Abstract

The paper presents artificial neural network models to evaluate the fatigue life of unidirectional glass fiber-reinforced epoxy-based composites under tension-tension and tension-compression loading. The fatigue behavior of the composite materials was analyzed using three parameters: fiber orientation angle, stress ratio, and maximum stress. These parameters formed the input vectors, and the number of cycles corresponding to the failure was taken as the output parameter for the assessment of the fatigue life. The architecture of the network was selected based on a detailed parametric study and it was trained and tested with data generated analytically using finite element analysis. The predicted results of the neural network model were compared with the available experimental values and were found to be in good agreement. Three different networks such as feedforward, recurrent, and radial basis function networks were used in the present investigation, and a comparative study was carried out to get the optimum network. The significance of the present work is that the same network could be used for assessing the fatigue strength of unidirectional glass/epoxy composite specimens with different fiber orientation angles tested under different stress ratios.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Fiber-reinforced composite materials are finding increasing applications in aerospace structures, naval industry, and other emerging areas, because of their high specific stiffness and strength. Life assessment of these materials forms an important part in design phase in order to assess its useful life. In industrial applications, most of the materials are subjected to cycling loading, and the prolonged testing time is one of the complex steps in the fatigue test. The design of structures and components using newly developed composite materials usually requires extensive and expensive testing programs. Ideally, the designer should be able to accurately assess the performance of a new material or an existing material under untested conditions using a relatively small database of test results. For these situations when it is difficult to find an accurate mathematical-based solution and the existing data is incomplete, noisy, or complex, the biologically motivated computing paradigm of artificial neural network (ANN) has emerged as a superior modeling tool. ANN has recently been used in monitoring and modeling the manufacturing and mechanical behavior of fiber-reinforced composites.

A number of researchers have conducted fatigue tests on unidirectional composite under different states of loading (Hashin and Rotem 1973Tang et al.2000Abdelal et al.2002Epaarachchi and Clausen 2005). The fatigue performance of plain woven glass/epoxy composite materials and the numerical modeling and finite element analysis of these composites behavior under fatigue were investigated by VanPaepegem and Degrieck (200120022004PaepegemW andDegrieck 2005Van Paepegem et al.20012006Degrieck and VanPaepegem 2001). Some studies were also done to evaluate the fatigue life of hybrid composites (Belingardi et al.2006Liu and Mahadevan 2004Kumar and Vijayarangan 2007).

A lot of works were dedicated to the analytical and experimental studies to assess the fatigue behavior of composite materials and found to be expensive in terms of time requirement and cost. Lately, ANN evolved as a tool capable of solving such problems efficiently. El Kadi and Al-Assaf (2002abAl-Assaf and ElKadi 20012007ElKadi 2006) used ANN to predict fatigue behavior of unidirectional glass fiber/epoxy composite laminae under tension-tension and tension-compression loading.

An ANN model for fatigue life prediction of carbon fiber-reinforced plastics was developed by Mathur et al. (2007). Freire Jr et al. (2005) noticed a generalization of neural network when using only three S-N curves in predicting the fatigue life of composite materials and on building constant life diagrams. Lee et al. (1999) reported the results of the feasibility of using ANNs as an alternative to the constant life model.Wong and Hsu (2006) used support vector machines and ANN for the classifications of shapes. Some studies were also done using ANN to assess the damage in fiber-reinforced concrete beams (Jeyasehar and Sumangala2006Adhikary and Mutsuyoshi 2006).

The present study was focused on assessing the fatigue strength of unidirectional glass/epoxy composite using artificial neural network with different paradigms and thus to find the optimum network. The networks were developed for the specimens of different fiber orientation angles tested under different stress ratios.

Methods

Finite element modeling

It was estimated that 50% to 90% of structural failure is due to fatigue; thus, there is a need for quality fatigue design tools. However, the availability of commercial fatigue tools was limited, while the ones that are available are usually quite expensive and difficult to use in the hands of a designer. Another option for the designers is to get the results from experimental studies, which is found to be time-consuming and costly. Hence in the present work, it was proposed to develop a neural network model which can consider the nonlinear behavior of the composite materials and thus to assess its fatigue strength. The data required for the formation of the network were developed using finite element analysis. The results obtained were compared with the available experimental results (ElKadi 2006) and analytical results generated using finite element analysis.

