Abstract

The longitudinal and transverse magnetoresistance curves MR(H) and the magnetization isotherms M(H) were measured at T = 3 K and 300 K up to high magnetic fields for a microcrystalline (µc) Ni foil with grain sizes above 1 µm (corresponding to bulk Ni) and for a nanocrystalline (nc) Ni foil with an average grain size of about 100 nm. At T = 3 K, the field-induced resistivity change was quite different for the two microstructural states of Ni and the evolution of resistivity with magnetic field was also different which could be explained as arising from their very different electron mean free paths. At T = 300 K, the MR(H) curves of both the μc-Ni and nc-Ni samples were very similar to those known for bulk Ni. The MR(H) data were analyzed at both temperatures with the help of Kohler plots from which the resistivity anisotropy splitting (ΔρAMR) and the anisotropic magnetoresistance (AMR) ratio were derived, the latter values being very similar at both temperatures and for both microstructural states of Ni metal. The present high-precision MR(H) data revealed that the available theoretical models do not accurately describe the suppression of thermally induced magnetic disorder at around room temperature in high magnetic fields.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The anisotropic magnetoresistance (AMR) of ferromagnetic metals and alloys has been extensively investigated experimentally in the past [1,2,3,4,5,6]. Parallel progress in theoretical methods of solid-state physics enabled also the calculation of magnetotransport properties of metallic ferromagnets [7,8,9,10]. Although the AMR effect in ferromagnets has long been used in various sensor applications [11], after the discovery of the giant magnetoresistance (GMR) effect in magnetic nanostructures [12, 13] which opened the way to spintronics, the interest in magnetoresistive sensors further increased. This has boosted a renewed interest in the studies of the MR characteristics of ferromagnetic metals and alloys which constitute an important ingredient in all spintronic devices. Especially exciting are the recent experimental and theoretical achievements [14,15,16,17] in clarifying the microscopic mechanisms of the AMR and related magnetotransport phenomena by distinguishing between extrinsic and intrinsic contributions.

In order to get more reliable experimental data on the MR characteristics of bulk ferromagnets, it is of importance, therefore, to carry out new studies on better-characterized specimens and eventually under improved and/or extended experimental conditions as done beforehand. These new results may, furthermore, provide a firmer basis for a comparison with the findings of theoretical calculations to test the validity of applied models and approximations.

In the spirit of the above considerations, we have turned our attention to studying the electrical transport properties of nanocrystalline (nc) Ni metal. The zero-field electrical resistivity has already been extensively studied for nc-Ni [18,19,20,21,22,23]. The investigation of the field dependence of the resistivity of nc-Ni has received much less attention [22, 24]. In the detailed work by Madduri and Kaul [22], the field dependence was measured in high magnetic fields (up to H = 90 kOe) in a wide temperature range (from T = 1.8 K to 300 K) in a configuration where the measuring current and the applied magnetic field were perpendicular to each other. In a recent paper [24], we have reported and analyzed room-temperature MR data on a series of nc-Ni samples with various grain sizes in a limited magnetic field range (up to H = 9 kOe) with the magnetic field and current either parallel (longitudinal MR = LMR) or perpendicular (transverse MR = TMR) to each other. The zero-field values of the resistivity were determined by extrapolation to H = 0 from the magnetically saturated (monodomain) state for both the LMR and TMR components (ρLs and ρTs, respectively) in a manner as described in Ref. 25. From these data [24], we have then derived parameters characterizing the AMR of ferromagnetic metals [4,5,6, 25] by determining the resistivity anisotropy splitting ΔρAMR = ρLs − ρTs and the anisotropic magnetoresistance ratio defined as AMR = ΔρAMR/ρis. The normalizing factor in the latter expression is the isotropic resistivity ρis = (1/3) ρ Ls + (2/3) ρTs, the quantity ρis being usually very close to the resistivity ρ0 measured in the absence of a magnetic field in the demagnetized state of a ferromagnetic specimen [4].

As an extension of our previous room-temperature study in a limited magnetic field range [24], the major purpose of the present work was to investigate the MR behavior of a nc-Ni and a bulk Ni sample at both low temperature (3 K) and high temperature (300 K) up to high magnetic fields. It was expected from this comparison to reveal the significance of the influence of a large density of grain boundaries on the MR characteristics. In order to relate the variation of the resistivity with magnetic field to the magnetization process, the magnetization isotherms were also measured at both temperatures.

The rationale behind this work is that the magnetoresistance of a nanocrystalline ferromagnetic metal is a very interesting issue. The reason for this is that in the nc state the large density of lattice defects such as grain boundaries represents excess scattering centers for the conduction electrons carrying the current and this leads finally to an increase of the resistivity [26]. Recently, we have summarized [23] all the room-temperature zero-field resistivity data available on nc-Ni and the resistivity of nc-Ni samples was found to be larger than the bulk value [27, 28]Footnote 1. Since the resistivity contribution due to the grain boundaries is present at any temperature, the nc state is characterized by a non-negligible residual resistivity as demonstrated, indeed, in several studies on nc-Ni [18,19,20,21,22]. As a consequence, it can be expected that the low-temperature magnetoresistance behavior can also be quite different for the microcrystalline (bulk) and nanocrystalline state of a metal for the following reason.

In pure and defect-free metals, at low temperatures where the phonon term to the resistivity is strongly diminished, the residual resistivity becomes very small and the electron mean free path becomes very long (up to the micrometer range). Under these conditions, the electrons can travel long distances in the large (at least micrometer-sized) grains without being scattered by the residual impurities and lattice defects. However, in a magnetic field H applied for measuring the longitudinal magnetoresistance (magnetic field is oriented along the current flow direction), the electrons move on a path turning around the magnetic field lines due to the Lorentz force while traveling toward lower electric potentials. As a consequence, due to the helical electron path, the distance traveled along the electric field lines will be shorter than the electron mean free path between two consecutive scattering events which then manifests itself in an increased resistance, the resistivity increase being the larger, the larger the applied magnetic field. For the TMR configuration (magnetic field perpendicular to the current flow direction), the resistivity increase in a given magnetic field is even stronger than for the LMR configuration. This is because in the TMR configuration the rotation of the electrons due to the Lorentz force happens around a direction perpendicular to the current flow and, therefore, the electrons move backward and forward with respect to the overall drift direction.

The resistivity contribution due to the presence of a magnetic field via the Lorentz force is termed as ordinary magnetoresistance (OMR) which is the only source of resistivity change due to the application of an external magnetic field in normal (non-magnetic) metals [5, 6, 29]. Since for sufficiently pure ferromagnetic metals, the OMR term dominates the observed variation of the resistivity with magnetic field at low temperatures, the determination of the ferromagnetic resistivity anisotropy [3,4,5,6] is not a straightforward task [30, 31].

However, as we have seen above, if we introduce a large amount of lattice defects, e.g., in the form of grain boundaries, into an otherwise chemically pure metal, this diminishes the electron mean free path even at low temperatures, resulting in a non-negligible residual resistivity. In such cases, the ferromagnetic resistivity anisotropy can be expected to be determined at low temperatures even for a pure ferromagnetic metal in the nc state.

The magnetoresistance of non-magnetic metals has been traditionally analyzed on the basis of Kohler’s rule [29] according to which the magnetic-field-induced relative resistivity change Δρ(H)/ρo = [ρ(H) − ρo]/ρo is a function of the ratio H/ρo only where ρ(H) is the resistivity ρ in a magnetic field H and ρo is the resistivity measured in the absence of a magnetic field. This can be formulated as Δρ(H)/ρo = F(H/ρo) where the Kohler function F is to be determined empirically from the measured MR(H) data. The Kohler function F cannot be derived theoretically; nevertheless, it was established to have some general features, e.g., it was found to be dependent on the relative orientation of the magnetic field H and the measuring current and, if the specimen is a single crystal, also on the crystal orientation. The function F is always of saturating form if the magnetic field and the current are parallel (LMR) and, for a single crystal, depending on the topology of the Fermi surface, F is either increasing or saturating if the magnetic field and the current are perpendicular to each other (TMR) [30]. The validity of Kohler’s rule has been demonstrated experimentally by using the so-called Kohler plots [Δρ(H)/ρo vs. H/ρo] for most normal (non-magnetic) metals [29, 32].

In the initial studies of the low-temperature magnetoresistance of ferromagnetic metals, the validity of Kohler’s rule was questioned until Schwerer and Silcox [30] recognized that in ferromagnets, instead of the magnetic field H, the magnetic induction B = H + 4πMs should be used (here Ms is the saturation magnetization of the ferromagnet) in Kohler’s rule. The rationale behind this is the fact that, in a ferromagnet, not the externally applied magnetic field H, but the magnetic induction B is the effective field acting on the electron trajectories [5, 6]. It is noted that for a correct treatment in the expression of B, the demagnetizing field should also be taken into account [5]. However, in our special strip-shaped specimen geometry, the demagnetizing field can be usually neglected besides the other terms for magnetic fields applied in the plane of the thin strip sample [25].)

