Abstract

The ultimate buckling capacity of the composite cylinders exposed to external hydrostatic pressure is identified as a critical factor in design, manufacturing and in-service life stages of these structures. This study deals with study and analysis of a new class of polymeric composite panels, consisting of metallic and fibrous layers and reinforced with functionally graded carbon nanotubes (FG-CNTs). Manufacturing-induced geometrical imperfection and CNT-agglomeration issues are among the commonly-reported problems associated with FG-CNT-reinforced composite panels under external pressure. On this account, this study will thoroughly scrutinize the influence of various parameters such as the fiber orientation, metal type and volume fraction, CNT volume fraction and distribution pattern, while both agglomeration and imperfection flaws are taken into account. The Galerkin method together with micromechanics models is employed in the solution procedure, and after verifying the proposed approach, the results are discussed in detail. Finally, key conclusions are presented to achieve the highest practical buckling capacity in the presence of agglomeration and imperfection problems.

Similar content being viewed by others

References

A. Tabatabaeian, A.R. Ghasemi, B. Asghari, Specification of non-uniform residual stresses and tensile characteristic in laminated composite materials exposed to simulated space environment. Polym Test 80, 106147 (2019). https://doi.org/10.1016/j.polymertesting.2019.106147

A. Tabatabaeian, M. Baraheni, S. Amini, A.R. Ghasemi, Environmental, mechanical and materialistic effects on delamination damage of glass fiber composites: analysis and optimization. J Compos Mater (2019). https://doi.org/10.1177/0021998319844811

A. Tabatabaeian, A. Ghasemi, Curvature changes and weight loss of polymeric nano-composite plates with consideration of the thermal cycle fatigue effects and different resin types: an experimental approach. Mech Mater 131, 69–77 (2019). https://doi.org/10.1016/j.mechmat.2019.01.017

Z. Asaee, F. Taheri, Enhancement of performance of three-dimensional fiber metal laminates under low velocity impact: a coupled numerical and experimental investigation. J Sandw Struct Mater (2017). https://doi.org/10.1177/1099636217740389

D. De Cicco, F. Taheri, Robust numerical approaches for simulating the buckling response of 3D fiber-metal laminates under axial impact: validation with experimental results. J Sandw Struct Mater (2018). https://doi.org/10.1177/1099636218789614

B. Soltannia, P. Mertiny, F. Taheri, Static and dynamic characteristics of nano-reinforced 3D-fiber metal laminates using non-destructive techniques. J Sandw Struct Mater (2020). https://doi.org/10.1177/1099636220924585

E. Grande, M. Imbimbo, V. Tomei, Role of global buckling in the optimization process of grid shells: design strategies. Eng Struct 156, 260–270 (2018). https://doi.org/10.1016/j.engstruct.2017.11.049

M. Nasihatgozar, S.M.R. Khalili, Vibration and buckling analysis of laminated sandwich conical shells using higher order shear deformation theory and differential quadrature method. J Sandw Struct Mater (2017). https://doi.org/10.1177/1099636217715806

M. Safarabadi, M. Haghighi-Yazdi, M. Sorkhi, A. Yousefi, Experimental and numerical study of buckling behavior of foam-filled honeycomb core sandwich panels considering viscoelastic effects. J Sandw Struct Mater (2020). https://doi.org/10.1177/1099636220975168

X.Y. Ni, B.G. Prusty, A.K. Hellier, Buckling and post-buckling of isotropic and composite stiffened panels: a review on analysis and experiment (2000–2012). Trans R Inst Nav Archit Part A Int J Marit Eng 157, A9-30 (2015). https://doi.org/10.3940/rina.ijme.2015.al.300

M.H. Hajmohammad, A. Tabatabaeian, A.R. Ghasemi, F. Taheri-Behrooz, A novel detailed analytical approach for determining the optimal design of FRP pressure vessels subjected to hydrostatic loading : analytical model with experimental validation. Compos Part B 183, 107732 (2020). https://doi.org/10.1016/j.compositesb.2019.107732

E. García-Macías, L. Rodríguez-Tembleque, R. Castro-Triguero, A. Sáez, Eshelby-Mori-Tanaka approach for post-buckling analysis of axially compressed functionally graded CNT/polymer composite cylindrical panels. Compos Part B Eng 128, 208–224 (2017). https://doi.org/10.1016/j.compositesb.2017.07.016

M. Nasihatgozar, V. Daghigh, M. Eskandari, K. Nikbin, A. Simoneau, Buckling analysis of piezoelectric cylindrical composite panels reinforced with carbon nanotubes. Int J Mech Sci 107, 69–79 (2016). https://doi.org/10.1016/j.ijmecsci.2016.01.010

A. Hajlaoui, E. Chebbi, F. Dammak, Buckling analysis of carbon nanotube reinforced FG shells using an efficient solid-shell element based on a modified FSDT. Thin-Walled Struct 144, 106254 (2019). https://doi.org/10.1016/j.tws.2019.106254

