Abstract

The manufacturing of Italian maiolica (tin-glazed pottery) was extremely appreciated during the Middle Ages and Renaissance, leading to the production and collection of a rich cultural heritage. This pilot study aims to characterize the production technique and the origin of the lead used as a flux in a set of samples of maiolica glazes made in the area of Florence over a wide time span, ranging from the fifteenth to the nineteenth century. In particular, this is the first study that applies provenance analysis, using lead isotopes, to tin-glazed artefacts made in the site of Montelupo Fiorentino and by the Ginori manufactory in Doccia (Florence, Italy), both important production centres of ceramics in Italy. The samples were first analysed by scanning electron microscopy to characterize their layer structure and chemical composition. Lead isotope analysis was then performed by thermal ionization mass spectrometry and showed that the samples tend to be distributed into distinct groups according to their period of production. Moreover, the comparison with the lead isotope composition of the deposits of the European and circum-Mediterranean area from which lead was historically extracted showed that the isotopic composition of the samples differs from that of the Italian deposits, suggesting that lead was imported from abroad. The isotopic composition of all the investigated maiolica glazes is compatible with German ore deposits, in agreement with what is reported by the historical sources relating to the lead supply areas.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Maiolica is a term of Italian origin indicating tin-glazed earthenware. Tin glaze technique arrived in Italy around the thirteenth century from the Islamic world, where it originated, through Spain. Italian maiolica developed its own shapes and styles, becoming a very important art form during the Middle Ages and the Renaissance. The main information about raw materials and the techniques used in the production of Medieval and Renaissance Italian maiolica are mainly reported in the treatise by Cipriano Piccolpasso (c. 1557) [1,2,3] and in the review by Tite [4] and references therein. According to what reported by Piccolpasso, the glaze was made by mixing sand, wine lees (containing potassium) and, optionally, natron (Na2CO3·10 H2O) with lead (PbO) and tin (SnO2) oxide. The latter were used as flux and opacifier, respectively. Indeed, the production of tin-opacified lead-alkali glazes require the preparation of a suspension containing a lead compound and silica, with the addition of tin oxide and an alkali element [5]. Although the lead and tin oxides can be added directly to the suspension, they are sometimes first pre-fritted with the alkali and silica, as documented by some frits found at Paterna and Denia in Spain dated to the thirteenth century [6]. The resulting frit is then ground to a powder and used in suspension. On the basis of Piccolpasso’s treatise, lead and tin metals were melted together to produce a mixture of lead and tin oxides [1]. The heating of tin alone produces a grey powder, probably as the result of the formation of a coating of tin oxide which prevents complete oxidation of tin metal. However, with the addition of lead oxide, the formation of a tin oxide coating is prevented by intermixture of the tin oxide (SnO2) with the lead oxide (PbO) [5].

Despite this overall comprehension of the materials and manufacturing techniques used in the maiolica production, very little is known about the provenance of the raw materials used to produce the tin-opacified glazes. Unlike ceramic bodies, which were often made with local raw materials, given that clays and tempers are typically widespread and of moderate economic value [3, 7, 8], the materials needed as glaze fluxes, opacifiers and colourants could be rather rare and expensive and a more complex and long-range supply chain could be needed. In support of this, Piccolpasso mentions an interesting proverb in his treatise: ‘piombo todesco, stagnio fiandresco’ ('German lead, Flemish tin') [1]. Tin ores deposits are not present in the Flanders: the association of tin with this area is due to the commercial routes through which the metal reached Italy (at the time of Piccolpasso the main trade centre in northern Europe was Anversa, also favoured by its geographical position which placed it on the routes connecting Venice and Milan to the North Sea [9]). On the contrary, the provenance of lead from German deposits is an actual possibility since significant galena (PbS) deposits are present in the area and have been exploited for the extraction of silver from the eleventh century. On the other hand, Vannoccio Biringuccio reported in his important treatise De la pirotechnia written in 1540 that lead was a widespread and easily available metal, but he only mentions the deposits of Andalusia (Spain) for their good quality [10]. Since from historical considerations and documents it is not possible to clearly identify the origin of lead used as flux in the production of glazes, the aim of this study is to acquire new information using lead isotope analysis.

Isotope geochemistry is based on the study of natural variations in the relative abundances of isotopes of different elements. These variations are measured by mass spectrometry and their ratios (206Pb/204Pb, 207Pb/204Pb, 208Pb/204Pb, 208Pb/206Pb, 207Pb/206Pb) can be successfully used as geochemical tracers [11,12,13]. Lead isotope analysis was proposed as an analytical technique for tracing the geological provenance of some archaeological artefacts more than 50 years ago and is now widely used in archaeometry, mainly for provenance studies of metallic artefacts (copper, silver, lead, tin, etc.). A large amount of data is available in the literature and is carefully discussed in the reviews by Artioli et al. [14] and Killick et al. [15]. These provenance studies contribute to the reconstruction of ancient metal trade routes and help us to better understand the economic, political and social aspects of ancient civilizations [16]. Numerous lead isotopic data are available to date and are collected in large databases such as OXALID (https://oxalid.arch.ox.ac.uk), BRETTSCAIFE (https://brettscaife.net), GlobaLID (https://globalid.dmt-lb.de) and the one reported by Tomczyk [17].

However, lead isotope composition of metal artefacts has some critical points, discussed extensively by Artioli et al. [14]. The method is very effective in excluding the origin of metal artefacts from deposits that are not isotopically compatible, but often it is not possible to identify a specific source of origin, due to the very similar isotopic signatures of ore deposits that are even very distant from each other geographically. The interpretation process should therefore be accompanied by complementary chemical, geological, historical, archaeological or archaeometallurgical information [16]. Another limitation of the technique is represented by the possible mixing or recycling of different lead sources which can determinate a distribution of isotopic ratios around a mixing line between two or more source clusters, making provenance interpretation difficult [15].

