Abstract

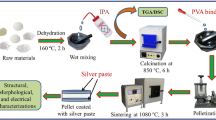

To replace lead containing (Pb, Zr)\(\hbox {TiO}_{3}\) in piezoelectric devices, the (K, Na)\(\hbox {NbO}_{3}\) system has shown great promise but has also encountered versatile properties, due to the volatilization of alkaline elements and difficulties in getting fully dense ceramics. \(\hbox {K}_{0.5}\hbox {Na}_{0.5}\hbox {O}_{3}\) (KNN) powders are prepared by solid-state synthesis with a short-time planetary ball milling and shaped in a series of ceramic pellets using spark plasma sintering technique (SPS), resulting in highly dense ceramics. This sintering process operates in reducing conditions, and post-annealing in oxygen flow is required to recover a good electrical insulator material, to remove the residual strains in the ceramics and to eliminate possible carbon contamination from the graphite die. The structural and microstructural states of the ceramics, observed before and after post treatment, lead to the identification of the major defects encountered during SPS treatment. The resulting piezoelectric functional properties obtained on the series of pellets after oxygen annealing post treatment are measured. This study confirms that SPS technique is really successful in achieving very high and reproducible densification of KNN ceramics. After a post-annealing treatment, substantial piezoelectric properties improvement can be expected in such high densification and defect-free ceramics, suitable for integration in lead-free devices.

Similar content being viewed by others

References

B. Jaffe, Piezoelectric Ceramics, Academic Press (London, 1971)

EU-Directive 2002/95/EC: RoHS, Off. J. Eur. Union, 46(L37) 19 (2003)

S. Zhang, R. Xia, T.R. Shrout, J. Electroceram. 19, 251 (2007)

H.-C. Thong, C. Zhao, Z. Zhou, C.-F. Wu, Y.-X. Liu, Z.-Z. Du, J.-F. Li, W. Gong, K. Wang, Mater. Today 29, 37 (2019)

J. Rödel, W. Jo, K.T.P. Seifert, E.-M. Anton, T. Granzow, D. Damjanovic, J. Am. Ceram. Soc. 92, 1153 (2009)

J. Wu, D. Xiao, J. Zhu, Chem. Rev. 115, 2559 (2015)

C.-H. Hong, H.-P. Kim, B.-Y. Choi, H.-S. Han, J.S. Son, C.W. Ahn, W. Jo, J. Materiom. 2, 1 (2016)

J. Rödel, J.-F. Li, MRS Bull. 43, 576 (2018)

L. Egerton, D.M. Dillon, J. Am. Ceram. Soc. 42, 438 (1959)

B. Malič, Acta Chim. Slov. 55, 719 (2008)

H. Jiang, T.T. Su, H. Gong, Y.C. Zhai, Cryst. Res. Technol. 46, 85 (2011)

B. Malič, J. Koruza, J. Hreščak, J. Bernard, K. Wang, J. Fisher, A. Benčan, Materials 8, 8117 (2015)

M. Bah, F. Giovannelli, F. Schoenstein, G. Feuillard, E. Le Clezio, I. Monot-Laffez, AIP Conf. Proc. 1627, 3 (2014)

M. Bah, F. Giovannelli, R. Retoux, J. Bustillo, E.L. Clezio, I. Monot-Laffez, Cryst. Growth Des. 16, 315 (2016)

J. Koruza, H. Liu, M. Höfling, M.-H. Zhang, P. Veber, J. Mater. Res. 35, 990 (2020)

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Nature 432, 84 (2004)

L. Jiang, J. Xing, Z. Tan, J. Wu, Q. Chen, D. Xiao, J. Zhu, J. Mater. Sci. 51, 4963 (2016)

D. Lin, K.W. Kwok, H. Tian, H.W.L. Chan, J. Am. Ceram. Soc. 90, 1458 (2007)

V. P, R. Jose, K. V. Saravanan, RSC Adv. 9, 34888 (2019)

L. Wang, W. Ren, P.C. Goh, K. Yao, P. Shi, X. Wu, X. Yao, Thin Solid Films 537, 65 (2013)

M.-S. Chae, J.-H. Koh, S.-K. Lee, J. Alloys Compd. 587, 729 (2014)

Y.G. Lv, C.L. Wang, J.L. Zhang, L. Wu, M.L. Zhao, J.P. Xu, Mater. Res. Bull. 44, 284 (2009)

D. Lin, Z. Li, S. Zhang, Z. Xu, X. Yao, J. Am. Ceram. Soc. 93, 941 (2010)

F. Jean, F. Schoenstein, M. Zaghrioui, M. Bah, P. Marchet, J. Bustillo, F. Giovannelli, I. Monot-Laffez, Ceram. Int. 44, 9463 (2018)

G.-Z. Zang, X.-J. Yi, J. Du, Y.-F. Wang, Mater. Lett. 64, 1394 (2010)

Y.S. Sung, Appl. Phys. Lett. 105, 142903 (2014)

J. Koruza, A.J. Bell, T. Frömling, K.G. Webber, K. Wang, J. Rödel, J. Materiom. 4, 13 (2018)

S. Garroni, N. Senes, A. Iacomini, S. Enzo, G. Mulas, L. Pardo, S. Cuesta-Lopez, Phys. Status Solidi A 215, 1700896 (2018)

