Abstract

The results of a study of the rheological properties (shrinkage on heating, viscosity) of porous glasses (PGs) obtained as a result of through acid leaching of two-phase sodium borosilicate glass doped with small additives of P2O5 and fluoride ions, as well as bismuth-containing PGs and quartzoid glasses based on them, depending on the temperature of the heat treatment of the PG and in comparison with the characteristics of the samples obtained from sodium borosilicate glass without additives, are presented. It is found that doping glass with the indicated impurities leads to a decrease in the thermal resistance of the obtained PGs and bismuth-containing PGs. The introduction of bismuth nitrate into PG in the case of the low-temperature treatment (at 120°C) lowers the temperature for the same viscosity values of quartzoid glasses by 15–20°C, in contrast to samples without additives, as well as from higher-temperature treatment (at 650°C) PGs with additives.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

One of the determining factors influencing the formation of bismuth active centers (BACs) in luminescent materials is the composition of the glassy matrix [1–6]. It is known that doping phosphate and phosphorosilicate glasses with bismuth is accompanied by a higher solubility of bismuth and lower temperatures for obtaining such glasses compared to silicate systems, which reduces the loss of bismuth during the synthesis of the glass (see review in [7]). In this case, the effect of the structure of the glassy matrix on the luminescent properties of bismuth-containing phosphate and phosphorosilicate glasses is noted [8–11]. The addition of P2O5 as a dopant effectively increases the light guide gain factor, but can lead to a decrease in the part of BACs responsible for IR luminescence.

To create bismuth-containing luminescent glass materials, the practical significance of which is due to the prospects of their use as preform materials for optical fibers with laser generation in the IR spectral region, high-silica porous glasses (PGs) can be successfully used [12–17]. PGs are obtained as a result of the through leaching of two-phase sodium borosilicate (SBS) glasses in aqueous solutions of mineral acids [18].

It is known that with the same composition of two-phase SBS glass, an increase in the heat treatment temperature (Tt. treat) of the received PG from 120 to 600–750°C leads to an increase in the pore size. All other things being equal, the pore size of PGs obtained by leaching two-phase glasses increases when the glass is alloyed with P2O5 and fluoride ions in comparison with PG made from the basic SBS glass [19, 20]. A larger pore size can contribute to an increase in the amount of incorporated bismuth salts in the PG and, thereby, to a decrease in the viscosity of bismuth-containing glass materials based on them [21]. When fluoride ions are introduced into two-phase SBS glass, the degree of connectivity of the silicon-boron-oxygen framework decreases due to the formation of oxyfluoride polar structural groups [BO3/2F]–, which leads to a decrease in its viscosity, that is, to a decrease in the viscosity of the resulting PG [22]. Reducing the viscosity of the glass makes it easier to pull the fiber from the preforms.

It is of interest to study the rheological properties of samples of bismuth-containing porous glasses (BPGs) and sintered quartz-like glass (BQGs) based on SBS glass doped with P2O5 and fluoride ions, in comparison with the samples obtained based on the basic SBS glass [23], to which this paper is devoted.

EXPERIMENTAL

The objects of study were samples of the PG and BPG based on them. The PG samples (in the form of polished sticks with a cross-sectional size of 3.5 × 3.5 mm2 and 37 mm long) were made according to the previously developed technique by the through leaching of two-phase glass NFF-I (composition according to the analysis, mol %: 6.8Na2O·22.1B2O3·70.4SiO2 0.19P2O5·0.52 |F | [20]) in an aqueous 4 M solution of HNO3 during boiling followed by washing in distilled water and drying at 120°C for 1 hour. The mean diameter D and specific surface Ssp of the pores of the PG samples of a similar thickness (3 mm), obtained from two-phase glass NFF-I, are 10 nm and 65 m2/g, respectively.

