Abstract

This paper describes cooperation of the Slovak University of Technology in Bratislava (STU) and the Slovak Institute of Metrology (SMU) in the verification of the calibration factors for the solid-state nuclear track detector utilized for radon dosimetry and establishing traceability for the STU laboratory. The SMU operates the Air Radon Standard which consists of a radon chamber and calibrated radon atmosphere monitoring system. A specification of the radon chamber is that the radon concentration changes during the exposure time. The radon atmosphere is created by the insertion of a specified amount of radon gas into the chamber, which subsequently decays over time. The STU laboratory is equipped with the TASLImage™ system for radon dosimetry with corresponding TASTRAK CR-39 type detectors and diffusion chambers. These chambers allow radon to diffuse inside and prevent dust and radon progeny to enter the container. Each diffusion container is characterized by its own diffusion rate, which should be considered in the metrology calibration approach, especially when the radon chamber is operated in the decay mode. Therefore, several measurements were carried out to determine the optimal condition for conversion factor verification. The experiments were conducted for low radon concentrations, but still in the range that the radon chamber can reliably provide (100 Bq m−3 to 100 kBq m−3) and in combination with several times of exposure. Based on the achieved results the default calibration factor was verified, and an optimal calibration approach was proposed. To improve the capability of the radon measurement, a custom diffusion container design was proposed. The design incorporates compact dimensions with an aerosol filter at the entrance to the container. This allows to increase in an entry hole and thus increases the diffusion rate. Subsequently, the homogeneity of the radon atmosphere in the chamber was tested.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Monitoring of isotopes of radon, as a radioactive gas naturally present in the upper layer of the earth’s crust, becoming a topic in Europe due to radon’s significant contribution to lung cancer occurrence [1]. However, the concentration of radon in the atmosphere is very low, a significant amount of the radon gas can be accumulated in underground parts of buildings and non-ventilated rooms directly from penetration of the radon from soil or building materials. To support the implementation of the national radon action plan and metrological services [2], two specific devices were developed and installed in Slovakia dedicated to Radon dosimetry and Radon metrology. To support radon metrology, Slovak Institute of Metrology (SMU) developed the air radon standard (AiRneSt) [3] and is fully capable to provide calibration and verification of various types of instruments for radon measurements in air and water. Generally, the radon measurement techniques can be divided into active and passive based on the way whether the data acquisition process needs a power supply or not. The AiRneSt was designed to work only in self-decay mode. Calibration chamber of the AiRneSt is filled with radon gas of specific concentration at the beginning and during calibration measurement the gas is not refilled, thus the concentration is decreasing over time by radon decay. The self-decay mode of AiRneSt can provide metrological calibration without specific modification or evaluation for active measurement techniques. Results from a device, which is calibrated, are compared to the reference radon decay curve and the accuracy with corresponding uncertainties is determined. This methodology is valid only for detection systems working in active measurement regime. Special attention should be paid to passive measurement techniques, where information on radon activity is accumulated over a certain period of time without the possibility of a reversed evaluation of the time evolution. This is the case of Solid-State Track Detectors CR-39 type detectors (SSTD), where the information about an ambient activity is collected in the form of the defects and tracks accumulated within a certain time. Therefore, in cases where the activity of the radon is continually decreasing over time, just a mean value of the activity or relevant dosimetry parameter can be given. Moreover, the CR-39 detectors are placed during the radon measurement in diffusion chambers with specific diffusion rates which must be also considered during calibration. To support the Radon dosimetry in Slovakia the TASLimage system was purchased and installed at the Slovak University of Technology in Bratislava (STU). TASLimage system was developed to fully automate SSTD dosimetry with all necessary aspects from the detector preparation, etching, scanning and evaluation [4]. Standardly, the national regulations require calibration of all devices used for certified dosimetry measurements, but in the case of SSTD where the detectors are not reusable, the whole SSTD preparational procedure and post-irradiation evaluation process must be certified [5]. The calibration measurements play a role in the certification to validate the calibration factors [6], determine corresponding uncertainty and define acceptance criteria for SSTD processing in STU laboratories. Special attention must be paid to the measurement in the self-decay mode, because each parameter, such as irradiation time; type of diffusion chamber; target radon average activity and target uncertainty, can influence the resulting accuracy [7].

