Abstract

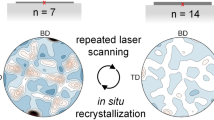

The appearance of ZhS6K grade alloy granules, the surface and internal structure, and the chemical composition thereof have been analyzed. It is shown that one can control the formation of a preset state of interfaces (tracks, crystallization cells, hatch block boundaries, grains, phases, and discontinuities such as pores and cracks) through the fractional composition, packing density upon filling, and scanning speed in order to obtain a better material quality. The initial structural state of the samples has been studied. An interrelation between the structure of crystallization cell boundaries, dispersed particles, and the structure of fragments has been established. It is shown that all the studied samples have different structural features at the same power and scanning strategy. The analysis has been performed using the methods of optical metallography and scanning electron microscopy (SEM).

Similar content being viewed by others

REFERENCES

Kablov, E.N., Additive technology—the dominant national technology initiative, Intellekt Tekhnol., 2015, no. 2 (11), pp. 52–55.

Kablov, E.N., The present and future of additive technologies, Met. Evrazii, 2017, no. 1, pp. 2–6.

Kablov, E.N., The key issue is materials, in Tendentsii i orientiry innovatsionnogo razvitiya Rossii (Trends and Guidelines for the Innovative Development of Russia), Moscow: Vseross. Inst. Aviats. Mater., 2015, pp. 458–464.

Gu, D., Meiners, D.W.,Wissenbach, K., and Poprawe, R., Laser additive manufacturing of metallic components: Materials, processes and mechanisms, Int. Mater. Rev., 2012, vol. 57, no. 3, pp. 133–164.

Thornton, A., Saad, J., and Clayton, J., Measuring the critical attributes of AM powders, Met. Powder Rep., 2019, vol. 74, no. 6, pp. 314–319. https://doi.org/10.1016/j.mprp.2019.01.006

Kalinina, N.E., Kalinin, V.T., Grekova, M.V., Mamchur, S.I., and Nosova, T.V., Mechanical and corrosion properties of multicomponent alloys modified with dispersed compositions, Stroit., Materialoved., Mashinostr., Ser. Starodub. Chteniya, 2018, pp. 146–150. https://doi.org/10.30838/P.CMM.2415. 200418.146.22

Chabina, E.B., Filonova, E.V., Raevskikh, A.N., and Tsvetkova, E.V., Dependence of nickel superalloy structural defects on selective laser fusion process parameters, Met. Sci. Heat Treat., 2018, vol. 60, pp. 373–380. https://doi.org/10.1007/s11041-018-0286-2

Evgenov, A.G., Nerush, S.V., and Vasilenko, S.A., The obtaining and testing of the fine-dispersed metal powder of the high-chromium alloy on nickel-base for laser metal deposition, Tr. VIAM, 2014, no. 5, art. ID 4. https://doi.org/10.18577/2307-6046-2014-0-5-4-4. https://www.viam-works.ru. Accessed October 15, 2017.

Evgenov, A.G., Shcherbakov, S.I., and Rogalev, A.M., Testing EP718 and EP648 superalloys powders produced by FSUE “VIAM” for repair of gas turbine engine components using laser-powder braze, Aviats. Mater. Tekhnol., 2016, no. S1 (43), pp. 16–23. https://doi.org/10.18577/2071-9140-2016-0-S1-16-23

Lashko, N.F., Zaslavskaya, L.V., Kozlova, M.N., et al., Fiziko-khimicheskii fazovyi analiz stalei i splavov (Physicochemical Phase Analysis of Steels and Alloys), Moscow: Metallurgiya, 1978.

Betteridge, W., The Nimonic Alloys, London: Edward Arnold, 1959.

Thijs, L., Verhaeghe, F., Craeghs, T., Humbeeck, J.V., and Kruth, J.P., A study of the microstructural evolution during selective laser melting of Ti–6Al–4V, Acta Meter., 2010, vol. 58, pp. 3303–3312.

Prashanth, K.G., Scudino, S., Maity,T., Das, J., and Eckert, J., Is the energy density a reliable parameter for materials synthesis by selective laser melting? Mater. Res. Lett., 2017, vol. 5, no. 6, pp. 386–390. https://doi.org/10.1080/21663831.2017.1299808

Li, R., Liu, J., Shi, Y., Wang, L., and Jiang, W., Balling behavior of stainless steel and nickel powder during selective laser melting process, Int. J. Adv. Manuf. Technol., 2012, vol. 59, pp. 1025–1035.

Sukhov, D.I., Mazalov, P.B., Nerush, S.V., and Khodyrev, N.A., The influence of SLS parameters on pores formation in stainless steel material, Tr. VIAM, 2017, no. 8 (56), art. ID 4. https://doi.org/10.18577/2307-6046-2017-0-8-4-4. http://www.viam-works.ru. Accessed October 10, 2020.

