Abstract

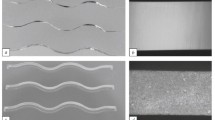

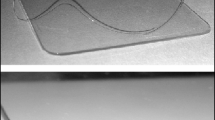

Cutting glass to shape with ultra short laser pulses is nowadays a well established industrial process. Pulses with an elongated straight focal volume (line focus) are used to modify the workpiece throughout its entire depth with one single laser shot. At the same time, processed glass is often required to have a seamed or round edge, which usually requires an extra grinding step. Here we demonstrate that curved line foci can be used to combine cutting and edge shaping of glass sheets in one laser process. We reconsider the Airy-Gauss beam for this purpose, and suggest modifications to the beam profile to avoid unwanted effects, in particular an asymmetric laser modification of the glass sheet. We provide a combined experimental and numerical analysis of the laser process, and show a symmetric convex edge created in a \({920}\,{\upmu }\mathrm{m}\) thick glass sheet.

Similar content being viewed by others

References

J. Deubener, G. Helsch, A. Moiseev, H. Bornhöft, Glasses for solar energy conversion systems. J. Eur. Ceram. Soc. 29, 1203–1210 (2009). https://doi.org/10.1016/j.jeurceramsoc.2008.08.009

J.-S. Park, H. Chae, H.K. Chung, S.I. Lee, Thin film encapsulation for flexible AM-OLED: a review. Semicond. Sci. Technol. 26, 034001 (2011). https://doi.org/10.1088/0268-1242/26/3/034001

S. Garner, S. Glaesemann, X. Li, Ultra-slim flexible glass for roll-to-roll electronic device fabrication. Appl. Phys. A 116, 403 (2014). https://doi.org/10.1007/s00339-014-8468-2

R.R. Gattass, E. Mazur, Femtosecond laser micromachining in transparent materials. Nat. Photonics 2(4), 219–225 (2008). https://doi.org/10.1038/nphoton.2008.47

F. Hendricks, V. Matylitsky, M. Domke, H.P. Huber, Time-resolved study of femtosecond laser induced micro-modifications inside transparent brittle materials. In: Frontiers in Ultrafast Optics: Biomedical, Scientific, and Industrial Applications XVI, vol. 9740. SPIE (2016), pp. 162–169. https://doi.org/10.1117/12.2214081

R.M. Herman, T.A. Wiggins, Production and uses of diffractionless beams. J. Opt. Soc. Am. A 8, 932–942 (1991). https://doi.org/10.1364/JOSAA.8.000932

K. Mishchik, R. Beuton, O. Dematteo Caulier, S. Skupin, B. Chimier, G. Duchateau, B. Chassagne, R. Kling, C. Hönninger, E. Mottay, J. Lopez, Improved laser glass cutting by spatio-temporal control of energy deposition using bursts of femtosecond pulses. Opt. Express 25(26), 33271 (2017). https://doi.org/10.1364/OE.25.033271

M. Jenne, D.l. Flamm, K. Chen, M. Schäfer, M. Kumkar, S. Nolte, Facilitated glass separation by asymmetric bessel-like beams. Opt. Express 28(5), 6552–6564 (2020). https://doi.org/10.1364/OE.387545

K. Bergner, M. Müller, R. Klas, J. Limpert, S. Nolte, A. Tünnerman, Scaling ultrashort laser pulse induced glass modifications for cleaving applications. Appl. Opt. 57(21), 5941–5947 (2018). https://doi.org/10.1364/AO.57.005941

A. Feuer, J.-U. Thomas, C. Freitag, R. Weber, T. Graf, Single-pass laser separation of 8 mm thick glass with a millijoule picosecond pulsed Gaussian-Bessel beam. Appl. Phys. A 125(5), 1–6 (2019). https://doi.org/10.1007/s00339-019-2624-7

D. Sohr, J.U. Thomas, S. Skupin, Shaping convex edges in borosilicate glass by single pass perforation with an airy beam. Opt. Lett. 46(10), 2529–2532 (2021). https://doi.org/10.1364/OL.423788

