Abstract

The Physikalisch-Technische Bundesanstalt (PTB) is the national metrology institute of the Federal Republic of Germany and has been using synchrotron radiation (SR) for more than 40 years. Starting at the former facility BESSY I, the storage ring BESSY II (see corresponding article in this volume) has been used for this purpose since 1998, especially in the X-ray range, as well as PTB's own metrology light source (MLS) for lower photon energies since 2008. Both facilities are located in Berlin-Adlershof and are operated by the Helmholtz-Zentrum Berlin within the framework of contractual agreements with PTB. The basic motivation of the work is radiometry. The two storage rings MLS and BESSY II are used as primary source standards and cryogenic radiometers as primary detector standards. The article gives a brief overview of the present status, scientific highlights, the technological development and upgrade plans for the decade 2023–2033 as well as a perspective of next scientific challenges.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The metrology light source (MLS, Fig. 1) is an electron storage ring with 48 m circumference in a double bend achromat lattice structure [1]. It is designed for flexible operation and highly automated. The electron energy can be set to any value from 105 up to 630 MeV. In addition, also the electron beam current can be adjusted within a range of more than 11 decades, i.e., from that of one stored electron up to 200 mA. Below 1000, the number of stored electrons can be counted by detecting their emitted synchrotron radiation with cooled photodiodes [2]. The possible variations in the spectral shape and intensity of the synchrotron radiation (SR) spectrum enable PTB to select tailor-made conditions for various applications. Because of its versatility, MLS is also used as accelerator physics test bed together with HZB.

Beamlines and instrumentation at the metrology light source (MLS) [3]

The work of the approximately 80 employees at a total of 14 beamlines at the MLS and in the PTB laboratory at BESSY II focuses on the following areas:

-

Fundamentals of metrology, radiometry

-

Metrology for industry, EUV lithography

-

Research and development for optical technologies, space instruments

-

Materials metrology, nanometrology

This includes services, contract research and third-party funded projects with a funding volume of more than 2 million € per year.

2 Present status and scientific highlights

The machine design of the MLS as a low-energy storage ring with highest operational flexibility is particularly suitable for applications in the photon energy ranges from terahertz (THz) to extreme ultraviolet (EUV) radiation. The electron optics are tunable with variable parameters, which are regularly used to generate coherently amplified synchrotron radiation in the THz wavelength range. In a so-called island bucket operation mode, the simultaneous operation of two transversely shifted orbits was demonstrated [4] resulting in a subsequent realization at BESSY II. Moreover, minimized electron energy dispersion with ultralow phase shift factors can realize a quasi-isochronous lattice structure as a basis for so-called steady-state microbunching (SSMB), i.e., coherently amplified undulator emission from laser-induced submicron electron bunches [5]. This paves the way for compact sources with high repetition rates and high power, which may eventually be used in the EUV range.

The EUV region at wavelengths close to 13.5 nm is of particular interest to the semiconductor industry. After more than 20 years of development, high-end semiconductor manufacturing relies on EUV lithography (EUVL) introduced in high-volume production in 2019. As the development of optical components, coatings, materials, and detection devices is highly dependent on precise measurement techniques, PTB has been supporting EUVL-related industry in this respect for many years within the framework of extensive direct cooperation. This ranges from reflectometry and scatterometry to spectroscopic analysis using IR/THz and X-ray spectrometry at MLS and BESSY II. Besides metrology for EUV lithography, new metrology concepts for semiconductor nanostructures on wafer using EUV and soft X-ray radiation are investigated, e.g. machine learning to reconstruct periodic nanostructures with element sensitivity from angle-resolved X-ray fluorescence (Fig. 2).

Reconstruction of a periodic Si3N4 nanostructure using machine learning and grazing incidence X-ray fluorescence spectroscopy [6]

In addition, techniques such as ellipsometry and electron spectroscopy in the vacuum ultraviolet (VUV) and EUV spectral regions are used to study functionalized surfaces, e.g., thin films of organic photovoltaic substances [7], or to reveal the orbital structure of single molecules on surfaces and their chemical reactions [8]. With scanning near-field optical microscopy (SNOM) using IR/THz radiation, it became possible to identify molecular fingerprints of soft materials [9]. IR/THz spectroscopy with synchrotron radiation thus gives new insights into biochemical processes. In general, the well-characterized beamlines and the radiometric instrumentation of PTB allow not only the qualitative but also the quantitative determination of material parameters traceable to the international system of units SI, i.e. materials metrology.

