Abstract

We review the works performed on whispering gallery mode (WGM) micro-optical resonators made in rare-earth (RE) doped glasses for implementing low threshold and narrow line coherent sources. These types of micro-lasers, because of their small size and ease of fabrication can be a useful tool for the characterization of laser glasses and have several applications, especially as sensors.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Whispering gallery mode (WGM) micro-optical resonators are dielectric structures with cylindrical symmetry, like spheroids or toroids, having diameters below a millimeter, and in which light can be resonantly guided inside the dielectric material by total internal reflection [1, 2]. When properly activated, they represent an ideal resonant cavity to exploit lasing action as demonstrated in the pioneering work on Sm2+:CaF2 crystal spheres by Garret [3], which was followed many years later by those on micro-droplets of ethanol containing Rhodamine 6G [4], and in dye-doped polystyrene microspheres [5].

The first demonstration of high Q factor (Q > 108) glass WGM micro-resonators was done in fused quartz microspheres [6], and since then, WGM resonators made in highly transparent glasses have gained a great interest because they can be rather easily fabricated using melting and/or reflowing processes [7, 8], and they can be used for both the investigation of fundamental processes [9, 10] and for several applications in photonics [11,12,13,14]. Specifically, high-Q WGM resonators made in rare earth (RE) doped glasses represent an ideal and simple platform to implement narrow line, compact, and low threshold laser sources [15, 16]. Because of their small size and ease of fabrication, they can be a useful tool for the characterization of laser glasses [17] and represent an ideal platform for several sensing applications [18, 19]. Indeed, we focus our review on WGM micro-lasers made in RE doped glasses, we describe their fabrication processes and their characterization including lasing threshold, RE dopant, emission wavelength. Since the first demonstration, which was done in neodymium-doped silica microspheres [20, 21], the vast literature that followed includes resonators with different shapes (microspheres [20], microdisks [22], microtoroids [23], microbottles [24], etc.), RE dopants (Er3+ [25], Er3+:Yb3+ [26], Nd3+ [20], Tm3+ [27], etc.), and glass matrices (silica [21], tellurite [28], phosphate [26], fluoride [29], etc.). This work ends presenting the unique advantages of active glass WGM resonators for applications in sensing.

2 Fabrication

The techniques to fabricate WGM micro-resonators in RE doped glass are similar to those used for undoped glass and are based on melting and/or reflowing submillimeter glass powders or tips. Depending on the glass type (silicate, phosphate, germanate, tellurite, chalcogenide, etc.), the right temperature has to be selected above the glass transition temperature but still keeping high viscosity so that surface tension can provide a spheroidal shape [7]. Additionally, the resulting ‘fire polished’ surface typically has very low roughness (RMS < 50 nm [6]), thus avoiding complex mechanical polishing, which are required for crystals [30], or semiconductors [31]. In fact, the total intrinsic Q of a WGM resonator is determined by contributions from curvature losses (Q−1rad), material losses (Q−1mat) and surface scattering losses (Q−1scat) according to the equation: Q−1 = Q−1rad + Q−1scat + Q−1mat [1]. Q−1rad vanishes exponentially with resonator size (for instance, for a sphere of diameter d, if d/λ ≥ 15 than Qrad > 1011) while Q−1mat is inversely proportional to the absorption coefficient α, and Q−1scat is inversely proportional to the square of roughness RMS [1]. Therefore, WGM resonators with extremely high optical Q factors (Q ≥ 108) can be easily obtained in low loss glasses, and outside the absorption band of the RE (where the so-called ‘cold’ Q factor is measured). It is worth pointing out that, for the lasing performances, the chosen type of glass matrix (silica, tellurite, phosphate, fluoride, etc.), strongly affect the RE solubility and phonon energy [21, 26, 28, 29].

2.1 Bulk glass resonators

In the seminal paper by Braginsky et al. [6], silica spheres with diameters in the range 40–400 μm were fabricated on the top of short fused quartz stems of different diameters. Upon heating the glass tip above the transition temperature, the glass reflows forming a spherical shape under the influence of surface tension and, if the glass viscosity is kept high, the reflowed structure is highly spherical with eccentricities e of the order of 1–2% [1]. Several heat sources can be used for heating the glass including gas torches [32], high power lasers (like CO2 for silica) [33], electric arcs [34], and resistive microheaters [35]. Indeed, this simple method can be applied to any type of RE glass rod or wire or to a fiber and allows a good control of the microsphere diameter. If only the fiber core is doped, the cladding has to be removed prior to heating, at least partially, and this process typically requires a combination of mechanical machining and chemical etching [36, 37]. The sphere is left attached to the glass stem (see Fig. 1a), which can be used for easy handling. A drawback of this method is that only one resonator at a time can be fabricated.

Images of microspheres fabricated in Er3+-doped glass. a Phosphate glass sphere fabricated by melting the tip of a glass wire to which it is kept attached; b phosphate glass sphere fabricated by melting glass powder; c silica sphere produced by the sol–gel route. Spheres b and c are both glued to the tip of a fiber for handling

Similarly, high Q WGM microbubble and microbottle resonators can be fabricated from RE-doped silica glass fibers or wires. Microbubble lasers [38] were made on active fibers using the so-called “soften and compress” method [39, 40]. This shape allows unique potentials for implementing low threshold, and high efficiency micro-lasers, as modeled in Ref. [41]. Microbubble lasers fabricated from RE doped capillaries made in tellurite glass have been demonstrated (see Fig. 2a) [42].

Glass microspheres or microtoroids can be fabricated on a chip, typically using silica on silicon wafers. Sol–gel technology is mainly used to deposit RE-doped silica glass thin films on the wafer. Indeed, sol–gel chemistry is a well-known, flexible, and convenient method for producing optical materials with enhanced performances, and moreover it allows precise control of the RE dopant concentration [43]. Films are deposited by spin coating and then disks are patterned by standard lithography and buffered oxide wet etching. The underlying silicon is then chemically etched using XeF2, leaving RE doped silica disks supported by silicon pillars. Finally, a CO2 laser is used to reflow the silica micro-disk to form a smooth microtoroid [44] or microsphere [45], with diameters of few tens of microns (see Fig. 2b for an on chip microsphere). Alternatively, direct femtosecond laser micromachining of RE doped glass substrates allows the formation of 3D structures like microdisks supported by thin pillar, which are then shaped into spheroids by using again a CO2 laser reflow step [46]. In this review, we consider on chip 3D micro-optical resonators whose level of integration does not include coupling to an planar waveguide [47, 48].

A different approach to fabricate many microspheres at the same time is based on crushing a piece of (RE doped) glass in powder of submillimeter grains and then dropping them through a microwave plasma torch [49]. The glass grains are melted and they acquire spherical shape by surface tension before being collected a few tens of centimeters below the torch. By adjusting the microwave power and the noble gas flow, it is possible to reach the desired temperature within a wide range up to 2000 °C and to produce spheres of different sizes (from 10 to 200 μm in diameter depending on the powder size), with a very low eccentricity e (e < 10–4). A similar approach uses an electric tube furnace, which operates at a lower temperature of up to 900 °C [50]. A third approach to fabricate free spheres consists of melting the oxide components in a furnace and dropping the viscous glass on a spinning plate [51]. The melted glass is spun out by centrifugal force and cooled down quickly, forming microspheres with a diameter ranging from several micrometers to several hundred micrometers. A disadvantage of these techniques is the large size distribution of the microspheres, which are difficult to manipulate and need to be picked up properly one by one, typically gluing them on the tapered tip of a fiber (see Fig. 1b, c).

A specific protocol has been developed by the authors to directly fabricate sol–gel silica spheres incorporating rare earths into the glass. By using acid catalysts, silica microspheres are fabricated with different diameters, ranging from a hundred nanometer to approximately 150 µm, always with a very high surface quality (see Fig. 1c) [52].