The specimen used in the study was unidirectional glass fiber/epoxy composite stacked in eight layers. The dimension of the specimen was taken as 250 mm long, 25 mm wide, with a thickness of 3.25 mm (ASTM1995). The fiber orientation angles were taken as 0°, 19°, 45°, 71°, and 90°.

To build the finite element model, the composite specimen with dimensions 250 × 25× 3.25 mm was meshed using a higher order three-dimensional element SOLID191, which was a layered version of the 20-node structural solid (SOLID95) designed to model layered thick shells or solids (ANSYS 10.0) (ANSYS2005) For conducting the fatigue analysis, the composite specimen was considered as a cantilever beam, with a given tensile loading at the free end.

To get the location of the maximum stress regions, static analysis was performed before doing fatigue analysis (Jones and Anil 2006). The results of static analysis for the given loading at five locations, where Von-Mises stress is at maximum, are shown in Table 1. These locations were chosen for carrying out the fatigue analysis.

Fatigue analyses were carried out by using the stresses obtained from the static analyses performed with a maximum of ten loading conditions. The stress life approach was used for determining the fatigue life of the composite material since it is useful for materials that will be subjected to high cyclic loading conditions. The advantage of this approach is that it represents both initiation and propagation of cracks in the aggressive environment.

Five fatigue locations, one event, and ten loadings were selected and given to memory storage for performing fatigue analysis. For the single event, ten loading conditions were applied. The stresses for each node obtained after performing static analysis were given as input for ten loading conditions. The stresses stored in one of the critical locations, say node 10, for the ten different loading conditions are shown in Figure 1.

The finite element analysis program calculated all possible stress ranges and keeps track of their number of occurrences, using ‘rain flow’ range counting method which is used to convert the irregular load histories to blocks of constant amplitude cycles. At a selected nodal location, a search was made throughout all of the events for the pair of loadings (stress vectors) that produces the most severe intensity range. The number of repetitions possible for this range was recorded, and the remaining number of repetitions for the events containing these loadings was decreased accordingly. The stress ranges having significance were stored, and the remaining occurrences of smaller stress ranges belonging to that event were ignored. This process continues until all ranges and numbers of occurrences have been considered.

The result of the fatigue calculation was expressed in terms of cumulative fatigue usage. In the stresses stored from the ten static analyses, the equivalent alternating stress was found out, and the allowed cycles for usage were computed. The fatigue calculation in general was based on empirical relations and probabilistic data. So the allowed usage was only an index. The required usage cycles should be entered and if the required usage was greater than that allowed, there was a higher probability of failure before the expected usage. The extent which the fatigue usage has exceeded was represented using cumulative fatigue usage.

From the fatigue calculation of ANSYS (2005), if the number of cycles used was found greater than the number of cycles allowed, the cumulative fatigue usage factor would be greater than 1 and there was a higher probability of failure. The present investigation aims at developing a model to assess the fatigue strength (cycles to failure) of glass fiber-reinforced composite under different stress ratios. The alternating stresses within endurance limit do not attribute to the failure of the component. If the cumulative fatigue usage was less than 1 for usage of 106 cycles, then it could infer that the stresses were below the endurance limit and the specimen had an infinite life. In the present case, the input given for number of cycles used was selected as 106. The results obtained on fatigue analysis are given in Table 2.

The alternating stresses and cumulative fatigue usage factor for the model at the five nodes in critical locations are given in Table 2, and it was found to be maximum at fifth location (at node 584). The alternating stress produced at this node was 621.79 N/mm2. The cumulative fatigue usage factor for this point was 136.91, indicating that the number of cycles before failure was only 7,304. This means the failure probability was very high within short period of usage. It could also be observed from the Table 2 that the location of maximum alternating stress due to fluctuating load was different from maximum stress obtained after a static analysis. Thus by performing fatigue analysis, the number of cycles to failure at different stress values was obtained for different fiber orientation angles and stress ratios. A representative set of these data was used for the formulation of the network; that is, during training phase and another set for checking the performance of the network; that is, during testing phase.