Beside the field of archaeometallurgy, lead isotope analysis has been effectively used also for provenance studies on non-metallic archaeological materials, such as ceramics, glasses and glazes (see, for example, [18,19,20,21,22,23,24,25]). In particular, some of the first applications of lead isotope analysis on glazed pottery were on artefacts from the early Islamic period [26, 27], known both for having been widely traded and for the existence of documentary sources relating to the long-distance trade of lead [24]. Other studies concerned lead-glazed ceramics from the American south-west, Roman and Medieval ceramics from the Mediterranean, and Tang period ceramics from China [18,19,20, 28, 29].

Studies on the origin of tin glazes are not widespread; some examples are represented by the articles published by Wolf et al. [27] and Habicht-Mauche et al. [29] on fragments produced in Fustat (Egypt) and Rio Grande (USA), respectively. Furthermore, Chiarantini et al. [30] studied the lead isotopic composition of the pigment Naples yellow (lead antimoniate) used in maiolica from Montelupo Fiorentino (Florence) between the fifteenth and sixteenth centuries: the authors analysed the lead isotopic composition of the yellow pigment and, for comparison, of a few white glazes. The interesting results of these studies suggested that the sources of lead in the glaze were very distant from the places of production of the artefacts, indicating potential long-distance trade of lead or lead frits for the production of maiolica glazes.

The focus of this pilot study is on the isotopic composition of the lead contained in the white tin glaze (without pigmentation) of artefacts made in the sites of Montelupo Fiorentino and Doccia (Florence, Italy) over the period of time from the fifteenth to the nineteenth century, with the aim of providing constraints on the origin of the lead ore(s) used in the maiolica production. Moreover, the study also aims to characterize the production technique and raw materials used in the production of tin glazes in these two sites.

2 Materials and methods

Ten samples of maiolica were analysed in this study: eight sherds from Montelupo Fiorentino (Florence), dated between the fifteenth and eighteenth centuries and currently preserved at the Museo della Ceramica di Montelupo Fiorentino, and two fragmentary objects made by the Ginori manufactory in Doccia (Florence) in the first half of the nineteenth century, which belong to a private collection (Fig. 1).

The layered structure and the chemical composition of the samples were characterized at the MEMA laboratory of the University of Florence. Polished cross sections of the glaze and the underlying ceramic bodies were first analysed by reflection microscopy using a Zeiss Axioskop optical microscope (equipped with Axio Vision6 software). The same sections were also analysed through scanning electron microscopy (SEM) equipped with an energy-dispersive X-ray spectrometer (EDS) using a Zeiss EVO MA15 instrument equipped with an Si–Li spectrometer and Oxford INCA250 software. The working conditions were as follows: accelerating voltage 15 kV, beam current 10 nA, working distance 8.5–9.5 mm and spot size about 1 μm.

The lead isotope composition of the samples was measured by thermal ionization mass spectrometry (TIMS) using a Thermo Scientific Triton-Plus at the Radiogenic Isotope Laboratory of the Earth Sciences Department of the University of Florence. A small quantity of glaze (ca. 1 mg) was sampled with a scalpel from each of the 10 samples. This sampling was performed in the same area investigated with SEM–EDS, taking care to change the tip of the scalpel between one sample and another to avoid contamination. Once collected, the glaze fragments were cleaned from the underlying ceramic material using a micro-drill to avoid any contribution to the isotopic composition not directly derived from the glaze. The fragments were dissolved in a mixture of concentrated HNO3 and HF, dried and redissolved twice in HNO3, and then refluxed in 6 M HCl to achieve the complete dissolution of the glaze. Once dried, the samples were dissolved in 0.7 M HBr and loaded onto Bio-Rad AG1-X8 anion exchange resin. After elution, the purified lead fractions were refluxed twice with HNO3 and HClO4 to ensure the complete destruction of any organic matter released by the resin. Once dried down, the samples were then diluted in 2 M HNO3 and loaded with H3PO4 and silica gel onto Re zone refined filaments for thermal ionization mass spectrometry (TIMS) analyses. Lead isotope composition was measured in static mode. Instrumental mass bias was corrected using replicate analyses of NIST SRM 981 standard. The external precision of NIST SRM981 was 208Pb/204Pb = 36.539 ± 49, 207Pb/204Pb = 15.441 ± 15, 206Pb/204Pb = 16.901 ± 12, 207Pb/206Pb = 0.9136 ± 3, 208Pb/207Pb = 2.3663 ± 9, 208Pb/206Pb = 2.1620 ± 14 (2σ, n = 46). The accuracy of Pb isotope data was further tested by measuring the reference material AGV-1 (Table 4) provided by USGS, which yielded 206Pb/204Pb, 207Pb/204Pb and 208Pb/204Pb in agreement with those reported in literature (e.g. [31,32,33,34]).

3 Results

3.1 Composition and layer structure

The chemical compositions of the investigated glazes are reported in Table 1. The glazes are of the lead-alkali type with SiO2 content of 45.7–57.7 wt% and PbO content of 17.2–36.2 wt%. The total alkali contents (Na2O + K2O), used as flux, are in the range of 3–8.7 wt%, with K2O being always more abundant than Na2O. Tin is present in the form of cassiterite (Sn2O) crystals, which act as opacifiers, and range between 3.4 and 12.7 wt%. Lime (CaO) and alumina (Al2O3) are present in amounts < 5 wt%. In some samples, Fe2O3 is also present in amounts < 1 wt%. An example of the typical distribution of the elements within the ceramic body and the opaque glaze is clearly visible in Fig. 2.