2.2 Glass coating-based resonators

A different approach to implement WGM micro-lasers is that of depositing an active layer on a high-Q passive resonator, i.e., a microsphere [53], a microtoroid [54], a microbubble [55] or a microbottle [56], typically made in silica. In this configuration, the RE ions are only inside the layer, whose thickness can vary from few hundreds of nanometer up to few microns. Sol–gel technology allows making very high quality glass films by the dip-coating method using several steps in order to obtain the desired thickness of the film [57]. Another method consists of depositing a thin layer of melted RE doped glass-like Er3+/Yb3+ codoped phosphate glass-on a silica microsphere [58]. The much lower melting temperature of the phosphate glass compared to silica easily allows using this procedure. Similarly, microbottle shaped lasers can be made by using a CO2 laser to melt Er3+/Yb3+ codoped phosphate glass directly onto silica microcapillaries or wires, as shown in Fig. 2c [24]. Finally, a special case is that of a thin layer of RE doped glass formed by high-energy ion implantation. Er ions have been implanted on high-Q silica on silicon microtoroids [23, 59] and microdisks [22], and on silica microspheres [60], using different energies and fluencies. Very recently, integrated white-light lasers have been demonstrated in high-Q silica microtoroids coated with silica sol–gel containing CaF2:Yb35Tm1.5Er0.5 nanocrystals [61]. Multiple lasing bands have been also obtained with PMMA assisted Er3+/Yb3+ co-doped ultra-high Q silica microspheres [62]. Similarly, liquid-based surface doping technology [63] has been recently implemented on silica microspheres to uniformly introduce Er3+ ions while keeping ultra-high quality factor [64].

3 Characterization

3.1 Coupling

In order to characterize active RE-doped WGM resonators, the best approach to efficiently couple pump light as well as to collect the output signal is based on phase-matched evanescent coupling and requires some overlap of the field of the WGM with the field of the coupler. The main coupling tools are waveguides such as tapered optical fibers [66] or integrated waveguides [67], or prisms [6] if free space optics is used. Two different fiber couplers for pump and signal can be used to optimize the coupling at both wavelengths [68], as sketched in Fig. 3 for an Er3+ doped microsphere. A half taper is used to couple the pump, while a second taper collects the signal (both the co-propagating and counter propagating one), with an output coupling efficiency that can be varied by changing the taper-resonator distance (as an output mirror with variable transmission). Figure 3 also shows the pump source operating either at 980 nm or at 1480 nm for the case of Er3+ ions. By using a finely tunable narrow line source, resonant pumping can be implement to improve the efficiency of the process and further lower the lasing threshold [23, 59]. The fiber-coupled signal spectrum around 1550 nm is collected using an optical spectrum analyzer (OSA). Different coupling regimes can be observed in active resonators by increasing the pump coupling rate from undercoupling to selective amplification, before lasing action takes place, as it has been done for Nd3+ [69] and Er3+ doped [70] glass microspheres.

Setup for Er3+ doped glass WGM micro-resonator characterization. A half taper is used for pumping the WGM microsphere by using a fiber pigtailed laser operating either at 980 nm or at 1480 nm. A second fiber taper collects both co-propagating and counter propagating signals around 1550 nm [68], which are then sent to an optical spectrum analyzer (OSA)

In a different approach, a special hybrid taper can be designed to optimize both pump and signal coupling [71]. Finally, a single half taper can be used to couple the pump and at the same time collect the counter propagating signal [72], and this approach has been exploited to implement miniaturized optical microwave sources using a dual-wavelength microlaser [73]. A similar architecture can be implemented using an optical nanoantenna made on the tip of a fiber, which is able to couple the pump and at the same collect the counter propagating signal from the resonator [74].

Prism-based coupling (see Fig. 4a) is quite robust and conveniently allows phase matching, but for efficient coupling it also requires mode matching of the far field free space pump beam with the WGM [75], which can be rather critical. Free-space coupling of a tangential beam into WGMs (see Fig. 4b) by using a microscope system is a robust and convenient approach, but it is extremely inefficient because of the large phase and mode mismatches, which can be quantitatively predicted [76]. The coupling efficiency to a high refractive index microsphere can be improved by using a ‘terrace’ structure made with a lower refractive index sol–gel [77, 78], as sketched in Fig. 4b. The beam is focused on different positions of the terrace to maximize the fluorescence/lasing emission from the counter propagating microsphere WGMs. In both the approaches of Fig. 4a, b, free space signal beams are collected and analyzed with a spectrometer.

Setup for active (Er3+ doped) WGM resonator characterization based on a prism evanescent coupling and b free space coupling using a microscope. Collimated or focused beams from the pump lasers are used, while output signal beams from the microspheres are sent and analyzed with a spectrometer. In b the counter propagating emission spectrum is collected with the same objective used for the excitation. A ‘terrace’ structure made of a sol–gel with lower refractive index compared to the glass can be attached to the sphere and used to improve pump coupling and to enhance the emission as compared to the uncoated sphere [77]

3.2 Spectroscopy and lasing

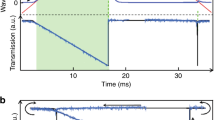

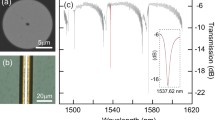

Cold-cavity Q factors, which are measured outside the absorption band of the RE ions, are typically in the range between 105 and 107 [32], but values up to 108 have been also measured [62, 79, 80]. An example of a ‘cold’ resonance measured in a microsphere of 75 µm in diameter made in a sodium–alumino–phosphate glass doped with 1.5 wt% of Er2O3 and 3 wt% of Yb2O3 is shown in Fig. 5a. The fine wavelength scan is performed around 1.6 µm, which is at the edge of the absorption band of the 4I13/2 level (σabs = 0.35 × 10–21 cm2). The corresponding resonance Q value of 0.8 × 106 is in agreement with that calculated taking into account only the residual material absorption at that wavelength [32].

a WGM resonance measured around 1600 nm of a 75 μm microsphere made in an Er3+/Yb3+ codoped phosphate glass and b WGM emission spectra including fluorescence spectrum below lasing threshold (black line), and lasing spectra corresponding to the maximum (blue line) and the minimum (red line) wavelength peak values; c image of an Er3+ doped phosphate microsphere with a diameter of 150 µm, and d–f of the green upconversion appearing after pumping at 980 nm, and mapping several different WGMs, depending on the excitation taper position (barely visible in the back, see also text)

RE doped spectroscopic properties are typically assessed on the bulk glass before the second melting occurs to shape the WGM micro-resonator. We have performed characterization of the spectroscopic properties of Er3+ ions after microsphere fabrication and compared these properties with those of bulk glass We found that photoluminescence spectra of the 4I13/2 → 4I15/2 transition of Er3+ ions after pumping at 980 nm, as well as the corresponding experimental lifetimes measured in the precursor glasses and in the corresponding microspheres can be dissimilar. Up to a doubling of the effective bandwidth and almost a halving of the lifetime was measured on the microsphere as compared to the bulk glass. Site-to-site inhomogeneities, most probably due to the fabrication process, can modify the local environment of the Er3+ ions in the microsphere, resulting in significant modification of the transition probability among the Starks levels. The experimental setup used for measuring the radiative lifetime of Er3+ ions in microspheres is the same typically used for the precursor bulk glass [81].

Typical emission spectra around 1550 nm of an Er3+ doped phosphate glass microsphere (with a diameter of 75 µm) are shown in Fig. 5b. We used a setup similar to the one sketched in Fig. 3, with the signal output coupled to a tapered fiber, which is then connected to an OSA. By switching the 980 nm or 1480 nm pump laser on, we first observed the typical Er3+-ions fluorescence spectrum with a series of peaks that can be assigned to several families of WGMs [82]. When increasing the pump intensity above a certain threshold we obtained laser oscillation, which results in a sudden increase in the output in narrow peaks at just one or few wavelengths. By varying the contact position of the tip of the half taper fiber coupler relative to the sphere and increasing the pump power the lasing spectrum moved toward WGMs of shorter wavelength. In fact, when the pump power is increased, the blue shift, which is due to the shift toward shorter wavelengths that occurs in the Er3+ gain spectrum peak when the inversion rate increases [83], effectively dominates on the thermal induced red shift. Figure 5b shows the two lasing spectra corresponding to the maximum (1601.8 nm) and the minimum (1561.0 nm) wavelength peak values we were able to obtain in this microsphere. The covered range is about 40 nm broad.