Additional processing of PG was carried out in air in a laboratory electric SNOL 6/10 (Russia) furnace at Tt.treat. of 600, 650 or 700°C for 1 hour, which leads to an increase in D and, accordingly, to a decrease in Ssp of the PG pores based on NFF-I glass by a factor of approximately 1.8, 2, or 2.5, respectively. The temperature deviation Tt.treat. from the average value, due to the inertia of the furnace, did not exceed ±10°C. To obtain BPGs, the PG samples were used after isothermal treatment at 120 or 650°C. The samples were impregnated in three stages (for a total of 72 h) in accordance with [14] in a 0.5 M solution of bismuth nitrate prepared based on an aqueous 2 M solution of HNO3 and Bi(NO3)3⋅5 H2O, with intermediate drying between impregnations at ~50°C and final drying at 120°C in an air thermostat. To obtain monolithic quartzoid glasses (QGs and BQGs), the PG and BPG samples were heated in an air atmosphere in an SNOL 6/10 furnace from room temperature to 850°C with isothermal treatment at this temperature for 15 min until the pores collapsed. During the heat treatment of the BPGs, a microcrystalline phase of Bi2O3 oxide was formed in the pores as a result of Bi(NO3)3 thermolysis [14]. Taking into account the data we received earlier, according to which the bismuth content in the BPG (BQG) samples made of NFF-I glass after one-stage (for 24 h) impregnation is ~2 wt % (in terms of Bi2O3), and taking into account that with a threefold increase in the duration of impregnation, the content of bismuth in BPG increases by ~1.4 times [16], it was concluded that the content of bismuth in the studied samples of BPG (BQG) made of NFF-I glass is no less than ~2.8 wt % Bi2O3.

The study of the shrinkage (relative change in linear dimensions ΔL/L0) of the samples and viscosity η during heating was carried out in accordance with the procedure [23] using a KB-1665 vertical quartz viscometer-dilatometer (Russia) with a low measuring force (0.05 N) of the design [24] with automatic recording of the experimental curves at a sample heating rate of 3 K/min from room temperature to ~850°C (sample load 5 g). The regulation and measurement of temperature T were carried out with an accuracy of ±1°C. The viscosity was measured by the rod bending method in the interval 1011–1013 P at T in the range 650–850°С. The error in determining the viscosity did not exceed ±0.05 log (η, P). The linear dependences of the logarithm of viscosity on the reciprocal temperature were constructed using the least squares method and approximation by the Frenkel equation similar to the procedure [23].

RESULTS AND DISCUSSION

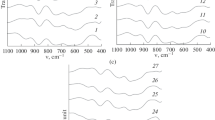

When studying shrinkage upon heating of the PG samples made of NFF-I glass, heat-treated at Tt.treat. = 120, 600, 650, or 700°C, the same tendency which is characteristic for the shrinkage of PG specimens from basic SBS glass [22, 23] was observed. The increase in Tt.treat. ≥ 600°C, which is accompanied by an increase in the size and a decrease in the specific surface area of the PG pores, leads to the fact that the shrinkage of the samples, caused by the onset of the viscous flow process in the silica frame of the PG, begins at higher temperatures (Fig. 1a). This indicates an increase in the viscosity of the framework and is consistent with the main provisions of the theory of sintering glasses with low density, including PGs, based on the Frenkel concept and developed in Scherer’s works (see [25–29] and reviews there), according to which an increase in viscosity, in addition to the indicated change in pore parameters, also causes a decrease in the amount of surface hydroxyl ions, which occurs, as is known, during the high-temperature treatment of PGs [30–32].

Temperature dependences of the relative change in linear dimensions (ΔL/L0) of PG NPF-I samples heat-treated at different temperatures (a, b) Tt.treat., °C: 120 (a, curve 1; b), 600 (a, curve 2), 650 (a, curve 3) and 700 (a, curve 4) before impregnation (a; b, curve 1) and after impregnation (b, curve 2) in Bi (NO3)3 solution.

Comparison with the previously obtained data [23] showed that the shrinkage of PG made of NFF-I glass (Fig. 1a) begins at a temperature ~100°C lower than the shrinkage of PG made of 8B-NT glass (D = 4 nm) [20]. This may be due to the increase in the D pores and loosening of the silicon-boron-oxygen framework due to the formation of groups [BO3/2F]–.

The introduction of bismuth compounds into PG barely changes the temperature of the onset of changes in the linear dimensions of the samples upon heating, but slightly decreases the value of ΔL/L0 (Fig. 1b), which, according to [26], may indicate a lower viscosity of the BPG samples than the PG samples.

Figure 2 shows the temperature dependences of the viscosity (in the heating mode) of the quartzoid glasses QG and BQG from SBS glass NFF-I doped with P2O5 and fluoride ions, depending on the Tt.treat. of the initial PG and in comparison with the data [23] for the samples obtained from the basic SBS glass 8B-NT without the indicated additives.