In contrast to the case of T = 3 K, in the high-temperature regime such as at 300 K, the phonon contribution to the resistivity is the dominant term and, thus, the mean free path is strongly reduced for any metal even in a pure, coarse-grained and defect-free sample. Therefore, at room temperature, the OMR term becomes negligible even in pure metals [33, 34]. In this case, the partial suppression of the thermally induced spin disorder by the increasing magnetic field is the only source of a field-induced resistivity change in the magnetically saturated state. Therefore, the MR(H) behaviors of the µc-Ni and nc-Ni samples were found to be very similar at 300 K.

In the present paper, the MR(H) data were successfully analyzed for both the µc-Ni and nc-Ni samples on the basis of Kohler’s rule. From this quantitative analysis, the AMR ratio and the functional form of the field dependence of the resistivity could be derived at both temperatures.

The rest of the paper is organized as follows. In Sect. 2, the preparation, microstructure and zero-field resistivity of the investigated Ni samples and the measurement techniques for the magnetoresistance and the magnetization will be presented. The experimental results for the MR behavior and magnetic properties of the µc-Ni and nc-Ni samples studied are presented separately for T = 3 K in Sect. 3 and for T = 300 K in Sect. 4. These sections also include a comparison of the results for µc-Ni and nc-Ni at each temperature as well as with previously reported relevant experimental data. A summary of the present results will be given in Sect. 5. In addition, Appendix A will be devoted to a discussion of the field dependence of the resistivity in the magnetically saturated (monodomain) state of Ni metal at T = 300 K in view of previous theoretical considerations [22, 34]. An analysis of the correlation between ΔρAMR and ρo, by using also the current low-temperature data, will be performed in Appendix B similarly to our recent work on a series of nc-Ni samples with various grain sizes [24].

2 Experimental

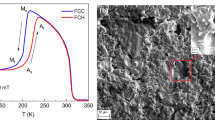

2.1 Samples investigated: preparation, microstructure and zero-field resistivity

The magnetotransport and magnetic measurements were performed on an nc-Ni and a µc-Ni thin foil sample. The nc-Ni foil (identical with sample #B2 in Refs. 23 and 24) with 9 μm thickness was produced by electrodeposition. Deposition was performed on a polished Ti sheet from which the Ni foil could be mechanically peeled off. The µc-Ni foil (identical with sample #B5 in Refs. 23 and 24) was obtained by cold rolling a bulk sample of commercial Ni (electrolytic nickel grade) down to a thickness of about 45 μm. After cold rolling, a heat treatment at about 700 °C for 1 h in a protecting hydrogen atmosphere was carried out to release the stresses introduced by the cold-rolling procedure.

According to an energy-dispersive X-ray spectroscopy analysis of the two samples [23], besides a small amount of C and O probably in the form of surface contamination, neither metallic nor non-metallic impurities could be detected up to a level of about 0.1 at.%.

A detailed structural characterization of these two samples by X-ray diffraction has been reported previously [23]. It was found that the size of the coherently scattering domains (termed as crystallite size) of sample #B5 is in the micrometer range and this justifies to call it as microcrystalline (µc) Ni. As a result of annealing, this is a coarse-grained sample corresponding actually to bulk Ni. The average crystallite size of sample #B2 was about 75 nm as deduced from X-ray diffraction, so it can be considered as a nanocrystalline (nc) Ni sample. It is noted that the grain size what could be observed by direct electron microscopic imaging methods was estimated to be about 100 nm.

The room-temperature zero-field resistivity data (ρo) of the two samples have been taken from Ref. 23: ρo(300 K) = 7.36 ± 0.21 µΩcm for the µc-Ni foil (sample #B5) and ρo(300 K) = 8.78 ± 0.21 µΩcm for the nc-Ni foil (sample #B2). The zero-field resistivity of the µc-Ni sample agrees well with the standard value of bulk Ni at T = 300 K (ρo = 7.24 µΩcm [27, 28]), whereas the somewhat larger value for nc-Ni is due to the presence of a large density of grain boundaries [18, 23, 26].

In the present work, a zero-field residual resistivity ratio of RRR = ρ(300K)/ρ(3K) = 331 was obtained for the µc-Ni foil, which indicates a fairly high purity and a defect-free state of sample #B5. For comparison, we note that for the Ni sample which was used to measure the standard resistivity data for bulk Ni [27, 28], the residual resistivity ratio was specified as RRR = ρ(273K)/ρ(4K) = 270 (in another often referenced bulk Ni resistivity study, the Ni sample had RRR = 310 [35])Footnote 2. It follows from our experimental RRR value that the zero-field resistivity of the µc-Ni foil at T = 3 K is ρo = ρ(H = 0) = 0.02222 µΩcm. On the basis of the reported residual resistivity contribution of Co and Fe in Ni [5], this value is in accordance with a possible slight contamination by Co and Fe somewhat below the detection limit of our chemical analysis.

The temperature dependence of the resistivity of the nc-Ni sample measured from 3 to 300 K in zero magnetic field was very similar as reported on nc-Ni in all previous studies [18,19,20,21,22]. The residual resistivity of the nc-Ni foil was 11% of the room temperature value which corresponds to RRR = 9. It follows from these data that the zero-field resistivity at T = 3 K is ρo = 0.9739 µΩcm for the presently investigated nc-Ni sample.

2.2 Magnetoresistance and magnetic measurements

The measurement of the resistivity of thin foils as a function of the externally applied magnetic field H can be conveniently carried out on strip-shaped samples [25]. Therefore, a rectangular strip of about 1 mm wide and about 5 mm long was cut from the Ni foils.

For the magnetoresistance measurements with a four-point probe, spot-welded contacts were attached to the strip-shaped sample. About a dozen contact wires at both ends of the strip served for providing a homogeneous current flow along the strip length. Contact wires were attached at both long edges of the strip to measure the voltage drop along the strip length. The magnetoresistance measurements were taken with the current flowing along the long axis of the strip; the magnetic field was in the plane of the strip and was oriented either parallel (LMR) or perpendicular (TMR) to the current.

By considering the above specified sample shapes and dimensions including the thickness, these samples can be approximated with a general ellipsoid [25] which facilitates the extrapolation of the resistivity to B = 0, a procedure necessary under certain circumstances to eliminate the OMR contribution.

For measuring the resistance, a d.c. current with alternating sign and with an amplitude of I = ± 100 μA was applied and the resulting d.c. voltage drop along the strip length was recorded with a nanovoltmeter. The resistance probe could be inserted into the cryostat of a superconducting magnet with magnetic fields up to H = 140 kOe. In the cryostat, the sample temperature could be varied from 3 to 300 K.

The in-plane magnetization isotherms M(H) were measured in a SQUID magnetometer at 3 K and 300 K up to H = 50 kOe and in a vibrating sample magnetometer (VSM) at 300 K up to H = 10 kOe.

3 Magnetoresistance and magnetic properties at T = 3 K

3.1 Experimental results for µc-Ni

Figure 1a and b shows the field dependence of the resistivity for µc-Ni at T = 3 K for the LMR and TMR configurations. It can be seen that at this temperature the resistivity minimum at H = 0 coincides for the longitudinal and transverse components with a zero-field resistivity ρo = 0.02222 µcm. The data displayed in Fig. 1b demonstrate that, in spite of the relatively large random noise (about 2% of the measured values), the average values are well reproducible during various field cycling directions for each configuration and also the ρo values for the two components agree very well. This is due to the extremely high stability and accuracy of our measurement setup.

a Field-dependence of the resistivity ρ at T = 3 K for µc-Ni with magnetic field orientations as indicated (LMR, TMR). b Enlarged version of the resistivity data at low magnetic fields. c High-field magnetization curve M(H) at 3 K for µc-Ni. d Low-field magnetization curve M(H) at 3 K for µc-Ni. Note: the vertical double-headed arrows in (a) and (b) indicate the specified relative resistivity change Δρ/ρo

The random noise of the resistivity measurement does not enable to directly see a hysteresis of the MR(H) data for the µc-Ni sample in Fig. 1b. However, a careful analysis of the TMR results at higher resolution revealed a hysteresis and yielded the peak positions to be at a magnetic field of about Hp = ± 85(10) Oe.

In order to assess the magnetization process, especially the onset of technical magnetic saturation (i.e., the achievement of the monodomain state), the magnetization curve M(H) of the µc-Ni sample was measured at 3 K by SQUID up to 50 kOe which is shown in Fig. 1c and d. Due to the low coercive field of µc-Ni, the SQUID magnetometer could not reveal a magnetic hysteresis (the reason for this is that the power supply of the superconducting magnet of the SQUID is not bipolar), we can only estimate that the coercive field (Hc) of the µc-Ni sample can be around 10 Oe.

The two quantities (Hc and Hp) reflect critical magnetic field points of the remagnetization process where the distribution of the domain magnetization orientations exhibits an extremum. Hc and Hp are usually close to each other although they are usually not equal. This is because the conditions for zero magnetization (H = Hc) during the magnetization reversal are not identical with the conditions for the occurrence of maximum/minimum resistivity peaks during cycling the external magnetic field.

It can be established from the measured M(H) data that saturation of the magnetization is achieved in a magnetic field of the order of a few kilooersted. The LMR(H) curve does not seem to reveal any specific feature in this magnetic field range whereas the TMR(H) curve exhibits a change in the slope around 0.5 to 1 kOe (see Fig. 1b) that may indicate the approach to saturation of the magnetoresistance.