Figure 5c shows a collection of images on how an Er3+doped glass microsphere typically appears under an optical microscope, when pumping it at 980 nm. In the first picture, behind the microsphere, which is about 150 µm in diameter, we can spot the coupling taper, slightly out of focus and not yet in contact with the resonator. In the other three pictures, depending on the taper position different WGMs are excited, whose spatial distribution can be mapped thanks to the green upconversion [1, 84]. Interestingly, in the last image several modes are simultaneously excited, including those with higher azimuthal mode number, resulting in the appearance of an almost uniform distribution on the whole sphere.

Figure 6 shows two characteristic laser curves plotting continuous wave (CW) fiber coupled signal output power vs absorbed pump power (i.e., the difference between the launched and the residual power in the fiber after coupling). Figure 6a plots the lasing power at 1579 as a function of pump power at 980 nm for an Er3+/Yb3+ doped tellurite glass bubble as the one shown in Fig. 2a. The red line represents a linear fit to the experimental data, from which a lasing threshold of 1.66 mW can be calculated [42]. Remarkably, laser emission wavelength tuning can be obtained not only by increasing pump power (which also affects the cavity temperature), but also changing the bubble internal pressure obtaining a tunability of − 6.6 GHz/bar. Figure 6b shows lasing power at 1046 nm versus pump power at 973 nm for a Yb3+ silica microsphere on a chip as the one shown in Fig. 2b. The mechanism of the 1040 nm lasers involves transition of Yb3+ ions from 2F5/2 to 2F7/2 levels. Compared to the monolithic microbubble, the smaller on chip microsphere has a much lower lasing threshold of 5.2 μW [65].

a Characteristic curve showing lasing power at 1579 nm as a function of pump power at 980 nm for an Er3+/Yb3+ doped tellurite glass bubble as the one shown in Fig. 2a. The red line represents a linear fit to the experimental data, with a lasing threshold of 1.66 mW. The inset is the output laser spectrum when the pump power is 1.71 mW (from [42]) and b characteristic curve showing lasing power at 1046 nm versus pump power at 973 nm for a Yb3+ silica microsphere fabricated on a silicon chip as the one shown in Fig. 2b (from [65]); a lasing threshold of around 5.2 μW is obtained through linear fitting (red curve)

Table 1 presents an exhaustive list of relevant contributions in the literature on glass WGM lasers from the early works in the mid-90’s till today. The table lists the most significant information available in each manuscript, including lasing wavelength, peak power, pump wavelength and pump threshold (typically the ‘absorbed’ pump threshold rather than the launched one), WGM resonator type and size (in brackets the size of the ‘demo’ resonator, on which the main tests were performed), and coupling tool. We then indicate the RE dopant (and the possible co-doping), the glass type (typically a monolithic glass resonator, otherwise an active coating deposited on a passive resonator and having a thickness from few hundreds nanometers to few microns) and its composition, and finally the measured cold cavity Q factor.

4 Applications in sensing

Sensing with optical WGM resonators is based on monitoring the change of their spectral characteristics induced by a perturbation happening within the WGM spatial extension, including the resonator surface and the region immediately surrounding it, where the WGM evanescent tail still extends. This change can be either the broadening of the resonances (with Q factor reduction) due to additional losses, or, more typically, the shift of the resonance frequencies due a refractive index change [14, 133]. Considering that the ability to detect a shift is directly proportional to the resonant linewidth, the strong narrowing (up to a few order of magnitude [134]) of the laser line compared to the cold cavity resonance linewidth translates into a corresponding significant improvement of the transducer sensitivity [18, 19]. More generally, the analysis of the relative intensity noise (RIN) level of the micro-laser source becomes important as RIN may limit the sensor sensitivity. In Ref. [72] we presented an approach that could be extended to WGM laser frequency noise and exploited in the analysis of the whole noise properties of micro-lasers used in sensor applications.

In case biosensing like DNA hybridization is performed on the resonator while it is lasing, care should be taken to avoid reaching temperature that can destabilize DNA. Indeed, depending on the RE ions and the glass matrix, non-radiative transitions can be quite effective [135] increasing the temperature up to melting the glass [84, 101].

Another sensing mechanism is based on mode splitting of a very high-Q resonance due to nanoparticles at the resonator surfaces that couple the clockwise (CW) mode with the counterclockwise modes (CCW), thus lifting the degeneracy of the two modes [136]. The frequency splitting of an ultranarrow emission line of a WGM microlaser in two lines that move apart can be resolved and measured by recording their beat note. Indeed, this approach has been used with integrated Er3+ doped silica toroids to demonstrate single virus and nanoparticle detection [137]. Interestingly, we have shown that depending on the glass matrix the coupling between clockwise and counterclockwise modes has not the same strength, which strongly impacts the WGM laser dynamics [138].

Finally, a crucial advantage of using active WGM resonators as sensors is the fact that a free space architecture with remote excitation and readout can be implemented, as in the scheme sketched in Fig. 4b. After focusing the pump onto the resonator, the emission spectrum is collected with the same objective used for the excitation pump (or with a second one placed orthogonally [139]) and then sent to a spectrometer. This interrogation approach overcomes a critical restriction hindering the development of practical devices based on passive resonators where the light coupling scheme typically requires physical contact with the fiber taper or the prism (see Figs. 3 and 4a).

5 Conclusions

This work presents an extensive review of the literature on WGM micro-optical resonators made in rare-earth doped glasses. We first describe the fabrication techniques for making different types of monolithic spheroidal glass cavities, including those made on a chip, or those obtained depositing active glass layers on passive resonators. We then introduce the systems to couple the pump light into the cavities and collect the output signal in order to characterize the laser performances. An exhaustive table, listing all the relevant contributions in the literature on glass WGM lasers, represents the core of this work. From the early works in the mid-90’s till today, more than 100 papers were reviewed and those presenting original contributions in any specification including pump threshold, emitting wavelength, RE dopant, glass composition, etc., were all listed in the table. Lasing wavelengths range from the visible (blue, 480 nm, and green, 540 nm) to the near infrared (from 800 nm up to 2300 nm), depending on the RE doping and the host glass. Pump lasing threshold below or of the order of tens of nanowatt (almost thresholdless) were measured when the pump was also resonant with a WGM. Because of their small size and ease of fabrication, these micro-laser sources can be a useful tool for the characterization of RE doped glasses. We finally identify the main application of these active cavities, which is that of optical transducer for sensing, listing their significant advantages compared to their passive counterparts.

Data Availability Statement

No Data associated in the manuscript.

