Abstract

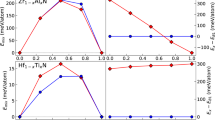

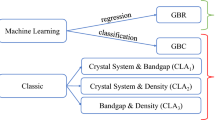

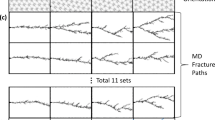

Superhard materials with good fracture toughness have found wide industrial applications, which necessitates the development of accurate hardness and fracture toughness models for efficient materials design. Although several macroscopic models have been proposed, they are mostly semiempirical based on prior knowledge or assumptions, and obtained by fitting limited experimental data. Here, through an unbiased and explanatory symbolic regression technique, we built a macroscopic hardness model and fracture toughness model, which only require shear and bulk moduli as inputs. The developed hardness model was trained on an extended dataset including more non-cubic systems. The obtained models turned out to be simple, accurate, and transferable. Moreover, we assessed the performance of three popular deep learning models for predicting bulk and shear moduli, and found that the crystal graph convolutional neural network and crystal explainable property predictor perform almost equally well, both better than the atomistic line graph neural network. By combining the machine-learned bulk and shear moduli with the hardness and fracture toughness prediction models, potential superhard materials with good fracture toughness can be efficiently screened out through high-throughput calculations.

Similar content being viewed by others

Data Availability Statement

This manuscript has associated data in a data repository. [Authors’ comment: The data that support the findings of this study are available within the article.]

References

J. Haines, J.-M. Leger, G. Bocquillon, Annu. Rev. Mater. Res. 31, 1 (2001). https://doi.org/10.1146/annurev.matsci.31.1.1

B. Xu, Y. Tian, Sci. China Mater. 58, 132 (2015). https://doi.org/10.1007/s40843-015-0026-5

J.J. Gilman, R.W. Cumberland, R.B. Kaner, Int. J. Refract. Metals Hard Mater. 24, 1 (2006). https://doi.org/10.1016/j.ijrmhm.2005.05.015

A.L. Ivanovskii, J. Superhard Mater. 33, 73 (2011). https://doi.org/10.3103/S1063457611020018

R. Riedel, Adv. Mater. 6, 549 (1994). https://doi.org/10.1002/adma.19940060705

W.L. Mao, H.K. Mao, P.J. Eng, T.P. Trainor, M. Newville, C.C. Kao, D.L. Heinz, J. Shu, Y. Meng, R.J. Hemley, Science 302(5644), 425–427 (2003). https://doi.org/10.1126/science.1089713

Q. Li, Y. Ma, A.R. Oganov, H. Wang, H. Wang, Y. Xu, T. Cui, H.K. Mao, G. Zou, Phys. Rev. Lett. 102(17), 175506 (2009). https://doi.org/10.1103/PhysRevLett.102.175506

H. Niu, X.-Q. Chen, S. Wang, D. Li, W.L. Mao, Y. Li, Phys. Rev. Lett. 108, 135501 (2012). https://doi.org/10.1103/PhysRevLett.108.135501

P. Avery, X. Wang, C. Oses, E. Gossett, D.M. Proserpio, C. Toher, S. Curtarolo, E. Zurek, NPJ Comput. Mater. 5, 1 (2019). https://doi.org/10.1038/s41524-019-0226-8

X. Cheng, W. Zhang, X.-Q. Chen, H. Niu, P. Liu, K. Du, G. Liu, D. Li, H.-M. Cheng, H. Ye, Y. Li, Appl. Phys. Lett. 103, 171903 (2013). https://doi.org/10.1063/1.4826485

H. Dong, A. Oganov, V. Brazhkin, Q. Wang, J. Zhang, M. Davari, X.-F. Zhou, F. Wu, Q. Zhu, Phys. Rev. B 98, 1 (2018). https://doi.org/10.1103/PhysRevB.98.174109

C. Zhao, Y. Duan, J. Gao, W. Liu, H. Dong, H. Dong, D. Zhang, A.R. Oganov, Phys. Chem. Chem. Phys. 20, 24665 (2018). https://doi.org/10.1039/C8CP04222E