It is easy to reveal from Fig. 1a that the µc-Ni sample exhibits a strongly non-linear field dependence of the resistivity at such a low temperature. The MR(H) data indicate that TMR > LMR in the whole range of magnetic fields investigated and both components tend to show a saturation character for high magnetic fields. These features correspond to the discussion in the introduction about the magnetoresistance behavior of pure ferromagnetic metals: The low residual resistivity (high RRR ratio) results in an extremely large electron mean free path owing to which the electron trajectories are strongly deflected by the magnetic field, i.e., a large OMR effect occurs and a transverse magnetic field causes a larger effect than a longitudinal field. Very similar low-temperature MR(H) curves were reported for high-purity Ni both for single-crystal [36, 37] and polycrystalline [38] samples although no attempt was made in those studies to determine the magnitude of the anisotropic magnetoresistance effect.

We will analyze the data on the basis of the Kohler plots. As suggested by Schwerer and Silcox [30], in applying Kohler’s rule for ferromagnets, the magnetic field H should be replaced by the magnetic induction B = H + 4πMs. Accordingly, Kohler’s rule for a ferromagnet will take the form Δρ(B)/ρ(B = 0) = [ρ(B) − ρ(B = 0)]/ρ(B = 0) = F[B/ρ(B = 0)] where we have now replaced the zero-field resistivity ρo = ρ(H = 0) with ρ(B = 0) to emphasize that the resistivity at zero induction is the normalizing factor for ferromagnets. Kohler’s rule can be transformed also into the following form: ρ(B)/ρ(B = 0) = 1 + F[B/ρ(B = 0)]. This implies that if we display ρ(B)/ρ(B = 0) as a function of B/ρ(B = 0) which is the Kohler plot, then the Kohler function F[B/ρ(B = 0)] should extrapolate to 1 when B → 0.

In order to carry out the data analysis on the basis of the Kohler plot, we should know the value of ρ(B = 0). To find the experimentally unattainable zero-induction resistivity ρ(B = 0), the procedure is the following. We display the ρ(B)/ρ(B = 0) data as a function of B/ρ(B = 0) by taking first ρ(B = 0) equal to the zero-field resistivity ρ(H = 0). Since the form of the Kohler function F is not known, we fit the data with a polynomial function by using the constraint that the Kohler function F[B/ρ(B = 0)] should extrapolate to 1 when B → 0. It was found that a fourth-order polynomial is sufficient since going to higher orders, the normalized fit quality parameter (R2) provided by the Excel fitting program as the square of the Pearson product moment correlation coefficient improved only insignificantly. By finely tuning the value of ρ(B = 0), after a few trials we can find the appropriate value which yields a fit with good quality (R2 > 0.99). This is done separately for both the LMR and TMR components.

Evidently, data in the magnetically saturated state should only be taken into account in the Kohler plot analysis. We have found that for the µc-Ni sample, the resistivity data for H ≥ 3 kOe correspond to this criterion by considering the measured M(H) isotherm (see Fig. 1c and d); by restricting data to higher fields did not improve the fit quality in the data analysis.

The Kohler plot with the fitting functions (solid lines) obtained at maximized fit quality parameter R2 is shown in Fig. 2 for the LMR(H) and TMR(H) data measured at T = 3 K for the µc-Ni sample.

Kohler plot ρ(B)/ρ(B = 0) versus B/ρ(B = 0) at T = 3 K for the MR(H) data of µc-Ni in the magnetically saturated field range. The experimental data are the symbols (squares: LMR; triangles: TMR), the solid lines are the fourth-order polynomial fitting functions providing an empirical analytical form of the Kohler function F. The fitting parameter values were obtained at the maximum values of the normalized fit quality parameter R2 specified in the text boxes attached to the LMR and TMR curves. The derived resistivity and magnetoresistance parameters are given in the text box in the upper left corner (see text for more details)

As a result of the fitting procedure, we obtained the zero-induction resistivities ρ(B = 0) for both the LMR and TMR components. These values are specified in Fig. 2 in the left upper corner text box and they correspond to the previously mentioned saturation resistivities [25]: ρL(B = 0) = ρLs and ρT(B = 0) = ρTs. From these fitted zero-induction resistivities, we can then derive the isotropic resistivity ρis, the resistivity anisotropy splitting ΔρAMR and the AMR ratio [25] which values are also specified in the same textbox.

The errors of the fit parameters ρL(B = 0) and ρT(B = 0) specified in the brackets after the parameter values correspond to the range within which the R2 value had a maximum and the errors given for the derived parameters were deduced from these uncertainties of the two fit parameters. The resulting final absolute error for the magnitude of the AMR ratio was then ± 0.32%. However, the actual error is certainly larger due to the uncertainty of the extrapolation to B = 0 in lack of an exact knowledge of the Kohler function F. Since the resistivity ρ(B = 0) is fairly small and the minimum value of the induction is B = Hs + 4πMs = 9.4 kG (where Hs = 3 kOe, i.e., the magnetic field considered as necessary for achieving the monodomain state), the extrapolation to B = 0 should be made from a fairly high value on the B/ρ(B = 0) axis.

This difficulty was already noticed also by Schwerer and Silcox [31] so they used Ni samples containing controlled small amounts of impurities resulting in higher resistivities to get data also close to B/ρ(B = 0) = 0, but here we have a single sample only. We will see in the next section that the difficulty of the extrapolation to B = 0 at T = 3 K is lifted for the nc-Ni sample with much higher residual resistivity.

Another source of uncertainty is the relatively large scatter of the LMR(H) data for which the fit quality parameter R2 was definitely smaller than for the TMR(H) data as can be seen in Fig. 2. As a consequence, the fitting function with the maximum R2 = 0.99075 value yielding the specified ρL(B = 0) = 0.01918 µΩcm value (from which 1.16% was deduced for the AMR ratio) did show some systematic deviation from the data when viewed at larger magnification. Therefore, we have analyzed the LMR(H) data also in a manner to get an optimum fit to the data by visual inspection (i.e., without apparent systematic deviation). This was achieved at the fit parameter value of about ρL(B = 0) = 0.01960 µΩcm with R2 = 0.99057 and this resulted in an AMR ratio of 3.34%. Evidently, the values of the fit quality parameter R2 of the two approaches are so close to each other that both fitted parameter values of ρL(B = 0) can be considered as of equal reliability. By taking formally the average of the above two AMR ratio values, we end up with an AMR ratio of (2.25 ± 1.10) % for the µc-Ni sample at T = 3 K.

In order to check the reliability of the above-determined resistivity anisotropy parameter values, we have made a further test by displaying the measured resistivity data against the magnetic induction B as shown in Fig. 3.

Resistivity ρ versus B at T = 3 K for the MR(H) data of µc-Ni in the magnetically saturated field range. The experimental data are the symbols (squares: LMR; triangles: TMR), the solid lines are the fourth-order polynomial fitting functions providing a proper description of the evolution of the measured resistivity data with magnetic induction. During fitting, the zero-induction resistivities ρ(B = 0) for the LMR and TMR components were fixed at the values taken from the Kohler plot of Fig. 2. The vertical dashed line indicates the value of the magnetic induction B at H = 0. The inset shows the data close to B = 0 in order to better resolve the relation ρLMR(B = 0) > ρTMR(B = 0) here

A similar fourth-order polynomial was fitted to the experimental data as in the Kohler plot (Fig. 2) with the same fixed ρ(B = 0) values as derived from the Kohler plot analysis. It can be seen in Fig. 3 that the fit quality, both in terms of R2 and a proper data fitting, is the same as in the Kohler plot of Fig. 2. (For the LMR(H) data, this was found to be valid for both above obtained ρL(B = 0) values.)

Furthermore, when fitting the ρ versus B data without fixing the value of ρ(B = 0) to that of the Kohler plot analysis, but rather allowing it as a free parameter, the fit quality parameter R2 remained the same up to the fifth digit. At the same time, the fitted ρT(B = 0) value also remained the same as obtained from the Kohler plot and ρL(B = 0) changed by 1 in the last (fifth) digit due to the more noisy LMR(H) data. This justifies that the forced fit used in evaluating the Kohler diagram is also appropriate for describing the experimental ρ versus B data.

We can also see in Fig. 3 that if we had extrapolated the resistivity to H = 0 (B = 6.4 kG), the position of which is indicated by the vertical dashed line, we would have obtained an opposite relation for the extrapolated LMR and TMR components [ρLMR(H = 0) < ρTMR(H = 0)] which would have resulted in a negative AMR ratio (AMR < 0). This is a clear indication that for these data, indeed, the Kohler plot analysis [ρ(B)/ρ(B = 0) vs. B/ρ(B = 0)] is required to determine the true magnetotransport parameters. This also implies, at the same time, that the observed field-induced resistivity change is dominated by the OMR effect.

The coefficients of the fitted fourth-order polynomial functions of the LMR and TMR components of the resistivity for the µc-Ni sample as a function of the magnetic induction are summarized in Table 1 in Sect. 3.3.