References

A. Chiasera, Y. Dumeige, P. Féron, M. Ferrari, Y. Jestin, G. Nunzi Conti, S. Pelli, S. Soria, G.C. Righini, Spherical whispering-gallery-mode microresonators. Laser Photonics Rev. 4, 457–482 (2010). https://doi.org/10.1002/lpor.200910016

G.C. Righini, Y. Dumeige, P. Féron, G. Nunzi Conti, D. Ristic, S. Soria, Whispering gallery mode microresonators: fundamentals and applications. La Rivista del Nuovo Cimento. 34, 435–488 (2011). https://doi.org/10.1393/ncr/i2011-10067-2

C.G.B. Garrett, W. Kaiser, W.L. Bond, Stimulated emission into optical whispering modes of spheres. Phys. Rev. 124, 1807–1809 (1961). https://doi.org/10.1103/PhysRev.124.1807

H.-M. Tzeng, K.F. Wall, M.B. Long, R.K. Chang, Laser emission from individual droplets at wavelengths corresponding to morphology-dependent resonances. Opt. Lett. 9, 499–501 (1984). https://doi.org/10.1364/OL.9.000499

M. Kuwata-Gonokami, K. Takeda, H.Y.H. Yasuda, K.E.K. Ema, Laser emission from dye-doped polystyrene microsphere. Jpn. J. Appl. Phys. 31, L99 (1992). https://doi.org/10.1143/JJAP.31.L99

V.B. Braginsky, M.L. Gorodetsky, V.S. Ilchenko, Quality-factor and nonlinear properties of optical whispering-gallery modes. Phys. Lett. A 137, 393–397 (1989). https://doi.org/10.1016/0375-9601(89)90912-2

J. Yu, E. Lewis, G. Farrell, P. Wang, Compound glass microsphere resonator devices. Micromachines. 9, 356 (2018). https://doi.org/10.3390/mi9070356

S. Berneschi, F. Cosi, D. Farnesi, G. Frigenti, G.C. Righini, S. Pelli, S. Soria, F. Baldini, F. Prudenzano, G. Persichetti, R. Bernini, Y. Dumeige, P. Féron, D. Ristić, M. Ivanda, G. N. Conti, Glass based microresonators, in Fiber Lasers and Glass Photonics: Materials through Applications (SPIE, 2018), pp. 75–82

S.M. Spillane, T.J. Kippenberg, K.J. Vahala, Ultralow-threshold Raman laser using a spherical dielectric microcavity. Nature 415, 621–623 (2002). https://doi.org/10.1038/415621a

D. Farnesi, A. Barucci, G.C. Righini, S. Berneschi, S. Soria, G. Nunzi Conti, Optical frequency conversion in silica-whispering-gallery-mode microspherical resonators. Phys. Rev. Lett. 112, 093901 (2014). https://doi.org/10.1103/PhysRevLett.112.093901

E. Kim, M.D. Baaske, F. Vollmer, Towards next-generation label-free biosensors: recent advances in whispering gallery mode sensors. Lab Chip. 17, 1190–1205 (2017). https://doi.org/10.1039/C6LC01595F

B.J. Thompson, A.B. Matsko, Practical Applications of Microresonators in Optics and Photonics (CRC Press, Boca Raton, 2019)

G.C. Righini, Glass Micro- and Nanospheres: Physics and Applications. https://www.routledge.com/Glass-Micro--and-Nanospheres-Physics-and-Applications/Righini/p/book/9789814774635

X. Jiang, A.J. Qavi, S.H. Huang, L. Yang, Whispering-gallery sensors. Matter 3, 371–392 (2020). https://doi.org/10.1016/j.matt.2020.07.008

L. He, ŞK. Özdemir, L. Yang, Whispering gallery microcavity lasers. Laser Photonics Rev. 7, 60–82 (2013). https://doi.org/10.1002/lpor.201100032

E.A. Anashkina, Laser sources based on rare-earth ion doped tellurite glass fibers and microspheres. Fibers 8, 30 (2020). https://doi.org/10.3390/fib8050030

W. von Klitzing, E. Jahier, R. Long, F. Lissillour, V. Lefèvre-Seguin, J. Hare, J.-M. Raimond, S. Haroche, Very low threshold green lasing in microspheres by up-conversion of IR photons. J. Opt. B Quantum Semiclass. Opt. 2, 204–206 (2000). https://doi.org/10.1088/1464-4266/2/2/324

T. Reynolds, N. Riesen, A. Meldrum, X. Fan, J.M.M. Hall, T.M. Monro, A. François, Fluorescent and lasing whispering gallery mode microresonators for sensing applications. Laser Photonics Rev. 11, 1600265 (2017). https://doi.org/10.1002/lpor.201600265

N. Toropov, G. Cabello, M.P. Serrano, R.R. Gutha, M. Rafti, F. Vollmer, Review of biosensing with whispering-gallery mode lasers. Light Sci. Appl. 10, 42 (2021). https://doi.org/10.1038/s41377-021-00471-3

Y.Z. Wang, B.L. Lu, Y.Q. Li, Y.S. Liu, Observation of cavity quantum-electrodynamic effects in a Nd:glass microsphere. Opt. Lett. 20, 770–772 (1995). https://doi.org/10.1364/OL.20.000770

V. Sandoghdar, F. Treussart, J. Hare, V. Lefèvre-Seguin, J.-M. Raimond, S. Haroche, Very low threshold whispering-gallery-mode microsphere laser. Phys. Rev. A 54, R1777–R1780 (1996). https://doi.org/10.1103/PhysRevA.54.R1777

T.J. Kippenberg, J. Kalkman, A. Polman, K.J. Vahala, Demonstration of an erbium-doped microdisk laser on a silicon chip. Phys. Rev. A 74, 051802 (2006). https://doi.org/10.1103/PhysRevA.74.051802

A. Polman, B. Min, J. Kalkman, T.J. Kippenberg, K.J. Vahala, Ultralow-threshold erbium-implanted toroidal microlaser on silicon. Appl. Phys. Lett. 84, 1037–1039 (2004). https://doi.org/10.1063/1.1646748

J.M. Ward, Y. Yang, S. Nic Chormaic, Glass-on-glass fabrication of bottle-shaped tunable microlasers and their applications. Sci Rep. 6, 25152 (2016). https://doi.org/10.1038/srep25152

F.Lissillour, P. Feron, N. Dubreuil, P. Dupriez, G.M. Stephan, M. Poulain, Whispering-gallery mode Er-ZBLAN microlasers at 1.56 um, in Laser Resonators II (SPIE, 1999), pp. 199–205

M. Cai, O. Painter, K.J. Vahala, P.C. Sercel, Fiber-coupled microsphere laser. Opt. Lett. 25, 1430–1432 (2000). https://doi.org/10.1364/OL.25.001430

H. Fujiwara, K. Sasaki, Upconversion lasing of a thulium-ion-doped fluorozirconate glass microsphere. J. Appl. Phys. 86, 2385–2388 (1999). https://doi.org/10.1063/1.371064

K. Sasagawa, K. Kusawake, J. Ohta, M. Nunoshita, Nd-doped tellurite glass microsphere laser. Electron. Lett. 38, 1355–1357 (2002)

K. Miura, K. Tanaka, K. Hirao, CW laser oscillation on both the 4F3/2–4I11/2 and 4F3/2–4I13/2 transitions of Nd3+ ions using a fluoride glass microsphere. J. Non-Cryst. Solids 213–214, 276–280 (1997). https://doi.org/10.1016/S0022-3093(96)00671-0

A.A. Savchenkov, A.B. Matsko, V.S. Ilchenko, L. Maleki, Optical resonators with ten million finesse. Opt. Express 15, 6768–6773 (2007). https://doi.org/10.1364/OE.15.006768

A.E. Shitikov, I.A. Bilenko, N.M. Kondratiev, V.E. Lobanov, A. Markosyan, M.L. Gorodetsky, Billion Q-factor in silicon WGM resonators. Optica 5, 1525–1528 (2018). https://doi.org/10.1364/OPTICA.5.001525

D. Ristić, S. Berneschi, M. Camerini, D. Farnesi, S. Pelli, C. Trono, A. Chiappini, A. Chiasera, M. Ferrari, A. Lukowiak, Y. Dumeige, P. Féron, G.C. Righini, S. Soria, G.N. Conti, Photoluminescence and lasing in whispering gallery mode glass microspherical resonators. J. Lumin. 170, 755–760 (2016). https://doi.org/10.1016/j.jlumin.2015.10.050

L. Collot, V. Lefèvre-Seguin, M. Brune, J.M. Raimond, S. Haroche, Very high-Q whispering-gallery mode resonances observed on fused silica microspheres. EPL 23, 327–334 (1993). https://doi.org/10.1209/0295-5075/23/5/005

K.-C. Fan, H.-Y. Hsu, P.-Y. Hung, W. Wang, Experimental study of fabricating a microball tip on an optical fibre. J. Opt. A Pure Appl. Opt. 8, 782–787 (2006). https://doi.org/10.1088/1464-4258/8/9/012