2 System description

The AiRneSt consists of three main parts: a radon source, a radon chamber and an electronic measuring device. The radon source is encapsulated dry flow source containing radium salts type RF 100, sr. no.: 221-01 and was manufactured by Czech Metrology Institute. The concentration range is achievable within a range from 100 Bq m−3 to 100 kBq m−3. The chamber is a horizontal cylinder made from stainless steel with a diameter of 0.8 m and a length of 2.0 m. The thickness of the stainless sheet is 5.0 mm. The inner volume of the chamber is approx. 1.0 m3. To determine the exact volume of the chamber, all inner dimensions such as radius, diameter and length were measured by calibrated devices based on processes and metrology standards developed at SMU. The construction of the chamber was designed to test devices by directly placing them into the chamber or by sampling the radon atmosphere through valves housed on the top and back cap of the chamber. Standard working pressure of the chamber is from 980 to 990 hPa to control the tightness of the chamber during measurement. A homogeneity of the radon atmosphere is maintained by the fan installed in the upper part of the chamber. Due to the negative pressure, several thermodynamic sensors are installed in the chamber, and a correction factor to atmospheric pressure is calculated for each measurement. Radon atmosphere is monitored by the AlphaGUARD DF2000 CMR detector and serve also for online monitoring of radon activity.

The TASLImage system is a radon and neutron dosimetry system based on analyses of the Solid-States Track Detectors (TASTRAK). The whole system includes etching equipment, scanning equipment and TASTRAC detectors with optional diffusion chambers (for radon measurement). The etching is carried out in the laboratory thermostatic bath for 1 h in 6.25 M NaOH solution at a temperature of 98 °C. Etched TASTRAK detectors are subsequently rinsed in demineralized water and neutralized in a 2% solution of glacial acetic acid for 30 min and again rinsed in demineralized water for 10 min. Clean TASTRAK detectors are finally dried in a drying oven. Scanning of the TASTRAK detectors is fully automated, where 49 detectors can be analyzed in one batch. The scanning equipment includes 2-axis movable pad, a microscope connected to a CCD camera and PC with read-out software that directly analyse and evaluates all parameters of scanned tracks. The TASTRAK detectors are made from transparent plastic polymer-poly allyl diglycol carbonate (PADC), in standard rectangular shape with dimensions 25 × 25 × 1.5 mm3. Prior to the utilization of the detectors, the antistatic bath is applied to minimize the contribution of the radon progeny during measurements. To maximally suppress the progeny contribution, diffusion chambers are used. TASL supplies the TASTRAK detectors with their own diffusion chambers with cylindrical shape, see Fig. 1, for radon measurements.

The calibration method was proposed based on the standard certification process established at the SMU. The target-specific activity of radon gas is achieved as the mean activity over a certain time while the detectors are inside the radon chamber. The initial concentration is calculated based on the decay law and required amount of radon gas is accumulated prior to measurement. To verify targeted specific radon activity, a reference measurement of the activity is carried out by the AlphaGUARD detector. The reference value and the contributing uncertainty are then calculated from the integration of the measured decay curve. The aim of the calibration is to determine or verify the calibration factor, which in the case of solid-state track detectors represent a relation between the track density (Tr cm−2) and the specific activity (kBq h m−3 or Bq m−3) [8]. The calibration factor of the TASLImage system is pre-defined in the software to 0.66 and can be altered based on local conditions. Unfortunately, this value does not represent a direct conversion between track density and specific activity. The software analyses several factors during the scan and uses AI to determine the final activity on case-by-case basis [5]. Therefore, this paper summarizes the experience with SSTDs calibration in the self-decay mode and specifies the applicability of this method for qualitative verification of the built-in TASLImage calibration factor.