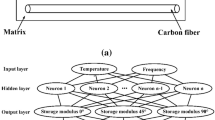

Neural network modeling

Artificial neural network is a nonlinear computational system consisting of a large number of highly interconnected processing units called nodes or artificial neurons. Each input signal is multiplied by an associated weight (representing the strength of connection) and summed at a neuron. The sum is allowed to pass through an activation function (to incorporate the nonlinearity of the problem) to generate the output of the neuron. The neural network is trained by determining the appropriate weight value at each link and the connection pattern associated with it. This process is accomplished by learning from the training set and applying a certain learning rule. The trained network can be used to estimate the outputs for those inputs which are not included in the training set (Simon 1999Wasserman 1989).

Among the different types of neural network, available algorithms, as well as multilayered, feedforward, and recurrent networks, and radial basis function were used in the present investigation to study the fatigue strength of fiber-reinforced composite. These networks approximate the nonlinear relationship between the input and the output. Further, they can be used for the generalization of the input which is not included in the data for training, even in a noise-contained environment.

Selection of input and output vector

It was found that the fatigue life of composite materials is primarily a function of fiber orientation angle, stress ratio, and the maximum stress. Hence, these parameters formed the input vector for the neural network, while the output was the number of cycles to failure.

Selection of training and test data

The successful implementation of a neural network model depends on the data which is used for training the network. In a neural network modeling, there is no explicit relation connecting the input and output data. But after training the network forms a relation between the input and output vector implicitly. The accuracy of this implicit relation depends, to a large extent, on the quality and quantity of the data used for training the network. Hence, the selection of input and output data for training the network is very important for the successful implementation of the network.

The preparation of data is a matter of considerable importance in training the neural network. In the present study, the number of training data was arrived at based on the hypercube rule (Rafiq et al.2001). Using this hypercube method, the number of training data was taken as 54 and test data as 15. After training the neural network is to produce output correctly for the input data that were not used either in creating or training the neural network model. This property of the neural network is called generalization. The ranges of all the input variables are shown in Table 3.

Formulation of network architecture

The formulation of network architecture involves the selection of the number and size of hidden layers, learning rate parameter, momentum term, error tolerance, and activation function. Usually, the choice of these parameters is based on trial-and-error process.

The following neural networks were considered in the present investigation for predicting the fatigue life of fiber-reinforced composite:

-

1.

Feedforward neural networks

-

2.

Recurrent networks with Elman back propagation algorithm and

-

3.

Radial basis function networks

In the case of feedforward and recurrent networks, an initial parametric study based on the results of the previous researchers was carried out for the selection of architecture of the network which includes number of hidden layers, nodes in the hidden layers, learning rate, momentum term, and the error tolerance. From the study it was observed that the two networks, 3-12-1 architecture with a learning rate of 0.92, momentum term of 0.1 and 3-18-6-1 with a learning rate of 0.9, momentum term of 0.3 showed good performance and hence considered in the investigation. To check the efficiency of these networks another study was conducted by varying the number of neurons in the hidden layers by keeping the learning rate as 0.9 and momentum term as 0.5. A sigmoid function was used as an activation function to achieve an error tolerance of 0.001.

The radial basis function for a neuron has a center and a radius (spread). With larger spread, neurons at a distance from a point have a greater influence. For the case of radial basis network, a spread factor of 4.18 was found to give better result.

In order to obtain acceptable and balanced neural network performance, normalization of the input and output data was conducted using the relation

Where C is a constant between −0.25 and 0.25 to ensure that the values are in the range of 0.2 and 0.8, n is the number of digits in the integer part of the variable V (Rafiq et al.2001).

