Abstract

Background

Ionic liquids have found uses in many applications, one of which is the joint solvation and catalysis of chemical transformations. Suitable Brønsted acidic ionic liquids can be formed by combining lactams with sulphonic acids. This work weighs up the relative benefits and disadvantages of applying these Brønsted acidic ionic liquid catalysts in esterifications through a series of comparisons using green chemistry metrics.

Results

A new bio-based ionic liquid was synthesised from N-methyl pyrrolidinone and p-cymenesulphonic acid, and tested as a catalyst in three Fischer esterifications under different conditions. An evaluation of the performance of this Brønsted acidic ionic liquid was made through the comparison to other ionic liquid catalysts as well as conventional homogeneous Brønsted acids.

Conclusion

Extending the argument to feedstock security as well as mass utilisation, ultimately in most instances traditional mineral acids appear to be the most sensible option for Brønsted acid esterification catalysts. Ester yields obtained from Brønsted acidic ionic liquid catalysed procedures were modest. This calls into question the diversity of research exploring esterification catalysis and the role of ionic liquids in esterifications.

Similar content being viewed by others

Background

Esters are useful products for a variety of applications, including plastics, fragrances and pharmaceuticals. The least complicated and most useful of several esterification methodologies is the Fischer esterification, which requires an acid catalyst, and in the case of solid reactants often a solvent as well. Fischer esterification combines a carboxylic acid and an alcohol to produce the desired ester, and water as the only by-product. Popular catalysts are the familiar Brønsted acidic mineral acids and Lewis acidic transition metal salts, but supported catalysts (including enzymes) and recyclable heterogeneous solid acids are becoming increasing popular because of the influence of green chemistry [1, 2]. Other methods of esterification may employ nucleophilic catalysts or stoichiometric activators, and as such are harder to justify except for the most unreactive substrates. Applying the philosophy of green chemistry to esterification, the use of equimolar quantities of each reactant to give 100% conversion, whilst minimising unnecessary VOC emissions, is desirable. Recycling of the catalyst and any solvent would then result in minimal waste. Nevertheless all auxiliary species should be sustainable, present low toxicity and health concerns, as well as effective in assisting the transformation.

Given the choice of available esterification protocols, metrics should be used to clarify the performance of a reaction relative to the context established by alternative routes to the same ester product. Yield is the most prevalent calculation of reaction efficiency, and will always be regarded as the primary means of determining if a reaction is successful in providing the desired result. But to fully understand the implications of choosing a certain esterification protocol over another, a more detailed analysis is certainly required. The following metrics impart an appreciation of material use extending beyond just the conversion of reactants to the product (Table 1). Atom economy (AE) is defined by the reaction stoichiometry and so favours Fischer esterification over more elaborate methodologies. Atom economy does not change when a particular product is made from different protocols so long as the reactants remain the same [4]. Reaction mass efficiency (RME) offers more precision in recording the utilisation of reactants than that implied by yield, but RME still does not encompass auxiliary species such as solvents. Process mass intensity (PMI), related to E-factor, has been chosen by the American Chemical Society Green Chemistry Institute’s Pharmaceutical Roundtable as the key mass-based metric [6]. As the ratio between input and useful mass output, solvents and catalysts are now accountable. By taking its inverse, PMI can be interpreted as a percentage that allows a comparison with RME and yield metrics. The name general reaction mass efficiency (gRME) has been given to the inverse of PMI [7].

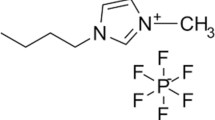

A new approach to Fischer esterification, developed to minimise waste, utilises Brønsted acidic ionic liquids [8]. The first benefit of these ionic liquids is the joint catalysis and solvation offered onto the reactants. This has been realised with high loadings of acidic ionic liquids (typically 25 mol%) applied at room temperature in otherwise solvent-free systems [9]. Whether these quantities adhere to the definition of solvent or not is debatable. Although described as solvents in the literature, at sub-stoichiometric loadings perhaps lubricant is a better descriptor of the role of these catalytic Brønsted acidic ionic liquids. The acidity of the ionic liquid may originate from a pendant sulphonic acid group on the cation, or the salt may be formed by the protonation of a lactam by a strong acid, while the resulting conjugate base acts as the anion (Scheme 1). Ionic liquids of the latter type, formed by the protonation of N-methyl pyrrolidine (NMP) have been demonstrated to assist several types of reaction including esterifications [10–12]. Although strictly speaking an acid–base equilibrium is unavoidable, the combination of NMP and a strong acid will be assumed to result wholly in the ionic product. The pKa values of protonated amides and arylsulphonic acids can differ by about 3 so this is a reasonable approximation under these circumstances.