M.V. Berry, N.L. Balazs, Nonspreading wave packets. Am. J. Phys. 47(3), 264–267 (1979). https://doi.org/10.1119/1.11855

G.A. Siviloglou, J. Broky, A. Dogariu, D.N. Christodoulides, Observation of accelerating airy beams. Phys. Rev. Lett. 99(21), 213901 (2007). https://doi.org/10.1103/PhysRevLett.99.213901

Z. Yang, M. Prokopas, J. Nylk, C. Coll-Lladó, F.J. Gunn-Moore, D.E.K. Ferrier, T. Vettenburg, K. Dholakia, A compact airy beam light sheet microscope with a tilted cylindrical lens. Biomed. Opt. Express 5(10), 3434–3442 (2014). https://doi.org/10.1364/BOE.5.003434

P. Panagiotopoulos, D.G. Papazoglou, A. Couairon, S. Tzortzakis, Sharply autofocused ring-airy beams transforming into non-linear intense light bullets. Nat. Commun. 4, 2622 (2013). https://doi.org/10.1038/ncomms3622

A. Mathis, F. Courvoisier, L. Froehly, L. Furfaro, M. Jacquot, P.A. Lacourt, J.M. Dudley, Micromachining along a curve: femtosecond laser micromachining of curved profiles in diamond and silicon using accelerating beams. Appl. Phys. Lett. 101(7), 071110 (2012). https://doi.org/10.1063/1.4745925

L. Froehly, F. Courvoisier, A. Mathis, M. Jacquot, L. Furfaro, R. Giust, P.A. Lacourt, J.M. Dudley, Arbitrary accelerating micron-scale caustic beams in two and three dimensions. Opt. Express 19(17), 16455–16465 (2011). https://doi.org/10.1364/OE.19.016455

P. Polynkin, M. Kolesik, J.V. Moloney, G.A. Siviloglou, D.N. Christodoulides, Curved plasma channel generation using ultraintense airy beams. Science 324(5924), 229–232 (2009). https://doi.org/10.1126/science.1169544

N.K. Efremidis, Z. Chen, M. Segev, D.N. Christodoulides, Airy beams and accelerating waves: an overview of recent advances. Optica 6(5), 686 (2019). https://doi.org/10.1364/OPTICA.6.000686

D.G. Papazoglou, S. Suntsov, D. Abdollahpour, S. Tzortzakis, Tunable intense airy beams and tailored femtosecond laser filaments. Phys. Rev. A 81(6), 061807 (2010). https://doi.org/10.1103/PhysRevA.81.061807

R.S. Grewal, A. Ghosh, G.K. Samanta: Simultaneous generation of high-power, ultrafast 1d and 2d airy beams and their frequency-doubling characteristics. Opt. Lett. 43(16), 3957–3960 (2018). https://doi.org/10.1364/OL.43.003957

J. Gottmann, Microcutting and hollow 3d microstructures in glasses by in-volume selective laser-induced etching (isle). J. Laser Micro/Nanoeng. 8(1), 15–18 (2013). https://doi.org/10.2961/jlmn.2013.01.0004

S. Matsuo, H. Sumi, S. Kiyama, T. Tomita, S. Hashimoto, Femtosecond laser-assisted etching of pyrex glass with aqueous solution of koh. Appl. Surf. Sci. 255(24), 9758–9760 (2009). https://doi.org/10.1016/j.apsusc.2009.04.065

L. Bergé, S. Skupin, R. Nuter, J. Kasparian, J.P. Wolf, Ultrashort filaments of light in weakly ionized, optically transparent media. Rep. Progr. Phys. 70, 1633 (2007)

O. Dematteo Caulier, K. Mishchik, B. Chimier, S. Skupin, A. Bourgeade, C. Javaux Léger, R. Kling, C. Hönninger, J. Lopez, V. Tikhonchuk, G. Duchateau, Femtosecond laser pulse train interaction with dielectric materials. Appl. Phys. Lett. 107, 181110 (2015)

L.V. Keldysh, Ionization in the field of a strong electromagnetic wave. Sov. Phys. JETP 20(5), 1307–1314 (1965)

