Abstract

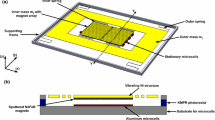

Nowadays, wireless sensor networks (WSN) are becoming essential in our daily life. However, a major constraint concerns the energy power supply. Indeed, batteries need to be recharged or replaced often which implies a limited lifetime for WSN nodes. One alternative consists in harvesting mechanical energy from surrounding vibrations of the environment. Using finite element simulations, we report here a complete guideline to optimize a MEMS electromagnetic energy harvester consisting of an in-plane vibrating silicon frame supporting an array of micromagnets that faces a static 2D micro-coil. The dimensioning of the magnet array and the specific design of the coil are addressed, considering patterned 50 \(\upmu \)m thick NdFeB films with out of plane magnetization. The optimization of the electromechanical coupling which allows to efficiently convert the energy results from a trade-off between the high magnetic flux gradients produced by the micromagnets and the maximum number of turns of the facing coil.

Similar content being viewed by others

Data Availability Statement

This manuscript has associated data in a data repository. [Authors’ comment: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.]

References

Energy Harvesting Technologies; Priya, S., Inman, D. J., Eds.; Springer US: Boston, MA, 2009. https://doi.org/10.1007/978-0-387-76464-1

C. Wei, X. Jing, A Comprehensive Review on Vibration Energy Harvesting: Modelling and Realization. Renew. Sustain. Energy Rev. 74, 1–18 (2017). https://doi.org/10.1016/j.rser.2017.01.073

Y. Tan, Y. Dong, X. Wang, Review of MEMS electromagnetic vibration energy harvester. J. Microelectromech. Syst. 26(1), 1–16 (2017). https://doi.org/10.1109/JMEMS.2016.2611677

M. Han, Z. Li, X. Sun, H. Zhang, Analysis of an In-Plane Electromagnetic Energy Harvester with Integrated Magnet Array. Sens. Actuators Phys. 219, 38–46 (2014). https://doi.org/10.1016/j.sna.2014.08.008

C.B. Williams, R.B. Yates, Analysis of a micro-electric generator for microsystems. Sens. Actuators Phys. 52, 8–11 (1996)

N.G. Stephen, On Energy Harvesting from Ambient Vibration. J. Sound Vib. 293(1–2), 409–425 (2006). https://doi.org/10.1016/j.jsv.2005.10.003

S. Roy, D. Mallick, K. Paul, MEMS-Based Vibrational Energy Harvesting and Conversion Employing Micro-/Nano-Magnetics. IEEE Trans. Magn.2019, 1–15 https://doi.org/10.1109/TMAG.2019.2896105

D. Mallick, K. Paul, T. Maity, S. Roy, Magnetic Performances and Switching Behavior of Co-Rich CoPtP Micro-Magnets for Applications in Magnetic MEMS. J. Appl. Phys. 125(2), 023902 (2019). https://doi.org/10.1063/1.5063860

M. Kustov, P. Laczkowski, D. Hykel, K. Hasselbach, F. Dumas-Bouchiat, D. O’Brien, P. Kauffmann, R. Grechishkin, D. Givord, G. Reyne, O. Cugat, N.M. Dempsey, Magnetic characterization of micropatterned Nd-Fe-B Hard magnetic films using scanning hall probe microscopy. J. Appl. Phys. 108(6), 063914 (2010). https://doi.org/10.1063/1.3486513

F.O. Keller, R. Haettel, T. Devillers, N.M. Dempsey, Batch Fabrication of 50 Lm Thick Anisotropic Nd-Fe-B Micromagnets. IEEE Trans. Magn.2021, 1–1. https://doi.org/10.1109/TMAG.2021.3101911

K. Paul, D. Mallick, S. Roy, Performance Improvement of MEMS Electromagnetic Vibration Energy Harvester Using Optimized Patterns of Micromagnet Arrays. IEEE Magn. Lett. 12, 1–5 (2021). https://doi.org/10.1109/LMAG.2021.3088403

P. Wang, K. Tanaka, S. Sugiyama, X. Dai, X. Zhao, J. Liu, A Micro Electromagnetic Low Level Vibration Energy Harvester Based on MEMS Technology. Microsyst. Technol. 15(6), 941–951 (2009). https://doi.org/10.1007/s00542-009-0827-0

R. Fujiwara, T. Devillers, D. Givord, N.M. Dempsey, Characterization of the Magnetic Properties of NdFeB Thick Films Exposed to Elevated Temperatures. AIP Adv. 8(5), 056225 (2018). https://doi.org/10.1063/1.5007674

J.M.D. Coey, Magnetism and Magnetic Materials (Cambridge University Press, Cambridge, 2010)

K. Yamaguchi, T. Fujita, Y. Tanaka, N. Takehira, K. Sonoda, K. Kanda, K. Maenaka, MEMS Batch Fabrication of the Bipolar Micro Magnet Array for Electromagnetic Vibration Harvester. J. Phys. Conf. Ser. 557, 012033 (2014). https://doi.org/10.1088/1742-6596/557/1/012033

Acknowledgements

This study has been partially supported through the French national project POMADE (ANR 19-CE09-0021-01), the EUR grant NanoX n°ANR-17-EURE-0009 in the framework of the “ Programme des Investissements d’Avenir” and the prematuration program of the Région Occitanie (AimCap). PM thanks the Région Occitanie and the Université Fédérale de Toulouse for phD funding.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Lecerf, I., Moritz, P., Angulo-Cervera, J.E. et al. Optimization of a vibrating MEMS electromagnetic energy harvester using simulations. Eur. Phys. J. Spec. Top. 231, 4205–4211 (2022). https://doi.org/10.1140/epjs/s11734-022-00577-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1140/epjs/s11734-022-00577-8