A crucial advantage of Brønsted acidic ionic liquids as esterification catalysts is that after a reaction performed at room temperature, an organic phase consisting of the ester product is often found to separate from the ionic liquid phase (Table 2). Any water and the remaining reactants remain in the ionic liquid phase while the ester can be removed as a pure component. High conversion under usually equilibrium limited conditions is possible because of this phase separation (Figure 1). Although high yields have been achieved with Brønsted acidic ionic liquid catalysts, a poor esterification yield is equally as common (Table 2). As a result, the catalytic reaction medium is potentially recyclable. The benefit of mild reaction conditions helps justify the method on the grounds of green chemistry. However not all reactions can be performed at room temperature. To reduce the very high catalyst loadings that are usually applied, an elevated temperature is necessary. Unfortunately these protocols then mirror the typical reaction conditions (e.g. 1 mol% sulphuric acid and an auxiliary organic solvent at 323–384 K) that the new system is meant to improve on. Also of note is the lack of a biphasic reaction system when employing the ionic liquid made from triethylamine and p-toluenesulphonic acid. Before any Brønsted acidic ionic liquid is adjudged to be an optimal solution, metrics must extend to encompass the synthesis of the catalyst to gain a greater appreciation of the environmental impact of the reaction.

Results and discussion

Brønsted acidic ionic liquids were created from the reaction between NMP and Brønsted acids according to the literature protocol [10]. It was felt necessary to consider the origins of the ingredients in making these ionic liquids to preserve the sustainability of the esterification methodology that is reliant on them as catalysts. A route to bio-based NMP has recently been described in the literature using the amino acid glutamic acid as the primary feedstock (Figure 2) [18]. Although sources of glutamic acid in food waste are abundant and renewable [19], the suggested one-pot synthesis from 4-aminobutyric acid onto NMP is currently less than 40% efficient after a nearly quantitative enzymatic decarboxylation [18, 20]. An alternative approach would be to recreate the existing manufacturing process for NMP [21], but replace the natural gas feedstock with the product of anaerobic digestion (Figure 2) [22]. This would lend some promise to the longevity of NMP production if it were not for legislative action based on product toxicity [23]. Issues with NMP are explained in more detail in the Additional file 1 that accompanies this article.

For the choice of ionic liquid anion, sulphuric acid or sulphonic acids can be used to protonate NMP. Sulphuric acid is produced via the oxidation of sulphur to sulphur trioxide in the contact process before hydration [24]. A significant amount of contemporary sulphur production relies on the hydrogen sulphide released with natural gas drilling operations [25]. The electrophilic substitution reaction between toluene (another product of the oil refinery) and either sulphuric acid or sulphur trioxide yields p-toluenesulphonic acid (p-TSA), another potential Brønsted acidic ionic liquid anion precursor [26]. There are however alternative renewable sources of chemicals suitable for making more environmentally sustainable Brønsted acidic ionic liquids. The large quantities of citrus waste accumulating annually around the world make value adding applications an attractive enterprise. Globally orange waste far exceeds 10 million tonnes per year [27]. The essential oil of these oranges consists almost entirely of (R)-(+)-limonene [28], henceforth referred to simply as limonene, from which the key commodity chemical product p-cymene can be made [29]. Although known for over a century [30, 31], the sulphonic acid of p-cymene, namely p-cymene-2-sulphonic acid (p-CSA), has only very recently been used as an acid catalyst to replace p-TSA [32, 33]. Similarly p-CSA can replace p-TSA in the synthesis of Brønsted acidic ionic liquids. Therefore the combination of NMP and p-CSA to make a renewable ionic liquid, namely [H-NMP][OCym] where OCym represents the conjugate base of p-CSA, is a potentially sustainable replacement for current options touted in the literature (Scheme 2). Both cation and anion are ultimately sourced predominately from waste streams and so the environmental impact of this Brønsted acidic ionic liquid, at least from a resource depletion point of view, need not be significant [34, 35]. Of course sulphuric acid and its downstream products are unsustainable because of the origin of sulphur is petrochemical, but presently certification of bio-based products is only reliant on the proportion of bio-based carbon atoms found in the final article [36, 37].

As with examples of equivalent syntheses in the literature, an auxiliary solvent was used to make the Brønsted acidic ionic liquids. For this work dichloromethane (DCM) was the solvent of choice. Other studies have employed benzene [9, 14], as well as DCM as the solvent [10]. Obviously in the case of [H-NMP][OCym] this compromises the bio-based label that may be attributed to the final product. Both DCM and benzene, aside from being suitably high performance but non-renewable solvents for esterification reactions (the sort that the ionic liquids synthesised in them were intended to replace) are quite toxic, which is certainly worth considering on a par with renewability arguments. After stirring the two reactants overnight, evaporation of the auxiliary organic solvent provided the Brønsted acidic ionic liquid in quantitative yield. The esterification reaction components could be added directly to the ionic liquid without formal isolation in order to obtain the desired ester. The salt formed between NMP and p-TSA, [H-NMP][OTs], was actually a solid (with a melting point of 355 K), unlike [H-NMP][OCym] which is a liquid at room temperature. This general class of acid–base salt pairs will still be referred to as ionic liquids anyway for convenience. In addition to [H-NMP][OTs] and [H-NMP][OCym] Brønsted acidic ionic liquids, [H-NMP][HSO4] the combination of triethylamine and p-TSA to give [H-NEt3][OTs] were also tested as potential esterification catalysts (Scheme 3).