Figure 3 shows the images of the samples observed by SEM in backscattered electrons (BSE). Cassiterite crystals are abundant in all samples and have a small size of ca. 2–10 μm, with the exception of samples 017, 018 and 007 where they form large agglomerates (from 15 to 35 μm). Furthermore, cassiterite crystals are evenly distributed throughout the thickness of the glaze layers.

Quartz and K-feldspar crystals are present in the glazes of all samples, with the exception of sample 023 in which only quartz was detected. They are present in large quantities only in six of the investigated samples (i.e. 023, 012, 007, 002, 022 and 006). The silicate crystals have very variable dimensions (in the range of 10–80 μm) and are distributed quite homogeneously throughout the thickness of the glaze.

The samples also show variability in the thickness of the opaque glaze layer: from about 40 to more than 250 μm (Table 2).

Although this study is mainly focused on the glazes, we also reported the results obtained from the SEM–EDS analysis on the ceramic bodies (Table 3), which was sampled, together with the opaque glaze, in only 7 samples: 017, 018, 023, 012, 022, 006 and M1. They revealed similar chemical compositions (except for sample 022, see below). The main constituent oxides are SiO2, CaO, Al2O3, Fe2O3, MgO, Na2O and K2O. SiO2 ranges between 47.2 and 65.4 wt% and Al2O3 between 14 and 18 wt%. The Ca-rich composition (c. 10–22 wt% CaO) is consistent with the pink cream colour of the body and with the local manufacturing technique: it is known indeed that potters from Montelupo used lime to whiten the ceramic body and reduce the amount of tin necessary to produce the white opaque glaze [3, 7]. In a few samples, the ceramic bodies contain PbO between 0.4 and 2.2 wt%, which is most likely related to a contamination from the glaze layer during the firing phase. Sample 022 differs from the others for its composition, which is rich in MgO (6.0 wt%), Al2O3 (20.0 wt%) and K2O (10.6 wt%) and poor in CaO (3.9 wt%) and Fe2O3 (0.8 wt%). This sample is also characterized by a high amount of PbO (7.0 wt%), probably because the analysis was performed in proximity of the opaque glaze layer.

3.2 Lead isotope results

The lead isotope composition of the analysed glaze samples is reported in Table 4. Sample M5 was analysed twice (indicated with A and B in Table 4) to check the reproducibility: consistent isotopic compositions were obtained.

In general, the samples are distributed in distinct and well-separated compositional groups according to their historical period of production, with the only exception of two samples. Namely, sample 012 (sixteenth century) has an isotopic composition more similar to the samples of fifteenth-century production, and sample 023 (fifteenth century) falls closer to the samples from the sixteenth century. Therefore, the samples were clustered into 3 different groups (Fig. 4): (i) Group A includes all the samples from the fifteenth century (i.e. 017, 018, 023) and the sixteenth century (i.e. 012, 007, 002) made in Montelupo Fiorentino, (ii) Group B contains samples from the seventeenth century (022) and the eighteenth century (006) made in Montelupo Fiorentino, and (iii) Group C identifies the samples from the nineteenth century (i.e. M5 and M1) made by the Ginori manufactory in Doccia.

Lead isotope composition of the investigated samples: a 207Pb/206Pb versus 208Pb/206Pb; b 206Pb/204Pb versus 208Pb/204Pb. The samples are clustered in 3 groups: Group A, Group B and Group C. The error ellipse represents the external reproducibility of the NIST SRM981 Pb standard at the 95% confidence level (2σ)

4 Discussion

The resulting chemical compositions of all the investigated samples are in agreement with those of Renaissance and late Renaissance maiolica reported by Tite in his review of Italian maiolica [4]. The occurrence of both potash and soda in the glazes is consistent with Piccolpasso’s description of the use of wine lees (potassium-rich) and sea salt in the production of the marzacotto [4, 35]. In addition, the measured SnO2/PbO ratios (0.1–0.6) match the estimated ranges from Piccolpasso’s recipes (0.1–0.5, [35]). Among the analysed samples, it is possible to highlight some compositional differences according to their historical period of production (Fig. 5, Table 1). Samples 017 and 018, dated 1440–1470, show a higher content of alkali (Na2O + K2O, 7.9 and 8.7 wt%) and a corresponding lower content of lead (PbO, 20.1 and 17.2 wt%) than the later samples; also, the SnO2 content is significantly higher than in the other samples (SnO2, 12.7 and 10.8 wt%). This composition is similar to that reported in the literature (e.g. [4, 7]) for the medieval production, during which large quantities of tin were used as glaze opacifier. Samples 023, 012, 007, 002, 022 and 006, dated from the second half of the fifteenth to the second half of eighteenth century, have a lower content of tin (SnO2, range of 3.4–6.3 wt%) and alkali (Na2O + K2O, range of 2.7–6.6 wt%) and a corresponding higher content of lead (PbO, range of 25.5–36.2 wt%). Instead, the samples by Ginori (M1 and M5, dated between the end of eighteenth first half of nineteenth century) show again a high SnO2 content, associated with a high PbO and low alkali content. The recipes for the production of glazes underwent a change between the end of the fourteenth century and the first half of the fifteenth century. The Medieval maiolica glazes tend towards the high lead type with a total alkali content less than 5 wt% (Na2O + K2O). In contrast, in the early and late Renaissance, glazes are consistently of the lead-alkali type with lower PbO content and total alkali content in the range of 2–11 wt% (Na2O + K2O). Also, the tin content is typically higher in Medieval archaic glazes (SnO2, from 7 up to even 28 wt%) than in later ones, in which the SnO2 does not exceed 10 wt% [4, 35]. Since the Renaissance, the recipe of maiolica glazes has remained unchanged and there are no significant changes in their chemical composition between the mid-fifteenth and early seventeenth centuries [4]. The Ginori manufacture resumed the recipe of Renaissance glazes [36, 37], albeit using higher quantities of tin as opacifier (SnO2, 7.5 and 9.3 wt%).