Terhaar, J., Poppenhäger, J., Bokelmann, D., Schafstall, H., and Kelkar, K., Considering the solidification structure of VAR ingots in the numerical simulation of the cogging process, Proc. 7th Int. Symp. on Superalloys 718 and Derivatives, Pittsburgh, PA, October 10–13, 2010, Boston: Wiley, 2011, pp. 65–77. https://doi.org/10.7449/2010/Superalloys_2010_65_77

Cole, V.J., Northrop, P.W.C., Tan, X.G., Chou, K., Wang, X.Q., and Keya, T., High-fidelity modeling and materials characterization of Inconel 718 component fabrication by selective laser melting additive manufacturing, 2016 JANNAF TIM–Additive Manufacturing, August 23–25, 2016, pp. 1–24. https://ntrs.nasa.gov/search.jsp?R=201600120802020-07-04T16:36:45+00:00Z. Accessed July 4, 2020.

Lapteva, M.A., Belova, N.A., Raevskikh, A.N., and Filonova, E.V., Dependence of roughness, surface morphology structure and number of defects on the power of the laser, scanning speed and the type of hatching in the high-temperature alloys synthesized by SLS, Tr. VIAM, 2016, no. 9 (45), art. ID 9. https://doi.org/10.18577/2307-6046-2016-0-9-9-9. http://www.viam-works.ru. Accessed February 17, 2021.

Tsivil’skii, I.V., Gil’mutdinov, A.Kh., Khamidullin, B.A., Nikiforov, S.A., and Rublya, R.S., Mathematical modeling of dynamics and phase transitions in powder materials in the process of additive manufacturing, Materialy XII Vserossiiskaya konferentsiya po ispytaniyam i issledovaniyam svoistv materialov “TestMat” po tematike “Sovremennye aspekty v oblasti issledovanii strukturno-fazovykh prevrashchenii pri sozdanii materialov novogo pokoleniya” (Proc. 12th All-Russian Conf. on Testing and Research of Properties of Materials “TestMat” on the Topic “Modern Aspects in the Field of Structural-Phase Transformations Research in the Creation of New Generation Materials”), Moscow: Vseross. Inst. Aviats. Mater., 2020, pp. 172–186.

Shalin, R.E., Svetlov, I.L., Kachanov, E.B., Toloraya, V.N., and Gavrilin, O.S., Monokristally nikelevykh zharoprochnykh splavov (Single Crystals of Nickel Superalloys), Moscow: Mashinostroenie, 1997.

Markovich, O.V., Orekhov, N.G., and Razumov-skii, I.M., Diffusion permeability and structural state of internal interfaces in single crystals of heat-resistant nickel alloy, Fiz. Met. Metalloved., 1994, vol. 78, no. 2, pp. 91–98. https://viam.ru/sites/default/ files/scipub/1993/1993-201486.pdf. Accessed March 22, 2021.

Evgenov, A.G., Lukina, E.A., and Korolev, V.A., Features of process of the selection laser synthesis with reference to cast alloys on the basis of nickel and Ni3Al intermetallic compound, Novosti Materialoved. Nauka Tekh., 2016, no. 5 (23), pp. 3–11. http://materialsnews.ru/plugins/content/journal/uploads/articles/pdf/219.pdf. Accessed February 7, 2022.

Raevskikh, A.N., Chabina, E.B., Filonova, E.V., and Belova, N.A., Electron back scatter diffraction (EBSD) method possibilities for selective laser melted nickel superalloys structure features investigation, Tr. VIAM, 2017, no. 12 (60), art. ID 12. https://doi.org/10.18577/2307-6046-2017-0-12-12-12. http://www.viam-works.ru. Accessed March 10, 2021.

Gockel, J. and Beuth, J., Understanding Ti–6Al–4V microstructure control in additive manufacturing via process maps, Proc. of Solid Freeform Fabrication Symp., Austin, TX, 2013, pp. 666–674. http://utw10945.utweb.utexas.edu/Manuscripts/2013/2013-53-Gockel.pdf. Accessed February 7, 2022.

Kablov, E.N., Innovative developments of FSUE “VIAM” SSC of RF on realization of “Strategic directions of the development of materials and technologies of their processing for the period until 2030,” Aviats. Mater. Tekhnol., 2015, no. 1 (34), pp. 3–33. https://doi.org/10.18577/2071-9140-2015-0-1-3-33

Funding

This work was financially supported by the Russian Foundation for Basic Research, project no. 14-29-10220, and in the scope of Strategic Directions for the Development of Materials and Technologies for Their Processing for the Period up to 2030 (10.3. Atomization Technologies for Obtaining Fine-Dispersed High-Quality Alloy Powders on Various Bases for Additive Technologies and Powders for Soldering) [25].

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by O. Polyakov

Rights and permissions

About this article

Cite this article

Raevskikh, A.N., Chabina, E.B. & Filonova, E.V. Effect of Initial Powder Characteristics on Microrelief Features in the ZhS6K Grade Alloy after Selective Laser Fusion. Inorg. Mater. Appl. Res. 13, 1592–1604 (2022). https://doi.org/10.1134/S207511332206020X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S207511332206020X