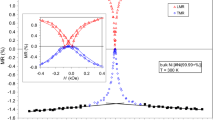

3.2 Experimental results for nc-Ni

Figure 4a and b shows the field dependence of the resistivity of nc-Ni for both measurement configurations (LMR, TMR) at 3 K. Similarly to the data on the µc-Ni sample (Fig. 1b), the resistivity values for the nc-Ni sample are also well reproducible during the various field cycling directions for each configuration. The ρo values for the two components also agree very well by noting that for the less noisy data of the TMR component (Fig. 4b) which reveal a clear hysteresis, ρo is identified as the peak value of the resistivity Hp, i.e., ρo = ρ(Hp). The peak positions of the TMR(H) curves are at Hp = ± 140 Oe.

The same as Fig. 1 but for nc-Ni

The M(H) curves of the nc-Ni sample as measured by the SQUID are displayed in Fig. 4c and d. The low-field M(H) curves (Fig. 4d) also reveal hysteresis with a coercive field of about 45 Oe.

As to the field dependence of the magnetization, the M(H) data in Fig. 4d show that technical magnetic saturation is certainly achieved in a few kilooersted of magnetic field. In the same magnetic field range, the MR(H) curves show a change in the field-evolution trend.

Besides the large difference in the magnitude of the zero-field resistivities of the µc-Ni and nc-Ni samples at T = 3 K [ρo(nc-Ni) ≈ 50 ρo(µc-Ni)], one can easily recognize further important differences also in the field dependence of the resistivities for the two microstructural states of Ni when comparing Fig. 1 with Fig. 4.

First, the low-field MR(H) behaviors are different: for µc-Ni, the resistivity has a minimum for both the LMR and TMR components around H = 0 and both components increase for all magnetic fields starting from H = 0 whereas for nc-Ni, the LMR increases and the TMR decreases at low fields just as known for the high-temperature behavior of Ni [24, 39, 40].

Second, at T = 3 K, the resistivity tends to show saturation towards high fields for both MR components for µc-Ni, whereas the MR(H) curves of nc-Ni show a permanent increase with magnetic field and their upward curvature implies that the rate of increase becomes larger and larger with increasing magnetic field. Third, the LMR(H) and TMR(H) curves do not cross each other for µc-Ni, whereas the rate of increase of the resistivity with magnetic field is definitely larger for TMR than for LMR for nc-Ni, so that at around H = 90 kOe, the TMR(H) curves even cross the LMR(H) data. Fourth, the relative change of the resistivity due to a magnetic field in the magnetically saturated region is much smaller for the nc-Ni sample; at H = 70 kOe, for example, Δρ/ρo ≈ 3% (both LMR and TMR) for nc-Ni whereas Δρ/ρo ≈ 50% (LMR) and 100% (TMR) for µc-Ni.

All the above-listed differences experienced at 3 K between µc-Ni and nc-Ni both in the magnitude of the zero-field resistivities and in the field evolutions of the resistivity are evidently a consequence of their strongly different electron mean free paths (λ). This is, on the other hand, a consequence of the difference in the microstructural states in that the nc-Ni sample has a large density of lattice defects in the form of grain boundaries whereas such defects are almost completely missing in the µc-Ni sample. It is generally considered [41] that for a given metal the product of the zero-field resistivity (ρ0) and the electron mean free path is a constant for any temperatures. According to the theoretical calculations of Gall [41], for Ni metal we have ρ0λ = 4.07 × 10–16 Ωm2 from which we get λ(µc-Ni;3 K) = 1832 nm with our measured ρ0(µc-Ni;3 K) = 0.02222 µΩcm value. We get similarly for nc-Ni that λ(nc-Ni;3 K) = 42 nm with our measured ρ0(nc-Ni;3 K) = 0.9739 µΩcm value. This means that the mean free path value for our nc-Ni sample is about half of the estimated grain size (100 nm) which may be due to some intragrain defects the presence of which is evidenced by the average crystallite size of about 75 nm deduced from XRD line broadening for this particular nc-Ni sample [23].

The much larger magnetoresistance ratio of µc-Ni than that of nc-Ni can be straightforwardly explained by the microstructural differences of the two samples. Due to the large grain size (well in the micrometer range) of the µc-Ni sample, the grain size is comparable or eventually even much larger than the electron mean free path (1832 nm) estimated for our µc-Ni sample at this temperature. As a consequence, the electrons subjected to the Lorentz force in a magnetic field are forced to turn around the magnetic field lines between the rare background scattering events (the larger the magnetic field, the more rotations per unit length along the travelling direction) and this induces a large resistivity increase. In the nc-Ni sample with a grain size of about 100 nm, the estimated electron mean free path implies that an electron is scattered about once within the grain and once at the grain boundary, traveling 42 nm between two scattering events. Due to the frequent background scattering events in nc-Ni, the rotational effect of the Lorentz field does not affect significantly the electron motion toward lower electric potentials or at least to a much lesser extent than in the µc-Ni sample and this clearly explains the much lower magnetoresistance ratio of nc-Ni in a given magnetic field as shown above.

The most striking difference between the two samples is the saturating and non-saturating character of the MR(H) curves for µc-Ni and nc-Ni, respectively, but this cannot be explained in such a straightforward manner as we could do it for the magnitude of the magnetic-field-induced resistivity change.

Before passing on to the analysis of the MR(H) data with help of the Kohler plot, it is mentioned that the behavior of resistivity with magnetic field in our nc-Ni sample at T = 3 K is very similar to what was observed for some Ni alloys at low temperatures. In the latter cases, the increase of the zero-field residual resistivity was achieved by introducing a sufficient concentration of impurities into the pure metal matrix, resulting in a similar reduction of the electron mean free path as caused in our nc-Ni sample by the structural defects (mainly grain boundaries). To demonstrate this similarity, we will quote here available relevant literature results. In Fig. 9 of their paper, Schwerer and Silcox [31] reported the LMR(H) and TMR(H) data at 4.2 K for a Ni(1300 ppm C) sample up to nearly H = 20 kOe magnetic field which strongly resemble the corresponding MR(H) curves in Fig. 5a for our nc-Ni sample. The agreement includes the evolution of resistivities before magnetic saturation (the immediate increase of LMR and decrease of TMR starting from H = 0), the increase and upward curvature of both MR(H) curves with clear sign of a crossing of the LMR and TMR data at higher magnetic fields. The residual resistivity of this Ni(1300 ppm C) sample [31] was given as 0.449 µΩcm and this corresponds roughly to RRR = 14. Both the residual resistivity and the RRR values are fairly close to the corresponding data for our nc-Ni sample (0.972 µΩcm and 9, respectively). From the residual resistivity and the extrapolated zero-induction resistivity anisotropy splitting between the LMR and TMR components, an AMR ratio of + 1.8% was deduced for the Ni(1300 ppm C) sample [31]. Another classical example is the case of a Ni99.42Co0.58 alloy (the subscripts refer to atomic percentage) [4, 42] for which the evolution of the LMR(H) and TMR(H) curves at 4.2 K as well as the residual resistivity of about 0.6 µΩcm and RRR = 13.7 is again very similar to the results on our nc-Ni sample. The resistivity anisotropy splitting can be estimated from Fig. 1c of Ref. 42 which then yields AMR = 5%. This large value is due to the relatively large concentration of the alloying element Co which is known to cause the largest increase of the AMR ratio among all elements when added to Ni [3,4,5, 24, 40, 43].

Kohler plot at T = 3 K for nc-Ni in the magnetically saturated field range similarly as Fig. 2 for µc-Ni. Note: a third-order polynomial function was used here for fitting

Finally, we should make a remark on the early magnetoresistance results of McGuire [42] at T = 4.2 K up to H = 25 kOe on a wire-shaped pure Ni polycrystalline sample with a residual resistivity ratio of 83 and residual resistivity of 0.087 µΩcm. In the magnetically saturated field range (above about 5 kOe), the relatively few data points measured indicate an approximately linear increase of the resistivity with magnetic field and with definitely higher slope for the TMR(H) component, resulting in a crossover with the LMR(H) data at around 10 kOe. Although the reported impurity content was fairly low (claimed to be less than 50 ppm of Mn, Co and Fe impurities) and the wire was well annealed before the MR measurement [42], the residual resistivity of this sample is higher by a factor of 4, indicating some other residual defects or impurities, in comparison with our µc-Ni sample having a residual resistivity of 0.02222 µΩcm. This may explain that the observed MR(H) behavior reported in Ref. 42 is different from our µc-Ni sample and rather resembles that of our nc-Ni sample, especially the higher slope of the TMR component with respect to the LMR component.

As was shown in Sect. 3.1 for the µc-Ni sample, if the RRR value is as high as several hundreds, an MR(H) behavior with saturating LMR and TMR components can be observed for pure Ni. On the other hand, for sufficiently low RRR values, a behavior corresponding to our nc-Ni sample can be expected. Apparently, there is a borderline RRR value for Ni metal which separates the regimes with long or short electron mean free paths from the viewpoint of the effectiveness of the Lorentz force inducing an OMR effect. Since the Ni sample of McGuire [42] exhibiting a similar MR(H) behavior to our nc-Ni sample has RRR = 83, we may roughly set about 100 as the borderline RRR value separating the two kinds of MR(H) behavior.