E. Bykova, S.V. Ovsyannikov, M. Bykov, Y. Yin, T. Fedotenko, H. Holz, S. Gabel, B. Merle, S. Chariton, V.B. Prakapenka, N. Dubrovinskaia, A.F. Goncharov, L. Dubrovinsky, J. Mater. Chem. A 10, 20111 (2022). https://doi.org/10.1039/D2TA02268K

V.N. Chuvil’deev, Y.V. Blagoveshchenskii, M.S. Boldin, N. Sakharov, A.V. Nokhrin, N.V. Isaeva, S.V. Shotin, Y.G. Lopatin, O.A. Belkin, E.S. Smirnova, Tech. Phys. Lett. 41, 397 (2015). https://doi.org/10.1134/S1063785015040203

C.M. Sung, M.F. Tai, Int. J. Refract. Metals Hard Mater. 15, 237 (1997). https://doi.org/10.1016/S0263-4368(97)00003-6

C.L. Gao, W. Wu, J.D. Shi, Z.Y. Xiao, A. Akbarzadeh, Addit. Manuf. 34, 101378 (2020). https://doi.org/10.1016/j.addma.2020.101378

V. Ivashchenko, S. Vepřek, A.S. Argon, P.E.A. Turchi, L. Gorb, F. Hill, J. Leszczynski, Thin. Solid Films 578, 83 (2015). https://doi.org/10.1016/j.tsf.2015.02.013

Y. Tian, B. Xu, D. Yu, Y. Ma, Y. Wang, Y.B. Jiang, W. Hu, C. Tang, Y. Gao, K. Luo, Z. Zhao, L.-M. Wang, B. Wen, J. He, Z. Liu, Nature 493, 385 (2013). https://doi.org/10.1038/nature11728

Y. Li, J. Hao, H. Liu, S. Lu, J.S. Tse, Phys. Rev. Lett. 115(10), 105502 (2015). https://doi.org/10.1126/science.1089713

Z. Zhao, B. Xu, Y. Tian, Annu. Rev. Mater. Res. 46, 383 (2016). https://doi.org/10.1146/annurev-matsci-070115-031649

W.D. Hovsepian, P. Eh. Münz, Synthesis, structure, and applications of nanoscale multilayer/superlattice structured pvd coatings, in Nanostructured Coatings, edited by A. Cavaleiro and J. T. M. De Hosson (Springer New York, New York, NY, 2006) pp. 555–644, https://doi.org/10.1007/978-0-387-48756-4_14

K. Choudhary, G. Cheon, E. Reed, F. Tavazza, Phys. Rev. B 98, 014107 (2018). https://doi.org/10.1103/PhysRevB.98.014107

A.G. Kvashnin, Z. Allahyari, A.R. Oganov, J. Appl. Phys. 126, 040901 (2019). https://doi.org/10.1063/1.5109782

E. Mazhnik, A.R. Oganov, J. Appl. Phys. 128, 075102 (2020). https://doi.org/10.1063/5.0012055

A.H. Cole, J. Econ. Hist. 17, 476–477 (1957). https://doi.org/10.1017/S0022050700086927

W.D. Nix, H. Gao, J. Mech. Phys. Solids 46, 411 (1998). https://doi.org/10.1016/S0022-5096(97)00086-0

G. Sun, X. Feng, X. Wu, S. Zhang, B. Wen, J. Mater. Sci. Technol. 114, 215 (2022). https://doi.org/10.1016/j.jmst.2021.10.032

Q. Li, H. Wang, Y. Ma, J. Superhard Mater. 32, 192 (2010). https://doi.org/10.3103/S1063457610030056

Y. Tian, B. Xu, Z. Zhao, Int. J. Refract Metal Hard Mater. 33, 93 (2012). https://doi.org/10.1016/j.ijrmhm.2012.02.021

J.J. Gilman, J. Appl. Phys. 44, 982 (1973). https://doi.org/10.1063/1.1662382

D.M. Teter, MRS Bull. 23, 22 (1998). https://doi.org/10.1557/S0883769400031420

X.-Q. Chen, H. Niu, D. Li, Y. Li, Intermetallics 19, 1275 (2011). https://doi.org/10.1016/j.intermet.2011.03.026

S.F. Pugh, The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science 45, 823 (1954). https://doi.org/10.1080/14786440808520496