Three model Fischer esterification reactions were attempted using the ionic liquids in Scheme 3. The first was the synthesis of benzyl acetate (Scheme 4). The rate of reaction at 323 K was monitored by 1H-NMR spectroscopy as established in previous esterification studies [38]. To begin with p-cymene was used as a renewable solvent replacement for toluene. This was in order to focus on the catalytic effect of the ionic liquids before being applied in greater quantities as both catalyst and solvent in the absence of a secondary auxiliary solvent. The reaction does actually occur in the absence of a catalyst but the slow rate is not practical, with reaction times running into weeks before appreciable ester concentrations were observed. It was found for the ionic liquids created from NMP and either p-TSA or p-CSA that their catalytic activity was marginally lower than that of the parent sulphonic acid (Figure 3). In addition, [H-NMP][OTs] provides a marginally superior reaction enhancement over the equivalent p-CSA derived ionic liquid, which may be a consequence of the relative strength of the acids [32]. The slightly lower acidity of p-CSA implies a greater interaction between proton and the conjugate base of the sulphonic acid which will hinder catalysis. Increasing the ionic liquid catalyst loading from 1 mol% to 10 mol% is required to trump the performance of the respective parent sulphonic acid at a 1 mol% loading, regardless of whether [H-NMP][OTs] or [H-NMP][OCym] is used. By not improving upon the reaction performance when it is catalysed by the more traditional sulphonic acids, and given the additional preparation required, it may be concluded that these Brønsted acidic ionic liquids are not a valid option if applied solely as catalysts. In the absence of an auxiliary solvent however, by also assuming the role of solvent in addition to acting as a catalyst, there is a greater scope for the application of this class of additive.

As already identified in previous studies, esters produced by Fischer esterification in certain Brønsted acidic ionic liquids will form a unique phase, offering a means of easy removal from the reaction system [39]. The continuous separation of the product will adjust the equilibrium position in the reactive ionic liquid phase, promoting further esterification. This is the same principle used in more typical esterification strategies, which include distillation and the use of an excess of one reactant [2]. The advantage of the ionic liquid phase is that it is low energy (often operating at room temperature) and reusable whilst also being compatible with the reaction of two solids. After stirring overnight at the ambient temperature without an auxiliary solvent, the synthesis of benzyl acetate assisted by 25 mol% of [H-NMP][HSO4] did indeed result in a biphasic system. The ester containing organic phase could be retrieved without additional workup.

Application of the sulphonate salts, for example [H-NMP][OCym], did not result in a biphasic system and so diethyl ether and water were used to partition the reaction mixture. All the ionic liquids tested were found to be hydrophilic; all being synthesised from water soluble reactants. The absence of a reaction enhancing phase split, and the need of a workup procedure, has obvious negative implications on the associated metrics of the reaction (as summarised subsequently). Contrary to rival reports, yields were modest at best, with the purity of the organic phase typically about 80% in favour of the ester (Figure 4). Without a phase split the productivity of the reaction was dictated by the catalytic activity of the Brønsted acidic ionic liquid, reflected by the trend in Figure 4[32]. Purity was compromised by the presence of the unreacted start materials, but also the ionic liquid catalyst was usually present to a small degree, as confirmed by 1H-NMR spectroscopy.

The reaction barely progressed at all with [H-NEt3][OTs], indicating the importance of an amide base as the basis of the Brønsted acidic ionic liquid catalyst. Because very strong acids are required to protonate weakly basic lactams such as NMP, it is likely that the proton is readily given up to the activated complex of the reaction. The conjugate base of the acid partner, be it bisulphate or a sulphonate, is stabilised by mesomeric resonance and so surely plays no active role in the catalysis of the reaction. Amines are more basic than amides and can be protonated by mild acids. If triethylamine exists as a quaternary salt this may explain the failure of [H-NEt3][OTs] to promote the reaction, which depends on proton transfer (Figure 5). Work conducted by Chiappe et al. also resulted in uninspiring esterification yields when using protonated amine and imidazole based ionic liquids as catalysts [40]. The yields of these experiments were successfully correlated to the Hammett acidity of the catalyst. This is consistent with the difference in catalytic activities observed throughout this work. One further consideration is the nature of the protonation experienced by NMP. Although the exponents of Brønsted acidic ionic liquid catalysts exclusively draw protonation of the nitrogen atom of lactams, it is known to be rare [41, 42]. Instead the carboxamide resonance which creates an electron deficient nitrogen atom results in an electron rich oxygen atom of the carbonyl moiety that logically is subject to protonation [43]. This isomer of the cation is shown catalysing the reaction in Figure 5.

The RME and gRME metrics defined earlier can be used to supplement yields and broaden understanding of the process (Figure 6). Whereas RME closely mirrors reaction yields in this reaction because of the 1:1 molar ratio of reactants, a reliance or absence of work up solvents makes a big impact on the gRME. As such the use of [H-NMP][HSO4] is appealing beyond the superior yield it offers as a catalyst. Reverting from gRME to PMI, the waste stream contributions of each reaction can be identified and separated into solvent, additional water, and the remaining waste caused by unreacted start materials and the water of reaction (Figure 7) [44]. The phase split induced by [H-NMP][HSO4] meant that no additional solvents were required, hugely reducing the waste common to other esterification protocols. The magnitude of the PMI is dictated by the observed conversion, which is why [H-NEt3][OTs] suffers under this analysis. The small contribution to waste by unreacted starting materials (and the by-product water) highlights the need to minimise or circumvent solvent intensive work up procedures. With this in mind only [H-NMP][HSO4] provides a reasonable option as a Brønsted acidic ionic liquid catalyst.