The mineralogical analysis highlights that the occurrence of angular quartz and potassium feldspar particles in the glazes is almost certainly the result of the addition of sand, which Piccolpasso reported being sometimes added to the glazing mixture of marzacotto (i.e. glaze mix), and which underwent only limited dissolution during the firing [35]. The addition of sand to the glaze mix is known to make the unfired opaque glaze more robust, less powdery and to increase the suitability of incorporation of the coloured decoration as well, while it does not provide a significant contribution to the opacity, since the refractive indices of quartz and feldspars are comparable to those of the glaze [5, 35, 40]. This addition of sand to the glaze mixture is documented starting from the Renaissance (as reposted by Piccolpasso). Indeed, it is interesting to note that the samples from the mid-fifteenth century and the nineteenth century (i.e. 017, 018, M1 and M5) show low amounts of silicate inclusions (5% of quartz and K-feldspar crystals) and present large agglomerates of cassiterite in the size range of 15–35 µm. On the other hand, the Renaissance and late Renaissance samples (i.e. 023, 012, 007, 002, 022 and 006) have a higher amount of silicate inclusions, and the cassiterite crystals have lower size (c. 2–10 µm) and abundant and homogeneously distribution throughout the thickness of the glaze (see Fig. 3).

The thicknesses of the opaque glaze layers are quite variable in the different samples (from around 30 to around 300 μm) and, in general, do not seem to be correlated with the period of production. Nevertheless, they are compatible with the thicknesses of the maiolica sherds investigated by Tite [4], which reported the range of 60–300 µm for the opaque glaze. It must be considered that the thickness of the glaze likely depends also on the type of artefact (i.e. shape) and on the area where the sample was taken, since the application of the glaze on the ceramic body can be inhomogeneous (e.g. occurrence of protruding elements or cavities). Furthermore, the number of samples studied is not sufficient to represent a historical period and further studies on a larger maiolica record would be necessary.

Finally, none of the samples has the transparent overglaze layer named coperta. The coperta was sometimes applied over the painting decoration of the pottery before firing the artefact for a second time [4]. An important advantage of applying this layer over the decoration is that it creates a smooth and shiny reflective surface and a protective layer for the decoration [35]. The coperta started to be applied from the fifteenth century, but it was not always used [2, 4], as confirmed also by the present study.

4.1 Potential sources of lead

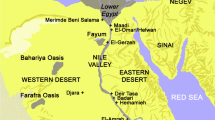

The lead isotope results obtained in this study (Fig. 4) allowed to make some hypothesis regarding the sources of lead used in Montelupo and Ginori maiolica production on the basis of the lead isotopic data currently available in the literature and the historical and archaeological evidence for the exploitation of lead ores. It is necessary to stress that in this type of studies it is not possible to exclude a mixing or recycling of lead from different sources and this represents the main limitation of the technique [14, 15]. However, the investigated samples, do not plot along 'mixing lines' between two or more lead ore deposits, possibly arguing against multiple sources. The isotopic composition of the samples was compared with that of the main lead ore deposits of the European and circum-Mediterranean area exploited in Antiquity, in the Renaissance times and/or in the Modern era (Fig. 7) combining the isotopic data from the open-access databases OXALID (https://oxalid.arch.ox.ac.uk), BRETTSCAIFE (http://www.brettscaife.net) and globaLID (https://globalid.dmt-lb.de/) with those published during the last decades by several authors [41, 42]. At a first observation, it was possible to exclude some lead deposits which have an isotopic composition significantly different from the samples investigated such as those of Cyprus, Czech Republic, Egypt, Finland, Greece, Hungary, Ireland, Macedonia, Morocco, Norway, Romania, Serbia, Sweden, Spain, Syria, Tunisia and Turkey (not reported in Fig. 7). Notably, the Spanish deposits mentioned by Biringuccio in his treatise De la pirotechnia written in 1540 not isotopically compatible with the maiolica samples analysed. Indeed, as discussed in paragraph 1, this method is very useful for excluding some possible deposits, but it is more difficult to unequivocally identify a specific source, due to the overlap of the isotopic fields of the different lead deposits. Therefore, a limited number of lead deposits were selected for further considerations: Italy, Germany, Austria, England, Bulgaria, France and Switzerland (Fig. 7). Among these deposits, we first considered the compatibility of the lead isotope composition of maiolica glaze with the local Italian deposits (Fig. 6). We took into consideration those located in Sardinia, Tuscany (southern Tuscany and the Apuan Alps) and Veneto (Monte Civillina, Vicentine Alps) regions characterized by Pb-Ag-Zn mineralizations and exploited since the Bronze Age (Sardinia and southern Tuscany), the late Roman era or the early Middle Ages (Monte Civillina and Apuan Alps). Sardinia has many ore deposits located in the Sulcis-Iglesias and Fluminimaggiore area (Cagliari, SW Sardinia), Silius (Cagliari, SE Sardinia) and Fonni, Lula and Torpè area (Nuoro, NE Sardinia). Their exploitation began in the Bronze Age and continued intensely through the centuries until the twentieth century, crossing only a period of decline during the Aragonese and the Spanish domination between the sixteenth and seventeenth centuries [43]. The metal deposits of Tuscany experienced intense but time-restricted exploitation during the Granducato of the Medici family in the sixteenth century [30, 44], while the Monte Civillina deposits reached their peak of extraction between the fifteenth and sixteenth centuries under the government of the Serenissima Republic of Venice [30].