Temperature dependences of the logarithm of viscosity log (η, P) (in heating mode) of quartzoid glasses based on PG 8V-NT (dependences 1, 2) [23] and PG NFF-I (dependences 3, 4) before impregnation (dependences 1, 3) and after impregnation (dependences 2, 4) in Bi (NO3)3 solution. Heat treatment temperature of PG Tt.treat., °C: 120 (a), 650 (b, dependences 3, 4), 750 (b, dependences 1, 2).

When introducing small additions of phosphorus and fluorine into SBS glass, the viscosity of the obtained quartzoid glasses decreases (Fig. 2a, dependences 1 and 3), which is consistent with the data presented in Fig. 1a, and the results obtained earlier in the study of samples with a smaller cross-sectional area of 2 × 2 mm2 [22]. In Fig. 2a it can be seen that the temperature values at the same viscosity values η = 1013 P (T13) for a QG sample based on 8B-NT glass without additives (dependence 1) are ~70–80°C higher compared to NFF-I glass (dependence 3).

With the same composition of two-phase SBS glass, the increase in Tt.treat. of the PG samples (obtained, respectively, from the SBS glasses of basic or doped compositions) in the studied intervals 120–750°C and 120–650°C barely affects the viscosity of the monolithic QG, i.e., PG sintered until the pores collapse. It can be seen that with increasing Tt.treat. values T13 vary in the intervals 763–759°C and 680–677°C, respectively (Figs. 2a, 2b, dependences 1, 3).

The effect of impregnating the PG in a solution of bismuth nitrate on the viscosity of quartzoid glasses is uncertain and depends on both the glass composition and the temperature of the preliminary heat treatment of the PG (Figs. 2a, 2b, dependences 2 and 4). At a lower Tt.treat. = 120°C (Fig. 2a), the introduction of bismuth into PG lowers the viscosity of BQG based on doped SBS glass (T13 decreases by 15–20°C), in contrast to glass without additives. At a higher Tt.treat. of PG (Fig. 2b), the opposite result is observed: the decrease in the viscosity of the BQG made of doped SBS glass is insignificant (the change in T13 does not exceed 5°C), while in the case of 8B-NT glass, the decrease in the value of T13 of the BQG samples is 10–15°C.

In order to interpret the results obtained, additional studies are required, during which it is necessary to take into account the provisions of the current models of sintering (viscous flow) materials with low density, open porosity, and rigid (not sintered during heating) inclusions (see [25–29] and the reviews in them).

CONCLUSIONS

The rheological properties of PG obtained as a result of leaching two-phase SBS glass doped with small additions of phosphorus oxide and fluoride ions (~0.2 and ~0.5 mol %, respectively), as well as bismuth-containing quartzoid glasses based on it, are studied. The experimental temperature dependences of the shrinkage and viscosity of the PG samples during heating from room temperature to ~850°C, depending on their thermal history and impregnation in a solution of bismuth nitrate, were obtained.

REFERENCES

Firstov, S.V., Alyshev, S.V., Kharakhordin, A.V., Riumkin, K.E., and Dianov, E.M., Laser-induced bleaching and thermo-stimulated recovery of luminescent centers in bismuth-doped optical fibers, Opt. Mater. Express, 2017, vol. 7, no. 9, pp. 3422–3432.

Ignatieva, L.N., Marchenko, Yu.V., Savchenko, N.N., Merkulov, E.B., and Mirochnik, A.G., Bismuth containing fluorozirconate glasses doped with BiPO4. A glass formation, structural, crystallization and luminescent properties, J. Phys. Chem. Solids, 2021, vol. 152, p. 109979-1–109979-6.

Pynenkov, A.A., Nishchev, K.N., Kyashkin, V.M., Tomilin, O.B., Boyarkina, O.V., and Firstov, S.V., Near-infrared luminescent barium gallium-germanate glasses and glass-ceramics doped with bismuth, J. Non-Cryst. Solids, 2018, vol. 480, pp. 111–117.

Romanov, A.N., Haula, E.V., and Korchak, V.N., Formation and optical properties of IR photoluminescence centres in bismuth-containing aluminophosphate glass, Quantum Electron., 2020, vol. 50, no. 10, pp. 910–916.

Savelyev, E.A., Butov, O.V., Yapaskurt, V.O., and Golant, K.M., Near-infrared luminescence of bismuth in silica-based glasses with different additives, J. Commun. Technol. Electron., 2018, vol. 63, no. 12, pp. 1458–1468.