3 Technological development and upgrade plans for the decade 2023–2033

The MLS has been in operation for about 15 years and is already being continuously upgraded with new machine components as part of various special projects in collaboration with the HZB, such as the further development of the MLS machine control, electron beam diagnostics or the MLS cavity using semiconductor technology. Regular upgrade programs of beamlines and end stations are based on new scientific and technological requirements and especially on the needs of industrial partners. Figure 3 shows as an example PTB's new EUV reflectometer with lubricant-free vacuum mechanics, which can also accommodate very large optical systems of industrial wafer steppers for semiconductor manufacturing and was recently put into operation at the MLS.

Optimization in industrial EUVL processes relies in many cases on accurate knowledge of optical material parameters. For the VUV and EUV range, the lack of sound data is obvious. PTB has already started to build an optical constants database (ODBC) [10] to provide the community with reliable and metrologically sound material data. These data are generated with complementary measurement methods and with validated uncertainties. Due to the steadily increasing demand for beamtime, another EUV beamline is planned for the near future at the MLS.

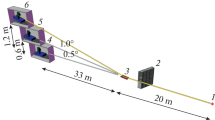

At PTB, reflectometry is also used for optics development outside EUVL. For the planned large-scale X-ray mission Advanced Telescope for High ENergy Astrophysics (ATHENA) of the European Space Agency (ESA), for example, special silicon pore optics (SPOs) are currently being investigated [11]. SPO modules consist of stacked reflective wafers with ribs on the backside. About 600 mirror modules must be integrated into the telescope, providing several hundred square meters of mirror surface. The characterization measurements are performed with a highly collimated X-ray beam in the PTB laboratory at BESSY II. Two additional X-ray parallel beam facilities are to be implemented in the next few years.

A new soft-to-tender X-ray undulator beamline for battery research is planned together with HZB at BESSY II to be optimized in terms of spectral purity and beam stability. Calibrated instrumentation for complementary experiments (XRF, XAS, XRD, XPS, SAXS, RIXS, X-ray tomography, …) and automation including metadata storage will ensure reliable quality management. The goal is user access for quantitative material characterization including in-operando experiments within a sophisticated laboratory infrastructure for sample preparation. The aging mechanisms in lithium-sulfur batteries during cycling have already been the subject of extensive measurements with quantitative X-ray spectroscopy in the PTB laboratory at BESSY II (Fig. 4). The HZB-PTB battery beamline is part of the BESSY II+ upgrade program, which is currently being prepared.

Operando cell for investigation with X-ray spectrometry of dissolved polysulfides at the cathode (left) and anode side (right) in lithium-sulfur batteries [12]

4 Perspective of next scientific challenges to be address at the facility

The upgrade programs for MLS and BESSY II are also preparing the science case and Conceptual Design Report (CDR) for the post-2035 MLS II and BESSY III successor facilities, where quantitative and metrology materials science will play a major role. Metrological measurements with synchrotron radiation imply unique characterization tools providing quantitative data with known uncertainty. Such accurate data sets form an indispensable basis for many industrial applications and the future economy in Europe, including the semiconductor industry and sustainable energy technologies. They are also becoming increasingly important in academic research, as they enable a deeper understanding of materials and exploit multimodal approaches. Over the course of several decades, PTB has established a world-leading position in metrology with synchrotron radiation and offers experimental capabilities specifically tailored to the increasing demands of industry and academia.

The first pillar of PTB's current and future activities with synchrotron radiation is radiometry, i.e. the measurement technology for electromagnetic radiation. This requires the accurate measurement of storage ring parameters such as electron energy, electron current and bending magnetic field and must therefore be an elementary component in the planning of a new source. Based on its capabilities in radiometry, PTB secondly offers various measurement capabilities to industry. In order to maintain the leading position in this field, state-of-the-art measurement capabilities are an indispensable prerequisite, and successor facilities are essential after decades of operation of BESSY II and MLS.

