Abstract

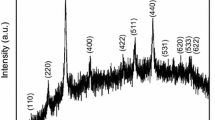

Conducting polymers with metal/metal oxide nanocomposites have recently attracted more attention from both the scientific sector and industry, with a focus on electrical and electromagnetic interference (EMI) shielding applications. Free-standing PPY-PVA/Ni (1, 2, 3, 4, and 5) ternary composite films were chemically synthesized by in situ chemical oxidative polymerization of pyrrole and polyvinyl alcohol (PVA, binder matrix) using ammonium persulfate as the oxidizing agent and coated with different concentrations (0.01, 0.02, 0.03, 0.04, and 0.05 M) of Ni+ ions using Adathoda vasica leaf extract as a reducing agent. The effect of PPY-PVA/Ni nanocomposites on the electrical and EMI shielding properties of nanocomposites was studied. The crystal structure of the dopant (Ni nanoparticles), thermal degradation and morphology of these composites were characterized by XRD, FESEM and TG analysis. The maximum electrical conductivity (4.2 × 10–4 S/cm) was also achieved by doping PPY-PVA binary composites with 0.01 M Ni+ ions to form PPY-PVA/Ni-1 ternary nanocomposites. This significant increase in electrical conductivity achieves an EMI shielding effect of up to ~16.5 dB in the frequency range from 2.1 to 3 GHz (S-Band). An increase in electrical conductivity and EMI shielding for composites with hybrid fillers (PPY-PVA/Ni) demonstrates the synergistic benefits of such fillers when used together. Hence, these conducting polymers with metal/metal oxide nanocomposites could have the potential to be advantageous materials for technological applications.

Similar content being viewed by others

REFERENCES

D. Davis, L. Birnbaum, P. Ben-Ishai, H. Taylor, M. Sears, T. Butler, and T. Scarato, Curr. Probl. Pediatr. Adolesc. Health Care 53, 101374 (2023).

V. Karthik, B. Karuna, P. S. Kumar, A. Saravanan, and R. V. Hemavathy, Chemosphere 299, 134427 (2022).

B. Wang, C. Lin, H. Cheng, X. Duan, Q. Wang, and D. Xu, Int. J. Environ. Res. Public Health 18, 11409 (2021).

P. Wang, L. Cheng, and L. Zhang, Carbon 125, 207 (2017).

R. R. Mohan, A. Abhilash, M. Mani, S. J. Varma, and S. Jayalekshmi, Mater. Chem. Phys. 290, 126647 (2022).

Z. Shen, H. Yang, C. Liu, E. Guo, S. Huang, and Z. Xiong, Carbon 185, 464 (2021).

S. Li, Y. Sun, M. Guan, X. Jiang, and H. Yu, Chem. Eng. J. 462, 141983 (2023).

B. Zhao, M. Hamidinejad, S. Wang, P. Bai, R. Che, R. Zhang, and C. B. Park, J. Mater. Chem. A 9, 8896 (2021).

Y. Zhao, L. Hao, X. Zhang, S. Tan, H. Li, J. Zheng, and G. Ji, Small Sci. 2, 2100077 (2022).

J. J. Licari, Coating Materials for Electronic Applications–Polymers, Processes, Reliability, Testing (William Andrew, Norwich, NY, 2003).

Z. Osawa and S. Kuwabara, Polym. Degrad. Stab. 35, 33 (1992).

S. Uday, H. Chawla, A. Chandra, and S. Garg, in Photocatalysis for Environmental Remediation and Energy Production: Recent Advances and Applications (Springer, 2023), pp. 417–438.

C. Wang, Y. Liu, Y. Sun, L. Cui, and J. Liu, J. Mater. Chem. A 11, 7639 (2023).

A. N. Al-hakimi, F. Alminderej, I. A. Alhagri, S. M. Al-Hazmy, M. O. Farea, and E. M. Abdallah, J. Mater. Sci. Mater. Electron. 34, 238 (2023).

B. Patel, M. Revanasiddappa, S. Yallappa, and D. R. Rangaswamy, J. Mater. Sci. Mater. Electron. 34, 1 (2023).

X. Fu, H. Tong, Y. Wu, K. Zhang, X. Sheng, L. Douadji, G. He, Z. Qiu, B. Zhou, and S. Kang, ACS Appl. Nano Mater. 6, 8772 (2023).

W. Song, X. Zhao, Z. Jin, L. Fan, X. Ji, J. Deng, and J. Duan, J. Clean. Prod. 394, 136390 (2023).

U. Riaz, N. Singh, F. Rashnas Srambikal, and S. Fatima, Polym. Bull. 80, 1085 (2023).

Y. Zhao, H. Liu, Y. Yan, T. Chen, H. Yu, L. O. Ejeta, G. Zhang, and H. Duan, Energy Environ. Mater. 6, e12303 (2023).

T. S. Gaaz, A. B. Sulong, M. N. Akhtar, A. A. H. Kadhum, A. B. Mohamad, and A. A. Al-Amiery, Molecules 20, 22833 (2015).

M. Das and D. Sarkar, Polym. Bull. 75, 3109 (2018).

W. Gan, C. Chen, M. Giroux, G. Zhong, M. M. Goyal, Y. Wang, W. Ping, J. Song, S. Xu, and S. He, Chem. Mater. 32, 5280 (2020).

A. Iqbal, T. Hassan, Z. Gao, F. Shahzad, and C. M. Koo, Carbon 203, 542 (2023).

J. T. Orasugh and S. S. Ray, ACS Omega 8, 8134 (2023).

Y. K. Min, T. Eom, H. Kim, D. Kang, and S.-E. Lee, Polymers 15, 1171 (2023).

J. Yang, Y. Chen, C. Liu, H. Wang, X. Yan, X. Chai, Z. Chen, Y. Xia, H. Gao, and H. Zhang, J. Mater. Res. Technol. 23, 5115 (2023).

