Abstract

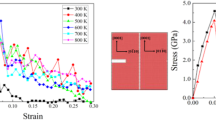

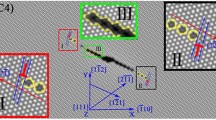

The crack growth behavior of single crystal aluminum is investigated under tensile test at room temperature by molecular dynamics simulations. Three crack models are selected, which are [001](010) crack, (\(\overline{1}\)10)[110] crack and [11\(\overline{2}\)](111) crack. The results present that the mechanical properties and deformation mechanisms are significantly influenced by the orientation of initial crack. The [\(\overline{1}\)10] (110) crack has the maximum yield strength, the [11\(\overline{2}\)] (111) crack has the maximum elastic modulus. The [001](010) crack propagates in the form of micro-cracks and shows ductility fracture, and the main deformation mechanisms are blunting and slip bands at crack tip. The (\(\overline{1}\)10)[110] crack evolves into a void with the loading increasing, presents ductile extension, and the slip bands divide the crystal structure into mesh region. For (111) [11\(\overline{2}\)] crack, it has very good toughness and ductility and can effectively reduce structural damage caused by crack propagation.

Graphical abstract

The initial models of crack. (a) [001](010) crack, (b) [110] (110) crack (c) [11 2] (111) crack

Similar content being viewed by others

Data Availability Statement

This manuscript has no associated data or the data will not be deposited. [Authors' comment: Due to the large amount of data of all simulation results, it was not put into the data system. But I have stored it myself. If readers need it, they can contact me directly at Email: mlml6277@126.com.].

References

P. Gumbsch, J. Riedle, A. Hartmaier, H.F. Fischmeister, Science 282, 1293–1295 (1998)

A. Hartmaier, P. Gumbsch, Phys. Rev. B 71, 024108 (2005)

B. Decelis, A.S. Argon, S. Yip, J. Appl. Phys. 54, 4864–4878 (1983)

G.P. Potirniche, M.F. Horstemeyer, Philos. Mag. Lett. 86(3), 185–193 (2006)

T. Tang, S.H. Kim, M.F. Horstemeyer, Comput. Mater. Sci. 48, 42439 (2010)

Y.F. Guo, D.L. Zhao, Mater. Sci. Eng. A 448, 281–186 (2007)

W.D. Wang, C.L. Yi, K.Q. Fan, Trans. Nonferrous Met. Soc. China. 23(11), 3353–3361 (2013)

D. Terentyev, E.E. Zhurkin, G. Bonny, Comput. Mater. Sci. 55, 313–321 (2012)

S. Chandra, N. Naveen Kumar, M.K. Samal, Comput. Mater. Sci. 130, 268–281 (2017)

H.X. Xie, C.Y. Wang, T. Yu, Chin. Phys. B 18, 0251 (2009)

A. Uhnakova, A. Machova, P. Hora, Int. J. Fatigue 33, 1182–1188 (2011)

L. Ma, S.F. Xiao, H.Q. Deng, W.Y. Hu, Int. J. Fatigue 68, 253 (2014)

L. Ma, S.F. Xiao, H.Q. Deng, W.Y. Hu, Appl. Phys. A 118, 1399–1406 (2015)

W. Fang, H.X. Xie, F.X. Yin, Mater. Sci. Eng. A 666, 314–319 (2016)

M. Yaghoobi, G.Z. Voyiadjis, Acta Mater. 121, 190–201 (2016)

P. White, Int. J. Fatigue 44, 141–150 (2012)

J. Ding, L.S. Wang, K. Song et al., J. Nanomater. 2017, 1–12 (2017)

A.J. Cao, Y.G. Wei, Phys. Rev. B 76, 1–5 (2007)

G.P. Potirniche, M.F. Horstemeyer, B. Jelinek et al., Int. J. Fatigue 2, 1179–1185 (2005)

D. Farkas, M. Willemann, B. Hyde, Phys. Rev. Lett. 94, 165502 (2005)

G.P. Potirniche, M.F. Horstemeyer, Mag. Lett 86, 185–193 (2006)

K. Nishimura, N. Miyazaki, Comput. Mater. Sci 31, 269–278 (2004)

J. Dana Honeycutt, H.C. Andersen, J. Phys. Chem. 91, 4950–4963 (1987)

S. Plimpton, J. Comp. Phys. 117, 1–19 (1995)

Acknowledgements

The authors thank the financial support from the Surface Project of National Natural Science Foundation of China (No. 12072110), the key projects of Hunan education department (No. 20A344) and the project of Hunan University of Arts and Science (No. 20ZD05 and No. 19BSQD38).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, L., Deng, Y., Ren, Y. et al. Influence of orientation on crack propagation of aluminum by molecular dynamics. Eur. Phys. J. B 95, 25 (2022). https://doi.org/10.1140/epjb/s10051-022-00285-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjb/s10051-022-00285-1