P. Wang, G.S. Murugan, T. Lee, X. Feng, Y. Semenova, Q. Wu, W. Loh, G. Brambilla, J.S. Wilkinson, G. Farrell, Lead silicate glass microsphere resonators with absorption-limited Q. Appl. Phys. Lett. (2011). https://doi.org/10.1063/1.3586771

V.S. Ilchenko, X.S. Yao, L. Maleki, Microsphere integration in active and passive photonics devices. Presentato al Symposium on High-Power Lasers and Applications, San Jose, CA maggio 12 (2000)

Z. Chen, X. Tu, J. Zhao, H.Y. Fu, An erbium-doped fiber whispering-gallery-mode microcavity laser. IEEE Photonics Technol. Lett. 31, 1650–1653 (2019). https://doi.org/10.1109/LPT.2019.2942046

M. Sumetsky, Lasing microbottles. Light Sci. Appl. 6, e17102 (2017). https://doi.org/10.1038/lsa.2017.102

G.S. Murugan, J.S. Wilkinson, M.N. Zervas, Selective excitation of whispering gallery modes in a novel bottle microresonator. Opt. Express 17, 11916–11925 (2009). https://doi.org/10.1364/OE.17.011916

S.B. Gorajoobi, G.S. Murugan, M.N. Zervas, Mode-selective spectrally-cleaned-up microbottle resonator laser, in 2016 IEEE Photonics Conference (IPC) (2016), pp. 105–106

S.B. Gorajoobi, G.S. Murugan, M.N. Zervas, Design of rare-earth-doped microbottle lasers. Opt. Express 26, 26339–26354 (2018). https://doi.org/10.1364/OE.26.026339

J. Yu, J. Yu, J. Zhang, R. Wang, A. Li, A. Li, M. Zhang, S. Wang, P. Wang, P. Wang, P. Wang, J.M. Ward, J.M. Ward, S.N. Chormaic, S.N. Chormaic, A tellurite glass optical microbubble resonator. Opt. Express 28, 32858–32868 (2020). https://doi.org/10.1364/OE.406256

A. Chiappini, A. Chiasera, S. Berneschi, C. Armellini, A. Carpentiero, M. Mazzola, E. Moser, S. Varas, G.C. Righini, M. Ferrari, Sol–gel-derived photonic structures: fabrication, assessment, and application. J. Sol-Gel Sci. Technol. 60, 408–425 (2011). https://doi.org/10.1007/s10971-011-2556-y

E.P. Ostby, L. Yang, K.J. Vahala, Ultralow-threshold Yb3+:SiO2 glass laser fabricated by the solgel process. Opt. Lett. 32, 2650–2652 (2007). https://doi.org/10.1364/OL.32.002650

Y. Ding, H. Fan, X. Zhang, X. Jiang, M. Xiao, Ultralow-threshold neodymium-doped microsphere lasers on a silicon chip. Opt. Commun. 395, 51–54 (2017). https://doi.org/10.1016/j.optcom.2016.01.028

J. Lin, Y. Xu, J. Song, B. Zeng, F. He, H. Xu, K. Sugioka, W. Fang, Y. Cheng, Low-threshold whispering-gallery-mode microlasers fabricated in a Nd:glass substrate by three-dimensional femtosecond laser micromachining. Opt. Lett. 38, 1458–1460 (2013). https://doi.org/10.1364/OL.38.001458

G.N. Conti, A. Barucci, S. Berneschi, M. Brenci, F. Cosi, D. Farnesi, S. Pelli, G.C. Righini, S. Soria, Coupling approaches and new geometries in whispering-gallery-mode resonators, in Laser Resonators, Microresonators, and Beam Control XIV (SPIE, 2012), pp. 195–202

D. Farnesi, G.C. Righini, A. Barucci, S. Berneschi, F. Chiavaioli, F. Cosi, S. Pelli, S. Soria, C. Trono, D. Ristic, M. Ferrari, G.N. Conti, Coupling light to whispering gallery mode resonators, in Silicon Photonics and Photonic Integrated Circuits IV (SPIE, 2014), pp. 179–187

F. Lissillour, K.A. Ameur, N. Dubreuil, G.M. Stephan, M. Poulain, Whispering-gallery-mode Nd-ZBLAN microlasers at 1.05 um, in Infrared Glass Optical Fibers and Their Applications (SPIE, 1998), pp. 150–156

J.M. Ward, Y. Wu, K. Khalfi, S.N. Chormaic, Short vertical tube furnace for the fabrication of doped glass microsphere lasers. Rev. Sci. Instrum. 81, 073106 (2010). https://doi.org/10.1063/1.3455198

X. Peng, F. Song, S. Jiang, N. Peyghambarian, M. Kuwata-Gonokami, L. Xu, Fiber-taper-coupled L-band Er3+-doped tellurite glass microsphere laser. Appl. Phys. Lett. 82, 1497–1499 (2003). https://doi.org/10.1063/1.1559653

G.C. Righini, C. Armellini, A. Chiasera, Y. Jestin, M. Ferrari, A. Chiappini, M. Montagna, C.A. Duverger, P. Féron, S. Berneschi, M. Brenci, G.N. Conti, S. Pelli, C. Gonçalves, R.M. Almeida, Er3+-activated sol–gel silica derived spherical microresonators. Glass Technol. 48, 4 (2006)

L. Yang, K.J. Vahala, Gain functionalization of silica microresonators. Opt. Lett. 28, 592–594 (2003). https://doi.org/10.1364/OL.28.000592

L. Yang, D.K. Armani, K.J. Vahala, Fiber-coupled erbium microlasers on a chip. Appl. Phys. Lett. 83, 825–826 (2003). https://doi.org/10.1063/1.1598623

Y. Yang, F. Lei, S. Kasumie, L. Xu, J.M. Ward, L. Yang, S.N. Chormaic, Tunable erbium-doped microbubble laser fabricated by sol–gel coating. Opt. Express 25, 1308–1313 (2017). https://doi.org/10.1364/OE.25.001308

S. Zhu, L. Shi, B. Xiao, X. Zhang, X. Fan, All-optical tunable microlaser based on an ultrahigh-Q erbium-doped hybrid microbottle cavity. ACS Photonics 5, 3794–3800 (2018). https://doi.org/10.1021/acsphotonics.8b00838

D. Ristić, A. Rasoloniaina, A. Chiappini, P. Féron, S. Pelli, G.N. Conti, M. Ivanda, G.C. Righini, G. Cibiel, M. Ferrari, About the role of phase matching between a coated microsphere and a tapered fiber: experimental study. Opt. Express 21, 20954–20963 (2013). https://doi.org/10.1364/OE.21.020954

C.-H. Dong, Y.-F. Xiao, Z.-F. Han, G.-C. Guo, X. Jiang, L. Tong, C. Gu, H. Ming, Low-threshold microlaser in Er:Yb phosphate glass coated microsphere. IEEE Photonics Technol. Lett. 20, 342–344 (2008). https://doi.org/10.1109/LPT.2007.915642

B. Min, T.J. Kippenberg, L. Yang, K.J. Vahala, J. Kalkman, A. Polman, Erbium-implanted high-Q silica toroidal microcavity laser on a silicon chip. Phys. Rev. A. 70, 033803 (2004). https://doi.org/10.1103/PhysRevA.70.033803

J. Kalkman, A. Polman, T.J. Kippenberg, K.J. Vahala, M.L. Brongersma, Erbium-implanted silica microsphere laser. Nucl. Instrum. Methods Phys. Res. Sect. B 242, 182–185 (2006). https://doi.org/10.1016/j.nimb.2005.08.160

L. Jin, L. Jin, Z. Liu, Y. Zhang, Y. Wu, Y. Liu, H. Deng, Q. Song, Q. Song, Q. Song, Q. Song, S. Xiao, S. Xiao, S. Xiao, S. Xiao, Lanthanide-doped nanocrystals in high-Q microtoroids for stable on-chip white-light lasers. Photonics Res. 10, 1594–1601 (2022). https://doi.org/10.1364/PRJ.456381