Results and discussion

In the present investigation, three types of networks were developed. Bar charts were plotted between the analytical, predicted, and the available experimental results (El Kadi and Al-Assaf2002ab), and a comparative study was made among the different neural networks.

Feedforward network with single hidden layer

Feedforward network with number of neurons in the hidden layer varying from 12 to 30 were considered in the present study. Graphs were plotted for the comparison of results and are presented in Figures 2, 3, 4, 5, and 6.

From Figures 2, 3, 4, 5, and 6 it was observed that among the 15 data tested, all the networks showed good agreement except for two to three data. Hence, a comparative study was made among these networks to get the optimum feedforward network with single hidden layer and is presented in Figure 7.

Figure 7 showed a comparative study between the actua l values (experimental values) and predicted values (obtained using neural network model). From the graph it was found that the network with 20 neurons in the hidden layer showed good agreement compared to the other networks.

Feedforward network with two hidden layers

A comparative study was made among the feedforward networks with two hidden layers and is shown in Figures 8, 9, 10, 11, and 12.

Similar to the feedforward network with one hidden layer, the feedforward network with two hidden layers showed good agreement between the results except for two to three data. To get the architecture which represents the optimum one, a comparative study was made between the various networks and is shown in Figure 13.

From Figure 13 it was found that the network with two hidden layers having ten neurons in each hidden layer presented the optimum architecture in the case of feedforward network with two hidden layers.

Radial basis network

These networks are nonlinear hybrid networks usually containing a single hidden layer. The activation function of the hidden layer neurons is a Gaussian transfer function. The centers and widths (spread value) of such functions are obtained by unsupervised learning and are used to update the connection weights between the hidden and output layers. In the present work, radial basis networks with spread values of 3.45, 4.18, 4.31, 4.88, and 5 were investigated. The comparison between the predicted results, analytical results, and experimental results for various stress ratios, fiber orientation angles and spread values are shown in Figures 14, 15, 16, 17, and 18.

Since all the networks showed equally good performance, a comparative study among these networks was made and presented in Figure 19.

From the Figure 19 it was found that the radial basis function network with a spread value of 4.31 showed good agreement.

Recurrent networks with Elman back propagation algorithm

Recurrent neural networks contain connections from output nodes to hidden layer and/or input layer nodes, and they allow interconnections between nodes of same layer, particularly between the nodes of hidden layers.

For the Elman network, even though different architectures with different hidden layers were tested, the network with 3-12-1 architecture (Figure 20) alone showed better performance.

Comparison of the networks

In the present investigation three types of networks were used for assessing the fatigue performance of the composite material. In order to get the optimum network, a comparative study was made between the actual values (experimental) and predicted values (neural network) and is given in Figure 21.

From Figure 21 it was found that the performance of Elman network was poor compared to the remaining networks. It was observed that the predictability of the radial basis network was better compared to other networks. In the case of feedforward network, the two hidden layer network showed better performance compared to the feedforward network with a single hidden layer.

Conclusions

Artificial neural network or ANN is gaining momentum in the area of modeling and analysis of composite structures. Most of the theoretical models depend on the evaluation of a mathematical expression or solution explicitly, while the neural network model is formulated implicitly. Basing the entire process on a set of examples presented to the network, it can reasonably capture the underlying functional relationship between the input and the output parameters. Hence, this technique is increasingly finding applications.

Assessment of the fatigue behavior of composite materials is a complex and tedious task due to its heterogeneous nature as well as the long testing time requirement. In the present work, prediction of fatigue life of unidirectional glass fiber-reinforced composite under tension-tension and tension-compression loading using artificial neural network was investigated.

Fatigue analysis was carried out using the finite element analysis for the formation of data required for training and testing the network. Initially, a static analysis was done to get the critical locations for conducting the fatigue analysis. The stresses corresponding to these positions were given as input to the fatigue analysis. The analysis was conducted for various stress ratios, fiber orientation angles, and stress values and these were taken as input to the neural network model. The result of fatigue analysis in terms of number of failure cycles was taken as the output to the network.

