposite in characteristics, which follows from comparison with the data presented in [2]. The characteristics of RGO-based oxygen electrodes were stable in the course of 6-month tests.

Conclusions

The proposed procedure for the reduction of graphene oxide allows one to obtain highly efficient materials for the oxygen electrodes of electrochemical power sources. The synthesis procedure is simple and does not require the use of highly toxic reagents.

Methods

Preparation of reduced graphene oxide

MCNTs were chosen as a precursor, for they resemble, in structure, several graphene layers rolled into a tube; therefore, using a strong oxidant, one can ‘break’ nanotubes to form oxidized graphene nanostrips [12]. To this end, a procedure for the oxidation of MCNTs with heptavalent manganese [12] with subsequent reduction was chosen. We used alkaline solutions of sodium hypophosphite and sodium sulfite as oxidized-graphene reductants [32, 33].

Electrochemical measurements

Two-layer oxygen electrodes were prepared by pressing. The hydrophobic layer contained 0.07 g/cm2 acetylene black with 25% polytetrafluoroethylene, and the active layer contained 0.02 g/cm2 RGO, with 5% polytetrafluoroethylene. The investigations were carried out on a fuel cell mock-up, a zinc electrode being used as the anode. A mock-up for the testing of gas diffusion electrodes is described in [34]. The electrolyte was a solution of 5 M KOH with 1 M LiOH. A silver chloride electrode connected through a salt bridge was used as a reference electrode. The electrochemical characteristics were recorded under galvanostatic conditions. The oxygen source was a U-shaped electrolyzer with alkaline electrolyte. Oxygen was supplied to the gas electrodes under an excess pressure of 0.01 MPa. Before measurements, the oxygen electrode was blown through with oxygen for an hour. The electron micrographs have been obtained with the aid of a JEM-100 CXII electron microscope (JEOL Ltd., Akishima-shi, Japan). The X-ray phase analysis was performed with the aid of a DRON-4 X-ray diffractometer with CuKα radiation (Bourevestnik, Inc., Saint Petersburg, Russia). The electronic absorption spectra were recorded on a PerkinElmer UV/VIS Lambda 35 spectrophotometer (Waltham, MA, USA) and the fluorescence spectra on a PerkinElmer LS 55 spectrophotometer in a range of 300 to 700 nm.

References

Bidault F, Brett D, Middleton P, Brandon N: Review of gas diffusion cathodes for alkaline fuel cells. J. Power Sources 2009, 187: 39–48.

Soehn M, Lebert M, Wirth T, Hofmann S, Nicoloso N: Design of gas diffusion electrodes using nanocarbon. J. Power Sources 2008, 176: 494–498.

Danilov M, Melezhyk A: Carbon nanotubes modified with catalyst—promising material for fuel cells. J. Power Sources 2006, 163: 376–381.

Hsieh C, Lin J, Wei J: Deposition and electrochemical activity of Pt-based bimetallic nanocatalysts on carbon nanotube electrodes. Int. J. Hydrogen Energy 2009, 34: 685–693.

Wang X, Waje M, Yan Y: CNT-based electrodes with high efficiency for PEMFCs. Electrochem. Solid-State Lett. 2005, 8: A42-A44.

Wang G, Shen X, Yao J, Park J: Graphene nanosheets for enhanced lithium storage in lithium ion batteries. Сarbon 2009, 47: 2049–2053.

Xin Y, Liu J, Jie X, Liu W, Liu F, Yin Y, Gu J, Zou Z: Preparation and electrochemical characterization of nitrogen doped graphene by microwave as supporting materials for fuel cell catalysts. Electrochim. Acta 2012, 60: 354–358.

Lin Z, Waller G, Liu Y, Liu M, Wong C: Facile synthesis of nitrogen-doped graphene via pyrolysis of graphene oxide and urea and its electrocatalytic activity toward oxygen reduction reaction. Adv. Energy Mater. 2012, 2: 884–888.

Qu L, Liu Y, Baek J, Dai L: Nitrogen-doped graphene as efficient metal-free electrocatalyst for oxygen reduction in fuel cells. ACS Nano 2010, 4: 1321–1326.

Lin Z, Song M, Ding Y, Liu Y, Liu M, Wong C: Facile preparation of nitrogen-doped graphene as a metal-free catalyst for oxygen reduction reaction. Phys. Chem. Chem Phys. 2012, 14: 3381–3387.

Shao Y, Zhang S, Wang C, Nie Z, Liu J, Wang Y, Lin Y: Highly durable graphene nanoplatelets supported Pt nanocatalysts for oxygen reduction. J. Power Sources 2010, 195: 4600–4605.

Kosynkin D, Higginbotham A, Sinitskii A, Lomeda J, Dimiev A, Price B, Tour J: Longitudinal unzipping of carbon nanotubes to form graphene nanoribbons. Nature 2009, 458: 872–876.

Hummers W, Offeman R: Preparation of graphitic oxide. J. Am. Chem. Soc. 1958, 80: 1339.

Park S, An J, Potts J, Velamakanni A, Murali S, Ruoff R: Hydrazine-reduction of graphite- and graphene oxide. Carbon 2011, 49: 3019–3023.