Using the Brønsted acidic ionic liquid formed between NMP and sulphuric acid (25 mol%), the related Fischer esterification to give butyl acetate was attempted to extend the study of the phase separating esterification process (Scheme 5). At ambient temperature the yield of the reaction was an unsatisfactory: 49% of the theoretical maximum after 18 hours. The product purity was a similar standard to the previously discussed benzyl acetate synthesis. In order to improve the reaction between 1-butanol and acetic acid, [H-NMP][HSO4] was applied in reactions at elevated temperatures. The resulting yield and the purity of the organic phase only became satisfactory at 373 K (Figure 8). Regardless of what the catalyst contributes to the reaction system, at this temperature elimination of water will improve productivity by presumably removing the reaction equilibrium. Although it was assumed that the formation of two distinct liquid phases would disrupt the reaction equilibrium, the jump in yield upon reaching 373 K suggests that at lower temperatures the hydrolysis of the ester product is only discouraged and the reversible reaction not fully eliminated. It is only at ambient or near-ambient temperatures that a Brønsted acidic ionic liquid catalysed reaction becomes appealing because of the effort required to synthesise the catalyst needs to be off-set. Reactions conducted at the boiling point of water will have to compete with the benchmark set by Dean-Stark apparatus assisted esterifications, which could be run using bio-based limonene or p-cymene as the solvent to minimise environmental sustainability concerns while still affording high yields [45, 46]. Because (barring temperature) the reaction procedure was equivalent in all runs, the mass-based metrics of the reaction all follow a standard dictated by the yield of the reaction.

The third model reaction was the Fischer esterification to give ethyl levulinate (Scheme 6). Levulinic acid and ethanol are both recognised bio-based platform molecules [47, 48]. As such the synthesis of ethyl levulinate provides a more elaborate yet topical model system to study. It also emphasises the broader role of potentially bio-based auxiliaries such as [H-NMP][OCym] for the synthesis of bio-based products, which would be severely undermined if non-renewable chemicals were required to bring about their production.

Catalyst loadings of 25 mol% at ambient temperature were applied in an attempt to maximise yields of ethyl levulinate under benign conditions, as they were with the benzyl acetate case study. A three-fold excess of ethanol was used because of the solid carboxylic acid reactant when [H-NMP][OTs] was applied as the catalyst needed more fluid to create a homogeneous reaction mixture. To a large extent this defeats the point of using a Brønsted acidic ionic liquid because they are not remarkable catalysts in their own right and in this case do not serve in their additional role as the solvent. Even though it was not strictly necessary an excess of ethanol was also used in the remaining reactions to maintain a fair comparison. The product was extracted after 18 hours by adding diethyl ether because a biphasic separation of the product was not observed. The use of water was avoided because of the aqueous solubility of the ester product. Sulphuric acid was introduced as a benchmark catalyst and proved to be the most effective (85% yield). The NMP derived Brønsted acidic ionic liquids afforded the ester in yields of between 50-60% (Figure 9). The product purity resulting from catalysis by sulphuric acid was the only example to reach an acceptable level. This makes it hard to justify the use of ionic liquid catalysts, themselves synthesised from sulphuric acid, to produce inferior results in this instance.

It is important to consider the synthesis of the Brønsted acidic ionic liquids when considering the metrics that define the reaction productivity. For the example of [H-NMP][OCym], encompassing the synthesis of NMP from glutamic acid and p-CSA from limonene drastically worsens the PMI associated with ethyl levulinate production (Figure 10). A lot of this hidden impact is solvent, specifically the non-renewable DCM currently utilised to make [H-NMP][OCym]. The majority of the mass input is actually the water needed for the steam distillation of citrus waste to obtain the limonene used to make p-cymene and on to p-CSA. Energy use is not accounted for, nor are the consequences of toxicity or pollution, as is the case for all of the prominent mass based metrics. This would need to be factored in when choosing a suitable Fischer esterification catalyst. The synthesis of [H-NMP][OTs] obviously differs from [H-NMP][OCym] in the sourcing of the precursor arene, which being toluene will be sourced by fractionating catalytically reformed cuts of petroleum [21], whereas p-cymene can be made from citrus waste. Although there is negligible waste associated with the separation of toluene from petroleum, sulphonation followed by addition to NMP introduces the possibility of waste streams similiar to those in the synthesis of [H-NMP][OCym]. One advantage in the process of toluene sulphonation is that an excess of arene is reacted and recycled by distillation [26]. Because of its higher boiling point p-cymene is sulphonated with an excess of sulphuric acid [32], the surplus ultimately translating to waste.