P. Audebert, P. Daguzan, A. Dos Santos, J. Gauthier, J. Geindre, S. Guizard, G. Hamoniaux, K. Krastev, P. Martin, G. Petite et al., Space-time observation of an electron gas in si o 2. Phys. Rev. Lett. 73(14), 1990 (1994). https://doi.org/10.1103/PhysRevLett.73.1990

C. Mauclair, A. Mermillod-Blondin, K. Mishchik, J. Bonse, A. Rosenfeld, J.P. Colombier, R. Stoian, Excitation and relaxation dynamics in ultrafast laser irradiated optical glasses. High Power Laser Sci. Eng. 4, 1065 (2016). https://doi.org/10.1017/hpl.2016.45

W. Liu, S. Petit, A. Becker, N. Aközbek, C.M. Bowden, S.L. Chin, Intensity clamping of a femtosecond laser pulse in condensed matter. Opt. Commun. 202(1), 189–197 (2002). https://doi.org/10.1016/S0030-4018(01)01698-4

A. Schmitt-Sody, H.G. Kurz, L. Bergé, S. Skupin, P. Polynkin, Picosecond laser filamentation in air. New J. Phys. 18(9), 093005 (2016). https://doi.org/10.1088/1367-2630/18/9/093005

U. Eppelt, S. Russ, C. Hartmann, M. Sun, C. Siebert, W. Schulz, Diagnostic and simulation of ps-laser glass cutting. In: International Congress on Applications of Lasers & Electro-Optics, vol. 2012, pp. 835–844 (2012). Laser Institute of America

Y. Hu, G.A. Siviloglou, P. Zhang, N.K. Efremidis, D.N. Christodoulides, Z. Chen, Self-accelerating airy beams: generation, control, and applications. In Nonlinear Photonics and Novel Optical Phenomena, ed. by Z. Chen, R. Morandotti. Springer Series in Optical Sciences, vol. 170 (Springer, New York, 2012), pp. 1–46

B.E.A. Saleh, M.C. Teich, Fundamentals of Photonics Wiley Series in Pure and Applied Optics (Wiley-Interscience, Hoboken, 2001). https://doi.org/10.1002/0471213748

D.M. Cottrell, J.A. Davis, T.M. Hazard, Direct generation of accelerating airy beams using a 3/2 phase-only pattern. Opt. Lett. 34(17), 2634–2636 (2009). https://doi.org/10.1364/OL.34.002634

N.L. Boling, M.D. Crisp, G. Dubé, Laser induced surface damage. Appl. Opt. 12(4), 650 (1973). https://doi.org/10.1364/ao.12.000650

D. Bischof, M. Kahl, M. Michler, Laser-assisted etching of borosilicate glass in potassium hydroxide. Opt. Mater. Express 11(4), 1185 (2021). https://doi.org/10.1364/OME.417871

C. Ungaro, A. Liu, Single-pass cutting of glass with a curved edge using ultrafast curving Bessel beams and oblong airy beams. Opt. Laser Technol. 144, 107398 (2021). https://doi.org/10.1016/j.optlastec.2021.107398

D. Flamm, M. Kaiser, M. Feil, M. Kahmann, M. Lang, J. Kleiner, T. Hesse, Protecting the edge: ultrafast laser modified c-shaped glass edges. J. Laser Appl. 34(1), 012014 (2022). https://doi.org/10.2351/7.0000592

Acknowledgements

Simulations were performed using HPC resources from GENCI (Grants # A0070506129 and A0080507594). SS acknowledges support by the QNRF (Grant # NPRP 12S-0205-190047).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

Data underlying the results presented in this paper are not publicly available at this time but may be obtained from the authors upon reasonable request.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sohr, D., Thomas, J.U. & Skupin, S. All-round: combining laser cutting and edge shaping of glass. Eur. Phys. J. Spec. Top. 232, 2253–2264 (2023). https://doi.org/10.1140/epjs/s11734-022-00672-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1140/epjs/s11734-022-00672-w