B. Jiang, S. Zhu, L. Ren, L. Shi, X. Zhang, Simultaneous ultraviolet, visible, and near-infrared continuous-wave lasing in a rare-earth-doped microcavity. AP 4, 046003 (2022). https://doi.org/10.1117/1.AP.4.4.046003

F. Kotz, K. Arnold, W. Bauer, D. Schild, N. Keller, K. Sachsenheimer, T.M. Nargang, C. Richter, D. Helmer, B.E. Rapp, Three-dimensional printing of transparent fused silica glass. Nature 544, 337–339 (2017). https://doi.org/10.1038/nature22061

Y. Guo, Z. Li, N. An, Y. Guo, Y. Wang, Y. Yuan, H. Zhang, T. Tan, C. Wu, B. Peng, G. Soavi, Y. Rao, B. Yao, A monolithic graphene-functionalized microlaser for multispecies gas detection. Adv. Mater. (2022). https://doi.org/10.1002/adma.202207777

Y.-Q. Hu, X. Mao, H. Yang, M. Wang, G.-Q. Qin, G.-L. Long, Demonstration of Yb3+-doped and Er3+/Yb3+-codoped on-chip microsphere lasers. Opt. Express 29, 25663–25674 (2021). https://doi.org/10.1364/OE.427356

J.C. Knight, G. Cheung, F. Jacques, T.A. Birks, Phase-matched excitation of whispering-gallery-mode resonances by a fiber taper. Opt. Lett. 22, 1129–1131 (1997). https://doi.org/10.1364/OL.22.001129

G.N. Conti, S. Berneschi, F. Cosi, S. Pelli, S. Soria, G.C. Righini, M. Dispenza, A. Secchi, Planar coupling to high-Q lithium niobate disk resonators. Opt. Express 19, 3651–3656 (2011). https://doi.org/10.1364/OE.19.003651

A. Rasoloniaina, V. Huet, T.K.N. Nguyên, E. Le Cren, M. Mortier, L. Michely, Y. Dumeige, P. Féron, Controling the coupling properties of active ultrahigh-Q WGM microcavities from undercoupling to selective amplification. Sci. Rep. 4, 4023 (2014). https://doi.org/10.1038/srep04023

K. Totsuka, M. Tomita, Optical microsphere amplification system. Opt. Lett. 32, 3197–3199 (2007). https://doi.org/10.1364/OL.32.003197

A. Rasoloniaina, S. Trebaol, V. Huet, E.L. Cren, G.N. Conti, H. Serier-Brault, M. Mortier, Y. Dumeige, P. Féron, High-gain wavelength-selective amplification and cavity ring down spectroscopy in a fluoride glass erbium-doped microsphere. Opt. Lett. 37, 4735–4737 (2012). https://doi.org/10.1364/OL.37.004735

M. Cai, K. Vahala, Highly efficient hybrid fiber taper coupled microsphere laser. Opt. Lett. 26, 884–886 (2001). https://doi.org/10.1364/OL.26.000884

J.-B. Ceppe, M. Mortier, P. Féron, Y. Dumeige, Theoretical and experimental analysis of rare earth whispering gallery mode laser relative intensity noise. Opt. Express 25, 32732–32744 (2017). https://doi.org/10.1364/OE.25.032732

L. Xiao, S. Trebaol, Y. Dumeige, Z. Cai, M. Mortier, P. Feron, Miniaturized optical microwave source using a dual-wavelength whispering gallery mode laser. IEEE Photonics Technol. Lett. 22, 559–561 (2010). https://doi.org/10.1109/LPT.2010.2040269

A. Li, A. Li, K. Tian, J. Yu, J. Yu, R.A. Minz, J.M. Ward, S. Mondal, P. Wang, P. Wang, P. Wang, S.N. Chormaic, S.N. Chormaic, Packaged whispering gallery resonator device based on an optical nanoantenna coupler. Opt. Express 29, 16879–16886 (2021). https://doi.org/10.1364/OE.422830

M.L. Gorodetsky, V.S. Ilchenko, Optical microsphere resonators: optimal coupling to high-Q whispering-gallery modes. J. Opt. Soc. Am. B 16, 147–154 (1999). https://doi.org/10.1364/JOSAB.16.000147

X. Zambrana-Puyalto, D. D’Ambrosio, G. Gagliardi, Excitation mechanisms of whispering gallery modes with direct light scattering. Laser Photonics Rev. 15, 2000528 (2021). https://doi.org/10.1002/lpor.202000528

T. Kishi, T. Kumagai, S. Shibuya, F. Prudenzano, T. Yano, S. Shibata, Quasi-single mode laser output from a terrace structure added on a Nd3+-doped tellurite-glass microsphere prepared using localized laser heating. Opt. Express 23, 20629–20635 (2015). https://doi.org/10.1364/OE.23.020629

T. Kishi, On-chip fabrication of micrometer-size super-hemispherical and spherical optical devices from molten glass droplets. J. Ceram. Soc. Jpn. 126, 495–503 (2018). https://doi.org/10.2109/jcersj2.18030

L.N. Chung, C.T.T. Ha, N.T. Trang, P.T. Nga, P.V. Hoi, B.V. Thien, High-power microcavity lasers based on highly erbium-doped sol–gel aluminosilicate glasses. Mater. Sci. Eng. B 131, 27–31 (2006). https://doi.org/10.1016/j.mseb.2005.12.033

G. Lin, O. Tillement, Y. Candela, M. Martini, Z. Cai, V. Lefèvre-Seguin, J. Hare, Ultra-low threshold lasing in silica whispering-gallery-mode microcavities with Nd3+:Gd2O3 nanocrystals, in Micro-Optics 2010 (SPIE, 2010), pp. 600–607

G. Nunzi Conti, A. Chiasera, L. Ghisa, S. Berneschi, M. Brenci, Y. Dumeige, S. Pelli, S. Sebastiani, P. Feron, M. Ferrari, G.C. Righini, Spectroscopic and lasing properties of Er3+-doped glass microspheres. J. Non-Cryst. Solids 352, 2360–2363 (2006). https://doi.org/10.1016/j.jnoncrysol.2006.01.089

F. Lissillour, D. Messager, G. Stéphan, P. Féron, Whispering-gallery-mode laser at 1.56 μm excited by a fiber taper. Opt. Lett. 26, 1051–1053 (2001). https://doi.org/10.1364/OL.26.001051

C. Arnaud, M. Boustimi, M. Brenci, P. Feron, M. Ferrari, G. Nunzi-Conti, S. Pelli, G.C. Righini, Microsphere laser in Er3+-doped oxide glasses, in 5th Iberoamerican Meeting on Optics and 8th Latin American Meeting on Optics, Lasers, and Their Applications (SPIE, 2004), pp. 315–320

C. Pérez-Rodríguez, L. Labrador-Páez, I.R. Martín, S. Ríos, Temperature response of the whispering gallery mode resonances from the green upconversion emission of an Er3+–Yb3+ co-doped microsphere. Laser Phys. Lett. 12, 046003 (2015). https://doi.org/10.1088/1612-2011/12/4/046003

V. Lefèvre-Seguin, Whispering-gallery mode lasers with doped silica microspheres. Opt. Mater. 11, 153–165 (1999). https://doi.org/10.1016/S0925-3467(98)00041-X

W. von Klitzing, E. Jahier, R. Long, F. Lissillour, V. Lefevre-Seguin, J. Hare, J.-M. Raimond, S. Haroche, Very low threshold lasing in Er3+ doped ZBLAN microsphere. Electron. Lett. 35, 1745–1746 (1999). https://doi.org/10.1049/el:19991009

F. Lissillour, P. Féron, N. Dubreuil, P. Dupriez, M. Poulain, G.M. Stéphan, Erbium-doped microspherical lasers at 1.56 µm. Electron. Lett. 36, 1382–1384 (2000). https://doi.org/10.1049/el:20001012