Three different networks were developed and compared. The results of the study were compared with the analytical results obtained using finite element analysis and also with the available experimental results. The predicted results were found to agree very well with the analytical and experimental results. From the results it was observed that the predictive capability of the radial basis network was better compared to the other two networks. The significance of the present work was that the same network could be used for the assessment of the fatigue strength of unidirectional glass/epoxy fiber reinforced composite with different fiber orientation angles tested under different stress ratios.

The present study has demonstrated the capability and advantage of using ANNs in modeling physical processes. Unlike in regression analysis, no functional relationship need be assumed among the variables before developing the ANN model. ANN automatically constructs the relationships among the variables implicitly and adapt these based on the training data presented to them. The study also showed the importance of validating the performance of ANN models in simulating the physical processes especially when experimental data were insufficient.

References

Abdelal GF, Caceres A, Barbero EJ: A micro-mechanics damage approach for fatigue of composite materials. Compos Struct 2002, 56: 413–422. 10.1016/S0263-8223(02)00026-0

Adhikary BB, Mutsuyoshi H: Prediction of shear strength of steel fiber RC beams using neural networks. Construct Build Mater 2006, 20: 801–811. 10.1016/j.conbuildmat.2005.01.047

Al-Assaf Y, El Kadi H: Fatigue life prediction of unidirectional glass fiber/epoxy composite laminae using neural networks. Compos Struct 2001, 53: 65–71. 10.1016/S0263-8223(00)00179-3

Al-Assaf Y, El Kadi H: Fatigue life prediction of composite materials using polynomial classifiers and recurrent neural networks. Compos Struct 2007, 77: 561–569. 10.1016/j.compstruct.2005.08.012

ANSYS: ANSYS theory reference manual, release 10. Ansys Inc., Canonsburg; 2005.

ASTM: ASTM 3039/D3039M-95a. Standard test method for tensile properties of polymer composite materials. ASTM Book of Standards 1995, 15: 3.

Belingardi G, Cavatorta MP, Frasca C: Bending fatigue behavior of glass-carbon/epoxy hybrid composites. Compos Sci Technol 2006, 66: 222–232. 10.1016/j.compscitech.2005.04.031

Degrieck J, Van Paepegem W: Fatigue damage modeling of fibre-reinforced composite materials: review. Appl Mech Rev 2001,54(4):279–300. 10.1115/1.1381395

El Kadi H, Al-Assaf Y: Energy-based fatigue life prediction of fiberglass/epoxy composites using modular neural networks. Compos Struct 2002, 57: 85–89. 10.1016/S0263-8223(02)00071-5

El Kadi H, Al-Assaf Y: Prediction of fatigue life of unidirectional glass fiber/epoxy composite laminae using different neural network paradigms. Compos Struct 2002, 55: 239–246. 10.1016/S0263-8223(01)00152-0

El Kadi H: Modeling the mechanical behavior of fibre-reinforced polymeric composite materials using artificial neural networks - a review. Compos Struct 2006, 73: 1–23. 10.1016/j.compstruct.2005.01.020

Epaarachchi JA, Clausen P: A new cumulative fatigue damage model for glass fibre-reinforced plastic composites under step/discrete loading. Composites: Part A 2005, 36: 1236–1245. 10.1016/j.compositesa.2005.01.021

Freire RCS Jr, Neto AD, de Aquino EM: Building of constant life diagrams of fatigue using artificial neural networks. Inter J Fat 2005, 27: 746–751. 10.1016/j.ijfatigue.2005.02.003

Hashin Z, Rotem A: A fatigue failure criterion for fiber-reinforced materials. Scientific Report no.3. National Technical Information Service, Springfield; 1973:1–40.