Yu, P., Su, L., Guo, W., and Xu, J., Broadband infrared luminescence in Bi-doped silicate glass, J. Non-Cryst. Solids, 2017, vol. 464, pp. 34–38.

Zhang, Z., Cao, J., Xue, Y., Tan, L., Xu, S., Yang, Z., and Peng, M., Tunable luminescence from bismuth-doped phosphate laser glass by engineering photonic glass structure, J. Am. Ceram. Soc., 2018, vol. 101, no. 5, pp. 1916–1922.

Song, Z., Yang, Z., Zhou, D., Yin, Z., Li, C., Wang, R., Shang, J., Lou, K., Xu, Y., Yu, X., and Qiu, J., The effect of P2O5 on the ultra broadband near-infrared luminescence from bismuth-doped SiO2–Al2O3–CaO glass, J. Lumin., 2011, vol. 131, pp. 2593–2596.

Saitoh, A., Hayashi, K., Hanzawa, K., Ueda, S., Kawachi, S., and Yamaura, J.-I., Ide, K., Kim, J., Tricot, G., Matsuishi, S., Mitsui, K., Shimizu, T., Mori, M., Hosono, H., and Hiramatsu, H., Origins of the coloration from structure and valence state of bismuth oxide glasses, J. Non-Cryst. Solids, 2021, vol. 560, pp. 120720-1–120720-14.

Eltabey, M.M., Rady, K.E., Saad, S.A., and Higazy, A.A., Synthesis and characterization of bismuth phosphate nanoparticle in glass matrix, J. Therm. Anal. Calorim., 2017, vol. 128, pp. 755–764.

Firstova, E.G., Bufetov, I.A., Khopin, V.F., Vel’miskin, V.V., Firstov, S.V., Bufetova, G.A., Nishchev, K.N., Gur’yanov, A.N., and Dianov, E.M., Luminescence properties of IR-emitting bismuth centers in SiO2-based glasses in the UV to near-IR spectral region, Quantum Electron., 2015, vol. 45, no. 1, pp. 59–65.

Zhou, S., Jiang, N., Zhu, B., Yang, H., Ye, S., Lakshminarayana, G., Hao, J., and Qiu, J., Multifunctional bismuth-doped nanoporous silica glass: From blue-green, orange, red, and white light sources to ultra-broadband infrared amplifiers, Adv. Funct. Mater., 2008, vol. 18, no. 9, pp. 1407–1413.

Antropova, T.V., Girsova, M.A., Anfimova, I.N., Golovina, G.F., Kurilenko, L.N., and Firstov, S.V., RF Patent No. 2605711, Byul. Izobret., 2016, no. 36.

Vtyurina, D.N., Romanov, A.N., Zaramenskikh, K.S., Vasil’eva, M.N., Fattakhova, Z.T., Trusov, L.A., Loiko, P.A., and Korchak, V.N., IR luminescence of bismuth-containing centers in materials prepared by impregnation and thermal treatment of porous glasses, Russ. J. Phys. Chem. B, 2016, vol. 10, no. 2, pp. 211–214.

Dianov, E.M., Yang, L., Iskhakova, L.D., Vel’miskin, V.V., Plastinin, E.A., Milovich, F.O., Mashinskii, V.M., and Firstov, S.V., Use of nanoporous glass for the fabrication of heavily bismuth-doped active optical fibres, Quantum Electron., 2018, vol. 48, no. 7, pp. 658–661.

Girsova, M.A., Firstov, S.V., and Antropova, T.V., The influence of the bismuth concentration and heat treatment on the properties of bismuth-containing high-silica glass II: Luminescence properties, Glass Phys. Chem., 2019, vol. 45, no. 2, pp. 98–103.

Iskhakova, L.D., Mashinsky, V.M., Milovich, F.O., Velmiskin, V.V., Plastinin, E.A., Firstov, S.V., Lukashova, M.V., Somov, P.A., and Dianov, E.M., Microstructure, composition, and luminescent properties of bismuth-doped porous glass and optical fiber preforms, J. Non-Cryst. Solids, 2019, vols. 503–504, pp. 28–35.

Antropova, T.V., Inorganic functional glass-forming materials based on eliminating alkali borosilicate systems, in IKhS RAN-80 let. Sovremennye problemy neorganicheskoi khimii (To the 80th Anniversary of the Institute of Glass Chemistry, Russian Academy of Sciences. Modern Problems of Inorganic Chemistry), Shevchenko, V.Ya., Ed., St. Petersburg: Art-Ekspress, 2016, pp. 117–137.