Even though they were the most successful conditions, a 25 mol% loading of sulphuric acid at ambient temperature is not a representative of typical operating conditions. Historically methodologies employing higher temperatures but lower catalysts loadings have been preferred instead. Several examples in the literature can be used to illustrate this. The Fischer esterification between ethanol (now just one equivalent) and levulinic acid at 323 K using only 1 mol% of p-CSA as a catalyst gave an improved yield (Table 3) [32]. In another example, the esterification of levulinic acid in an excess of ethanol could be promoted using a sulphonated mesoporous carbon supported catalyst (5) [49]. Sulphuric acid in combination with the classic but carcinogenic solvent benzene provided ethyl levulinate in 81% of the theoretical maximum [50].

In terms of metric analysis, the bio-based Brønsted acidic ionic liquid catalysed methodology developed in this work fares poorly by comparison to procedures using less catalyst but at higher temperatures (Figure 11). Temperature, or rather more precisely energy, along with toxicity etc. are not accounted for in mass-based metrics which makes a holistic comparison difficult. It has a superior RME to the supported sulphonic acid catalysed methodology but this is due to the large excess of ethanol used in the latter instance [49]. The best mass utilisation comes from the use of sulphuric acid in benzene as a reaction system [50]. Given the precedent of p-cymene as a solvent [32], which should narrowly outperform benzene in esterifications based on polarity arguments [38], the substitution of benzene in sulphuric acid catalysed Fischer esterification would create a more benign but similarly efficient reaction system. The supported sulphonic acid catalysed protocol uses excess alcohol as the solvent, which may be considered as the ultimate solvent in terms of greenness and reaction productivity. However this is an unrepresentative scenario of esterification as a whole, with fine chemicals and pharmaceuticals often constructed from expensive solid alcoholic reactants that are unsuitable in the role of solvent.

The most typical of catalysts, sulphuric acid arguably offers the best performance as a function of catalyst loading, whilst maintaining low environmental impact, if in fact ultimately unsustainable. Thus it is important to ask why so much effort has been invested into the development of more elaborate catalysts, often requiring sulphuric acid as a reagent anyway. Sulphuric acid is known to be corrosive [51], and also able to dehydrate alcohols [52]. It is also not recyclable, which becomes a concern in high volume processes. Designing and implementing heterogeneous acid catalysts that can be reused, or employing sulphonic acids or their salts which are considered to be less corrosive than sulphuric acid [15], has been a major topic within green chemistry, and work will continue in this area for as long as the productivity of sulphuric acid catalysed reactions continues to provide the best product returns.

Experimental

All reactions were performed under air without any effort made to exclude water. p-Cymene-2-sulphonic acid was prepared by the method previously described in the literature [32]. All other chemicals were used as received. Characterisation of the ester products was consistent with authentic samples.

N-Methyl pyrrolidinonium p-cymene-2-sulphonate

To p-CSA, crystallised as the dihydrate (2.50 g, 0.01 mol), dissolved in DCM (20 mL) was added NMP (0.96 mL, 0.01 mol) dropwise. The resultant reaction mixture was stirred overnight to give N-methyl pyrrolidinonium p-cymene-2-sulphonate as a pale yellow liquid (3.05 g, 97% of the theoretical yield). NMR: δH (400 MHz, DMSO-d6) 0.98 (6H, d, 3 J = 6.9 Hz, CHCH3), 1.70 (2H, q, CH2-4), 2.00 (2H, t, CH2-5), 2.28 (3H, s, NCH3), 2.65 (1H, m, CHCH3), 3.11 (2H, t, CH2-3), 6.88 (2H, m, ar), 7.43 (1H, d, ar)/ppm; NMR: δC (100 MHz, DMSO-d6) 17.32, 19.69, 24.03, 29.18, 20.30, 33.09, 48.70, 124.46, 126.97, 131.02, 132.96, 144.97, 145.25, 174.13 /ppm. IR: ν (neat) 2962, 1659, 1489, 1456, 1404, 1229, 1156, 1084, 1015, 964, 907, 828, 720, 687, 619/cm-1.

Benzyl acetate

In the absence of an auxiliary solvent acetic acid (12 mmol) and benzyl alcohol (12 mmol) were added to the chosen catalyst (3 mmol) and stirred for 18 hours at the ambient temperature at 300 rpm. If [H-NMP][HSO4] was used as the catalyst the product could be decanted from the reaction. Otherwise diethyl ether (10 mL) and water (10 mL) was added, the organic phase separated and washed with water (2 × 10 mL), dried with magnesium sulphate, filtered and concentrated in vacuo to give benzyl acetate as a yellow liquid.

The kinetics of benzyl acetate synthesis were monitored by taking 1H-NMR spectra at suitable intervals and integrating the benzylic CH2 signal of the product and comparing it to the corresponding benzyl alcohol signal. The procedure mirrors that utilised by Wells et al. previously [53]. Typically acetic acid (0.32 mL, 5.50 mmol) and benzyl alcohol (0.52 mL, 5.00 mmol) were added to the desired quantity of catalyst as a preheated solution in p-cymene (5 mL) at 323 K.

Butyl acetate

Acetic acid (0.46 mL, 8.00 mmol) and 1-butanol (0.73 mL, 8.00 mmol) were added to [H-NMP][HSO4] (0.394 g, 25 mol%) and stirred at 300 rpm at the desired temperature for 18 hours. After this time the product was decanted from the reaction mixture and characterised.

