Abstract

Boron is an elective element for the Prompt Gamma Activation Analysis (PGAA), due to its exceptionally large neutron capture cross section. This technique, usually performed in nuclear reactors with neutron fluxes as high as 108 cm−2 s−1, can determine quantities of boron as low as tens of nanograms. Some applications, such as the industry of neutron shielding materials, would better benefit from a less sensitive but more portable and accessible boron PGAA, which could be established at construction or fabrication sites. For these purposes ENEA and INFN jointly setup a compact PGAA based on a 0.5 cm3 Cadmium–Zinc–Telluride gamma spectrometer and the HOTNES thermal neutron source. Relying on a series of borated resins with known composition and on comprehensive experimental and Monte Carlo evaluations, this technique features a detection limit in the order of few milligrams in terms of boron mass. As the facility consists simply on a lab-scale neutron source and a polyethylene block with well-established geometry, this simplified PGAA system is suited to be replicated or transported to construction or fabrication sites for QA/QC purposes on borated construction materials for the nuclear sector.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Boron is a key element for various sectors. However, most analytical techniques such as X-ray fluorescence (XRF), inductively coupled plasma-mass spectrometry (ICP-MS) and Electron microprobe analysis (EMPA) not always are suited for its determination in small amounts. Their main limitations are low sensitivity, interference from other elements, and time-consuming sample preparation procedures [1]. A powerful alternative is the Prompt Gamma Activation Analysis (PGAA) [2,3,4], an analytical technique that has gained increased attention in recent years due to its ability to quantify various elements in different materials with high sensitivity and accuracy. Due to the high radiative capture neutron cross section of 10B (3840 b at 25 meV) and the large abundance of 10B in natural boron (20%), boron is an elective element for PGAA [5, 6]. This was conveniently exploited in various sectors like geology [1], neutron capture cancer therapy [7, 8], cosmochemistry [9], ceramic materials [10], semiconductor industry [11], food safety [12], biology [13] and boron chemistry [14, 15]. At nuclear reactors, where cold to thermal neutron beams with fluence rate in the order of 107–108 cm−2 s−1 are available, quantities of boron as low as nanograms can be detected. Although the detection limit, LD, depends on many factors, it roughly varies as the inverse of the thermal neutron fluence delivered to the sample. It was found that the product LD × dΦ/dt, between the detection limit of boron PGAA and the thermal neutron fluence rate, ranges in the interval 5–20 g × cm−2 × s−1 for reactor-based facilities [16]. Some applications such as the neutron shielding industry [17, 18] are mainly interested in detecting boron amounts in the order of milligrams to grams. According to the mentioned scaling law, neutron fluxes below 103 – 104 cm−2 s−1 would be enough to determine these amounts of boron. Radionuclide neutron sources in moderating assemblies can produce thermal neutron fluxes of 103 – 104 cm−2 s−1, thus are good candidates for PGAA systems with improved portability and accessibility for the mentioned industrial applications.

ENEA and INFN already established [16] a compact PGAA system in the Frascati research Centre, based on the HOTNES thermal neutron irradiation facility [19,20,21] and a NaI(Tl) scintillation detector. This method is referred to as NaI-PGAA. With a thermal neutron fluence rate at the sample position of only 16.8 cm−2 × s−1, this system allowed determining amounts of boron of about 1 g in 60 g borated concrete samples with an uncertainty in the order of 6%. The LD was in the order of 0.3 g of boron. The main factors limiting the LD were the large background and the poor energy resolution of the detector. Consequently, the 478 keV peak only emerged after a complex background subtraction process.

Recently, a study was undertaken to lower the LD of the method to 10 mg or below, using a 0.5 cm3 Cadmium–Zinc–Telluride gamma spectrometer and a different test position in HOTNES. This method is referred to as CZT-PGAA. Like the NaI-PGAA, the new method is also suited to be displaced to construction or fabrication sites to operate in-situ quality controls, but its LD is lower than 10 mg.

2 Irradiation set-up

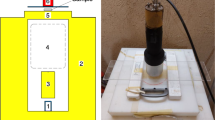

The CZT-PGAA system (Fig. 1) includes the following elements:

-

A 241Am-B fast neutron source with emission rate 3.5 × 106 s−1 surrounded by a 5 mm thick lead shield to attenuate the 60 keV gammas from the 241Am (label 1 in Fig. 1).