Lee Y, Song M, Lee K, Kim I, Hwang S: Synthesis and electrochemical characterization of reduced graphene oxide-manganese oxide nanocomposites. J. Electrochem. Sci. Technol. 2011, 2: 1–7.

Pei S, Cheng H: The reduction of graphene oxide. Carbon 2012, 50: 3210–3228.

Steven G: Standard electrode potentials and temperature coefficients in water at 298.15 K. J. Phys. Chem. 1989, 18: 1–21.

Dubin S, Gilje S, Wang K, Tung V, Cha K, Hall A, Farrar J, Varshneya R, Yang Y, Kaner R: A one-step, solvothermal reduction method for producing reduced graphene oxide dispersions in organic solvents. ACS Nano 2010, 4: 3845–3852.

Moon I, Lee J, Ruoff R, Lee H: Reduced graphene oxide by chemical graphitization. Nat. Commun. 2010. 10.1038/ncomms1067

Krishnamoorthy K, Veerapandian M, Mohan R, Kim S: Investigation of Raman and photoluminescence studies of reduced graphene oxide sheets. Appl. Phys. A 2012, 106: 501–506.

Wang G, Wang B, Park J, Yang J, Shen X, Yao J: Synthesis of enhanced hydrophilic and hydrophobic grapheme oxide nanosheets by a solvothermal method. Carbon 2009, 47: 68–72.

Sun Z, Popa D, Hasan T, Torrisi F, Wang F, Kelleher E, Travers J, Nicolosi V, Ferrari A: A stable, wideband tunable, near transform-limited, graphene-mode-locked, ultrafast laser. Nano. Res. 2010, 3: 653–660.

Eda B, Lin Y, Mattevi C, Yamaguchi H, Chen H, Chen I, Chen C, Chhowalla M: Blue photoluminescence from chemically derived graphene oxide. Adv. Mater. 2010, 22: 505–509.

Loh K, Bao Q, Eda G, Chhowalla M: Graphene oxide as a chemically tunable platform for optical applications. Nat. Chem. 2010, 2: 1015–1024.

Shang J, Ma L, Li J, Ai W, Yu T, Gurzadyan G: The origin of fluorescence from graphene oxide. Sci. Reports 2012. 10.1038/srep00792

Hu Y, Wang K, Zhang Q, Li F, Wu T, Niu L: Decorated graphene sheets for label-free DNA impedance biosensing. Biomaterials 2012, 33: 1097–1106.

Li D, Muller M, Gilje S, Kaner R, Wallace G: Processable aqueous dispersions of graphene nanosheets. Nat. Nanotech. 2008, 3: 101–105.

Galande C, Mohite A, Naumov A, Gao W, Ci L, Ajayan A, Gao H, Srivastava A, Weisman R, Ajayan P: Quasi-molecular fluorescence from graphene oxide. Sci. Reports 2011. 10.1038/srep00085

Cuong T, Pham V, Tran Q, Hahn S, Chung J, Shin E, Kim E: Photoluminescence and Raman studies of graphene thin films prepared by reduction of graphene oxide. Mater. Lett. 2010, 64: 399–401.

Luo Z, Lu Y, Somers L, Johnson A: High yield preparation of macroscopic graphene oxide membranes. J. Am. Chem. Soc. 2009, 131: 898–899.

Chien C, Li S, Lai W, Yeh Y, Chen H, Chen I, Chen L, Chen K, Nemoto T, Isoda S, Chen M, Fujita T, Eda G, Yamaguchi H, Chhowalla M, Chen C: Tunable photoluminescence from graphene oxide. Angew. Chem. Int. Ed. 2012, 51: 6662–6666.

Danilov M, Kolbasov G, Rusetskii I, Slobodyanyuk I: Electrocatalytic properties of reduced graphene oxide in oxygen electrode [abstract]. ABAF 2012, 13: 18.

Danilov M, Kolbasov G, Rusetskii I, Slobodyanyuk I: Electrocatalytic properties of reduced graphene oxide in oxygen electrode. 13th International Conference, August 2012; Brno. In ABAF'2012: Advanced Batteries, Accumulators and Fuel Cells. Brno: Brno University of Technology; 2012:17–22.

Danilov M, Kolbasov G, Rusetskii I, Slobodyanyuk I: Electrocatalytic properties of nanocomposites for electrochemical power sources from the standpoint of localization of reactions. ECS Trans. 2012, 40: 133–137.

Acknowledgements

The authors are most grateful to the STCU (no. 5335) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

MOD carried out the electrochemical investigations and drafted the manuscript, IAS carried out the synthesis of reduced graphene oxide, IAR carried out the electronic absorption spectra, and GYK carried out the XRD characterization of samples and rechecked the whole manuscript. All authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Danilov, M.O., Slobodyanyuk, I.A., Rusetskii, I.A. et al. Reduced graphene oxide: a promising electrode material for oxygen electrodes. J Nanostruct Chem 3, 49 (2013). https://doi.org/10.1186/2193-8865-3-49

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2193-8865-3-49