Lead isotope composition of the samples compared with the Italian ore deposit signatures. a 207Pb/206Pb versus 208Pb/206Pb b 206Pb/204Pb versus 208Pb/204Pb. Isotope data from south Tuscany: Stos-Gale et al. [45] and OXALID database; Apuan Alps: D’Orazio et al. [42]; Monte Civillina: Chiarantini et al. [30] and Sardinia: OXALID and globaLID databases and Tomczyk [17]

The samples from Montelupo and those by Ginori in Doccia provided different results and will be discussed separately. Importantly, all the samples made in Montelupo Fiorentino are isotopically incompatible with the ore deposits of Tuscany (south Tuscany and the Apuan Alps) and also, more in general, with the other Italian lead ore deposits (Monte Civillina in the Vicentine Alps and Sardinia) (Fig. 6). We can, therefore, exclude that lead was supplied from Tuscan deposits but also from other main Italian deposits reasonably available at the time.

On the other side, the two samples by Ginori, dated to the end of the eighteenth and the first half of the nineteenth century (M1, M5) and belonging to Group C, fall in a different area of the isotopic diagram with respect to the other samples from Montelupo (Fig. 4). This could be due to the fact that the Ginori manufactory had lead supply sites different from those exploited by the Montelupo potters in previous centuries, although no historical information is available in the literature to the authors’ knowledge. The lead isotope composition of these two samples is comparable with that of the Apuan Alps deposits (Fig. 6). The consistency of the most recent production with an Italian deposit could be related to a possible change in the supply of raw materials, including lead. Historical information regarding lead ores exploitation in the first half of the nineteenth century is available only for the Bottino mine (Apuan Alps, Tuscany) [44]. This site is the most important Pb(Zn)-Ag mineral deposit in the Apuan Alps [49, 5019] and, after a period of exploitation in the sixteenth century, was reopened for the supply of silver in 1829. In 1836 the ‘Compagnia del Bottino’ was established and the mine flourished, becoming the most important in Italy for the production of silver, before its final closure in 1969 [44]. Given its proximity to the area of Doccia (Sesto Fiorentino, Florence) and the large amount of lead produced as a waste of silver smelting (the total lead production is estimated to have been of the order of 4000t [50, 51]), this mine can be indicated as a probable source of lead for the production of Ginori maiolica glazes in the first half of nineteenth century.

A detailed comparison with other European ore deposits (Fig. 7) was made to investigate the potential provenance of the samples clearly not related to the Italian lead ore supply. (The comparison between the samples and the individual lead ore deposits divided by country are reported in the Supplementary materials.)

Lead isotope composition of the investigated samples compared with that of the main European lead ores. a 207Pb/206Pb versus 208Pb/206Pb; b 206Pb/204Pb versus 208Pb/204Pb. Isotopic data from the OXALID and globaLID (https://oxalid.arch.ox.ac.uk; https://globalid.dmt-lb.de/) database and Leveque and Haack [41]; Koppel et al. [46]; Guènette-Beck [47]; Höppner et al. [48]; Lehmann [49]; D’Orazio et al. [42] and Tomczyk [17]

Samples of the fifteenth (017, 018, 023) and sixteenth centuries (012, 007, 002), all belonging to Group A, have an isotopic composition broadly overlapping that of the Harz Mountains and the Rhine Massif in Germany, Carinthia and Bleiberg in Austria, Derbyshire in England, northern Bulgaria and south-western Switzerland, suggesting these polymetallic districts characterized by Cu-Pb–Zn (Ag) mineralizations as a source for glazing raw materials. The Harz Mountains, Rhine Massif, Bleiberg, Derbyshire, south-west Switzerland deposits were active in the twelfth–thirteenth century [47, 52,53,54], but only the Harz mountains and Derbyshire deposits intensified their extraction between the fifteenth and sixteenth centuries becoming one of the most important producers in Europe [55, 56]. Instead, the mineral districts of Bulgaria were already exploited in prehistoric times and extensively in Roman era [57], but the substantial mining activity dates back to the mid-twentieth century [58] and there is no indication about the possible fifteenth–sixteenth-century exploitation.

Samples from the seventeenth century (022) and the eighteenth century (006), belonging to Group B, are found to be isotopically compatible with the same deposits of Group A and, moreover, with those of Somerset in England, southern Bulgaria and of Massif Central in France. With the exception of the Harz Mountains, Somerset and south-western Switzerland deposits, whose extraction was flourishing in the seventeenth century and in the eighteenth century [47, 52, 55], the information on the mining activity of the other deposits in this historical period is very scarce.

The provenance of the lead from the German area is in agreement with the historical sources, in particular with the ‘piombo todesco’ mentioned by Piccolpasso and with the study by Chiarantini et al. [30], which was mainly focused on the Naples yellow pigment but also included one sample of white glaze from Montelupo. On the basis of lead isotope composition, these authors suggested that the lead used for the pigments did not have a local origin but was imported from abroad, likely from Turkey deposits, whereas the white glaze sample showed affinity with the German deposits. Moreover, a study by Wedepohl and Baumann [56] on a group of lead glasses extracted from archaeological contexts in north-western Europe and dated between the twelfth and fifteenth century showed lead isotope compatibility with the deposits of the Harz and the Rhine Massif, highlighting how much lead from Germany was widespread and traded in Europe.

At the same time, also the English lead sources are rather plausible from a historical point of view. It is known indeed that the tin, used as opacifier in the production of Italian glazes, probably had an English origin (Cornwall and Devon deposits), whose trade was managed by the Flemings since the fifteenth century [7, 59]; it is then possible to hypothesize that lead could circulate together with tin along the same commercial routes.

Among the European deposits, Ginori samples are compatible with the isotopic composition of some of the deposits discussed for groups A and B (Rhine Massif in Germany, Carinthia in Austria, Massif Central in France) as well as to those of the Apuan Alps deposits in Italy, as discussed before (Fig. 6). Considering that the information on the historical sources of extraction and trade of lead in this historical period are scarce and incomplete, it is not possible to exclude the provenance of the lead from other supply areas or to formulate further hypothesis.