H. Niu, X.-Q. Chen, P. Liu, W. Xing, X. Cheng, D. Li, Y. Li, Sci. Rep. 2, 718 (2012). https://doi.org/10.1038/srep00718

O.N. Senkov, D.B. Miracle, Sci. Rep. 11, 1 (2021). https://doi.org/10.1038/s41598-021-83953-z

X.-Q. Chen, H. Niu, C. Franchini, D. Li, Y. Li, Phys. Rev. B 84, 121405 (2011). https://doi.org/10.1103/PhysRevB.84.121405

M. Zhang, M. Lu, Y. Du, L. Gao, C. Lu, H. Liu, J. Chem. Phys. 140, 174505 (2014). https://doi.org/10.1063/1.4871627

G. Zhang, R. Gao, Y. Zhao, T. Bai, Y. Hu, J. Alloy. Compd. 723, 802 (2017). https://doi.org/10.1016/j.jallcom.2017.06.303

J. Zhang, Y. Jin, C. Zhang, Y. Wang, L. Tang, S. Li, M. Ju, J. Wang, W. Sun, X. Dou, RSC Adv. 12, 11722 (2022). https://doi.org/10.1039/D2RA01593E

E. Mazhnik, A. Oganov, J. Appl. Phys. 126, 125109 (2019). https://doi.org/10.1063/1.5113622

F. Gao, J. He, E. dong Wu, S. Liu, D. Yu, D. Li, S. Zhang, Y. Tian, Phys. Rev. Lett. 91,015502, (2003) https://doi.org/10.1103/PhysRevLett.91.015502

X. Guo, L. Li, Z. Liu, D. Yu, J. He, R. Liu, B. Xu, Y. Tian, H.-T. Wang, J. Appl. Phys. 104, 023503 (2008). https://doi.org/10.1038/s41598-021-83953-z

K. Li, X. Wang, F. Zhang, D. Xue, Phys. Rev. Lett. 100(23), 235504 (2008). https://doi.org/10.1103/PhysRevLett

A. Šimůnek, Phys. Rev. B 75, 172108 (2007). https://doi.org/10.1103/PhysRevB.75.172108

A. Simunek, J.C.V. Vackar, Phys. Rev. Lett. 96, 085501 (2006). https://doi.org/10.1103/PhysRevLett.96.085501

F. Dai, Y. Zhou, Sci. Rep. 6, 33085 (2016). https://doi.org/10.1038/srep33085

X.L. Sheng, Q.B. Yan, F. Ye, Q.R. Zheng, G. Su, Phys. Rev. Lett. 106(15), 155703 (2011). https://doi.org/10.1103/PhysRevLett.106.155703

E.V. Podryabinkin, A.G. Kvashnin, M. Asgarpour, I.I. Maslenikov, D.A. Ovsyannikov, P.B. Sorokin, M.Y. Popov, A.V. Shapeev, J. Chem. Theory Comput. 18, 1109 (2022)

A.E. Carlsson, R. Thomson, Fracture toughness of materials: From atomistics to continuum theory, in Solid State Physics - Advances in Research and Applications,Solid State Physics - Advances in Research and Applications, Vol. 51 (Academic Press Inc., 1998), https://doi.org/10.1016/S0081-1947(08)60192-7pp.233–280,c ed

A.A. Griffith, G.I. Taylor, Ser. A Contain. Pap. Math. Phys. Charact. 221, 163 (1921). https://doi.org/10.1098/rsta.1921.0006

R.M. Thomson, J. Phys. Chem. Solids 48, 965 (1987). https://doi.org/10.1016/0022-3697(87)90114-4

H. Niu, S. Niu, A.R. Oganov, J. Appl. Phys. 125, 065105 (2019). https://doi.org/10.1063/1.5066311

K. Rajan, Annu. Rev. Mater. Res. 45, 153 (2015). https://doi.org/10.1146/annurev-matsci-070214-021132

H. Malik, IIUM Eng. J. 3, 871 (1970). https://doi.org/10.31436/iiumej.v3i1.353

S. Curtarolo, W. Setyawan, S. Wang, J. Xue, K. Yang, R.H. Taylor, L.J. Nelson, G.L. Hart, S. Sanvito, M. Buongiorno-Nardelli, N. Mingo, O. Levy, Comput. Mater. Sci. 58, 227 (2012). https://doi.org/10.1016/j.commatsci.2012.02.002