Materials metrology, the third pillar of PTB's activities, is becoming increasingly important for applications in optics, semiconductor electronics, quantum technology, photovoltaics, energy storage, catalysis or biotechnology. Driven by the structural complexity of modern materials, PTB is further developing its methodology for the characterization of materials on the nanoscale and is increasingly investigating materials under realistic conditions, i.e., in-operando, in-situ or in-synthesis. Therefore, the applied methods will also benefit greatly from the availability of smaller focal lengths and higher brightness and coherence of a fourth-generation light source.

Data Availability

With the exception of the photograph in Fig. 3, this review article refers exclusively to the results of the publications listed below and their references. New data are not associated with the manuscript.

References

A. Gottwald, R. Klein, R. Müller, M. Richter, F. Scholze, R. Thornagel, G. Ulm, Metrologia 49, S146–S151 (2012). https://doi.org/10.1088/0026-1394/49/2/S146/meta

R. Klein, G. Brandt, R. Fliegauf, A. Hoehl, R. Müller, R. Thornagel, G. Ulm, M. Abo-Bakr, J. Feikes, M.V. Hartrott, K. Holldack, G. Wüstefeld, Phys. Rev. ST Accel. Beams 11, 110701 (2008). https://doi.org/10.1103/PhysRevSTAB.11.110701

M. Richter, G. Ulm, Metrology with synchrotron radiation, in Synchrotron Light Sources and Free-Electron Lasers. ed. by E. Jaeschke, S. Khan, J.R. Schneider, J.B. Hastings (Springer, 2020)

T. Arion, W. Eberhardt, J. Feikes, A. Gottwald, P. Goslawski, A. Hoehl, H. Kaser, M. Kolbe, J. Li, C. Lupulescu, M. Richter, M. Ries, F. Roth, M. Ruprecht, T. Tydecks, G. Wüstefeld, Rev. Sci. Instrum. 89, 103114 (2018). https://doi.org/10.1063/1.5046923?class=pdf

X. Deng, A. Chao, J. Feikes, A. Hoehl, W. Huang, R. Klein, A. Kruschinski, J. Li, A. Matveenko, Y. Petenev, M. Ries, C. Tang, L. Yan, Nature 590, 576–579 (2021). https://doi.org/10.1038/s41586-021-03203-0

A. Andrle, P. Hönicke, G. Gwalt, P.-I. Schneider, Y. Kayser, F. Siewert, V. Soltwisch, Nanomaterials 11, 1647 (2021). https://doi.org/10.3390/nano11071647

F. Roth, M. Herzig, C. Lupulescu, E. Darlatt, A. Gottwald, M. Knupfer, W. Eberhardt, J. Appl. Phys. 118, 185310 (2015). https://doi.org/10.1063/1.4935623

X. Yang, L. Egger, P. Hurdax, H. Kaser, D. Lüftner, F.C. Bocquet, G. Koller, A. Gottwald, P. Tegeder, M. Richter, M.G. Ramsey, P. Puschnig, S. Soubatch, F.S. Tautz, Nat. Commun. 10, 3189 (2019)

G. Ulrich, E. Pfitzner, A. Hoehl, J.-W. Liao, O. Zadvorna, G. Schweicher, H. Sirringhaus, J. Heberle, B. Kästner, J. Wunderlich, D. Venkateshvaran, Nanophotonics 9, 14 (2020). https://doi.org/10.1515/nanoph-2020-0316

R. Ciesielski, Q. Saadeh, V. Philipsen, K. Opsomer, J.-P. Soulié, M. Wu, P. Naujok, R.W.E. van de Kruijs, C. Detavernier, M. Kolbe, F. Scholze, V. Soltwisch, Appl. Opt. 61, 2060–2078 (2022). https://doi.org/10.1364/AO.447152

M. Bavdaz et al., Proc. of SPIE 11852, 1185220-1–1185220-16 (2021). https://doi.org/10.1117/12.2599341

C. Zech, P. Hönicke, Y. Kayser, S. Risse, O. Grätz, M. Stamm, B. Beckhoff, J. Mater. Chem. A 9, 10231 (2021). https://doi.org/10.1039/D0TA12011A

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gottwald, A., Krumrey, M., Scholze, F. et al. Metrology with synchrotron radiation at PTB. Eur. Phys. J. Plus 137, 1238 (2022). https://doi.org/10.1140/epjp/s13360-022-03417-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-022-03417-9