5 Conclusion

The compositional analysis of the glaze samples investigated allowed to highlight some important aspects concerning both the methods and the materials use to produce the glaze for maiolica in the area of Florence between the fourteenth and nineteenth centuries. The maiolica glazes analysed are of the lead-alkali type, opacified with tin oxide, and their stratigraphy and composition are compatible with the artefacts investigated by Tite [4] in his review on Italian maiolica.

Lead isotope analysis provided promising results for the reconstruction of the evolution of Italian maiolica technology and the commercial and cultural relations in the European and Mediterranean area over time. The lead isotope composition showed that the samples are distributed into distinct groups according to their historical period of production. This indicates that lead isotopes could be a robust tool to discriminate maiolica wares made in different periods. The comparison with the lead isotope composition of the deposits of the European and circum-Mediterranean area, from which lead was historically extracted, showed that the isotopic composition of the samples of Montelupo Fiorentino (Florence), dated between the fifteenth and eighteenth centuries, differs from that of the Italian deposits (south Tuscany, Apuan Alps, Monte Civillina and Sardinia) suggesting an import of lead from abroad. The isotopic composition of the samples is instead compatible with German ore deposits, in agreement with the proverb reported by Cipriano Piccolpasso in his famous treatise about maiolica written in c. 1557 ‘piombo todesco, stagnio fiandresco’ (‘German lead, Flanders tin’). At the same time, also the lead deposits of Great Britain (Somerset and Derbyshire), Bulgaria, France (Massif Central) and south-western Switzerland are isotopically compatible with the investigated maiolica glazes and cannot be excluded as possible centres of supply. A mixing or recycling of different lead sources cannot be excluded, but the limited number of samples examined did not allow us to identify any ‘mixing lines’. Therefore, the isotopic compatibility with the German lead ore and the agreement with the historical source of Piccolpasso suggest this area as the most probable source of lead for the production of the investigated glazes. It is interesting to note that other studies on the origin of lead used in the production of tin-opacified glazes have highlighted the existence of a long-distance trade for lead ores: see, for example, [27, 60], related to maiolica sherds produced in Fustat (Egypt) and Rio Grande (USA), respectively. On the other hand, exploitation of local deposits has been identified only for Spanish medieval and post-medieval productions to date [28].

Regarding the lead isotope composition of the two samples made by the Ginori manufactory in Doccia between the end of eighteenth and the first half of nineteenth century, they are compatible with the Apuan Alps lead ore deposits, suggesting, along with the proximity to the production area, a possible lead supply from the nearby Bottino mine. However, the European lead ore deposits of Rhine Massif in Germany, Carinthia in Austria, Massif Central in France and south-western Switzerland cannot be excluded as possible lead supply areas for these samples as well.

In conclusion, although this is a pilot study carried out on a small number of samples, it provides important constraints on the production techniques and on the origin of lead used in the maiolica manufacture in Montelupo Fiorentino and Ginori in Doccia, which were among the most important production centres in the area of Florence (Italy). The prosecution of the study on a larger dataset will be very useful to implement the knowledge and valorization of this rich cultural heritage.

Data Availability Statement

All data generated or analysed during this study are included in this article.

References

C. Piccolpasso, Li Tre Libri Dell’arte Del Vasajo (Nobili, Pesaro, 1879)

W.D. Kingery, Painterly maiolica of the Italian Renaissance. Technol. Cult. 34, 28 (1993). https://doi.org/10.2307/3106454

F. Berti, Storia della ceramica di montelupo: uomini e fornaci in un centro di produzione dal XIV al XVIII secolo (Aedo, Montelupo Fiorentino, 1997)

M.S. Tite, The production technology of Italian maiolica: a reassessment. J. Archaeol. Sci. 36, 2065 (2009). https://doi.org/10.1016/j.jas.2009.07.006

M.S. Tite, I. Freestone, R. Mason, J. Molera, M. Vendrell-Saz, N. Wood, Lead glazes in antiquity—methods of production and reasons for use. Archaeometry 40, 241 (1998). https://doi.org/10.1111/j.1475-4754.1998.tb00836.x

J. Molera, T. Pradell, N. Salvadó, M. Vendrell-Saz, Technology and colour development of Hispano‐Moresque lead‐glazed potter. Archaeometry (1997). https://doi.org/10.1111/j.1475-4754.1997.tb00788.x

M. Caroscio, La maiolica in Toscana tra Medioevo e Rinascimento. Il rapporto fra centri di produzione e di consumo nel periodo di transizione`, (All’insegna del giglio, Sesto Fiorentino, 2009)

F. Antonelli, A.L. Ermeti, L. Lazzarini, M. Verità, G. Raffaelli, An archaeometric contribution to the characterization of Renaissance maiolica from Urbino and a comparison with coeval maiolica from Pesaro (the Marches, central Italy). Archaeometry 56, 784 (2014). https://doi.org/10.1111/arcm.12045

G. Agresti, I gialli di piombo, stagno, antimonio: colore e materia dell’opera d’arte. PhD Thesis, Università degli studi della Tuscia (2013).