S. Kirklin, J.E. Saal, B. Meredig, A. Thompson, J.W. Doak, M. Aykol, S. Rühl, C. Wolverton, NPJ Comput. Mater. 1, 15010 (2015). https://doi.org/10.1038/npjcompumats.2015.10

A. Jain, S. Ong, G. Hautier, W. Chen, W. Richards, S. Dacek, S. Cholia, D. Gunter, D. Skinner, G. Ceder, K. Persson, APL Mater. 1, 011002 (2013). https://doi.org/10.1063/1.4812323

K. Choudhary, K. F. Garrity, A. C. E. Reid, B. DeCost, A. J. Biacchi, A. R. Hight Walker, Z. Trautt, J. Hattrick-Simpers, A.G. Kusne, A. Centrone, A. Davydov, J. Jiang, R. Pachter, G. Cheon, E. Reed, A. Agrawal, X. Qian, V. Sharma, H. Zhuang, S.V. Kalinin, B.G. Sumpter, G. Pilania, P. Acar, S. Mandal, K. Haule, D. Vanderbilt, K. Rabe, F. Tavazza, NPJ Comput. Mater. 6,173, (2020) https://doi.org/10.1038/s41524-020-00440-1

K. Choudhary, B. DeCost, C. Chen, A. Jain, F. Tavazza, R. Cohn, C.W. Park, A. Choudhary, A. Agrawal, S. Billinge, E. Holm, S. Ong, C. Wolverton, NPJ Comput. Mater. 8, 59 (2022). https://doi.org/10.1038/s41524-022-00734-6

D. Morgan, R. Jacobs, Annu. Rev. Mater. Res. 50, 1 (2020). https://doi.org/10.1146/annurev-matsci-070218-010015

Z. Rao, P.-Y. Tung, R. Xie, Y. Wei, H. Zhang, A. Ferrari, P. Klaver, F. Körmann, P. Sukumar, A. Kwiatkowski da Silva, Y. Chen, Z. Li, D. Ponge, J. Neugebauer, O. Gutfleisch, S. Bauer, D. Raabe, Science 378, 78 (2022). https://doi.org/10.1126/science.abo4940

T.D. Sparks, S.K. Kauwe, M.E. Parry, A.M. Tehrani, J. Brgoch, Annu. Rev. Mater. Res. 50, 27 (2020). https://doi.org/10.1146/annurev-matsci-110519-094700

C. Suh, C. Fare, J.A. Warren, E.O. Pyzer-Knapp, Annu. Rev. Mater. Res. 50, 1 (2020). https://doi.org/10.1146/annurev-matsci-082019-105100

G.L.W. Hart, T.O. Mueller, C. Toher, S. Curtarolo, Nat. Rev. Mater. 6, 730 (2021). https://doi.org/10.1038/s41578-021-00340-w

J.E. Saal, A.O. Oliynyk, B. Meredig, Annu. Rev. Mater. Res. 50, 49 (2020). https://doi.org/10.1146/annurev-matsci-090319-010954

O. Isayev, C. Oses, C. Toher, E. Gossett, S. Curtarolo, A. Tropsha, Nat. Commun. 8, 15679 (2017). https://doi.org/10.1038/ncomms15679

Z. Alizadeh, M. Mohammadizadeh, Phys. C Amsterdam. Neth. 558, 7 (2019). https://doi.org/10.1016/j.physc.2018.12.008

V.G. Stanev, C. Oses, A.G. Kusne, E. Rodriguez, J. Paglione, S. Curtarolo, I. Takeuchi, NPJ Comput. Mater. 4, 1 (2017). https://doi.org/10.1038/s41524-018-0085-8

L. Ward, A. Agrawal, A. Choudhary, C. Wolverton, NPJ Comput. Mater. 2, 16028 (2016). https://doi.org/10.1038/npjcompumats.2016.28

Z. Shi, E. Tsymbalov, M. Dao, S. Suresh, A.V. Shapeev, J. Li, Proc. Natl. Acad. Sci. U.S.A. 116, 4117 (2019). https://doi.org/10.1073/pnas.1818555116