3 Discussion and results

The current certification methodology of the AiRneSt is aimed at the active or continual measurement of the radon activity. Measurements are carried out within short periods (24–72 h) and the measured status is continuously monitored, where an average value or time evolution is evaluated. Within these short time periods for active measurement, the determination of the radon activity is quite straightforward as well as the interpretation of the uncertainties. To define a methodology for SSTD calibration measurements, several assumptions were considered. In previous analyses, the lowest detection limit for TASTRAK detectors was determined at approx. 1 kBq day m−3 [5], which is quite a challenging value in the case of TASL diffusion chambers in combination with the self-decay operation of the AiRneSt. The mean value of the radon activity for measurement in AiRneSt was set up to 1 kBq m−3 and the corresponding initial radon activity was calculated based on the measurement time. The lowest detection limit 1 kBq m−3 is then achieved within one day measurement. To obtain the overall performance of the SSTD the measurement times were defined as 0.5, 1, 2, 3, 5, 10 and 21 days. Compared to the radon half-life, which is 3.82 days, the purpose of the short-day measurements (0.5, 1 and 2 days) is to provide a relatively stable concentration of the radon around the intendent mean value. As the measurement time increases, the difference between maximal and minimal radon activity is also increased. In the case of the 21-day measurement, the initial radon activity is higher than 7 kBq m−3, almost half of the measurement time, the radon activity is less than 1 kBq m−3 and last days of the measurement, the radon activity is less than 300 Bq m−3. Due to the small shape of the diffusion chambers compared to AiRneSt internal volume, the chambers can be freely distributed on the measurement platform and in a large amount. The standard position of the measurement devices subjected to the calibration is in front of the AlphaGuard detector, position #3 in Fig. 2. For 3- and 21-days measurements, 12 positions were defined on the working platform with four diffusion chambers at each position, as it is shown in Fig. 2, to investigate the effect of the number of detectors on the final standard deviation. Moreover, the spatial distribution of the radon activity was evaluated to validate the radon atmosphere homogeneity, which was demonstrated in previous analyses [3].

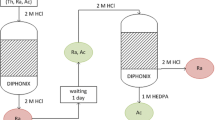

To be sure that all measurements can provide measurable data, the in-house developed diffusion chambers were used in parallel with TASL diffusion chambers. The in-house developed diffusion chamber was designed to provide a fast diffusion rate. It has a cylindrical shape, where the SSTD is placed in a vertical position in the center of the cylinder. Vertical orientation should avoid the accumulation of the fallout of the radon progeny, even though the antistatic treatment was applied. Sidewalls of the cylinders were equipped with big square windows, but to prevent penetration of aerosols to the diffusion chambers, a HEPA filter was used as a second sidewall. Compared to the in-house diffusion chamber, TASL diffusion chambers feature a very small diffusion area, what can have an influence on the time when an equilibrium between inner and outer radon concertation is obtained. This was confirmed within short-term measurements, where the first results for the TASL diffusion chambers were obtained for 5-days and longer measurements, see Fig. 3. For 5-days and 10-days measurements the radon activity determined based on SSTD detectors (orange dots in Fig. 3) almost fits the reference values measured by AlphaGuard detector (blue triangles in Fig. 3). Small discrepancy can be seen for 21-days measurement, where the difference between reference value and SSTD value was 104 Bq m−3, which is higher than one sigma of both values (AlphaGuard and SSTD).