Ethyl levulinate

Levulinic acid (0.464 g, 12 mmol) and the chosen catalyst (1 mmol) were added to ethanol (0.70 mL, 12 mmol), and the resultant mixture stirred for 18 hours at the ambient temperature at 300 rpm. At this point diethyl ether (10 mL) and potassium carbonate were added, and the mixture filtered before concentrated in vacuo to give ethyl levulinate as a colourless oil.

Conclusions

The synthesis of Brønsted acidic ionic liquids for implementation in esterification chemistries has become popular in the last decade, but the state of the art lacked a greater context with respect to what benefits these catalysts actually provide in the widest sense. To address this, a bio-based ionic liquid, [H-NMP][OCym], was synthesised for the first time and compared to its non-renewable analogues and more typical Brønsted acid catalysts. Although generally the shift from unsustainable chemicals to renewable bio-waste derived alternatives cannot be viewed as anything but agreeable, adequate yields whilst minimising waste could only realistically be achieved with sulphuric acid in the synthesis of ethyl levulinate. The results of other authors are consistent with this [13]. The other case studies presented in this work could only be concluded in a similar way, provoking a rethink towards the design, synthesis, implementation, and inevitable waste disposal issues of Brønsted acidic ionic liquids. This is particularly poignant for esterifications, which are in fact suited to low polarity solvents [38], and not ionic liquids [53].

Abbreviations

- AE:

-

Atom economy

- Bmim:

-

1-Butyl-3-methylimidazolium

- b(SO3H)bim:

-

3-butyl-1-(butyl-4-sulfonyl)imidazolium

- p-CSA:

-

p-Cymenesulphonic acid

- DCM:

-

Dichloromethane

- G:

-

Gramme

- gRME:

-

General reaction mass efficiency

- H-NMR:

-

Proton nuclear magentic resonance

- h(SO3H)mim:

-

1-Hexylsulphonate-3-methylimidazolium

- mL:

-

Millilitre

- mmol:

-

Millimole

- NMP:

-

N-Methyl pyrrolidinone

- NMR:

-

Nuclear magnetic resonance

- OCym:

-

p-Cymenesulphonate

- OTs:

-

p-Tosylate

- PMI:

-

Process mass intensity

- Ref.:

-

Reference

- RME:

-

Reaction mass efficiency

- RMM:

-

Relative molecular mass

- rpm:

-

Revolutions per minute

- RT:

-

Room temperature

- p-TSA:

-

p-Toluenesulphonic acid.

References

Yadav GD, Mehta PH: Heterogeneous catalysis in esterification reactions: preparation of phenethyl acetate and cyclohexyl acetate by using a variety of solid acidic catalysts. Ind Eng Chem Res. 1994, 33: 2198-2208. 10.1021/ie00033a025.

Otera J: Esterification Methods, Reactions, and Applications. 2003, Wiley-VCH: Weinheim

Trost BM: The atom economy-a search for synthetic efficiency. Science. 1991, 254: 1471-1477. 10.1126/science.1962206.

Curzons AD, Constable DJC, Mortimer DN, Cunningham VL: So you think your process is green, how do you know?-Using prinicples of sustainability to determine what is green-a corporate perspective. Green Chem. 2001, 3: 1-6.

Sheldon RA: Atom efficiency and catalysis in organic synthesis. Pure Appl Chem. 2000, 72: 1233-1246. 10.1351/pac200072071233.

Jimenez-Gonzalez C, Ponder CS, Broxterman QB, Manley JB: Using the right green yardstick: why process mass intensity is used in the pharmaceutical industry to drive more sustainable processes. Org Process Res Dev. 2011, 15: 912-917. 10.1021/op200097d.

Augé J: A new rationale of reaction metrics for green chemistry. Mathematical expression of the environmental impact factor of chemical processes. Green Chem. 2008, 10: 225-231. 10.1039/b711274b.

Cole AC, Jensen JL, Ntai I, Tran KLT, Weaver KJ, Forbes DC, Davis JH: Novel Brønsted acidic ionic liquids and their use as dual solvent-catalysts. J Am Chem Soc. 2002, 124: 5962-5963. 10.1021/ja026290w.

Zhang H, Xu F, Zhou X, Zhang G, Wang C: A Brønsted acidic ionic liquid as an efficient and reusable catalyst system for esterification. Green Chem. 2007, 9: 1208-1211. 10.1039/b705480g.

Hajipour AR, Rajaei A, Ruoho AR: A mild and efficient method for preparation of azides from alcohols using acidic ionic liquid [H-NMP]HSO4. Tetrahedron Lett. 2009, 50: 708-711. 10.1016/j.tetlet.2008.11.111.

Qureshi ZS, Deshmukh KM, Bhor MD, Bhanage BM: Bronsted acidic ionic liquid as an efficient and reusable catalyst for transesterification of β-ketoesters. Catal Commun. 2009, 10: 833-837. 10.1016/j.catcom.2008.12.048.