Kreisberg, V.A. and Antropova, T.V., Changing the relation between micro- and mesoporosity in porous glasses: the effect of different factors, Microporous Mesoporous Mater., 2014, vol. 190, pp. 128–138.

Antropova, T.V., Volkova, A.V., Petrov, D.V., Stolyar, S.V., Ermakova, L.E., Sidorova, M.P., Yakovlev, E.B., and Drozdova, I.A., Effect of structure parameters and composition of high-silica porous glasses on their thermal and radiation resistant properties, Opt. Appl., 2005, vol. 35, no. 4, pp. 717–723.

Shilov, A.L., Stolyar, S.V., Stolyarova, V.L., and Ojovan, M.I., The viscosity of Bi2O3-B2O3-SiO2 glasses and melts, Glass Technol.: Eur. J. Glass Sci. Technol., 2019, vol. 60, no. 4, pp. 105–110.

Stolyar, S.V., Antropova, T.V., Petrov, D.V., Anfimova, I.N., viscosity and shrinkage of porous and quartzoid glasses of the Na2O–B2O3–SiO2 system, Russ. J. Appl. Chem., 2008, vol. 81, no. 6, pp. 974–977.

Stolyar, S.V., Antropova, T.V., Girsova, M.A., Konon, M.Yu., Anfimova, I.N., and Kurilenko, L.N., Shrinkage of bismuth-containing porous glass during the sintering process and the viscosity of quartz-like glass based on them, Glass Phys. Chem., 2018, vol. 44, no. 6, pp. 564–568.

Klyuev, V.P. and Chernousov, M.A., Automatic dilatometer with low measuring force, Materialy III Vsesoyuznogo soveshchaniya “Metody i pribory dlya tochnykh dilatometricheskikh issledovanii materialov v shirokom diapazone temperature,” Tezisy dokladov (Proc. III All-Union Conf. “Methods and Devices for Exact Dilatometric Investigations of Materials in a Wide Temperature Range,” Abstracts of Papers), Leningrad, 1984, pp. 53–54.

Scherer, G.W., Sintering of low-density glasses: I. Theory, J. Am. Ceram. Soc., 1977, vol. 60, nos. 5–6, pp. 236–239.

Scherer, G.W. and Bachman, D.L., Sintering of low-density glasses: II. Experimental study, J. Am. Ceram. Soc., 1977, vol. 60, nos. 5–6, pp. 239–243.

Scherer, G.W., Sintering of low-density glasses: III. Eflect of a distribution of pore sizes, J. Am. Ceram. Soc., 1977, vol. 60, nos. 5–6, pp. 243–246.

Scherer, G.W., Viscous sintering of a bimodal pore-sixe distribution, J. Am. Ceram. Soc., 1984, vol. 67, no. 11, pp. 709–715.

Scherer, G.W., Sintering with rigid inclusions, J. Am. Ceram. Soc., 1987, vol. 70, no. 10, pp. 719–725.

Elmer, T.H., Sintering of porous glass, Am. Ceram. Soc. Bull., 1983, vol. 62, no. 4, pp. 513–516.

Ovechko, V.S., Dmytruk, A.M., Fursenko, O.V., and Lepeshkina, T.P., Ellipsometry and spectroscopy of porous glass surfaces, Vacuum, 2001, vol. 61, pp. 123–128.

Antropova, T.V., Baran, J., Gavrilko, T., Gnatyuk, I., Morawska-Kowal, T., Melnik, V., Puchkovska, G., and Vorobjev, V., Interface interactions and optical properties of novel photonics nanocomposites consisting of porous classes doped with organic luminophore molecules, Opt. Appl., 2005, vol. 35, no. 4, pp. 725–733.

Funding

This study was supported by a state assignment of the Institute of Chemistry and Science of the Russian Academy of Sciences and the Russian Ministry of Education and Science, project AAAA-A19-119022290087-1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Antropova, T.V., Stolyar, S.V., Anfimova, I.N. et al. Effect of P2O5 Impurities and Fluoride Ions on The Rheological Properties of Porous Glasses and Bismuth-Containing Composites Based on Them. Glass Phys Chem 47, 329–333 (2021). https://doi.org/10.1134/S1087659621040040

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1087659621040040