-

A polyethylene moderator (label 2) with approximated size 100 cm (h) × 70 cm × 70 cm with an internal cylindrical cavity (30 cm diameter, 70 cm in height);

-

The internal cavity contains a high-density polyethylene shadow bar (10 cm in diameter × 20 cm in height, label 3) with the purpose to prevent fast neutrons to directly reach the irradiation volume, where samples are exposed to a nearly pure thermal field.

-

The irradiation volume is accessible through a removable polyethylene cover, also acting as neutron reflector. When the cover is in place, the direction distribution of the neutron fluence in the cavity is nearly isotropic.

-

The sample (label 4) is located on top of an aluminum plate at the reference position of 50 cm from the source, where the thermal fluence rate is about 760 cm−2 s−1. According to the scaling rule from Ref [16], the product between LD and the thermal fluence ranges from 5 to 20 g cm−2 s−1. With a fluence rate of 760 cm−2 s−1, the detection limit is expected to vary from 6.6 to 26 mg of boron.

-

The CZT detector (label 5, Fig. 2) is located inside the HOTNES cavity on top of the sample. The crystal size is 1 cm × 1 cm × 0.5 cm and is enclosed in a 2.4 cm (diameter) × 3.3 cm (height) cylindrical capsule. The detector was biased at 1 kV and connected to a nuclear spectroscopy chain with shaping time 1 μs. The spectra were recorded by a portable computer. The energy resolution is 2.5% at the gamma energy of the 137Cs.

3 Samples

The target of the PGAA are borated concrete samples with size 5 cm × 5 cm × h, where h ranges from 1 to 1.5 cm (Fig. 3 right).

The algorithm to determine the boron mass in a sample from the gamma spectrum recorded in the CZT would ideally require a set of reference samples with known mass composition and various boron contents. These were manufactured from commercial UV-curing transparent resin of known chemical composition. Known amounts of ultrapure boron carbide in powder were thoroughly mixed with the liquid resin and poured in molds with size 5 cm × 5 cm × 1 cm (Fig. 3 left). The samples were hardened in a few minutes by exposure to an intense UV source. The resulting compact matrix has density 1.05 g × cm−3. Two are the advantages of such resin standards:

-

As the resin components have low atomic number, the sample does not self-absorb the 478 keV photons. The mass composition of the basic UV-resin is: carbon (55.8%), Oxygen (31.4%), Hydrogen (5.8%) and Nitrogen (7.0%).

-

As the UV hardening process is very fast, the boron carbide remains uniformly suspended in the resin.

The following borated resin standard samples were produced: 0.01 (g boron), 0.05, 0.1, 0.2, 0.5, 1.0, 2.0, 3.0. In addition, various non-borated (blank) resin samples were produced.

4 Calibration and detection limit curve

Figure 4 reports the typical CZT gamma spectra obtained from standard resin samples containing 100 mg of boron or no boron (blank sample), respectively. In addition to the 478 keV peak arising from the neutron capture in boron, the 558 keV and about 650 keV photons from the neutron capture in Cadmium and Tellurium of the detector itself are visible. A tiny 478 keV peak is visible in the blank sample, due to the neutron captures in the boron contained in neutron source active material (Americium-Boron).

CZT prompt gamma spectra of standard resin samples containing 100 mg of boron or no boron (blank sample). In addition to the 478 keV boron peak, the prompt γ-rays from Cadmium (558 keV) and Tellurium (about 650 keV) of the detector itself are visible. The exposure time was 13,000 s (resin 100 mg) and 24,000 s (blank sample)

Figure 5 shows the "net boron" spectrum or "difference spectrum” (DS), obtained by subtracting the average spectrum of a series of ten blank resins from the borated resin one.

The area of the boron peak in the DS is assumed to be related to the sample boron content. The peak is fitted using a gaussian function and its area is derived. This is called “net count rate”, or R(m), where m is the boron mass in the sample. The standard resin samples were analyzed in the CZT-PGAA with exposure time varying from 13,000 s (10 mg of boron) to 2000s (3 g of boron), obtaining the “calibration curve” shown in Fig. 6 (blue line). The saturating trend arises from the self-absorption of the thermal neutrons in the sample. The curve was interpolated as follows:

where R (s−1) is the count rate in the boron peak, \({R}_{0}\) is the saturation value (1.22 s−1), m the boron mass in the sample (g) and m0 is the attenuation parameter (0.36 g).