D.G. Ninh, Nonlinear thermal torsional post-buckling of carbon nanotube-reinforced composite cylindrical shell with piezoelectric actuator layers surrounded by elastic medium. Thin-Walled Struct 123, 528–538 (2018). https://doi.org/10.1016/j.tws.2017.11.027

S. Chakraborty, T. Dey, R. Kumar, Stability and vibration analysis of CNT-Reinforced functionally graded laminated composite cylindrical shell panels using semi-analytical approach. Compos Part B Eng 168, 1–14 (2019). https://doi.org/10.1016/j.compositesb.2018.12.051

N.D. Khoa, H.T. Thiem, N.D. Duc, Nonlinear buckling and postbuckling of imperfect piezoelectric S-FGM circular cylindrical shells with metal-ceramic-metal layers in thermal environment using Reddy’s third-order shear deformation shell theory. Mech Adv Mater Struct 26, 248–259 (2017). https://doi.org/10.1080/15376494.2017.1341583

P.T. Hieu, H.V. Tung, Postbuckling behavior of CNT-reinforced composite cylindrical shell surrounded by an elastic medium and subjected to combined mechanical loads in thermal environments. J. Thermoplast. Compos. Mater. 32, 1–28 (2018). https://doi.org/10.1177/0892705718796551

S. Zghal, S. Trabelsi, F. Dammak, Post-buckling behavior of functionally graded and carbon-nanotubes based structures with different mechanical loadings. Mech. Based Des. Struct. Mach. (2020). https://doi.org/10.1080/15397734.2020.1790387

S. Trabelsi, S. Zghal, F. Dammak, Thermo-elastic buckling and post-buckling analysis of functionally graded thin plate and shell structures. J. Braz. Soc. Mech. Sci. Eng. (2020). https://doi.org/10.1007/s40430-020-02314-5

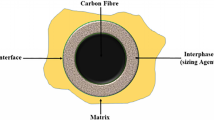

M.A. Maghsoudlou, R. Barbaz Isfahani, S. Saber-Samandari, M. Sadighi, Effect of interphase, curvature and agglomeration of SWCNTs on mechanical properties of polymer-based nanocomposites: Experimental and numerical investigations. Compos Part B Eng 175, 107119 (2019). https://doi.org/10.1016/j.compositesb.2019.107119

Z. Asaee, M. Mohamed, S. Soumik, F. Taheri, Experimental and numerical characterization of delamination buckling behavior of a new class of GNP-reinforced 3D fiber-metal laminates. Thin-Walled Struct 112, 208–216 (2017). https://doi.org/10.1016/j.tws.2016.12.015

A.R. Ghasemi, M. Soleymani, Effects of carbon nanotubes distribution on the buckling of carbon nanotubes / fiber / polymer / metal hybrid laminates cylindrical shell. J Sandw Struct Mater (2020). https://doi.org/10.1177/1099636220909786

K. Hosseinpour, A.R. Ghasemi, Agglomeration and aspect ratio effects on the long-term creep of carbon nanotubes / fiber / polymer composite cylindrical shells. J Sandw Struct Mater (2019). https://doi.org/10.1177/1099636219857200

H.N.R. Wagner, E. Petersen, R. Khakimova, C. Hühne, Buckling analysis of an imperfection-insensitive hybrid composite cylinder under axial compression – numerical simulation, destructive and non- destructive experimental testing. Compos Struct 225, 111152 (2019). https://doi.org/10.1016/j.compstruct.2019.111152

Z. Sadovský, J. Kriváček, Influential geometric imperfections in buckling of axially compressed cylindrical shells: a novel approach. Eng Struct 223, 111170 (2020). https://doi.org/10.1016/j.engstruct.2020.111170

H. Wu, S. Kitipornchai, J. Yang, Imperfection sensitivity of thermal post-buckling behaviour of functionally graded carbon nanotube-reinforced composite beams. Appl Math Model 42, 735–752 (2017). https://doi.org/10.1016/j.apm.2016.10.045

V.V. Vasiliev, Mechanics of Composite Structures.pdf (Taylor & Francis, Washington DC, 1993)

M. Nejati, R. Dimitri, F. Tornabene, Y.M. Hossein, Thermal buckling of nanocomposite stiffened cylindrical shells reinforced by functionally graded wavy carbon nanotubes with temperature-dependent properties. Appl Sci 7, 1223 (2017). https://doi.org/10.3390/app7121223

T. Messager, Buckling of imperfect laminated cylinders under hydrostatic pressure. Compos Struct 53, 301–307 (2001)

A. Tabatabaeian, M. Lotfi, A. Reza, S. Roohollahi, Development of a new analytical framework for deflection analysis of un-symmetric hybrid FRP laminates with arbitrary ply arrangement and MWCNT reinforcement. Eng Struct 228, 111490 (2020). https://doi.org/10.1016/j.engstruct.2020.111490

A.R. Ghasemi, A. Tabatabaeian, M. Moradi, Residual stress and failure analyses of polymer matrix composites considering thermal cycling and temperature effects based on classical laminate plate theory. J Compos Mater (2019). https://doi.org/10.1177/0021998318812127