T. Zheng, J. Wu, D. Xiao, J. Zhu, Prog. Mater. Sci. 98, 552 (2018)

H. Thong, Z. Xu, C. Zhao, L. Lou, S. Chen, S. Zuo, J. Li, and K. Wang, J. Am. Ceram. Soc. JACE. 16070 (2018)

J.-F. Li, Y. Zhen, B.-P. Zhang, L.-M. Zhang, K. Wang, Ceram. Int. 34, 783 (2008)

N. Liu, K. Wang, J.-F. Li, Z. Liu, J. Am. Ceram. Soc. 92, 1884 (2009)

M. Bah, F. Giovannelli, F. Schoenstein, G. Feuillard, E. Le Clezio, I. Monot-Laffez, Ceram. Int. 40, 7473 (2014)

G. Corapcioglu, M. A. Gulgun, K. Kisslinger, S. Sturm, Shikhar. K. Jha, R. Raj, J. Ceram. Soc. Jpn. 124, 321 (2016)

R. Pinho, A. Tkach, S. Zlotnik, M.E. Costa, J. Noudem, I.M. Reaney, P.M. Vilarinho, Appl. Mater. Today 19, 100566 (2020)

M. Michálek, M. Michálková, G. Blugan, J. Kuebler, J. Eur. Ceram. Soc. 38, 193 (2018)

K. Morita, B.-N. Kim, H. Yoshida, K. Hiraga, Y. Sakka, J. Eur. Ceram. Soc. 38, 2588 (2018)

Y. Kizaki, Y. Noguchi, M. Miyayama, Appl. Phys. Lett. 89, 142910 (2006)

G. Bernard-Granger, N. Benameur, A. Addad, M. Nygren, C. Guizard, S. Deville, J. Mater. Res. 24, 2011 (2009)

G. Bernard-Granger, A. Néri, C. Navone, M. Soulier, J. Simon, M. Marinova-Atanassova, J. Mater. Sci. 47, 4313 (2012)

J.G. Fisher, S.-J.L. Kang, J. Eur. Ceram. Soc. 29, 2581 (2009)

R. Cong, G. Qiu, C. Yue, M. Guo, F. Cheng, M. Zhang, Ceram. Int. 44, 19764 (2018)

M.I. Morozov, H. Kungl, M.J. Hoffmann, Appl. Phys. Lett. 98, 132908 (2011)

W.E. Vargas, G.A. Niklasson, Appl. Opt. 36, 5580 (1997)

L.-P. Tran Huu Hue, Ultrasonics 219 (2000)

R. Krimholtz, D.A. Leedom, G.L. Matthaei, Electron. Lett. 6, 398 (1970)

Int. J. M Aterials Chem. 5 (2013)

R. Wang, R. Xie, T. Sekiya, Y. Shimojo, Mater. Res. Bull. 39, 1709 (2004)

J.-F. Li, K. Wang, B.-P. Zhang, L.-M. Zhang, J. Am. Ceram. Soc. 89, 706 (2006)

B.-P. Zhang, J.-F. Li, K. Wang, H. Zhang, J. Am. Ceram. Soc. 89, 1605 (2006)

F. Delorme, M. Bah, F. Schoenstein, F. Jean, M. Zouaoui Jabli, I. Monot-Laffez, F. Giovannelli, Mater. Lett. 162, 24 (2016)

D. Kuscer, A. Kocjan, M. Majcen, A. Meden, K. Radan, J. Kovač, B. Malič, Ceram. Int. 45, 10429 (2019)

M. Lun, X. Zhou, S. Hu, Y. Hong, B. Wang, A. Yao, W. Li, B. Chu, Q. He, J. Cheng, Y. Wang, Ceram. Int. 47, 28797 (2021)

S. Kumar, M. Shandilya, S. Thakur, N. Thakur, J. Sol. Gel Sci. Technol. 88, 646 (2018)

K. Shalini, D. Prabhu, N.V. Giridharan, Appl. Phys. A 124, 866 (2018)

S.K. Ojha, S.K. Gogoi, P. Mandal, S.D. Kaushik, J.W. Freeland, M. Jain, S. Middey, Phys. Rev. B 103, 085120 (2021)

F. Delorme, R. Dujardin, F. Schoenstein, B. Pintault, P. Belleville, C. Autret, I. Monot-Laffez, F. Giovannelli, Ceram. Int. 45, 8313 (2019)

Acknowledgements

The authors are grateful to the French METSA network (FR3507) for the financial support of the Transmission Electron Microscope experiment, and to T. Chartier (GREMAN, IUT Blois) for DTA–TGA measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Monot-Laffez, I., Retoux, R., Zaghrioui, M. et al. Microstructural features and piezoelectric properties of spark plasma sintered lead-free \(\hbox {K}_{\mathbf {0.5}}{} \mathbf{Na} _{\mathbf {0.5}}{} \mathbf{NbO} _{\mathbf {3\,}}\) ceramics. Eur. Phys. J. Spec. Top. 231, 4185–4193 (2022). https://doi.org/10.1140/epjs/s11734-022-00573-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1140/epjs/s11734-022-00573-y