V. Biringuccio, De La Pirotechnia, 1540, ed. A. Carugo (Il Polifilo, Milano, 1977). https://doi.org/10.1007/978-3-319-02848-4_715-1

Z.A. Stos-Gale, N.H. Gale, Metal provenancing using isotopes and the Oxford archaeological lead isotope database (OXALID). Archaeol. Anthropol. Sci. 1, 195 (2009). https://doi.org/10.1007/s12520-009-0011-6

I.M. Villa, Lead isotopic measurements in archeological objects. Archaeol. Anthropol. Sci. 1, 149 (2009). https://doi.org/10.1007/s12520-009-0012-5

J. Blichert-Toft, H. Delile, C.T. Lee, Z. Stos-Gale, K. Billstrom, T. Andersen, H. Han-nu, F. Albarede, Large‐scale tectonic cycles in Europe revealed by distinct Pb isotope provinces. Geochem. Geophys. Geosyst. 17, 3854 (2016). https://doi.org/10.1002/2016GC006524

G. Artioli, C. Canovaro, P. Nimis, I. Angelini, LIA of prehistoric metals in the Central Mediterranean area: a review. Archaeometry (2020). https://doi.org/10.1111/arcm.12542

D.J. Killick, J.A. Stephens, T.R. Fenn, Geological constraints on the use of lead isotopes for provenance in archaeometallurgy. Archaeometry (2020). https://doi.org/10.1111/arcm.12573

S. Baron, C.G. Tămaş, C. Le Carlie, How Mineralogy and geochemistry can improve the significance of pb isotopes in metal provenance studies. Archaeometry 56, 4 (2014). https://doi.org/10.1111/arcm.12037

C. Tomczyk, A database of lead isotopic signatures of copper and lead ores for Europe and the Near East. J. Archaeol. Sci. 146, 105657 (2022). https://doi.org/10.1016/j.jas.2022.105657

S. Stos-Gale, Lead-isotope analyses of glass, glazes, and some metal artifacts. Serce Limani: an eleventh-century shipwreck. (Texas A&M University Press, College Station, 2004)

M.S. Walton, M.S. Tite, Production technology of Roman lead‐glazed pottery and its continuance into late antiquity. Archaeometry 52, 5 (2010). https://doi.org/10.1111/j.1475-4754.2009.00506.x

J.Y. Shen, J. Henderson, J. Evans, S. Chenery, F.Y. Zhao, A study of the glazing techniques and provenances of Tang sancai glazes using elemental and lead isotope analyses. Archaeometry (2019). https://doi.org/10.1111/arcm.12436

L. Medeghini, M. Fayek, S. Mignardi, F. Coletti, A. Contino, C. De Vito, A provenance study of Roman lead-glazed ceramics using lead isotopes and secondary ion mass spectrometry (SIMS). Microchem. J. 154, 104519 (2020)

L. Dussubieux, C. Cloquet, and T. O. Pryce, Isotope Analysis and Its Applications to the Study of Ancient Indian Glass. In: Kanungo, A.K., Dussubieux, L. (eds) Ancient Glass of South Asia. Springer, Singapore (2021). https://doi.org/10.1007/978-981-16-3656-1_6

V. Renson, H. Neff, A. Martinez-Cortizas, J.P. Blomster, D. Cheetham, M.D. Glascock, Lead and strontium isotopes as tracers for Early Formative pottery exchange in ancient Mexico. J. Archaeol. Sci. (2021). https://doi.org/10.1016/j.jas.2020.105307

C. Klesner, V. Renson, Y. Akymbek, D. Killick, Investigation of provenances of Early Islamic lead glazes from northern central Asia using elemental and lead isotope analyses. Archaeol. Anthropol. Sci. 13, 203 (2021). https://doi.org/10.1007/s12520-021-01444-8

E. Giomi, M.F. Ownby, V. Renson, J.A. Stephens, Petrographic and lead isotope analyses to assess regional variability in rio grande glaze wares from New Mexico. J. Archaeol. Sci. Reports (2023). https://doi.org/10.1016/j.jasrep.2023.104185

R. B. Mason, R. M. Farquhar and P. E. Smith, Muqarnes 9 (1992)

S. Wolf, S. Stos, R. Mason, M.S. Tite, Lead isotope analyses of Islamic pottery glazes from Fustat, Egypt. Archaeometry 45, 405 (2003). https://doi.org/10.1111/1475-4754.00118

P. Marzo, F. Laborda and J. Perez-Arantegui, Medieval and postmedieval Hispano-Moresque glazed ceramics: new possibilities of characterization by means of lead isotope ratio determination by Quadrupole ICP-MS. In: P. Degryse, J. Henderson, hod (eds) Isotopes in Vitreous Materials (Leuven University Press, Leuven Belgium, 2009)

A.M. Thibodeau, J.A. Habicht-Mauche, D.L. Huntley, J.T. Chesley, J. Ruiz, High precision isotopic analyses of lead ores from New Mexico by MC-ICP-MS: implications for tracing the production and exchange of Pueblo IV glaze-decorated pottery. J. Archaeol. Sci. (2013). https://doi.org/10.1016/j.jas.2013.02.034

L. Chiarantini, F. Gallo, V. Rimondi, M. Benvenuti, P. Costagliola, A. Dini, Early renaissance production recipes for naples yellow pigment: a mineralogical and lead isotope study of Italian Majolica from Montelupo (Florence). Archaeometry 57, 879 (2015). https://doi.org/10.1111/arcm.12146

M.F. Thirlwall, Inter-laboratory and other errors in Pb isotope analyses investigated using a 207Pb–204Pb double spike. Chem. Geol. 163, 299 (2000). https://doi.org/10.1016/s0009-2541(99)00135-7

J. Baker, D. Peate, T. Waight, C. Meyzen, Pb isotopic analysis of standards and samples using a 207Pb–204Pb double spike and thallium to correct for mass bias with a double-focusing MC-ICP-MS. Chem. Geol. 211, 275 (2004). https://doi.org/10.1016/j.chemgeo.2004.06.030

M.F. Thirlwall, Long-term reproducibility of multicollector Sr and Nd isotope ratio analysis. Chem. Geol. Isotope Geosci. sect. 94, 85 (1991). https://doi.org/10.1016/0168-9622(91)90002-E