G. Turán, Computational learning theory and neural networks: A survey of selected topics, in Theoretical Advances in Neural Computation and Learning, edited by V. Roychowdhury, K.Y. Siu, and A. Orlitsky (Springer US,Boston, MA, 1994) pp. 243–293, https://doi.org/10.1007/978-1-4615-2696-4_7

E. Tsymbalov, Z. Shi, M. Dao, S. Suresh, J. Li, A.V. Shapeev, NPJ Comput. Mater. 7, 1 (2021). https://doi.org/10.1038/npjcompumats.2016.28

C. Chen, W. Ye, Y. Zuo, C. Zheng, S.P. Ong, Chem. Mater. 31, 3564 (2019). https://doi.org/10.1021/acs.chemmater.9b01294

C. Chen, S.P. Ong, NPJ Comput. Mater. 7, 1 (2021). https://doi.org/10.1038/s41524-021-00639-w

T. Xie, J.C. Grossman, Phys. Rev. Lett. 120(14), 145301 (2017). https://doi.org/10.1103/PhysRevLett.120.145301

A.M. Tehrani, A.O. Oliynyk, M.E. Parry, Z. Rizvi, S. Couper, F. Lin, L. Miyagi, T.D. Sparks, J. Brgoch, J. Am. Chem. Soc. 140(31), 9844 (2018). https://doi.org/10.1021/jacs.8b02717

Y. Wang, N. Wagner, J.M. Rondinelli, MRS Communications 9, 793 (2019). https://doi.org/10.1557/mrc.2019.85

T. Stephens, Gplearn, https://gplearn.readthedocs.io/en/latest/intro.html (2015)

B. Weng, Z. Song, Z. Rilong, Q. Yan, Q. Sun, C. Grice, Y. Yan, W.-J. Yin, Nat. Commun. 11, 3513 (2020). https://doi.org/10.1038/s41467-020-17263-9

L.M. Ghiringhelli, J. Vybiral, S.V. Levchenko, C. Draxl, M. Scheffler, Phys. Rev. Lett. 114, 105503 (2015). https://doi.org/10.1103/PhysRevLett.114.105503

J.R. Koza, Stat. Comput. 4, 87 (1994). https://doi.org/10.1007/BF00175355

S. Forrest, Science 261, 872 (1993). https://doi.org/10.1126/science.8346439

S.P. Ong, W.D. Richards, A. Jain, G. Hautier, M. Kocher, S. Cholia, D. Gunter, V.L. Chevrier, K.A. Persson, G. Ceder, Comput. Mater. Sci. 68, 314 (2013). https://doi.org/10.1016/j.commatsci.2012.10.028

P. Wei, Y. Sun, X.-Q. Chen, D. Li, Y. Li, Appl. Phys. Lett. 97, 061910 (2010). https://doi.org/10.1063/1.3479478

Y. Xu, F. Gao, X. Hao, Phys. Status Solidi RRL Rapid Res. Lett. 4, 200 (2010). https://doi.org/10.1002/pssr.201004187

W. Lambrecht, B. Segall, Phys. Rev. B 45, 1485 (1992). https://doi.org/10.1103/PhysRevB.45.1485

G. Hui-Yang, G. Fa-Ming, Z. Jing-Wu, L. Zhi-Ping, Chin. Phys. B 20, 016201 (2011). https://doi.org/10.1088/1674-1056/20/1/016201

H. Niu, J. Wang, X.-Q. Chen, D. Li, Y. Li, P. Lazar, R. Podloucky, A. Kolmogorov, Phys. Rev. B 85, 144116 (2012). https://doi.org/10.1103/PhysRevB.85.144116

J. He, L. Guo, X. Guo, R. Liu, Y. Tian, H. Wang, C. Gao, Appl. Phys. Lett. 88, 101906 (2006). https://doi.org/10.1063/1.2182109

F. Kalarasse, B. Bennecer, J. Phys. Chem. Solids 69, 1775 (2008). https://doi.org/10.1016/j.jpcs.2008.01.007

K. Choudhary, B. DeCost, NPJ Comput. Mater. 7, 1 (2021). https://doi.org/10.1038/s41524-021-00650-1

K. Das, B. Samanta, P. Goyal, S.-C. Lee, S. Bhattacharjee, N. Ganguly, NPJ Comput. Mater. 8, 43 (2022). https://doi.org/10.1038/s41524-022-00716-8

