Abstract

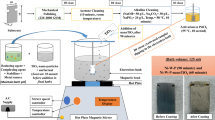

In order to investigate the effect of M7C3 and TiC carbides on electrochemical synthesis behavior of Fe–Cr–C and Fe–Cr–C/TiC coatings, Fe-based composite layer was prepared on medium carbon steel surface by using tungsten inert gas coating technique. The microstructure and phase structure of the coatings were analyzed by optical microscope with clemex image analyse, scanning electron microscope (SEM) equipped with an energy-dispersive spectroscopy (EDS) and X-ray diffractometer (XRD). The samples were exposed EIS (electrochemical impedance spectroscopy) method in sea water. Frequence diagrams and Nyquist diagrams were obtained. As a result, adding TiC improved the electrochemical behavior of FeCrC coating.

Similar content being viewed by others

REFERENCES

Badaruddin, M., Sugiyanto, Wardono, H., Andoko, Wang, C.J., and Rivai, A.K., Int. J. Fatigue, 2019, vol. 125, p. 406. https://doi.org/10.1016/j.ijfatigue.2019.04.020

Sharma, R.K., Das, R.K., and Kumar, S.R., Mater. Today Commun., 2021, vol. 26, p. 101826. https://doi.org/10.1016/j.mtcomm.2020.101826

Sharma, D., Ghosh, P.K., Kumar, N., and Anant, R., Surf. Coat. Technol., 2019, vol. 380, p. 125002. https://doi.org/10.1016/j.surfcoat.2019.125002

Velashjerdi, M., Soleymani, M., and Zarezadeh Mehrizi, M., Mater. Today Commun., 2020, vol. 25, p. 101316. https://doi.org/10.1016/j.mtcomm.2020.101316

Rodríguez-Villanueva, C., Encinas, N., Abenojar, J., and Martínez, M.A., Surf. Coat. Technol., 2013, vol. 236, p. 450. https://doi.org/10.1016/j.surfcoat.2013.10.036

Houdková, Š., Pala, Z., Smazalová, E., Vostřák, M., and Česánek, Z., Surf. Coat. Technol., 2017, vol. 318, p. 129. https://doi.org/10.1016/j.surfcoat.2016.09.012

Sola, R., Metall. Ital., 2010, vol. 102, no. 5, p. 21.

Yoon, S.Y., Lee, K.O., Kang, S.S., and Kim, K.H., J. Mater. Process. Technol., 2002, vols. 130–131, p. 260. https://doi.org/10.1016/S0924-0136(02)00746-X

PalDey, S. and Deevi, S.C., Mater. Sci. Eng., A, 2003, vol. 342, nos. 1–2, p. 58. https://doi.org/10.1016/S0921-5093(02)00259-9

Dewan, M.W., Liang, J., Wahab, M.A., and Okeil, A.M., Mater. Des., 2014, vol. 54, p. 6. https://doi.org/10.1016/j.matdes.2013.08.035

Corengia, P., Ybarra, G., Moina, C., Cabo, A., and Broitman, E., Surf. Coat. Technol., 2005, vol. 200, no. 7, p. 2391. https://doi.org/10.1016/j.surfcoat.2005.01.060

Sharma, R.K., Das, R.K., and Kumar, S.R., Mater. Today Commun., 2021, vol. 26, p. 101826. https://doi.org/10.1016/j.mtcomm.2020.101826

Fan, C., Chen, M.C., Chang, C.M., and Wu, W., Surf. Coat. Technol., 2006, vol. 201, nos. 3–4, p. 908. https://doi.org/10.1016/j.surfcoat.2006.01.010

Xu, J., Liu, W., Kan, Y., and Zhong, M., Mater. Des., 2006, vol. 27, no. 5, p. 405. https://doi.org/10.1016/j.matdes.2004.11.011

He, X., Song, R.G., and Kong, D.J., Opt. Laser Technol., 2019, vol. 112, p. 339. https://doi.org/10.1016/j.optlastec.2018.11.037

Afroukhteh, S., Dehghanian, C., and Emamy, M., Prog. Nat. Sci.: Mater. Int., 2012, vol. 22, no. 5, p. 480. https://doi.org/10.1016/j.pnsc.2012.10.005

Wang, G., Xing, C., Tao, F., Ding, P., and Zhongjia, H., Surf. Coat. Technol., 2016, vol. 305, p. 62. https://doi.org/10.1016/j.surfcoat.2016.08.009

Onuoha, C.C., Kipouros, G.J., Farhat, Z.N., and Plucknett, K.P., Int. J. Refract. Met. Hard Mater., 2014, vol. 44, p. 129. https://doi.org/10.1016/j.ijrmhm.2014.02.002

Meddings, N., et al., J. Power Sources, 2020, vol. 480. https://doi.org/10.1016/j.jpowsour.2020.228742

Buytoz, S., Mater. Lett., 2006, vol. 60, no. 5, p. 605. https://doi.org/10.1016/j.matlet.2005.09.046

Chang, C.M., Chen, Y.C., and Wu, W., Tribol. Int., 2010, vol. 43, nos. 5–6, p. 929. https://doi.org/10.1016/j.triboint.2009.12.045

Husain, A., Chakkamalayath, J., and Al-Bahar, S., Eng. Failure Anal., 2017, vol. 82, p. 765. https://doi.org/10.1016/j.engfailanal.2017.06.041

Liu, J., Li, S., Han, Z., and Cao, R., Mater. Chem. Phys., 2021, vol. 257, p. 123753. https://doi.org/10.1016/j.matchemphys.2020.123753

Zhu, Z., Li, J., Peng, Y., and Shen, G., Surf. Coat. Technol., 2020, vol. 391, p. 125671. https://doi.org/10.1016/j.surfcoat.2020.125671

Qin, Y., Zhao, H., Li, C., Lu, J., and He, J., Surf. Coat. Technol., 2020, vol. 398, p. 126086. https://doi.org/10.1016/j.surfcoat.2020.126086

ACKNOWLEDGMENTS

This study was supported by project number FHD-2020-3338 of Canakkale Onsekiz Mart University Scientific Searches and Project Department (COMUBAP).

Author information

Authors and Affiliations

Contributions

The microstructure investigations were performed by Dr. Soner Buytoz, EIS investigations were performed by Dr. Hulya Demiroren.

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

About this article

Cite this article

Demiroren, H., Buytoz, S. Electrochemical Synthesis of High Chromium Fe-Based TiC Composite Coating. Prot Met Phys Chem Surf 58, 109–118 (2022). https://doi.org/10.1134/S2070205122010063

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2070205122010063