D. Weis, B. Kieffer, C. Maerschalk, J. Barling, J. De Jong, G.A. Williams, D. Hanano, W. Pretorius, N. Mattielli, J.S. Scoates, A. Goolaerts, R.M. Friedman, J.B. Mahoney, High-precision isotopic characterization of USGS reference materials by TIMS and MC-ICP-MS. Geochem. Geophys. Geosyst. (2006). https://doi.org/10.1029/2006GC001283

M. Spataro, The Old Potter’s. Almanack 17, 20 (2012)

A. Moore Valeri, Am. Ceram. Circ. J. 16, 32 (2011).

R. Manca, Plinius 47, 36 (2021). https://doi.org/10.19276/plinius.2021.01006

M. Gulmini, F. Scognamiglio, G. Roselli, G. Vaggelli, Appl. Phys. A 120, 1643 (2015). https://doi.org/10.1007/s00339-015-9376-9

B. Moroni, C. Conti, Technological features of Renaissance pottery from Deruta (Umbria, Italy): an experimental study. Appl. Clay Sci. 33, 230 (2006). https://doi.org/10.1016/j.clay.2006.05.002

M. Michael, Ceramic production, provenance and use—a review. Archaeometry 50, 216 (2008). https://doi.org/10.1111/j.1475-4754.2008.00391.x

J. Leveque, U. Haack, Mineral 30, 197 (1993)

M. D’Orazio, C. Biagioni, A. Dini, S. Vezzoni, Miner. Deposita 52, 687 (2017). https://doi.org/10.1007/s00126-016-0697-1

F. Lo Schiavo, A. Giumlia-Mair, U. Sanna and R. Valera, Archaeometallurgy in Sardinia from the origins to the beginning of the Early Iron Age, ed. Monique Mergoil (Montagnac, 2005).

C. Biagioni, A. Dini, M. Lorenzoni, P. Orlandi and S. Pardini, The Mineralogical Record 49, (2018).

Z. Stos-Gale, N.H. Gale, J. Houghton, R. Speakman, Archaeometry 37, 407 (1995). https://doi.org/10.1111/j.1475-4754.1995.tb00753.x

V. Koppel, W. Hansmann, M. Maggetti, Schweiz. Mineral. Petrogr. Mitt. 77, 325 (1997)

B. Guènette-Beck, Minérais, Métaux, Isotopes: Recherches Archéométrique Sur Les Mines de Plomb et d’Argent En Valais, Suisse. PhD Thesis, Université de Lausanne (2005)

B. Höppner, M. Bartelheim, M. Huijsmans, R. Krauss, K.P. Martinek, E. Pernicka, R. Schwab, Archaeometry 47, 293 (2005). https://doi.org/10.1111/j.1475-4754.2005.00203.x

R. Lehmann, Leibniz Universität Hannover Naturwissenschaftliche Fakultät (2011) https://doi.org/10.15488/7682

M. Benvenuti, I. Mascaro, F. Corsini, M. Ferrari, P. Lattanzi, P. Parrini, P. Costagliola, G. Tanelli, Ejm 12, 441 (2000). https://doi.org/10.1127/0935-1221/2000/0001-0441

P. Lattanzi, M. Benvenuti, P. Costagliola, G. Tanelli, Memorie Società Geol. Italia. 48, 613 (1994)

T. Stöellner, In: Th. Stöllner, G. Körlin, G. Steffens, J. Cierny, Man and Mining. Studies in honour of Gerd Weisgerber. Der Anschnitt, Beiheft 16 (Bochum, 2003).

E. Schroll, V. Köppel, I. Cerny, Mineral. Petrol. 86, 129 (2006). https://doi.org/10.1007/s00710-005-0107-3

L. Chiarantini, I.M. Villa, V. Volpi, G. Bianchi, M. Benvenuti, C. Cicali, A. Donati, R. Manca, R. Hodges, J. Archaeol. Sci. Rep. 39, 103139 (2021). https://doi.org/10.1016/j.jasrep.2021.103139

R. Tylecote, The Prehistory of Metallurgy in the British Isles: 5, 1st ed. (Routledge, 1986). https://doi.org/10.4324/9781351199476

K.H. Wedepohl, A. Baumann, Miner. Deposita 32, 292 (1997). https://doi.org/10.1007/s001260050094

C.M. Rice, R.J. McCoyd, A.J. Boyce, P. Marchev, Miner. Deposita 42, 691 (2007). https://doi.org/10.1007/s00126-007-0130-x

G. Bird, P.A. Brewer, M.G. Macklin, M. Nikolova, T. Kotsev, M. Mollov, C. Swain, Environ. Pollut. 158, 2158 (2010). https://doi.org/10.1016/j.envpol.2010.02.020

A. McSweeney, Al-Masāq 23, 155 (2011). https://doi.org/10.1080/09503110.2011.617061

J.A. Habicht-Mauche, S.T. Glenn, M.P. Schmidt, R. Franks, H. Milford, A.R. Flegal, Stable lead isotope analysis of Rio Grande glaze paints and ores using ICP-MS: a comparison of acid dissolution and laser ablation techniques. J. Archaeol. Sci. 29, 1043 (2002). https://doi.org/10.1006/jasc.2001.0804

Acknowledgements

The Soprintendenza Archeologia, Belle Arti e Paesaggio per la città metropolitana di Firenze, the Province di Pistoia e Prato, the Museo della Ceramica di Montelupo and Dr Anna Moore Valeri are acknowledged for authorizing the study and providing the objects for the analysis.

Funding

Open access funding provided by Università degli Studi di Firenze within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Paghi, D., Manca, R., Casalini, M. et al. Tracing the lead source of maiolica: a pilot isotopic study on artefacts from the area of Florence, Italy (fifteenth–nineteenth century). Eur. Phys. J. Plus 139, 260 (2024). https://doi.org/10.1140/epjp/s13360-024-05024-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-024-05024-2