C. Chen, W. Ye, Y. Zuo, C. Zheng, S. Ong, Chem. Mater. 31, 1 (2019). https://doi.org/10.1021/acs.chemmater.9b01294

Y. Zhang, C. Ling, NPJ Comput. Mater. 4, 25 (2018). https://doi.org/10.1038/s41524-018-0081-z

X. Jiang, J. Zhao, X. Jiang, Comput. Mater. Sci. 50, 2287 (2011). https://doi.org/10.1016/j.commatsci.2011.01.043

Q. Gu, G. Krauss, W. Steurer, Adv. Mater. 20, 3620 (2008). https://doi.org/10.1002/adma.200703025

P. Wang, R. Kumar, E.M. Sankaran, X. Qi, X. Zhang, D. Popov, A.L. Cornelius, B. Li, Y. Zhao, L. Wang, Inorg. Chem. 57, 1096 (2018). https://doi.org/10.1021/acs.inorgchem.7b02550

D. Ying-chun, C. Min, G. Xiu-ying, J. Meng-heng, Chin. Phys. B 21, 067101 (2012). https://doi.org/10.1088/1674-1056/21/6/067101

J. Yang, F. Gao, Phys. Status Solidi B 247, 2161 (2010). https://doi.org/10.1002/pssb.201046127

Z. Zhao, L. Cui, L.-M. Wang, B. Xu, Z. Liu, D. Yu, J. He, X.-F. Zhou, H.-T. Wang, Y. Tian, Cryst. Growth Des. 10, 5024 (2010). https://doi.org/10.1021/cg100659g

H. Gou, N. Dubrovinskaia, E. Bykova, A.A. Tsirlin, D. Kasinathan, W. Schnelle, A. Richter, M. Merlini, M. Hanfland, A.M. Abakumov, D. Batuk, G. Van Tendeloo, Y. Nakajima, A.N. Kolmogorov, L. Dubrovinsky, Phys. Rev. Lett. 111, 157002 (2013). https://doi.org/10.1103/PhysRevLett.111.157002

S. Ma, K. Bao, Q. Tao, Y. Huang, C. Xu, L. Li, X. Feng, X. Zhao, P. Zhu, T. Cui, Int. J. Refract Metal Hard Mater. 85, 104845 (2019). https://doi.org/10.1016/j.ijrmhm.2018.12.010

Q. Gan, H. Liu, S. Zhang, F. Wang, J. Cheng, X. Wang, S. Dong, Q. Tao, Y. Chen, P. Zhu, ACS Appl. Mater. Interfaces 13, 58162 (2021). https://doi.org/10.1021/acsami.1c17631

A. Šimunek, M. Dušek, Mech. Mater. 112, 71 (2017). https://doi.org/10.1016/j.mechmat.2017.05.009

D. Pu, Y. Pan, Ceram. Int. 47, 2311 (2021). https://doi.org/10.1016/j.ceramint.2020.09.073

M.B. Kanoun, I.R. Shein, S. Goumri-Said, Solid State Commun. 150, 1095 (2010). https://doi.org/10.1016/j.ssc.2010.03.014

S. Ma, K. Bao, Q. Tao, C. Xu, X. Feng, X. Zhao, Y. Ge, P. Zhu, T. Cui, Phys. Chem. Chem. Phys. 21, 2697 (2019). https://doi.org/10.1039/C8CP05870A

Acknowledgements

This work was supported by the National Key R &D Program of China (Grant No. 2021YFB3501503), the National Natural Science Foundation of China (Grant No. 52201030, Grant No. 52188101), the National Science Fund for Distinguished Young Scholars (No. 51725103), and Chinese Academy of Sciences (No. ZDRW-CN-2021-2-5). All calculations were performed on the high performance computational cluster at the Shenyang National University Science and Technology Park.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Appendix: Summary of experimental data on hardness and fracture toughness

Appendix: Summary of experimental data on hardness and fracture toughness

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, J., Liu, P., Wang, J. et al. Hardness and fracture toughness models by symbolic regression. Eur. Phys. J. Plus 138, 643 (2023). https://doi.org/10.1140/epjp/s13360-023-04273-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-023-04273-x