The uncertainty of the AlphaGuard measurements is evaluated based on the procedure developed at SMU and incorporate corrections to the pressure and temperature. TASLImage software calculates uncertainty corresponding to the scanned value. This uncertainty mostly represents the statistical nature of the alpha particle tracks identification during scanning and previous experience from the TASLImage system calibration. More precisely, calculated uncertainty covers four main contributors represented by corresponding standard deviation: background of alpha track scanning (including scanning noise); repeatability of the scans; random counting error; and inter-dosemeter reproducibility [4]. More information can be found in the TASLImage manual, but it is worth mentioning that the standard deviations of background, repeatability of scans and inter-dosemeter reproducibility are predetermined and only random counting error (based on 214Po contribution) and scanning noise is calculated. Several preconditions on which the TASLImage software uncertainty is calculated are not valid for this analysis. The presence of aerosols in the radon chamber is at a minimum level which was confirmed by measurements of radon progeny activity and evaluation of scans by TASLImage software (TASLImage software has capability to distinguish between alpha tracks of radon and its progeny). Moreover, the decay mode introduced additional variability in the measured activity where at the beginning the radon activity is relatively high, compared to the mean value, and at the end the activity approaches the limits of detectability. Therefore, the uncertainty of the radon activity was evaluated as a standard deviation from the set of scans of all SSTD detectors. In each measurement at least 4 SSTD detectors were used, for both TASL and in-house diffusion chamber, and each SSTD detector is scanned at least four times with different starting positions. The TASL algorithm randomly chooses positions of the scanning to speed up the process of evaluation. In case of the high concentration of the tracks this approach can provide reliable information about the measured activity, but in case of the measurements at the SSTD sensitivity level, an increase of the scanned area is desirable. Therefore, more than 16 values of the radon activity are provided for each measurement and each type of diffusion chamber. However, the standard deviation of these sets (with an increasing number of scans or the number of SSTD detectors used) converges to the TASLImage software uncertainty, merely calculated standard deviation is used and presented with all results. In the 10-days measurement re-use of the TASL diffusion chambers was tested. Four SSTD detectors were placed in new diffusion chambers and four SSTD detectors were placed in one time used diffusion chambers. For both groups of SSTD detectors, the radon activity was determined within one sigma range of the reference value; new diffusion chambers—1008.13 ± 59.01 Bq m−3, re-used diffusion chamber—1048.96 ± 73.32 Bq m−3, reference value—1041.93 ± 40.44 Bq m−3.

The in-house diffusion chambers were able to provide radon activity for all measurements. Despite that the standard deviations of short-term measurements were high, the mean values of the radon activity provided by SSTD detectors (orange dots) were in good accordance with the reference value (blue triangle), see Fig. 4. The best match between SSTD and reference radon activity was obtained for 5-days measurement and the worst case was for 21-days measurement. The 21-days measurement was designed with a higher mean concentration of radon, compared to other measurements, to suppress the effect of low activity at the end of the decay curve, see Fig. 5 (right-down). Unfortunately, almost double radon mean activity was not sufficient for so long measurement and the highest deviation from the reference value was obtained. Inconsistency can be seen also in the comparison of two diffusion chambers. The SSTD used in TASL diffusion chambers provided a closer value to the reference activity with a lower standard deviation (σin-house = 7.53%, σTASL = 7.65%). This difference can be caused by the different diffusion rates of used diffusion chambers, where the TASL diffusion chamber needs more than three days to reach a saturated level of radon concentration. In Fig. 5 (right-down) can be seen, that at the end of the measurement, last three days, the radon activity was lower than 200 Bq m−3, which can be considered as the source of obtained discrepancy. This activity is comparable to the values measured in houses and residential premises, but the measurements are carried out for several months to obtain reliable results. Several days at the level of a few hundreds of Bq m−3 activity can thus bring just additional error to collected tracks. In addition, the process of finalization of the measurement can influence the final activity. At a pre-determined time, the radon atmosphere in the chamber is blown out, the radon chamber is opened and the diffusion chambers with detectors are packed to the antistatic backs. The detectors are stored in these backs for several hours before they are etched and scanned. The reason is to let the rest of the radon accumulated inside of the chamber decay. In the case of diffusion chambers with fast diffusion rates, such as the in-house diffusion chamber, the time between voiding of the radon atmosphere and packing of the detectors can be very important. The internal atmosphere of the diffusion chamber reaches a new equilibrium very quickly and can thus influence the final specific activity. Results from all measurements are summarized in Table 1.