Guo H, Li X, Wang JL, Jin XH, Lin XF: Acidic ionic liquid [NMP]H2PO4 as dual solvent-catalyst for synthesis of β-alkoxyketones by the oxa-Michael addition reactions. Tetrahedron. 2010, 66: 8300-8303. 10.1016/j.tet.2010.08.017.

Zhou B, Fang Y, Gu H, Zhang S, Huang B, Zhang K: Ionic liquid mediated esterification of alcohol with acetic acid. Front. Chem. Eng. China. 2009, 3: 211-214. 10.1007/s11705-009-0054-3.

Zhou H, Yang J, Ye L, Lin H, Yuan Y: Effects of acidity and immiscibility of lactam-based Brønsted-acidic ionic liquids on their catalytic performance for esterification. Green Chem. 2010, 12: 661-665. 10.1039/b921081d.

Tao DJ, Lu XM, Lu JF, Huang K, Zhou Z, Wu YT: Noncorrosive ionic liquids composed of [HSO4] as esterification catalysts. Chem Eng J. 2011, 171: 1333-1339. 10.1016/j.cej.2011.05.042.

Ganeshpure PA, George G, Das J: Brønsted acidic ionic liquids derived from alkylamines as catalysts and mediums for Fischer esterification: study of structure-activity relationship. J Mol Catal A Chem. 2008, 279: 182-186. 10.1016/j.molcata.2007.06.025.

Joseph T, Sahoo S, Halligudi SB: Brønsted acidic ionic liquids: a green efficient and reusable catalyst system and reaction medium for Fischer esterification: study of structure-activity relationship. J Mol Catal A Chem. 2005, 234: 107-110. 10.1016/j.molcata.2005.03.005.

Lammens TM, Franssen MCR, Scott EL, Sanders JPM: Synthesis of biobased N-methylpyrrolidone by one-pot cyclization and methylation of γ-aminobutyric acid. Green Chem. 2010, 12: 1430-1436. 10.1039/c0gc00061b.

Lammens TM, Franssen MCR, Scott EL, Sanders JPM: Availability of protein-derived amino acids as feedstocks for the production of bio-based chemicals. Biomass Bioenerg. 2012, 44: 168-181.

Lammens TM, de Biase D, Franssen MCR, Scott EL, Sanders JPM: The application of glutamic acid α-decarboxylase for the valorization of glutamic acid. Green Chem. 2009, 11: 1562-10.1039/b913741f.

Weissermel K, Arpe HJ: Industrial organic chemistry. 1997, VCH: Weinheim, 3

Gunaseelan VN: Anaerobic digestion of biomass for methane production: a review. Biomass Bioenerg. 1997, 13: 83-114. 10.1016/S0961-9534(97)00020-2.

REACH regulated candidate substances of very high concern (SVHC): European Chemical Agency (ECHA). published online 20/06/13, [http://echa.europa.eu/candidate-list-table]

Donovan JR, Salamone JM: Sulfuric acid and sulfur trioxide. Kirk-Othmer Encyclopedia of Chemical Technology. Volume 22. Edited by: Grayson M. 1983, New York: John Wiley and Sons, 190-232. 3

Nehb W, Vydra K, Öl L: Sulfur. Ullmann’s Encyclopedia of Industrial Chemistry. Volume A25. Edited by: Elvers B, Hawkins S, Russey W. 1994, Weinweim: VCH, 507-568. 5

Linder O: Benzenesulfonic acids and their derivatives. Ullmann’s Encyclopedia of Industrial Chemistry. Volume A3. Edited by: Elvers B, Hawkins S, Russey W. 1994, Weinweim: VCH, 507-537. 5

Pfaltzgraff LA, De bruyn M, Cooper EC, Budarin V, Clark JH: Food waste biomass: a resource for high-value chemicals. Green Chem. 2013, 15: 307-314. 10.1039/c2gc36978h.

Pourbafrani M, Forgács G, Horváth IS, Niklasson C, Taherzadeh MJ: Production of biofuels, limonene and pectin from citrus waste. Bioresource Technol. 2010, 101: 4246-4250. 10.1016/j.biortech.2010.01.077.

Martin-Luengo MA, Yates M, Seaz Rojo E, Huerta Arribas D, Aguilar D, Ruiz Hitzky ER: Sustainable p-cymene and hydrogen from limonene. Appl Catal A Gen. 2010, 387: 141-146. 10.1016/j.apcata.2010.08.016.

Spica P: Ueber cymolsulfosäuren. Ber Dtsch Chem Ges. 1881, 14: 652-655. 10.1002/cber.188101401146.

Phillips M: The sulfonation of para-cymene. J Am Chem Soc. 1924, 46: 686-694. 10.1021/ja01668a019.

Clark JH, Fitzpatrick EM, Macquarrie DJ, Pfaltzgraff LA, Sherwood J: p-Cymenesulphonic acid: an organic acid synthesised from citrus waste. Catal Today. 2012, 190: 144-149. 10.1016/j.cattod.2011.12.007.

Clark JH, Macquarrie DJ, Sherwood J: The combined role of catalysis and solvent effects on the Biginelli reaction: improving efficiency and sustainability. Chem Eur J. 2013, 19: 5174-5182. 10.1002/chem.201204396.