It is noted furthermore in connection with the Ni sample of McGuire [42] that the absence of both a saturating character and an upward curvature of the MR(H) curves, but rather a nearly linear field variation of the resistivity also suggests that this sample is indeed in the vicinity of the borderline RRR value from the magnetoresistance point of view. McGuire [42] reported an AMR ratio of + 2.2% which is close to our result, but we cannot consider it as a reliable value for the low-temperature AMR ratio of pure bulk Ni due to the way of determination. Namely, for calculating the AMR ratio, McGuire [42] took the difference between the ρL and ρT values arbitrarily at H = 4 kOe which is incorrect. This is because whereas due to the wire-shaped specimen, the ρ(B = 0) condition is approximately fulfilled for the TMR component, an extrapolation to zero induction would have been necessary for the LMR component.

The Kohler plot for the LMR and TMR data at T = 3 K for the nc-Ni sample is shown in Fig. 5. This plot also reveals a stronger increase of the resistivity with magnetic field for the TMR component than for the LMR one. A similar fitting analysis was carried out for the data of nc-Ni as was done for the µc-Ni sample in the previous section with the difference that, due to the about 50 times larger residual resistivity of the nc-Ni sample, the resistivity data are now less scattered and a third-order polynomial fitting was sufficient since it provided even better fit quality parameter values (R2) than the fourth-order polynomial for the µc-Ni sample.

Furthermore, due to the larger residual resistivity, the extrapolation to B = 0 on the B/ρ(B = 0) axis could be carried out from much lower abscissa values and all these improvements resulted in more accurate values for ρ(B = 0) of both the LMR and TMR components from which we can get more reliable values for ΔρAMR and for the AMR ratio. All these derived data are included in the textboxes in Fig. 5.

We have prepared the ρ versus B plot also for the nc-Ni sample (Fig. 6). Due to the significantly higher accuracy of the MR(H) data for the nc-Ni sample, as a consequence of its much higher residual resistivity, when leaving the ρ(B = 0) parameter as a free variable for the fitting, we got the same ρ(B = 0), ΔρAMR and AMR values (within about 0.1%) as from the Kohler plot analysis which again justifies the reliability of the latter data.

Resistivity ρ versus B at T = 3 K for the MR(H) data of nc-Ni in the magnetically saturated field range. The experimental data are the symbols (squares: LMR; triangles: TMR), the solid lines are the third-order polynomial fitting functions providing an accurate description of the field evolution of the measured data with magnetic induction. During fitting, the zero-induction resistivities ρ(B = 0) for the LMR and TMR components were free variables and the same values were obtained as derived from the Kohler plot of Fig. 5

The ρ versus B plot in Fig. 6 clearly demonstrates that ρL(B = 0) > ρT(B = 0), i.e., the nc-Ni sample has definitely a positive AMR. Furthermore, when displaying the MR(H) data on a ρ versus H plot and letting ρ(H = 0) as a free parameter, we get ρL(H = 0) and ρT(H = 0) values which yield an AMR ratio of + 1.54% which value is quite close to + 1.62%, the value deduced from the Kohler plot by extrapolating the resistivity to B = 0 (cf. Figure 5). This implies that the OMR contribution to the field dependence of the resistivity for the present nc-Ni sample even at a temperature as low as T = 3 K is fairly small, although it is still the only source of a magnetic-field-induced resistivity change in the monodomain state since at this temperature, there is no magnetic disorder. This is in very good agreement with the considerations put forward earlier in this section when comparing the different microstructural features and the concomitant mean free path difference between the µc-Ni and nc-Ni samples investigated in the present work.

3.3 Comparison of the magnetic-field-induced resistivity change in µc-Ni and nc-Ni at T = 3 K

A comparison of Figs. 1a and 4a a reveals that the magnetic-field-induced resistivity changes at 3 K for the µc-Ni and nc-Ni samples are of comparable magnitude although the field dependencies of the resistivity for the two samples are quite different. As demonstrated in Figs. 3 and 6, the variation of the resistivity with magnetic induction could be properly described for the measured data in the magnetically saturated (monodomain) state by an empirical fourth-order polynomial fitting function ρ(B) = ρ(B = 0) + α ·B + β ·B2 + γ·B3 + δ ·B4 for the µc-Ni sample whereas a third-order polynomial fitting function (i.e., δ = 0) was sufficient for the nc-Ni sample. For convenience, the values of the parameters α, β, γ and δ as well as the ρ(B = 0) values are collected in Table 1.

In order to better visualize the different behaviors of the field dependence of the resistivity for the two microstructural states of Ni, the induced resistivity change Δρ(B) = ρ(B) − ρ(B = 0) is displayed in Fig. 7a as a function of the magnetic induction B for both samples. This means that for each component (LMR and TMR), the resistivity change Δρ(B) is referred to its zero-induction value.

a Resistivity change Δρ(B) = ρ(B) − ρ(B = 0) versus B in the magnetically saturated state at T = 3 K for µc-Ni and nc-Ni. The experimental data are the symbols (squares: LMR; triangles: TMR), the solid lines are the corresponding fitting functions with the same of polynomial order as in the Kohler plot. b The same data displayed as the relative change of the resistivity in the form of Δρ(B)/ρ(B = 0) versus B plots. The reference resistivity in each case was the zero-induction resistivity ρ(B = 0) determined for the given measurement configuration (LMR and TMR) from a Kohler plot analysis. Note the different ordinate scales for the µc-Ni (left axis) and nc-Ni (right axis) samples in (b)

Both samples exhibit a resistivity increase of comparable magnitude up to not very high magnetic inductions, but since the curvature is quite different for the two samples at higher inductions, the divergence of the datasets for the two different microstructural states is strongly enhanced (Fig. 7a).

As discussed already earlier in this section, the different behaviors of the resistivity variation with magnetic induction for the two samples reflect the differences in their electron mean free paths what, on the other hand, is a direct consequence of their different microstructural states. Furthermore, we can also see that for any induction value B, the relation Δρ(TMR) > Δρ(LMR) holds for both samples in the magnetically saturated (monodomain) state as expected for a dominant OMR contribution to the field-induced resistivity change.

Figure 7b shows the relative change Δρ(B)/ρ(B = 0) with magnetic induction for the two samples. With reference to the different left-hand and right-hand scales, it can be clearly seen that at such a low temperature the relative resistivity change is much larger for the µc-Ni sample having low resistivity than for the nc-Ni sample which has a substantial residual resistivity.

3.4 Comparison with relevant reported low-temperature experimental data

For µc-Ni, the Kohler plot shown in Fig. 2 is very similar for both the TMR and LMR components to the results for the “recovery series” of Schwerer and Silcox [30] except that the ρ(B)/ρ(B = 0) values for the highest magnetic field are by about 20% smaller for the latter than for our sample. The quantitative differences between the results for a given magnetic field orientation (LMR or TMR) are due to the different kinds and concentrations of impurities in our µc-Ni sample and in the sample series of Schwerer and Silcox [30] which were obtained subjecting the as-received Ni samples to various heat treatments in order to get samples with varying residual resistivities. Unfortunately, the zero-induction resistivities ρL(B = 0) and ρT(B = 0) were not reported in the latter paper, so no AMR ratio can be assessed from these data to compare with our result.

As to the nanocrystalline state, the only available relevant report on a nc-Ni sample is the work of Madduri and Kaul [22] who observed an increase of the transverse component of the magnetoresistance with magnetic field at T = 2 K for nc-Ni samples with crystallite sizes from 10 to 40 nm similarly as in our study at T = 3 K. However, the measured resistivity increase at their maximum field of H = 90 kOe was by about a factor of 250 smaller for the sample with 40 nm crystallite size than the corresponding value on our nc-Ni sample with a crystallite size of 75 nm although the residual resistivities in zero magnetic field were quite comparable for the two samples (our nc-Ni sample: 0.9739 µΩcm; nc-Ni sample in Ref. 22: 0.42 µΩcm). We have no explanation for the discrepancy in these low-temperature results.

It is worth mentioning, however, that Rüdiger et al. [44] reported longitudinal and transverse Kohler plots at T = 1.5 K for a 2-µm-wide Fe wire lithographically patterned from a 100-nm-thick bcc-Fe film epitaxially grown on a sapphire substrate which are very similar to our Kohler plots for the nc-Ni sample (Fig. 5). The zero-field resistivity of the Fe wire was 0.74 µΩcm at T = 1.5 K (yielding RRR = 20) which compares well with our 0.9739 µΩcm value for the nc-Ni sample (RRR = 9). The similar resistivity and RRR values of the pure Fe wire indicate that it may consist of fine grains and/or surface scattering effects may also yield a finite contribution to the resistivity which altogether yield a reduced electron mean free path with respect to pure bulk Fe. Therefore, the results of Rüdiger et al. [44] on a nanoscale Fe wire give support to the findings on our nc-Ni sample in that the behavior reported in the present work is indeed a general phenomenon. This means that, in conformity with the results of early studies on some Ni alloys as discussed in Sect. 3.2 (see, e.g., the results on the Ni(1300 ppm C) sample of Ref. 31), a very similar MR behavior can also be achieved in a pure metal by reducing the electron mean free path via the introduction of excess static scatterers in the form of lattice defects (e.g., grain boundaries) and/or via finite size effects (electron scattering at external surfaces).