T. Hayakawa, H. Ooishi, M. Nogami, Optical bistability of stimulated-emission lines in Sm3+-doped glass microspheres. Opt. Lett. 26, 84–86 (2001). https://doi.org/10.1364/OL.26.000084

X. Peng, F. Song, M. Kuwata-Gonokami, S. Jiang, N. Peyghambarian, Temperature dependence of the wavelength and threshold of fiber-taper-coupled L-band Er3+-doped tellurite glass microsphere laser. Appl. Phys. Lett. 83, 5380–5382 (2003). https://doi.org/10.1063/1.1637454

C. Arnaud, M. Boustimi, P. Feron, G. Nunzi-Conti, G. Righini, Microsphere laser in Er3+/Yb3+-codoped phosphate glass: coupling with an external cavity, in Laser Resonators and Beam Control VII (SPIE, 2004), pp. 140–149

K. Sasagawa, Z. Yonezawa, R. Iwai, J. Ohta, M. Nunoshita, S-band Tm3+-doped tellurite glass microsphere laser via a cascade process. Appl. Phys. Lett. 85, 4325–4327 (2004). https://doi.org/10.1063/1.1810628

L. Yang, T. Carmon, B. Min, S.M. Spillane, K.J. Vahala, Erbium-doped and Raman microlasers on a silicon chip fabricated by the sol–gel process. Appl. Phys. Lett. 86, 091114 (2005). https://doi.org/10.1063/1.1873043

X. Peng, F. Song, M.K. Gonokami, S. Jiang, N.N. Peyghambarian, Er3+-doped tellurite glass microsphere laser: optical properties, coupling scheme, and lasing characteristics. Opt. Express. 44, 034202 (2005). https://doi.org/10.1117/1.1869995

P.T. Snee, Y. Chan, D.G. Nocera, M.G. Bawendi, Whispering-gallery-mode lasing from a semiconductor nanocrystal/microsphere resonator composite. Adv. Mater. 17, 1131–1136 (2005). https://doi.org/10.1002/adma.200401571

P. Van Hoi, C.T.T. Ha, H.Q. Hung, Long-band emission of microsphere lasers based on erbium-doped sol–gel silica-alumina glasses. Appl. Phys. Lett. 87, 161110 (2005). https://doi.org/10.1063/1.2089186

G.C. Righini, C. Arnaud, S. Berneschi, M. Bettinelli, M. Brenci, A. Chiasera, P. Feron, M. Ferrari, M. Montagna, G. Nunzi Conti, S. Pelli, H. Portales, C. Siligardi, A. Speghini, L. Zampedri, Integrated optical amplifiers and microspherical lasers based on erbium-doped oxide glasses. Opt. Mater. 27, 1711–1717 (2005). https://doi.org/10.1016/j.optmat.2004.11.041

J. Wu, S. Jiang, T. Qua, M. Kuwata-Gonokami, N. Peyghambarian, 2 μm lasing from highly thulium doped tellurite glass microsphere. Appl. Phys. Lett. 87, 211118 (2005). https://doi.org/10.1063/1.2132532

J. Wu, S. Jiang, N. Peyghambarian, 15-μm-band thulium-doped microsphere laser originating from self-terminating transition. Opt. Express 13, 10129–10133 (2005). https://doi.org/10.1364/OPEX.13.010129

H. Takashima, H. Fujiwara, S. Takeuchi, K. Sasaki, M. Takahashi, Fiber-microsphere laser with a submicrometer sol–gel silica glass layer codoped with erbium, aluminum, and phosphorus. Appl. Phys. Lett. 90, 101103 (2007). https://doi.org/10.1063/1.2711384

H. Takashima, H. Fujiwara, S. Takeuchi, K. Sasaki, M. Takahashi, Control of spontaneous emission coupling factor β in fiber-coupled microsphere resonators. Appl. Phys. Lett. 92, 071115 (2008). https://doi.org/10.1063/1.2884329

J.M. Ward, P. Feron, S. Nic Chormaic, A taper-fused microspherical laser source. IEEE Photonics Technol. Lett. 20, 392–394 (2008). https://doi.org/10.1109/LPT.2008.916904

T. Lu, L. Yang, R.V.A. van Loon, A. Polman, K.J. Vahala, On-chip green silica upconversion microlaser. Opt. Lett. 34, 482–484 (2009). https://doi.org/10.1364/OL.34.000482

H.-S. Hsu, C. Cai, A.M. Armani, Ultra-low-threshold Er:Yb sol–gel microlaser on silicon. Opt. Express 17, 23265–23271 (2009). https://doi.org/10.1364/OE.17.023265

Y. Wu, J.M. Ward, S. Nic Chormaic, Ultralow threshold green lasing and optical bistability in ZBNA (ZrF4–BaF2–NaF–AlF3) microspheres. J. Appl. Phys. 107, 033103 (2010). https://doi.org/10.1063/1.3277024

J.M. Ward, S.N. Chormaic, Thermo-optical tuning of whispering gallery modes in Er:Yb co-doped phosphate glass microspheres. Appl. Phys. B 100, 847–850 (2010). https://doi.org/10.1007/s00340-010-4153-0

G.R. Elliott, G.S. Murugan, J.S. Wilkinson, M.N. Zervas, D.W. Hewak, Chalcogenide glass microsphere laser. Opt. Express 18, 26720–26727 (2010). https://doi.org/10.1364/OE.18.026720

C.H. Dong, Y. Yang, Y.L. Shen, C.L. Zou, F.W. Sun, H. Ming, G.C. Guo, Z.F. Han, Observation of microlaser with Er-doped phosphate glass coated microsphere pumped by 780nm. Opt. Commun. 283, 5117–5120 (2010). https://doi.org/10.1016/j.optcom.2010.07.018

G.S. Murugan, M.N. Zervas, Y. Panitchob, J.S. Wilkinson, Integrated Nd-doped borosilicate glass microsphere laser. Opt. Lett. 36, 73–75 (2011). https://doi.org/10.1364/OL.36.000073

T. Kishi, T. Kumagai, T. Yano, S. Shibata, On-chip fabrication of air-bubble-containing Nd3+-doped tellurite glass microsphere for laser emission. AIP Adv. 2, 042169 (2012). https://doi.org/10.1063/1.4769888

A. Pal, S.Y. Chen, R. Sen, T. Sun, K.T.V. Grattan, A high-Q low threshold thulium-doped silica microsphere laser in the 2 μm wavelength region designed for gas sensing applications. Laser Phys. Lett. 10, 085101 (2013). https://doi.org/10.1088/1612-2011/10/8/085101

H. Fan, S. Hua, X. Jiang, M. Xiao, Demonstration of an erbium-doped microsphere laser on a silicon chip. Laser Phys. Lett. 10, 105809 (2013). https://doi.org/10.1088/1612-2011/10/10/105809

A.J. Maker, A.M. Armani, Nanowatt threshold, alumina sensitized neodymium laser integrated on silicon. Opt. Express 21, 27238–27245 (2013). https://doi.org/10.1364/OE.21.027238

Y. Huang, Y. Huang, P. Zhang, C. Guo, Ultralow-threshold laser and blue shift cooperative luminescence in a Yb3+ doped silica microsphere. AIP Adv. 4, 027113 (2014). https://doi.org/10.1063/1.4866446

Y. Deng, R.K. Jain, M. Hossein-Zadeh, Demonstration of a cw room temperature mid-IR microlaser. Opt. Lett. 39, 4458–4461 (2014). https://doi.org/10.1364/OL.39.004458

F. Vanier, F. Côté, M.E. Amraoui, Y. Messaddeq, Y.-A. Peter, M. Rochette, Low-threshold lasing at 1975 nm in thulium-doped tellurite glass microspheres. Opt. Lett. 40, 5227–5230 (2015). https://doi.org/10.1364/OL.40.005227