The uncertainty on R(m) in terms of s.d. ranges from 47% (m = 10 mg) to 2% (m = 1 g and above) and was derived as follows. The DS exhibits fluctuations coming from subtraction process. The amplitude of these fluctuations is nearly constant over the 100 keV energy interval around the 478 keV peak considered for the analysis. The following algorithm was then applied to each borated sample:

-

The amplitude of the DS fluctuations was estimated in terms of standard deviation, s.

-

A smoothing procedure was applied to the DS to obtain the smoothed difference spectrum, SDS (See Fig. 5).

-

About 10,000 "variated" DS were generated by applying to SDS a Gaussian perturbation with standard deviation s.

-

For each variated DS, the integral of the 478 keV peak was derived.

-

The uncertainty of the peak integral was obtained as the standard deviation of the distribution of the variated peak integrals. Examples of these distributions are given in Fig. 7.

To verify that the physical processes are all understood, a complete Monte Carlo simulation of the CZT-PGAA was performed with MCNPX [22], whose geometry is represented in Fig. 1. The coupled neutron-gamma-electron calculation allowed generating the prompt gammas in the boron of the sample and follow them to the CZT detector, in turn producing the corresponding pulse height distribution. The area of the 478 keV peak from the simulation, Rs, is reported in Fig. 6 as a function of the sample boron content.

A constant scaling factor was applied to the simulated values to compare with the experimental data. Interestingly, the simulated and experimental functions are in very good agreement.

Finally, it is interesting to investigate the minimum quantities that are detectable with CZT-PGAA. By adopting the Currie formalism [23] in “well-known blank” condition with 5% probability of both type I (false negative) and type II (false positive) errors, the following levels can be derived:

-

Critical level LC: the signal level above which an observed instrument response may be reliably recognized as “detected”, LC = 1.64 × sb, where sb is the standard deviation of the background.

-

Detection limit LD, the true net signal level that may be expected a priori to lead to detection, LD = 3.29 × sb.

From the analysis of ten blank resin samples counted for about 20,000 s, sb was found to be 0.01 s−1. Consequently, LC = 0.016 s−1 and LD = 0.0329 s−1. Using the experimental curve of Fig. 6, these correspond to 5 mg and 10 mg of boron, respectively. Particularly, the LD level at 10 mg interestingly coincides with the standard resin sample with lowest mass. According to Currie formalism, the value of LD is such that at this level it is accepted a fraction of false negatives of 5%, where false negatives means “deciding that the signal is absent when it is in fact present”. By analyzing the occurrence distribution for 10 mg in Fig. 7, it can be seen that the fraction of estimations falling below 0, i.e. false negatives, is 2.2%. This means that the 10 mg is a slightly pessimistic estimation for LD. By contrast, if the same distribution is shifted on the left by 0.01 cps, the percentage of false negatives becomes 5%. Thus, a more realistic estimation for LD is LD (new) = (0.0329–0.01) = 0.0229 s−1, corresponding to 7 mg in terms of boron mass.

5 Conclusions

The PGAA system based on the HOTNES facility and on a 0.5 cm3 Cadmium–Zinc–Telluride gamma spectrometer allows determining quantities of boron in the order of tens on milligrams, referred to standard samples made of resins with well-known composition. The relation between the amount of boron in the sample and the 478 keV signal in the CZT was studied, finding a saturating trend due to the sample self-absorption. This was fully confirmed by the results of a detailed Monte Carlo model of the system. The detection limit of the system is about 7 mg in terms of boron mass. Clearly, when this method will be applied to samples having different composition than the standard resins, such as borated concretes, a”matrix” correction factor will be needed in order to apply the calibration curve of Fig. 6. As done in a previous study [16], this factor can be derived via simulation. Compared to the previously studied NaI-PGAA, which proved to be suited for amounts of boron in the order of the gram, the CZT-PGAA can be conveniently used for amounts of boron in the order of tens – hundreds of milligrams. The thermal neutron fluence required to achieve this performance is in the order of 760 cm−2 s−1, and can be easily obtained with a lab-scale radionuclide neutron source enclosed in a moderating cavity. The CZT-PGAA method can be adopted as verification method for borated materials in the nuclear industry and related research. One of these application is the selection of neutron attenuating building materials for the SORGENTINA project [24,25,26], aimed at developing a high intensity 14 MeV fusion neutron source. The present work can be regarded as testing bed for designing a similar facility at the SORGENTINA installation, where well-controlled high-intensity thermal neutron fields will be made avaialble thanks to especially designed moderating assemblies [27]. With an expected neutron emission rate of 5–7 × 1013 s−1, a well-designed thermal neutron beamline could easily reach few 106 cm−2 s−1, thus lowering the Detection limit LD to the range of the microgram. These levels are of interest for a series of applications in nuclear industry, environmental protection, geology, ceramics, food safety, biology and boron chemistry.

