Abstract

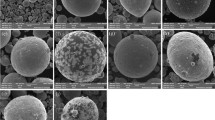

The practical possibility of synthesizing micron-size corrosion-resistant powder materials based on lower and higher nitrides of the Fe-N system in the form of both a bulk composition and a “core-shell” system was implemented at relatively low temperatures. Information on the elemental and chemical composition of iron nitrides was obtained using the methods of Auger electron spectroscopy and X-ray quantitative analysis. Fe3N and Fe4N phases were identified in the volume of microcrystals in the form of compositions with unreacted α-Fe without foreign impurities in the temperature range of 300–350°C. The highest mass concentration of the Fe4N phase was observed at 350°C and a nitriding time of 60 min (α-Fe, 14.70%; Fe3N, 24.50%; and Fe4N, 60.80%). Porous nanocoatings were synthesized on the surfaces of carbonyl iron microparticles at 165°C and a synthesis time of 420 min. This nanocoating has a thickness of ∼10–15 nm and, in the first approximation, corresponds to the ∼Fe15.7N2 compound.

Similar content being viewed by others

References

Minagawa, M., Yanagihara, H., Kishimoto, M., and Kita, T., Synthesis of ɛ-FexN (2 ≤ x ≤3) submicron particles and the diffusion mechanism of nitrogen atoms, Mater. Trans., 2010, vol. 51, pp. 2173–2176.

Leineweber, A., Mobility of nitrogen in ɛ-Fe3N below 150°C: The activation energy for reordering, Acta Mater., 2007, vol. 55, pp. 6651–6658.

Lehrer, E., Magnetishe Untersuchungen über das System Eisen-Stickstof, Zt. Elektrochemie, 1930, vol. 37, pp. 460–473.

Jack, K.H., The occurrence and the crystal structure of α-iron nitride; A new type of interstitial alloy formed during the tempering of nitrogen-martensite, Proc. Roy. Soc., A, 1951, vol. 208, pp. 216–224.

Coey, J.M.D., O’Donnell, K., Qinian, Q., Touchais, E., and Jack, K.H., The magnetization of α″-Fe16N2, J. Phys. Condens. Matter, 1994, vol. 6, pp. L23–L28.

Takahashi, M., and Shoji, H.J., α″-Fe16N2 problemgiant magnetic moment or not, J. Magn. Magn. Mater., 2000, vol. 208, pp. 145–147.

Kikkawa, S., Kubota, K., and Takeda, T., Particle size dependence in low temperature nitridation reaction for Fe16N2, J. Alloys Compd., 2008, vol. 449, pp. 7–10.

Ji, N., Liu, X., and Wang, J.-P., Theory of giant saturation magnetization in α″-Fe16N2: Role of partial localization in ferromagnetism of 3d transition metals, New J. Phys., 2010, vol.12, pp. 1–8.

Wang, J.-P., Ji, N., Liu, X., Xu, Yunhao., and Sanchez-Hanke, C., Origin of Giant Saturation Magnetization in Fe16N2 thin film, Proc. Am. Phys. Soc. Meeting, 2010.

Koyano, T. and Mizutani, U., US Patent 5330554, 1994.

Masada, K., Amino, T., and Nagatomi, A., US Patent 7241501, 2007.

Masada, K., Amino, T., and Nagatomi, A., US Patent 7371458, 2008.

Inoue, T. and Sasaki, Y., US Patent Application 20100 035 086, 2010.

Sankar, S.G., Simizu, S., Zande, B.J., and Obermyer, R.T., US Patent Application 20110059005, 2011.

Gusarov, A.V. and Kovalev, E.P., Effective thermal conductivity of freely scattered and weekly baked powders. I. Model, Fiz. Khim. Obrab. Mater., 2009, no. 1, pp. 70–82.

Gusarov, A.V. and Kovalev, E.P., Model of thermal conductivity in powder beds, Phys. Rev. B: Condens. Matter Mater. Phys., 2009, vol. 80, p. 024202.

Alymov, M.I., Ankudinov, A.B., Gnedovets, A.G, et al., Low temperature nitration of iron nanopowders in ammonia atmosphere, XIX Mendeleevskii s”ezd po obshchei i prikladnoi khimii (Proc. 19th Mendeleev’s Meeting on General and Applied Chemistry), Volgograd, 2011.

Coey, J.M.D. and Smith, P.A.I., Magnetic nitrides, J. Magn. Magn. Mater., 1999, vol. 200, pp. 405–424.

Kikkawa, S., Yamada, A., Masubuchi, Y., and Takeda, T., Fine Fe16N2 powder prepared by low-temperature nitridation, Mater. Res. Bull., 2008, vol. 43, p. 3352–3357.

Alymov, M.I., Ankudinov, A.B., Gnedovets, A.G., and Zelenskii, V.A., Low temperature synthesis of nitrides in micro- and nanopowders of iron in ammonia flow. Physics and chemistry of ultradispersed nanosystems, Materialy X Vserossiiskoi konferentsii i Rossiiskoi molodezhnoi nauchnoi shkoly (Proc. 10th All-Russ. Conf. and Russ. Young Sci. School), Rostov-on-Don, 2012.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © E.P. Kovalev, M.I. Alymov, A.B. Ankudinov, A.G. Gnedovets, V.A. Zelenskii, 2013, published in Perspektivnye Materialy, 2013, No. 7, pp. 61–66.

Rights and permissions

About this article

Cite this article

Kovalev, E.P., Alymov, M.I., Ankudinov, A.B. et al. Low-temperature synthesis of micron nitride powders of the Fe-N system. Inorg. Mater. Appl. Res. 5, 168–172 (2014). https://doi.org/10.1134/S2075113314020105

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113314020105