4 Magnetoresistance and magnetic properties at T = 300 K

4.1 Experimental results for µc-Ni

Figure 8a shows the field dependence of the resistivity for µc-Ni at 300 K for the LMR and TMR measurement configurations as measured up to H = 70 kOe, in qualitative agreement with the well-known room-temperature MR(H) curves reported for bulk Ni up to about H = 18 kOe [39].Footnote 3 The low-field sections of the measured magnetoresistance curves are shown in Fig. 8b in the form of magnetoresistance ratio Δρ/ρo versus magnetic field. As for the low-temperature measurements, the resistivity ρo is identified with the peak value of the resistivity, i.e., ρo = ρ (Hp), for MR(H) curves with a clear hysteresis. It should be noted, nevertheless, that due to the high accuracy of the measurement setup, the resistivity peak values measured for the LMR and TMR components agreed within about 0.2%.

a Field-dependence of the resistivity ρ at T = 300 K for µc-Ni with magnetic field orientations as indicated (LMR, TMR); b Low-field resistivity data in the form of magnetoresistance ratio Δρ/ρo versus magnetic field where ρo = ρ(Hp); c High-field magnetization curve M(H) at 300 K for µc-Ni; d Low-field magnetization curve M(H) at 300 K for µc-Ni

The low-field MR(H) data in Fig. 8b reflect the magnetization process [3, 4] the field evolution of which depends on sample shape, magnetic anisotropy, stresses, etc. To illustrate this, Fig. 8c displays the room-temperature magnetization curve M(H) of the µc-Ni foil up to H = 50 kOe as measured by SQUID which shows that technical saturation is achieved around a few kilooersted of magnetic field. In compliance with this, the break in the MR(H) curves roughly at around H = 1 kOe magnetic field (Fig. 8b) indicates that saturation is achieved for both the LMR and TMR components at similarly small magnetic fields as was found for the magnetization. It can be seen furthermore from Fig. 8a and b that in the saturated (monodomain) state, the field dependence of the MR(H) curves is very similar for the LMR and TMR components.

From the MR(H) curves in Fig. 8b, the peak positions were found to be at Hp = ± 75 Oe for the LMR component at room temperature. (The TMR curves were too broad to determine the exact peak positions.)

The SQUID magnetometer could not reveal the hysteresis either at 300 K due to the low coercive field of the µc-Ni sample. Therefore, Fig. 8d shows the low-field section of the M(H) curve measured by VSM at 300 K which reveals a hysteresis with a coercive field of Hc = 13 Oe.

The experimental results for the magnetoresistance of µc-Ni at T = 300 K correspond well to the schemes depicted in Fig. 3 of Ref. 25 for the high-temperature behavior of ferromagnets. (At room temperature, for nickel metal with TC = 631 K, we have T = 300 K ~ 0.5 TC.) One can also observe at T = 300 K an approximately linear decrease of the resistivity above the saturation field.

The decrease of the resistivity with increasing magnetic field in the saturation region is due to the gradual suppression of the thermally induced spin disorder [22, 33, 34] since at finite temperatures the scattering of conduction electrons on non-aligned individual magnetic moments also gives a contribution to the resistivity. By increasing the magnetic field after technical saturation (in the monodomain state), the thermally disordered magnetic moments are more and more aligned along the magnetic field [4] (this is often termed also as paraprocess [33]) and, therefore, this kind of scattering is diminished and, thus, one can observe a resistivity decrease.

We have displayed the room-temperature MR(H) data of the µc-Ni sample for |H|≥ 3 kOe on a Kohler plot in Fig. 9. A second-order polynomial was found to be satisfactory for a sufficiently accurate fitting of the data, with all the fitted and derived parameters specified in the figure. It is noted that the derived parameters agree fairly well with the room-temperature data reported in our previous work [24] for the same µc-Ni sample: ΔρAMR = + 0.176(12) µΩcm, ρ0 = 7.36(21) µΩcm and AMR = + 2.39(16) %. In that work, a detailed comparison with previous bulk Ni data was also discussed.

Kohler plot ρ(B)/ρ(B = 0) versus B/ρ(B = 0) at T = 300 K for the MR(H) data of µc-Ni in the magnetically saturated field range. The experimental data are the symbols (squares: LMR; triangles: TMR), the solid lines are the second-order polynomial fitting functions providing an empirical analytical form of the Kohler function F. The fitting parameter values were obtained at the maximum values of the normalized fit quality parameter R2 specified in the text boxes attached to the LMR and TMR curves. The derived resistivity and magnetoresistance parameters are given in the text box in the lower left corner (see text for more details)

We have displayed the same data for the magnetic field range |H|≥ 3 kOe also on a ρ versus B plot (Fig. 10) which properly reveals the resistivity anisotropy splitting between the LMR and TMR components in the magnetically saturated state. Similarly to the Kohler plot (Fig. 9), a second-order polynomial fit provided a sufficiently accurate description of the experimental data. The ρ(B = 0) values were allowed as free parameters and the same fitted values were obtained as derived from the Kohler plot, justifying the latter data.

Resistivity ρ versus B at T = 300 K for the MR(H) data of µc-Ni in the magnetically saturated field range. The experimental data are the symbols (squares: LMR; triangles: TMR), the solid lines are the second-order fitting functions providing an accurate description of the field evolution of the measured data. During fitting, the zero-induction resistivities ρ(B = 0) for the LMR and TMR components were free variables and the same values were obtained as derived from the Kohler plot (Fig. 9)

Furthermore, a ρ versus H plot was also prepared and a similar fit with ρ (H = 0) as free parameter yielded ρLMR(H = 0) and ρTMR(H = 0) values which agreed within 0.1% with the corresponding ρLMR(B = 0) and ρTMR(B = 0) data, the slight difference coming from the shift of the resistivity data along the abscissa (B = H + 4πMs where 4πMs(300 K) = 6.1 kG for Ni). The coefficients of the second-order terms agreed up to the fourth digit and the coefficients of the first-order terms agreed within 2%.

Since in our previous work [24] the magnetoresistance study of the same µc-Ni sample was carried out in magnetic fields up to 9 kOe only, we have analyzed the present data also in the field range from 3 to 10 kOe and the AMR ratio remained the same up to the specified three digits.

The small difference between the zero-field and zero-induction resistivity data implies that in µc-Ni at T = 300 K, the OMR contribution to the magnetoresistance is negligible as was suggested also from theoretical considerations [34]. The reason for this is that at room temperature, due to the strong electron–phonon scattering, the mean free path of bulk Ni metal is short. According to the theoretical calculations of Gall [41], for Ni metal we have ρ0λ = 4.07 × 10–16 Ωm2 from which we get λ(µc-Ni;300 K) = 5.5 nm with our measured ρ0(µc-Ni;300 K) = 7.36 µΩcm value. It is noted that by using a free-electron estimate formula by Ashcroft and Mermin for the electron mean free path [45], we have recently derived [46] λ(Ni;300 K) = 5.71 nm which is fairly close to the above obtained value for λ(µc-Ni;300 K).

4.2 Experimental results for nc-Ni

Figure 11a and b shows the field dependence of the resistivity for nc-Ni at 300 K for both measurement configurations (LMR, TMR). The experimental results for the room-temperature magnetoresistance of nc-Ni are very similar to those obtained for µc-Ni (cf. Fig. 8) and correspond well to the schemes depicted in Fig. 3 of Ref. 30 for the high-temperature MR behavior because for nickel metal (TC = 631 K) at room temperature, we have T = 300 K ~ 0.5 TC. It is noted that the resistivity peak values measured for the LMR and TMR components agreed within about 0.06%.

The same as Fig. 8 but for nc-Ni

The good quality of the MR(H) data enabled the determination of the field positions of the resistivity minima and maxima for both the LMR and TMR components (Fig. 11b) and Hp = ± 160 Oe was obtained for the nc-Ni sample. This is about twice as much as the value obtained for the µc-Ni sample (Hp = 75 Oe) and qualitatively well matches the factor of three difference between the measured coercive fields of the two samples.

The high-field M(H) curve of the nc-Ni sample as obtained by SQUID at T = 300 K is displayed in Fig. 11c. The low-field sections of the M(H) curves as obtained by both SQUID and VSM are displayed in Fig. 11d which reveal the same hysteretic behavior as can be seen in the MR(H) curves (Fig. 11b). From the VSM data in Fig. 11d, Hc = 37 Oe was obtained for the nc-Ni sample.

We can observe in Fig. 11b that the magnetoresistance reaches saturation along both the L and T orientations in fairly low, nearly identical magnetic fields, in compliance with the M(H) curves. It was found that the saturation of the MR(H) curves can be considered as complete for magnetic fields |H|≥ 3 kOe. (The behavior of the MR(H) data in this field range for nc-Ni was very similar to the behavior of µc-Ni shown in Fig. 8.) Therefore, these high-field data were used for the further analysis of the field dependence of the resistivity in the magnetically saturated (monodomain) state.