The 3-days and 21-days measurements were used to investigate the homogeneous distribution of the radon atmosphere in the AiRneSt. The radon gas is sprayed through the inlet valve once at the beginning of the measurement. Small fan is used to circulate the inlet atmosphere and keep radon concentration homogeneously distributed in the tank. All calibrations are carried out using a perforated working platform situated in the bottom part of the tank, see Fig. 2. Twelve positions were chosen at the platform to investigate radon homogeneity in all possible positions available for calibrations. The SSTD detectors were placed in four rows, where two detectors were placed close to the tank wall (Left and Right side in Figs. 6, 7 and 8) and in the center. Measured radon activities in 3-days measurement were distributed around the reference value, see Fig. 6. Due to short time measurement only data for the in-house diffusion chamber are presented. The best match with reference value was obtained for position 3, which is placed in the front of the AlphaGuard detector and is standardly used for calibration. For other positions, the center and side values are shifted from the reference value and also difference between side values to center value can be seen. The worst results were obtained in positions next to the front and back wall, but no systematic pattern can be seen, which can identify significant inhomogeneity.

Spatially dependent radon activities measured in 21 days are presented in Figs. 7 and 8, for in-house and TASL diffusion chambers, respectively. In both cases, all measured values are far from the reference value independently from the position. The effect of the diffusion rate and low activity of the radon in the last days of the measurement can be seen also in the spatial distribution measurement. None of the positions could provide relevant results compared to the reference value. However, better values were obtained for TASL diffusion chambers based on the effects described in the previous part, but the measurement cannot be considered as successful.

To verify the TASLImage calibration factor, the measured specific activities were transformed to the exposure and plotted against reference values. For in-house diffusion chamber, the obtained fit showed an acceptable linear response. Calculated gradient 0.8037, see Fig. 9, indicates that SSTD in combination with in-house diffusion chamber is able to provide only 80.37% of the expected value. If the 21-days measurement is excluded from the set, the gradient changes to 0.9305. The validity of short-term measurements is also questionable due to their high standard deviations.

The gradient of the linear fit for SSTDs and TASL diffusion chamber indicates better correspondence with the built-in calibration factor, see Fig. 10. The gradient is 0.9316, but the exclusion of the 21-days measurement increases it to 0.9699. Both numbers (0.8037 and 0.9316) represent the qualitative performance of the whole system, including the AiRneSt system, measurement procedures, detectors and in the case of the SSTD also used diffusion chambers. These values cannot directly replace the calibration factor but can be used for its alternation to match the reference values.

The radon atmosphere inside the chamber is monitored by the calibrated AlphaGuard detector, which works on the principle of an ionization chamber. The radon activity is measured in predetermined intervals and stored for evaluation. The data are corrected by the correction factors considering the current pressure and temperature in the chamber during measurement. The record from the 0.5 day (left-up), 5 days (right-up), 10 days (left-down) and 21 days (right-down) measurement can be seen in Fig. 5. The mean values, used in the analyses as reference values, were calculated from the integral of fitted functions corresponding to each measurement. Parameters of the fit served also for verification of the measurement and tightness of the chamber. Calculated decay constant of radon was compared to the theoretical value and agreement in all measurements were achieved.