Jeyasehar CA, Sumangala K: Damage assessment of pre-stressed concrete beams using artificial neural network (ANN) approach. Comput Struct 2006, 84: 1709–1718. 10.1016/j.compstruc.2006.03.005

Jones JH, Anil B: Fatigue analysis of endoskeletal prosthesis using FEA. Department of mechanical engineering; 2006. Accessed 20 September 2008 http://www.geocities.com/joyhjones/joyh.pdf Accessed 20 September 2008

Kumar MS, Vijayarangan S: Analytical and experimental studies on fatigue life prediction of steel and composite multi-leaf spring for light passenger vehicles using life data analysis. Mater Sci (Medžiagotyra) 2007, 13: 141.

Lee JA, Almond DP, Harris B: The use of neural networks for the prediction of fatigue lives of composite materials. Compos: Part 1999, A30: 1159–1169.

Liu YM, Mahadevan S 9th ASCE conference on probabilistic mechanics and structural reliability (PMC2004). In Probabilistic fatigue damage modeling of composite laminates. Albuquerque, New Mexico; 2004. 26–28 July 2004 26–28 July 2004

Mathur S, Gope PK, Sharma JK: Prediction of fatigue lives of composites material by artificial neural network, paper 260. Paper presented at the proceedings of the SEM 2007 annual conference and expositions. Society for Experimental Mechanics Inc, Bethel; 2007. 4–6 June 2007 4–6 June 2007

Rafiq MY, Bugmann G, Easterbrook DJ: Neural network design for engineering applications. Comput Struct 2001, 79: 1541–1552. 10.1016/S0045-7949(01)00039-6

Simon H: Neural networks: a comprehensive foundation. 2nd edition. Prentice Hall, New Jersey; 1999.

Tang H, Nguyen T, Chuang T, Chin J, Wu F: A fatigue model for fiber-reinforced polymeric composites in civil engineering applications. J Mater Civ Eng 2000,12(2):97–104. 10.1061/(ASCE)0899-1561(2000)12:2(97)

Van Paepegem W, Degrieck J: Experimental setup for and numerical modeling of bending fatigue experiments on plain woven glass/epoxy composites. Compos Struct 2001,51(1):1–8. 10.1016/S0263-8223(00)00092-1

Van Paepegem W, Degrieck J, de Baets P: Finite element approach for modeling fatigue damage in fibre-reinforced composite materials. Composites 2001,B32(7):575–588.

Van Paepegem W, Degrieck J: Coupled residual stiffness and strength model for fatigue of fibre-reinforced composite materials. Compos Sci Technol 2002,62(5):687–696. 10.1016/S0266-3538(01)00226-3

Van Paepegem W, de Baere I, Degrieck J: Modelling the non-linear shear stress–strain response of glass-fibre reinforced composites. Part I: experimental results. Compos Sci Technol 2006,66(10):1455–1464. 10.1016/j.compscitech.2005.04.014

Van Paepegem W, Degrieck J: Simulating inplane fatigue damage in woven glass-fibre reinforced composites subject to fully reversed cyclic loading. Fatigue and Fracture of Engineering Materials and Structures 2004,27(12):1197–1208. 10.1111/j.1460-2695.2004.00851.x

PaepegemW V, Degrieck J: Simulating damage and permanent strain in composites under in-plane fatigue loading. Comput Struct 2005,83(23–24):1930–1942.

Wasserman PD: Neural computing: theory and practice. Van Nostrand Reinhold, New York; 1989.

Wong W-T, Hsu S-H: Application of SVM and ANN for image retrieval. Euro J Oper Res 2006, 173: 938–950. 10.1016/j.ejor.2005.08.002

Author information

Authors and Affiliations

Corresponding author

Additional information

Competing interests

The authors declare that they have no competing interests.

Authors’ contributions

The idea of this paper was suggested, developed and modified by MKM. The modeling part was done by SM. Both authors read and approved the final manuscript.

Authors’ original submitted files for images

Below are the links to the authors’ original submitted files for images.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Mini, M.K., Sowmya, M. Neural network paradigms for fatigue strength prediction of fiber-reinforced composite materials. Int J Adv Struct Eng 4, 7 (2012). https://doi.org/10.1186/2008-6695-4-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/2008-6695-4-7