Due to the qualitative similarity of the room-temperature magnetoresistance data for µc-Ni and nc-Ni, we applied exactly the same procedure for nc-Ni as used for µc-Ni in Sect. 4.1 when constructing and analyzing the Kohler plot and the ρ versus B plot. These plots looked very similar to those shown above for µc-Ni (cf. Figures 9 and 10, respectively); therefore, they are not shown here. The obtained fit parameters for nc-Ni at T = 300 K are given Table 2. It is noted that when analyzing also the ρ versus H plot for nc-Ni, there was a good agreement (within 0.1%) of the fitted ρ(H = 0) values with the corresponding ρ(B = 0) values (with the same agreement between the coefficients of the first-order and second-order terms as for µc-Ni), implying again a negligible contribution of the OMR effect to the observed magnetoresistance at room temperature.

The derived transport parameters for nc-Ni at T = 300 K were as follows: ΔρAMR = + 0.168(2) µΩcm, ρis = 8.781(3) µΩcm and AMR = + 1.91(3) %. These parameters agree fairly well with the corresponding room-temperature data reported in our previous work [24] for the same nc-Ni sample (#B2): ΔρAMR = + 0.165 µΩcm, ρ0 = 8.78 µΩcm and AMR = + 1.88%.

4.3 Comparison of the magnetoresistance of µc-Ni and nc-Ni at T = 300 K in the magnetically saturated state

A comparison of Figs. 8a and 11a reveals that the magnetic-field-induced resistivity changes at T = 300 K are qualitatively the same for the µc-Ni and nc-Ni samples, just the values of the derived magnetoresistance parameters are slightly different. As demonstrated in Sects. 4.1 and 4.2, the variation of the resistivity with magnetic induction could be properly described for the measured data in the magnetically saturated (monodomain) state by a second-order polynomial empirical fitting function: ρ(B) = ρ(B = 0) + α ·B + β ·B2. For convenience, the values of the parameters α and β as well as the ρ (B = 0) values are collected in Table 2.

The presence of a quadratic term with a β > 0 coefficient for both samples and both measurement configurations imply that the magnetic-field-induced resistivity change Δρ(B) = ρ(B) − ρ(B = 0) shows a slight upward curvature with increasing magnetic induction with respect to the linear decrease corresponding to α < 0 as could be well observed in Fig. 10.

If we display all the Δρ(B) versus B data on a common plot corresponding to the parameters specified in Table 2, it can be established that for each microstructural state, the TMR component is more negative than the LMR component whereas for a given component (LMR or TMR), the data practically agree for the µc-Ni and nc-Ni samples, the agreement being especially good for the TMR component. All this means that for a given MR component, the magnetic-field-induced resistivity change is the same for both the microcrystalline (bulk) state and the nanocrystalline state (at least for the presently investigated 100 nm grain size). Furthermore, for both microstructural states, the resistivity change is definitely larger for the TMR configuration than for the LMR configuration.

For an explanation of the recent two features (close quantitative agreement of Δρ for µc-Ni and nc-Ni as well as the relation |Δρ(TMR)| > |Δρ(LMR)| for a given microstructural state), we can proceed along the following considerations. Due to the strong electron–phonon interaction at T = 300 K, the mean free path in Ni at this temperature is very short (λ(Ni,300 K) = 5.5 nm [41]). Therefore, the majority of the electron scattering events, even in the nc-Ni sample with an average grain size of about 100 nm, occur within the crystallites and only a small fraction of scattering events takes place at the grain boundaries. As a consequence, for a given magnetic field configuration with respect to the current flow direction (LMR or TMR), the influence of magnetic field on the spin-fluctuation-suppression process is not expected to be noticeably different for the two microstructural states. It may also be that this suppression process does not differ for scattering events within the crystallites and in the grain boundaries. As to the second feature, the stronger dependence of resistivity on induction for the TMR configuration may be simply a consequence of the stronger suppression influence of the induction on the transverse spin fluctuations than on the longitudinal ones. A proper theoretical description should take into account also this possibility in order to explain the observation that |Δρ(TMR)| > |Δρ(LMR)| and this will be further discussed in Appendix A.

It is noted here that, as discussed in the previous two subsections, the behavior of the field-induced resistivity change at T = 300 K would be practically the same if we display the data as a function of the applied magnetic field since ρ(H = 0) differs from ρ(B = 0) by at most 0.1% due to the negligible OMR contribution at such a high temperature [34].

Adjoining this last issue, a further remark is added here about the evaluation of the AMR ratio as usually done by displaying the relative resistance change ΔR/Ro = [R(H) − Ro]/Ro, which is equivalent to Δρ/ρo = [ρ(H) − ρo]/ρo, as a function of the magnetic field H. If there is no or at most a negligible hysteresis of the MR(H) curve (see, e.g., Fig. 1b for both LMR and TMR and Fig. 8b for the TMR component), then, evidently, the maximum or minimum value of the resistivity can be taken as ρo. However, Figs. 4b, 8b and 11b reveal a significant hysteresis of the MR(H) curve in which cases the zero-field resistivity ρ(H = 0) is definitely different from the ρ(Hp) value. As a consequence, when displaying the relative resistivity change as a function of the magnetic field, i.e., Δρ/ρo versus H, it is important whether the zero-field (or “remnant”) resistivity ρ(H = 0) or the peak resistivity ρ(Hp) is taken as reference value ρo since it will influence the value of AMR ratio. For example, according to Fig. 8b, if we take ρ(H = 0) as reference value for the LMR component [for the TMR component ρ(H = 0) ≈ ρ(Hp)], we get about 1.55% for the AMR ratio whereas if we take ρo = ρ(Hp), then we get about 2.35%. Intuitively, the common practice has always been to take ρo = ρ(Hp) because from magnetoresistance point of view the really “demagnetized” state is at the smallest (LMR) or largest (TMR) resistivity values around zero.

In Sects. 4.1 and 4.2, we were able to deduce the room-temperature AMR ratio with the help of the exact Kohler analysis on the basis of the accurately measured resistivities as a function of the magnetic induction B with values AMR(µc-Ni) = 2.35% and AMR(nc-Ni) = 1.91%. In this analysis, we were relying on the high-field resistivity data only, i.e., the uncertainty due to the low-field hysteresis is eliminated. By analyzing the same resistivity data in the form of Δρ/ρo versus H with the choice ρo = ρ(Hp), we obtained AMR(µc-Ni) = 2.36% and AMR(nc-Ni) = 1.98%. These excellent agreements justify that the peak resistivity is the proper choice as reference value when determining the AMR ratio from a Δρ/ρo versus H plot.

4.4 Comparison of the magnetoresistance at T = 300 K in the magnetically saturated state with previous experimental results

We will now compare with the help of Fig. 12 the field dependence of the induced resistivity change observed in our samples in the saturated region with relevant available earlier results [22, 33, 34]. In Fig. 12, the field-induced resistivity change Δρ (B) is displayed as a function of the magnetic induction B for our nc-Ni sample for both the LMR (□) and TMR (∆) components. As mentioned in Sect. 4.3 (and see also parameters in Table 2), the Δρ(B) versus B data for our µc-Ni sample agree very well with the nc-Ni data; therefore, they are not displayed in Fig. 12.

Field-induced resistivity change Δρ(B) = ρ(B) − ρ(B = 0) versus B at T = 300 K for our nc-Ni sample with magnetic field orientations as indicated (LMR, TMR) in comparison with available results on other nanophase Ni samples [22, 34]. For the nc-Ni samples, the XRD crystallite sizes are given in the brackets whereas the film thickness is given for the Ni film. In Ref. 34, the data displayed here by the dashed line extend up to 300 kG with the same trend. The straight solid line connecting the B = 0 and B = 150 kG data points of Ref. 34 was only added to better illustrate the deviation (upward curvature) of the Δρ(B) data from the linear behavior

Madduri and Kaul [22] investigated the field and temperature dependence of the resistivity of electrodeposited nc-Ni samples with XRD crystallite sizes from 10 to 40 nm. The field-induced resistivity change was measured in the TMR configuration up to H = 90 kOe from 2 to 300 K, and the temperature dependence of the zero-field resistivity was also reported for these samples. In zero magnetic field, the room-temperature resistivity and the residual resistivity as well as the RRR ratio of their nc-Ni sample with 40 nm crystallite size were well comparable with the corresponding parameters of our nc-Ni sample with 75 nm crystallite size. The TMR results of Madduri and Kaul [22] for their nc-Ni samples with the smallest and largest crystallite sizes are also displayed in Fig. 12. These data match relatively well our results, even the same deviation of the Δρ(B) data from a linear behavior (upward curvature) can be clearly established also for their nanocrystalline samples.