L. Peng, Y. Huang, Y. Duan, S. Zhuang, T. Liao, C. Xu, 2 μm laser oscillation of Ho3+:Tm3+-codoped silica microspheres. Appl. Opt. 56, 7469–7473 (2017). https://doi.org/10.1364/AO.56.007469

Z. Yang, Y. Wu, K. Yang, P. Xu, W. Zhang, S. Dai, T. Xu, Fabrication and characterization of Tm3+–Ho3+ co-doped tellurite glass microsphere lasers operating at ∼2.1 μm. Opt. Mater. 72, 524–528 (2017). https://doi.org/10.1016/j.optmat.2017.06.057

Z. Fang, S.N. Chormaic, S. Wang, X. Wang, J. Yu, Y. Jiang, J. Qiu, P. Wang, Bismuth-doped glass microsphere lasers. Photonics Res. 5, 740–744 (2017). https://doi.org/10.1364/PRJ.5.000740

A. Li, J. Yu, M. Zhang, X. Lu, J. Zhang, E. Lewis, G. Farrell, P. Wang, An Yb3+–Ho3+ codoped glass microsphere laser in the 2.0 µm wavelength regions. IEEE Photonics Technol. Lett. 30, 1543–1546 (2018). https://doi.org/10.1109/LPT.2018.2859053

X. Wang, Y. Yu, S. Wang, J.M. Ward, S.N. Chormaic, P. Wang, Single mode green lasing and multicolor luminescent emission from an Er3+–Yb3+ co-doped compound fluorosilicate glass microsphere resonator. OSA Contin. 1, 261–273 (2018). https://doi.org/10.1364/OSAC.1.000261

A. Li, J. Zhang, M. Zhang, W. Li, S. Wang, E. Lewis, G. Brambilla, P. Wang, Effect of Tm3+ concentration on the emission wavelength shift in Tm3+-doped silica microsphere lasers. Opt. Lett. 43, 4325–4328 (2018). https://doi.org/10.1364/OL.43.004325

D. Ristić, A. Chiappini, M. Mazzola, P. Féron, H. Gebavi, M. Ivanda, M. Ferrari, Lasing and mode selection in erbium doped 70SiO2–30HfO2 coated microspheres. Opt. Mater. 87, 98–101 (2019). https://doi.org/10.1016/j.optmat.2018.05.018

A. Li, W. Li, M. Zhang, Y. Zhang, S. Wang, A. Yang, Z. Yang, E. Lewis, G. Brambilla, P. Wang, Tm3+–Ho3+ codoped tellurite glass microsphere laser in the 1.47 μm wavelength region. Opt. Lett. 44, 511–513 (2019). https://doi.org/10.1364/OL.44.000511

J. Qin, Y. Huang, T. Liao, C. Xu, C. Ke, Y. Duan, 1.9 μm laser and visible light emissions in Er3+/Tm3+ co-doped tellurite glass microspheres pumped by a broadband amplified spontaneous emission source. J. Opt. 21, 035401 (2019). https://doi.org/10.1088/2040-8986/ab0264

A. Li, M. Zhang, X. Wang, S. Wang, B. Guo, E. Lewis, P. Wang, Directly pumped Ho3+-doped microspheres lasing at 2.0 µm. IEEE Photonics Technol. Lett. 31, 1366–1368 (2019). https://doi.org/10.1109/LPT.2019.2927085

H.Y. Zhao, A.Z. Li, Y.T. Yi, M. Tokurakawa, G. Brambilla, S.J. Jia, S.B. Wang, P.F. Wang, A Tm3+-doped ZrF4-BaF2-YF3-AlF3 glass microsphere laser in the 2.0 μm wavelength region. J. Lumin. 212, 207–211 (2019). https://doi.org/10.1016/j.jlumin.2019.04.046

X. Wang, J. Yu, H. Zhao, X. Lu, W. Li, K. Tian, G. Brambilla, P. Wang, 1.88 μm laser emission from Tm3+ doped fluorosilicate glass microspheres with excellent stability and high damage threshold. J. Lumin. 220, 117028 (2020). https://doi.org/10.1016/j.jlumin.2020.117028

A. Li, Y. Dong, S. Wang, S. Jia, G. Brambilla, P. Wang, Infrared-laser and upconversion luminescence in Ho3+–Yb3+ codoped tellurite glass microsphere. J. Lumin. 218, 116826 (2020). https://doi.org/10.1016/j.jlumin.2019.116826

J. Yu, X. Wang, W. Li, M. Zhang, J. Zhang, K. Tian, Y. Du, S. Nic Chormaic, P. Wang, An experimental and theoretical investigation of a 2 μm wavelength low-threshold microsphere laser. J. Lightwave Technol. 38, 1880–1886 (2020). https://doi.org/10.1109/JLT.2019.2958349

P. Wang, Y. Yi, X. Wang, A. Li, S. Jia, Y. Fan, G. Brambilla, S. Wang, H. Zhao, Tm3+-doped fluorotellurite glass microsphere resonator laser at 23 µm. Opt. Lett. 45, 3553–3556 (2020). https://doi.org/10.1364/OL.396843

Q. Xu, S. Peng, T. Liao, Y. Huang, A stable 1550nm WGM laser generated by Yb3+/Er3+ co-doped silica microspheres under µm ASE source pumping. J. Phys. Conf. Ser. 2112, 012013 (2021). https://doi.org/10.1088/1742-6596/2112/1/012013

T. Van Nguyen, T.B. Pham, H. Bui, T. Chi Do, V.H. Pham, Coherent up-conversion in Erbium-doped silica microspheres enhanced by thin-film metal deposition. Photonics Nanostruct. Fundam. Appl. 47, 100971 (2021). https://doi.org/10.1016/j.photonics.2021.100971

M.R. Foreman, J.D. Swaim, F. Vollmer, Whispering gallery mode sensors. Adv. Opt. Photonics 7, 168–240 (2015). https://doi.org/10.1364/AOP.7.000168

J. Yang, L.J. Guo, Optical sensors based on active microcavities. IEEE J. Sel. Top. Quantum Electron. 12, 143–147 (2006). https://doi.org/10.1109/JSTQE.2005.862953

F. Paz-Buclatin, Y. Perera-Suárez, I.R. Martín, S. Ríos, O. de Varona, A. Ródenas, L.L. Martin, Experimental and numerical validation of whispering gallery resonators as optical temperature sensors. Sensors 22, 7831 (2022). https://doi.org/10.3390/s22207831

D.S. Weiss, V. Sandoghdar, J. Hare, V. Lefèvre-Seguin, J.-M. Raimond, S. Haroche, Splitting of high-Q Mie modes induced by light backscattering in silica microspheres. Opt. Lett. 20, 1835–1837 (1995). https://doi.org/10.1364/OL.20.001835

L. He, ŞK. Özdemir, J. Zhu, W. Kim, L. Yang, Detecting single viruses and nanoparticles using whispering gallery microlasers. Nat. Nanotechnol. 6, 428–432 (2011). https://doi.org/10.1038/nnano.2011.99

J.-B. Ceppe, P. Féron, M. Mortier, Y. Dumeige, Dynamical analysis of modal coupling in rare-earth whispering-gallery-mode microlasers. Phys. Rev. Appl. 11, 064028 (2019). https://doi.org/10.1103/PhysRevApplied.11.064028

Y. Kim, H. Lee, H. Lee, On-chip label-free biosensing based on active whispering gallery mode resonators pumped by a light-emitting diode. Opt. Express 27, 34405–34415 (2019). https://doi.org/10.1364/OE.27.034405

Funding

Open access funding provided by Consiglio Nazionale Delle Ricerche (CNR) within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interests or competing interests to declare that are relevant to the content of this article.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Frigenti, G., Berneschi, S., Farnesi, D. et al. Rare earth-doped glass whispering gallery mode micro-lasers. Eur. Phys. J. Plus 138, 679 (2023). https://doi.org/10.1140/epjp/s13360-023-04275-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-023-04275-9