4 Conclusion

Presented analysis was devoted to the development of methodology for the calibration of the SSTD detectors in a radon calibration chamber operating in self-decay mode. Several measurements were carried out including the lowest detection limit (1 kBq day m−3) defined in previous analyses. The mean radon activity of 1 kBq m−3 was used in combination with several times of exposure to verify the built-in conversion factor of the TASLImage system. Two types of diffusion chambers were used to store the SSTD detectors during the measurements. The TASL diffusion chambers provided more stable results in the sense of the corresponding standard deviation. Calculated standard deviations were in the same range as the corresponding uncertainty of the reference value. Relatively low diffusion rate makes the TASL diffusion chambers insensitive to the short measurement times (less than 5 days). The in-house diffusion chambers were able to provide radon activity for all measurement times, but with a higher standard deviation, which was also reflected in a higher difference between reference and measured radon activity. In all cases, the standard deviation was several times higher than the uncertainty of the reference radon activity or radon activity measured using TASL diffusion chambers. Large penetration area allows for a more flexible response to changes in radon concentration but can be also the source of larger standard deviations. Therefore, a more compact design with optimized penetration windows will be proposed in future analyses. The long-term measurements showed the inapplicability of the AiRneSt for such calibration measurements. In the last three days of the measurement, the radon activity was below 200 Bq m−3, which was not sufficient and brought significant deviation to the final values. Different designs of the diffusion chambers demonstrated also sensitivity to these conditions. TASL diffusion chamber was able to provide a closer value to the reference radon activity, but the discrepancy is also unacceptable. Possibly higher initial radon activity could provide better results, but the end of calibration measurement is still in the range of 6–7 times of the radon half-life and the calibration will face the same problems. Based on the achieved results the default calibration factor was kept unchanged and will be used for future measurements without modifications. The optimal calibration result was obtained during 5-day measurements at the level of 1 kBq m−3. However, the in-house diffusion chamber was able to provide results from the exposure of 0.5 kBq day m−3, and the TASL diffusion chamber became sensitive from 5 kBq day m−3. The lowest detection limit determined in previous work should, therefore, be reconsidered for the TASL diffusion chamber and calibration in self-decay mode. For the AiRneSt system, the lowest applicable exposure for calibration measurement is proposed at the level of 5 kBq day m−3. This value was also defined as the minimum value to obtain acceptable consistency between the expected and the measured value [5]. It can vary from case to case, as it was demonstrated for in-house diffusion chamber, and may decrease, for example, for measurement with higher target activity. Determination of the exact lowest detection limit will be the topic of further investigation. Special attention was also paid to the corresponding uncertainties. Several conditions, which served as definition of the TASLImage software uncertainty, were not fulfilled within calibration measurement. Therefore, an alternative approach was proposed, but while maintaining the philosophy of conservatism, a higher value should be used (software uncertainty vs. standard deviation of scanned set). This approach will be recommended to SMU for calibration of the SSTD detectors at the lowest detectable activity level. Moreover, the homogeneity of the radon atmosphere in the AiRneSt chamber was tested. Selected measurements time were not able to determine spatial dependence based on the position inside the AiRneSt and in combination with other results the radon atmosphere is considered as homogenous.

Data availability statement

No data are associated with the manuscript.

References

F. Bochicchio et al., Int. J. Environ. Res. Public Health 19, 4114 (2022)

National action plan § 135, Law num. 87/2018 on radiation protection

P. Blahušiak et al., Rad. Prot. Dos. 191, 160 (2020)

TASLIMAGE Radon and Neutron Dosimetry System—A Complete System for Etching, Scanning and Analysing TASTRAK Plastic Nuclear Track Detector. Track Analysis Systems Ltd, Bristol (2020).

B. Tate, S. Iong, Acceptance Testing of the TASL Radon Dosimetry System (Australian Radiation Protection and Nuclear Safety Agency, Australia, 2016)

D. Schmithüsen et al., Atmos Meas. Tech. 10, 1299 (2017)

P. Wanabongse et al., Indian J. Phys. 83(6), 833–837 (2009)

J.H. Jebur et al., J. Phys. Conf. Ser. 1294, 022013 (2019)

Acknowledgements

This study has partially been financially supported by the Slovak Research Development Agency by projects No. APVV-20-0300, No. APVV-21-0170 and by the Scientific Grant Agency of the Ministry of Education of Slovak Republic No. VEGA 1/0615/21.

Funding

Open access funding provided by The Ministry of Education, Science, Research and Sport of the Slovak Republic in cooperation with Centre for Scientific and Technical Information of the Slovak Republic.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lüley, J., Filova, V., Blahušiak, P. et al. CR-39 detector-based Radon dosimetry system calibration in the self-decay mode. Eur. Phys. J. Spec. Top. 232, 1493–1500 (2023). https://doi.org/10.1140/epjs/s11734-023-00876-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1140/epjs/s11734-023-00876-8