Data Availability Statement

The data sets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request. The manuscript has associated data in a data repository.

References

K. Gméling et al., J. Radioanal. Nucl. Chem.Radioanal. Nucl. Chem. 271, 397 (2007)

Z.B. Alfassi, C. Chung, Prompt Gamma Neutron Activation Analysis (CRC Press, Boca Raton, FL, 1995)

Gabor L. Molnàr, Handbook of Prompt Gamma Activation Analysis, Springer New York, NY (2004).

Z. Kasztovszky, et al., Prompt-Gamma Activation Analysis and Its Application to Cultural Heritage. In: D'Amico, S., Venuti, V. (eds) Handbook of Cultural Heritage Analysis. Springer, Cham. (2022).

M. Crittin, et al., Boron detection by prompt gamma ray activation analysis (PGAA). Advances in Neutron Capture Therapy, Elsevier, B. Larsson, et al. (Eds.), Amsterdam (1996), p. 343

S. Söllradl et al., J. Radioanal. Nucl. Chem.Radioanal. Nucl. Chem. 298, 2069 (2013)

T. Kobayashi et al., Med. Phys. 27, 2124 (2000)

C. Grunewald et al., Nucl. Med. Biol.. Med. Biol. 44, 83 (2017)

M. Zhai, Meteoritics 29, 607 (1994)

T. Miura et al., J. Radioanal. Nucl. Chem.Radioanal. Nucl. Chem. 278, 653 (2008)

R.L. Paul, Analyst 130, 99 (2005)

M. Fukushima et al., J. Radioanal. Nucl. Chem.Radioanal. Nucl. Chem. 302, 1225 (2014)

H.-J. Cho et al., J. Radioanal. Nucl. Chem.Radioanal. Nucl. Chem. 264, 701 (2005)

S. Baechler et al., Nucl. Instr. Meth. A 488, 410 (2002)

A. El Abd, Nucl. Instr. Meth. B. Instr. Meth. B 337, 62 (2014)

A. Pietropaolo et al., Eur. Phys. J. Plus 138, 1114 (2023)

P. Gokul et al., Results Eng. 19, 101281 (2023)

Gunsing, F., Menelle, A ., Aberle, O. Determination of the boron content in polyethylene samples using the reactor Orphée. Report CERN-OPEN-2017–010. 2017.

A. Sperduti et al., JINST 12, P12029 (2017)

R. Bedogni et al., Nucl. Instr. Meth. A 843, 18 (2017)

R. Bedogni et al., Applied Radiat. Isot. 127, 68 (2017)

C. J. Werner (Ed.), MCNP Users’ Manual-Code Version6.2, Report LA-UR-17–29981, Los Alamos National Laboratory, USA (2017).

L.A. Currie, Applic. Radiochem. Anal. Chem. 40, 586 (1968)

A. Pietropaolo et al., Eur. Phys. J. Plus 136, 1140 (2021)

G.M. Contessa, N. Terranova, T. Pinna, D.N. Dongiovanni, M. D’Arienzo, F. Moro, P. Ferrari, A. Pietropaolo, Environments 9(6), 71 (2022)

P. Ferrari et al., Eur. Phys. J. Plus 138, 435 (2023)

A. Pietropaolo et al., Europhys. lett. 126, 12001 (2019)

Funding

Open access funding provided by Ente per le Nuove Tecnologie, l'Energia e l'Ambiente within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bedogni, R., Russo, L., Campoy, A.I.C. et al. Prompt gamma activation analysis for boron determination in the tens of milligram range at the HOTNES facility. Eur. Phys. J. Plus 139, 618 (2024). https://doi.org/10.1140/epjp/s13360-024-05390-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-024-05390-x