Raquet et al. [33, 34] measured the resistivity of an MBE-grown patterned Ni film (20 nm thickness and deposited on a MgO substrate) from 77 to 443 K up to B = 300 kG in the LMR configuration with the magnetic field in the film plane. No details about the structure of their Ni film were given and the absolute value of the resistivity was also not provided, only the field-induced resistivity change Δρ(B) was reported. The only note about sample characterization is that “a residual resistance ratio around 27 for the thicker films attests to their high structural quality” [34]. In the same report, these authors investigated 7-nm-thick Co films, 20-nm-thick Ni films and 80-nm-thick Fe films and it is not clear for which film the specified RRR = 27 refers to. However, even if we assume that their 20-nm-thick Ni film exhibited this RRR value, this does not testify for their Ni sample a high film quality in terms of impurities and lattice defects. The specified RRR = 27 value corresponds to a residual resistivity of about 0.25 µΩ·cm by assuming the bulk resistivity value for their Ni film at room temperature. This residual resistivity is of the same order of magnitude as the value for our nc-Ni sample or in the work of Madduri and Kaul [22]. Therefore, the Ni film studied by Raquet et al. [34] can also be considered as a nanophase Ni sample. (At such small thicknesses, thin films are typically nanocrystalline.)

In Fig. 12, we show the LMR result of Raquet et al. [34] for the 20-nm-thick Ni film at T = 284 K (the closest temperature to our measurement temperature) by the dashed line. It is clear that whereas the same kind of deviation from a linear behavior can be observed in their Ni film data as in the electrodeposited Ni samples, the slope of the Δρ(B) for the Ni film is definitely much larger. The reason for this discrepancy may arise from the fact that in a Ni thin film an additional term to the resistivity may stem from surface scattering effects [47]. Due to the short mean free path at around 300 K, in zero magnetic field this resistivity contribution may be negligible since the film thickness (20 nm) is about four times larger than the mean free path (5.5 nm). However, in a magnetic field the electrons do not only randomly move toward lower electric potentials, but during their free travel they are also often deflected from this direction due to the Lorentz force, making scattering events at the nearby film surface also possible which then causes an additional resistivity contribution in a thin film with respect to a massive sample, even having both the same microstructure (e.g., the same grain size). Therefore, we can see that the helical motion of electrons due to the Lorentz force further magnifies this zero-field surface (i.e., finite-size) scattering effect in high magnetic fields.

5 Summary

The basic purpose of this study was to establish if the magnetoresistance behavior of Ni metal changes with respect to the bulk state by introducing a large density of grain boundaries as two-dimensional scattering centers. The presence of grain boundaries yields an increase of the resistivity [18, 23, 26] at any temperature as a result of which the residual resistivity becomes substantial for the nc-Ni state as opposed to the vanishingly small residual resistivity of the microcrystalline (bulk) state. This difference results, at the same time, in a great difference of the electron mean free paths between the two microstructural states at low temperatures and this showed up in the different MR behaviors of the two samples. This is mainly because at low temperatures in pure bulk metals, as a consequence of the long mean free path, the Lorentz-force-induced contribution (OMR) to the resistivity in a magnetic field is very large whereas for a nanocrystalline metal the shorter mean free path effectively reduces the OMR contribution, although cannot completely eliminate it.

At low temperature (T = 3 K), both the TMR and LMR components increased continuously for the µc-Ni sample with a tendency for saturation towards high magnetic fields and the relation TMR(H) > LMR(H) persisted in the whole range of magnetic fields investigated.

By contrast, for nc-Ni at T = 3 K above magnetic saturation, both MR components increased without any sign of saturation up to the highest magnetic fields applied. The rate of increase with field was stronger for the TMR component, so that above around 90 kOe, TMR(H) became larger than LMR(H). On the other hand, the rate of the relative resistivity change for the nc-Ni sample at T = 3 K was by about an order magnitude smaller than for the µc-Ni sample that could be explained by the different electron mean free paths at this low temperature for the two microcrystalline states.

At T = 300 K, the MR(H) curves of nc-Ni were qualitatively the same as for µc-Ni. It could be established in Appendix A from the present high-precision resistivity data that there is a need for a refinement of the theoretical description of the field dependence of the spin-fluctuation resistivity contribution, especially concerning the observed stronger field dependence for the TMR component in comparison with the LMR component.

A Kohler-plot analysis of the MR(H) curves at both temperatures has enabled us to derive the resistivity anisotropy splitting (ΔρAMR) and the anisotropic magnetoresistance (AMR) ratio. The latter parameter obtained at T = 3 K was found for both samples to be close to their room-temperature values and, as discussed in Appendix B, fitted well into the scheme observed recently [24] for bulk Ni and nc-Ni samples when analyzing the data on a ΔρAMR versus ρ(H = 0) plot.

Data Availability Statement

The data that support the findings of this study are available from the author upon reasonable request.

References

J. Smit, Physica 17, 612 (1951)

H.C. van Elst, Physica 25, 708 (1959)

R.M. Bozorth, Ferromagnetism (Van Nostrand, New York, 1951)

T.R. McGuire, R.I. Potter, IEEE Trans. Magn. 11, 1018 (1975)

I.A. Campbell, A. Fert, Transport properties of ferromagnets, in Ferromagnetic Materials. ed. by E.P. Wohlfarth (Elsevier, Amsterdam, 1982), pp. 747–804

R.C. O’Handley, Modern Magnetic Materials. Principles and Applications (Wiley-Interscience, New York, 2000)

J. Banhart, H. Ebert, A. Vernes, Phys. Rev. B 56, 10165 (1997)

S. Khmelevskyi, K. Palotás, L. Szunyogh, P. Weinberger, Phys. Rev. B 68, 012402 (2003)

J. Kudrnovsky, V. Drchal, S. Khmelevskyi, I. Turek, Phys. Rev. B 84, 214436 (2011)

S. Wimmer, D. Kodderitzsch, H. Ebert, Phys. Rev. B 89, 161101 (2014)

J.M. Daughton, J. Magn. Magn. Mater. 192, 334 (1999)

M.N. Baibich, J.M. Broto, A. Fert, F. Nguyen Van Dau, F. Petroff, P. Etienne, G. Creuzet, A. Friederich, J. Chazelas, Phys. Rev. Lett. 61, 2472 (1988)

G. Binasch, P. Grünberg, F. Saurenbach, W. Zinn, Phys. Rev. B 39, 4828 (1989)

K.M. Seemann, F. Freimuth, H. Zhang, S. Blügel, Y. Mokrousov, D.E. Bürgler, C.M. Schneider, Phys. Rev. Lett. 107, 086603 (2011)

F.L. Zeng, Z.Y. Ren, Y. Li, J.Y. Zeng, M.W. Jia, J. Miao, A. Hoffmann, W. Zhang, Y.Z. Wu, Z. Yuan, Phys. Rev. Lett. 125, 097201 (2020)

L. Nádvorník, M. Borchert, L. Brandt, R. Schlitz, K.A. de Mare, K. Výborný, I. Mertig, G. Jakob, M. Kläui, S.T.B. Goennenwein, M. Wolf, G. Woltersdorf, T. Kampfrath, Phys. Rev. X 11, 021030 (2021)

J.H. Park, H.W. Ko, J.M. Kim, J.M. Park, S.Y. Park, Y.H. Jo, B.G. Park, S.K. Kim, K.J. Lee, K.J. Kim, Sci. Rep. 11, 20884 (2021)

I. Bakonyi, E. Tóth-Kádár, J. Tóth, Á. Cziráki, B. Fogarassy, in Nanophase Materials. ed. by G.C. Hadjipanayis, R.W. Siegel (NATO ASI Series E, Kluwer Academic Publishers, Dordrecht The Netherlands, 1994), p. 423

M.J. Aus, B. Szpunar, U. Erb, A.M. El-Sherik, G. Palumbo, K.T. Aust, J. Appl. Phys. 75, 3632 (1994)

J.L. McCrea, K.T. Aust, G. Palumbo, U. Erb, MRS Symp. Proc. 581, 461 (2000)

J.L. McCrea, Ph.D. Thesis (University of Toronto, Toronto, Canada, 2001)

P.V.P. Madduri, S.N. Kaul, Phys. Rev. B 95, 184402 (2017)

I. Bakonyi, V.A. Isnaini, T. Kolonits, Z. Czigány, J. Gubicza, L.K. Varga, E. Tóth-Kádár, L. Pogány, L. Péter, H. Ebert, Philos. Mag. 99, 1139 (2019)

V.A. Isnaini, T. Kolonits, Z. Czigány, J. Gubicza, S. Zsurzsa, L.K. Varga, E. Tóth-Kádár, L. Pogány, L. Péter, I. Bakonyi, Eur. Phys. J. Plus 135, 39 (2020)

I. Bakonyi, Eur. Phys. J. Plus 133, 521 (2018)

J.M. Ziman, Electrons and Phonons (Clarendon Press, Oxford, 1960)

M.J. Laubitz, T. Matsumura, P.J. Kelly, Can. J. Phys. 54, 92 (1976)

J. Bass, Chapter 1: electrical resistivity of pure metals and dilute alloys, in Landolt-Börnstein - Group III, New Series. (Springer-Verlag, Berlin, Heidelberg, New York, 1982), pp. 1–287

M. Kohler, Ann. Phys. 32, 211 (1938)

F.C. Schwerer, J. Silcox, J. Appl. Phys. 39, 2047 (1968)

F.C. Schwerer, J. Silcox, Phys. Rev. B 1, 2391 (1970)

J.M. Ziman, Electrons and Phonons (Clarendon Press, Oxford, 1960), p. 490