T. Kuang, M. Zhang, F. Chen, Y. Fei, J. Yang, M. Zhong, B. Wu, and T. Liu, Adv. Compos. Hybrid Mater. 6, 48 (2023).

J. Srivastava, P. Kumar Khanna, P. V More, and N. Singh, Adv. Mater. Lett. 8, 42 (2017).

A. Olad and S. Shakoori, J. Magn. Magn. Mater. 458, 335 (2018).

X. Tang and K. Hu, Mater. Sci. Eng., B 139, 119 (2007).

Y. Zhu, Y. Pan, H. Xu, and J. Guo, J. Non-Cryst. Solids 355, 785 (2009).

J. Bhadra and D. Sarkar, Indian J. Phys. 84, 1321 (2010).

A. M. Naji, I. Y. Mohammed, S. H. Mohammed, M. K. A. Mohammed, D. S. Ahmed, M. S. Jabir, and A. M. Rheima, Mater. Lett. 322, 132473 (2022).

P. B. Bhargav, V. M. Mohan, A. K. Sharma, and V. V. R. N. Rao, Int. J. Polym. Mater. 56, 579 (2007).

Y. Xia, Z. He, K. Hu, B. Tang, J. Su, Y. Liu, and X. Li, J. Alloys Compd. 753, 356 (2018).

G. M. Elkomy, S. M. Mousa, and H. A. Mostafa, Arab. J. Chem. 9, S1786 (2016).

A. S. Roy, S. Gupta, S. Sindhu, A. Parveen, and P. C. Ramamurthy, Composites, Part B 47, 314 (2013).

M. Hema, S. Selvasekerapandian, G. Hirankumar, A. Sakunthala, D. Arunkumar, and H. Nithya, J. Phys. Chem. Solids 70, 1098 (2009).

W. Chen, X. Li, G. Xue, Z. Wang, and W. Zou, Appl. Surf. Sci. 218, 216 (2003).

S. Mallakpour and F. Motirasoul, Prog. Org. Coatings 103, 135 (2017).

M. Helen, B. Viswanathan, and S. S. Murthy, J. Memb. Sci. 292, 98 (2007).

L. M. Al-Harbi, Q. A. Alsulami, M. O. Farea, and A. Rajeh, J. Mol. Struct. 1272, 134244 (2023).

A. A. Menazea, H. A. Ibrahium, N. S. Awwad, M. E. Moustapha, M. O. Farea, and M. A. Bajaber, J. Mater. Res. Technol. 18, 2273 (2022).

K. Bindu, K. M. Ajith, and H. S. Nagaraja, J. Alloys Compd. 735, 847 (2018).

P. S. Kanavi, S. Meti, R. H. Fattepur, V. B. Patil, S. M. Hunagund, S. A. Patil, and S. R. Inamdar, J. Nanoparticle Res. 24, 1 (2022).

N. Parvatikar, S. Jain, C. M. Kanamadi, B. K. Chougule, S. V Bhoraskar, and M. V. N. A. Prasad, J. Appl. Polym. Sci. 103, 653 (2007).

N. Rezlescu and E. Rezlescu, Phys. Status Solidi 23, 575 (1974).

J. E. Bao, J. Zhou, Z. X. Yue, L. T. Li, and Z. L. Gui, Mater. Sci. Eng. B 99, 98 (2003).

S. Mukherjee, N. M. Anjan Kumar, B. Karthikeyan, and N. Kamaraju, Appl. Phys. A 129, 343 (2023).

M. A. Chougule, G. D. Khuspe, S. Sen, and V. B. Patil, Appl. Nanosci. 3, 423 (2013).

A. Karthikeyan, P. Vinatier, and A. Levasseur, Bull. Mater. Sci. 23, 179 (2000).

D. R. Macfarlane, F. Zhou, and M. Forsyth, Solid State Ionics 113, 193 (1998).

S. Maity and A. Chatterjee, J. Ind. Text. 47, 2228 (2018).

P. Saini and M. Arora, New Polym. Spec. Appl. 3, 73 (2012).

L. Wang, H. Qiu, P. Song, Y. Zhang, Y. Lu, C. Liang, J. Kong, L. Chen, and J. Gu, Composites, Part A 123, 293 (2019).

J.-M. Chiou, Q. Zheng, and D. D. L. Chung, Composites 20, 379 (1989).

A. Das, H. T. Hayvaci, M. K. Tiwari, I. S. Bayer, D. Erricolo, and C. M. Megaridis, J. Colloid Interface Sci. 353, 311 (2011).

S.-T. Hsiao, C.-C. M. Ma, H.-W. Tien, W.-H. Liao, Y.‑S. Wang, S.-M. Li, C.-Y. Yang, S.-C. Lin, and R.‑B. Yang, ACS Appl. Mater. Interfaces 7, 2817 (2015).

J. Ling, W. Zhai, W. Feng, B. Shen, J. Zhang, and W. G. Zheng, ACS Appl. Mater. Interfaces 5, 2677 (2013).

Funding

The authors thank the management of PES University, Electronic City Campus, Bangalore, and the Vision Group on Science and Technology for their support in conducting this research under grant PESUIRF/Chemistry-ECC/2020/14 of September 30, 2020.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rashmi, H.M., Revanasiddappa, M., Ramakrishna, B.N. et al. Electrical Conductivity and EMI Shielding Efficiency of PPY-PVA-Ni Nanocomposite Films. Polym. Sci. Ser. B 65, 963–973 (2023). https://doi.org/10.1134/S1560090423600262

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1560090423600262