G. Sun, J.S. Hansen, Optimal design of laminated- composite circular-cylindrical shells subjected to combined loads. J Appl Mech 55 (1988)

M. Song, S. Kitipornchai, J. Yang, Free and forced vibrations of functionally graded polymer composite plates reinforced with graphene nanoplatelets. Compos Struct 159, 579–588 (2017). https://doi.org/10.1016/j.compstruct.2016.09.070

K. Baek, W. Lee, H. Shin, M. Cho, Multiscale study on determining representative volume elements size for mechanical behaviours of complex polymer nanocomposites with nanoparticulate agglomerations. Compos Struct 253, 112796 (2020). https://doi.org/10.1016/j.compstruct.2020.112796

J.A. Krishnaswamy, F.C. Buroni, F. Garcia-sanchez, R. Melnik, L. Rodriguez-tembleque, A. Saez, Lead-free piezocomposites with CNT-modified matrices : Accounting for agglomerations and molecular defects. Compos Struct 224, 111033 (2019). https://doi.org/10.1016/j.compstruct.2019.111033

A.R. Ghasemi, M. Mohandes, R. Dimitri, F. Tornabene, Agglomeration effects on the vibrations of CNTs / fiber / polymer / metal hybrid laminates cylindrical shell. Compos Part B 167, 700–716 (2019). https://doi.org/10.1016/j.compositesb.2019.03.028

S. Kamarian, M. Salim, R. Dimitri, F. Tornabene, Free vibration analysis of conical shells reinforced with agglomerated carbon nanotubes. Int J Mech Sci (2016). https://doi.org/10.1016/j.ijmecsci.2016.02.006

H. Hedayati, A.B. Sobhani, Influence of graded agglomerated CNTs on vibration of CNT-reinforced annular sectorial plates resting on Pasternak foundation. Appl Math Comput 218, 8715–8735 (2012). https://doi.org/10.1016/j.amc.2012.01.080

A.R. Ghasemi, M.M. Mohammadi, M. Mohandes, The role of carbon nanofibers on thermo-mechanical properties of polymer matrix composites and their effect on reduction of residual stresses. Compos Part B 77, 519–527 (2015). https://doi.org/10.1016/j.compositesb.2015.03.065

A. Tabatabaeian, A.R. Ghasemi, The impact of MWCNT modification on the structural performance of polymeric composite profiles. Polym Bull (2020). https://doi.org/10.1007/s00289-019-03088-0

A.R. Ghasemi, A. Tabatabaeian, B. Asghari, Application of slitting method to characterize the effects of thermal fatigue, lay-up arrangement and MWCNTs on the residual stresses of laminated composites. Mech Mater 134, 185–192 (2019). https://doi.org/10.1016/j.mechmat.2019.04.008

I. Inagaki, T. Tsutomu, S. Yoshihisa, A. Nozomu, Application and Features of Titanium for the Aerospace Industry. Nippon Steel Sumitomo Met Tech Rep 22–7 (2014)

B.L. Mordike, T. Ebert, Magnesium properties - applications - potential. Mater Sci Eng A 302, 37–45 (2001). https://doi.org/10.1016/S0921-5093(00)01351-4

A. Vlot, E. Kroon, G. La Rocca, Impact response of fiber metal laminates. Key Eng Mater 141–143, 235–276 (1998). https://doi.org/10.4028/www.scientific.net/KEM.141-143.235

A.R. Ghasemi, S. Kiani, A. Tabatabaeian, Buckling analysis of FML cylindrical shells under combined axial and torsional loading. Mech Adv Compos Struct 7 (2020)

B. Asghari, A.R. Ghasemi, A. Tabatabaeian, On the optimal design of manufacturing-induced residual stresses in filament wound carbon fiber composite cylindrical shells reinforced with carbon nanotubes. Compos Sci Technol 182, 107743 (2019). https://doi.org/10.1016/j.compscitech.2019.107743

A.R. Ghasemi, B. Asghari, A. Tabatabaeian, Determination of the influence of thermo-mechanical factors on the residual stresses of cylindrical composite tubes : Experimental and computational analyses. Int J Press Vessel Pip 183, 104098 (2020). https://doi.org/10.1016/j.ijpvp.2020.104098

A.V. Lopatin, E.V. Morozov, Buckling of composite cylindrical shells with rigid end disks under hydrostatic pressure. Compos Struct 173, 136–143 (2017). https://doi.org/10.1016/j.compstruct.2017.03.109

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Rights and permissions

About this article

Cite this article

Ghasemi, A.R., Soleymani, M. A new efficient buckling investigation of functionally graded CNT/fiber/polymer/metal composite panels exposed to hydrostatic pressure considering simultaneous manufacturing-induced agglomeration and imperfection issues. Eur. Phys. J. Plus 136, 1220 (2021). https://doi.org/10.1140/epjp/s13360-021-02197-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-021-02197-y