Abstract

The influence of Ʃ5 grain boundary on mechanical properties of Ni3Al alloy is investigated under uniaxial loading by molecular dynamics simulation. The results are that when Ʃ5 grain boundary is added to Ni3Al alloy at 300 K, the mechanical properties have changed from the stress strain curves, Ʃ5 grain boundary causes the yield platform generation, and leads to reduction of yield stress and yield strain. In addition, the symmetrical slip bands are the main deformation mechanism for Ni3Al-Ʃ5 alloy, which shows that Ʃ5 grain boundary can reinforce the plasticity of Ni3Al alloy and reduce the structure damage. As the temperature rises, the yield stress and yield strain increase at 700 K and 900 K, and the Ni3Al-Ʃ5 alloy has better mechanical properties at 700 K than other temperature and presents excellent mechanical properties. It also finds that decreasing Ʃ5 grain boundary size can also enhance the mechanical properties of Ni3Al alloy.

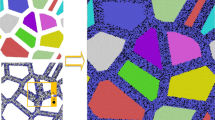

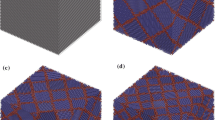

Graphical abstract

Similar content being viewed by others

Data availability statement

This manuscript has no associated data or the data will not be deposited. [Authors’ comment: Since this is an initial study, no relevant data are available. But I have stored the data in my study. If readers need it, they can contact me at Email: mlml6277@126.com].

References

T.M. Pollock, A.S. Argon, Creep resistance of CMSX-3 nickel base superalloys single crystals. Acta Mater. 40, 1–30 (1992)

R.C. Reed, The Superalloys: Fundamentals and Applications (Cambridge University Press, New York, 2006), p.372

D.B. Miracle, The physics and mechanical properties of NiAl. Acta Metall. Mater. 41, 649 (1993)

N.N. Stepanova, D.I. Davydov, D.P. Rodionov et al., Structure and mechanical properties of an Ni3Al single crystal upon high temperature deformation. Phys. Met. Metallogr. 111(4), 403–409 (2011)

H.X. Xie, C.Y. Wang, T. Yu et al., Dislocation formation and twinning from the crack tip in Ni3Al: molecular dynamics simulation. Chin. Phys. B 18, 0251 (2009)

H.X. Xie, L. Bo, T. Yu, Atomistic simulation of microtwinning at the crack tip in L12 Ni3Al. Phil. Mag. 92, 1542–1553 (2012)

H.X. Xie, T. Yu, F.X. Yin et al., The effects of crack orientation on the twin formation from the crack tip in Ni3Al. Mater. Sci. Eng., A 580, 99–104 (2013)

K. Gopinath, A.K. Gogia, S.V. Kamat et al., Tensile properties of Ni-based superalloy 720Li: temperature and strain rate effects. Metall. Mater. Trans. A 2, 2340–2350 (2008)

Q.I.N. Jian-chao, C.U.I. Ren-jie, Huang Zhao-hui, Effect of low angel grain boundaries on mechanical properties of DD5 single crystal Ni-base superalloy at medium temperature and high temperature. J. Mater. Eng. 48(10), 114–122 (2020)

M. Kolbe, The high temperature decrease of the critical resolved shear stress in nickel-base superalloys. Mater. Sci. Eng., A 319–321, 383–387 (2001)

J.-Q. Su, M. Demura, T. Hirano, Mechanical behaviour of Ʃ3 boundaries in Ni3Al. Acta Mater. 51, 2505–2515 (2003)

T. Kin, K.T. Hong, K.S. Lee, The relationship between the toughness and grain boundary character distribution in polycrystalline NiAl. Intermetallics 11, 33–39 (2003)

N.J. Burbery, R. Das, W.G. Ferguson, The observation of structural multiplicity in Ʃ5(310) grain boundaries in FCC metals. Mater. Lett. 158, 41–415 (2015)

Hu. Xue-Lan, R.-X. Zhao, Y. Luo et al., Effect of P impurity on NiAl Ʃ5 grain boundary from first-principles study. Chin. Phys. B 26(2), 023101 (2017)

G.P. Purja Pun, Y. Mishin, Development of an interatomic potential for the Ni-Al system. Philos. Mag. 89, 3245–3267 (2009)

L. Ma, S. Xiao, H. Deng, Hu. Wangyu, Atomic simulation of fatigue crack propagation in Ni3Al. Appl. Phys. A 118, 1399–1406 (2015)

L. Ma, S. Xiao, H. Deng et al., Tensile mechanical properties of Ni-based superalloy of nanophases using molecular dynamic simulation. Phys. Status Solid (b) 253(4), 716–732 (2016)

L. Ma, S. Xiao, H. Deng et al., Atomic simulation of fatigue crack propagation in Ni3Al. Appl. Phys. A 118, 1399–1406 (2015)

S. Plimpton, Fast parallel algorithms for short-range molecular dynamics. J. Comp. Phys. 117, 1–19 (1995)

J. Dana Honeycutt, H.C. Andersen, Molecular dynamics study of melting and freezing of small lennard-jones clusters. J. Phys. Chem. 91, 4950–4963 (1987)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO—the open visualization tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2010)

X. Luan, H. Qin, F. Liu et al., The Mechanical of Properties and Elastic Anisotropies of Cubic Ni3Al from First Principles Calculations. Curr. Comput.-Aided Drug Des. 307, 1–11 (2018)

Acknowledgements

The authors thank the financial support from the Surface Project of National Natural Science Foundation of China (No. 12072110), the projects of Hunan education department (Nos. 20A344 and 19B386) and the project of Hunan University of Arts and Science (No. 20ZD05).

Author information

Authors and Affiliations

Contributions

LM performed MD simulation and wrote this manuscript; SP analyzed the mechanical properties of Ni3Al and Ni3Al-Ʃ5 alloys; CL and WH supervised the research.

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, L., Peng, S., Li, C. et al. Atomic simulation of effects of Ʃ5 grain boundary on mechanical properties of Ni3Al. Eur. Phys. J. B 95, 186 (2022). https://doi.org/10.1140/epjb/s10051-022-00444-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjb/s10051-022-00444-4