Clark JH, Pfaltzgraff LA, Burdarin VL, Hunt AJ, Gronnow M, Matharu AS, Macquarrie DJ, Sherwood JR: From waste to wealth using green chemistry. Pure Appl Chem. 2013, 85: 1625-1631. 10.1351/PAC-CON-12-09-01.

Luque R, Clark JH: Valorisation of food residues: waste to wealth using green chemical technologies. Sustain Chem Processes. 2013, 1: 10-10.1186/2043-7129-1-10.

Norton GA, Devlin SL: Determining the modern carbon content of biobased products using radiocarbon analysis. Bioresource Technol. 2006, 97: 2084-2090. 10.1016/j.biortech.2005.08.017.

Norton GA, Hood DG, Devlin SL: Accuracy of radioanalytical procedures used to determine the biobased content of manufactured products. Bioresource Technol. 2006, 98: 1052-1056.

Clark JH, Macquarrie DJ, Sherwood J: A quantitative comparison between conventional and bio-derived solvents from citrus waste in esterification and amidation kinetic studies. Green Chem. 2012, 14: 90-93. 10.1039/c1gc16299c.

Zhang L, Xian M, He Y, Li L, Yang J, Yu S, Xu X: A Brønsted acidic ionic liquid as an efficient and environmentally benign catalyst for biodiesel synthesis from free fatty acids and alcohols. Bioresource Technol. 2009, 100: 4368-4373. 10.1016/j.biortech.2009.04.012.

Chiappe C, Rajamani S, D’Andrea F: A dramatic effect of the ionic liquid structure in esterification reactions in protic ionic media. Green Chem. 2013, 15: 137-143. 10.1039/c2gc35941c.

Cox C, Lectka T: Intramolecular catalysis of amide isomerization: kinetic consequences of the 5-NH- -Na hydrogen bond in prolyl peptides. J Am Chem Soc. 1998, 120: 10660-10668. 10.1021/ja9815071.

Cox C, Wack H, Lectka T: Strong hydrogen bonding to the amide nitrogen atom in an “amide proton sponge”: consequences for structure and reactivity. Agnew Chem Int Ed. 1999, 38: 798-800. 10.1002/(SICI)1521-3773(19990315)38:6<798::AID-ANIE798>3.0.CO;2-W.

Fraenkel G, Franconi C: Protonation of amides. J Am Chem Soc. 1960, 82: 4478-4483. 10.1021/ja01502a010.

Jiménez-González C, Ollech C, Pyrz W, Hughes D, Broxterman QB, Bhathela N: Expanding the boundaries: developing a streamlined tool for eco-footprinting of pharmaceuticals. Org Process Res Dev. 2013, 17: 239-246. 10.1021/op3003079.

Shanmugam S, Viswanathan B, Varadarajan TK: Esterification by solid acid catalysts-a comparison. J Mol Catal A Chem. 2004, 223: 143-147. 10.1016/j.molcata.2004.02.030.

Veillet S, Tomao V, Ruiz K, Chemat F: Green procedure using limonene in the Dean-Stark apparatus for moisture determination in food products. Anal Chim Acta. 2010, 674: 49-52. 10.1016/j.aca.2010.06.009.

McKenzie BF: Levulinic acid. Org synth Coll. 1941, 1: 335-336.

Sánchez ÓJ, Cardona CA: Trends in biotechnological production of fuel ethanol from different feedstocks. Bioresource Technol. 2008, 99: 5270-5295. 10.1016/j.biortech.2007.11.013.

Budarin VL, Clark JH, Luque R, Macquarrie DJ: Versatile mesoporous carbonaceous materials for acid catalysis. Chem Comm. 2007, 634-636.

Frank RL, Arvan PG, Richter JW, Vanneman CR: The preparation of cyclopentenones from lactones. J Am Chem Soc. 1944, 66: 4-6. 10.1021/ja01229a002.

Panossian Z, de Almeida NL, de Sousa RMF, Pimenta GS, Marques LBS: Corrosion of carbon steel pipes and tanks by concentrated sulfuric acid: a review. Corros Sci. 2012, 58: 1-11.

Smith MB, March J: March’s Advanced Organic Chemistry. 2007, Hoboken: John Wiley and Sons, 6

Wells TP, Hallet JP, Williams CK, Welton T: Esterification in ionic liquids: the influence of solvent basicity. J Org Chem. 2008, 73: 5585-5588. 10.1021/jo8005864.

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

JHC and DJM supervised this work, having also read and approved the manuscript. TJF helped prepare the manuscript, and JS designed and conducted the experiments. All authors read and approved the final manuscript.

Electronic supplementary material

40508_2013_21_MOESM1_ESM.docx

Additional file 1: The mass values for the metric calculations used in this work are supplied as additional files.(DOCX 36 KB)

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Clark, J.H., Farmer, T.J., Macquarrie, D.J. et al. Using metrics and sustainability considerations to evaluate the use of bio-based and non-renewable Brønsted acidic ionic liquids to catalyse Fischer esterification reactions. sustain chem process 1, 23 (2013). https://doi.org/10.1186/2043-7129-1-23

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2043-7129-1-23