Abstract

The explosive development of renewable energy in recent years is reshaping the geopolitical picture of the world. Solar panels and wind turbines have become the symbol of the new energy transition, while lithium-ion batteries have become its basis and the driver of development. It was lithium-ion batteries that made it possible to overcome the main problem of renewable energy – inconstancy and uncontrollability. The article highlights the lithium problem, the reasons for the volatility of lithium prices, the main sources of lithium and the difficulties of its production. In addition, the prospects of development of lithium industry in Russia and current domestic developments in lithium mining technology are considered.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Lithium electric current sources are also an integral part of portable electronics, electric vehicles, and self-driving vehicles that increasingly penetrate our lives. The optimal combination of performance characteristics and great prospects for improving lithium electric current sources allow us to confidently declare that the lithium boom will accompany us throughout the 21st century. Lithium is used not only in the production of batteries, but also in nuclear power industry, pharmaceuticals, metallurgy, as well as in ceramics, glasses, lubricants, and air purification systems.

Renewable energy, portable devices, electric vehicles, drones and, in the basis, lithium—all this will be cornerstone of national economies in the future. Countries that do not possess lithium mining technologies and lithium production facilities will not be able to take a leading position in the coming future. This perspective is understood and realized by developed countries, which spurs the competition of international companies for lithium deposits, in lithium mining technologies and lithium battery production. The greatest successes are achieved in such a struggle with the use of soft power, using various ways of supporting domestic researchers, specialists, companies; attracting highly qualified specialists; applying economic incentive measures (grants, investment, subsidies). Academic mobility with the proper policy of the State allows for “brain leakage” and, reversely, “draining”, stripping the valuable experience of domestic specialists coming from abroad. A clear example of skillful use of academic mobility is set by China, which has been able to develop the domestic technology sector in this way.

The structure of lithium consumption has changed dramatically in recent decades, and currently 80% of all lithium produced goes to the production of lithium-ion batteries (Fig. 1). Such changes, as already mentioned, are associated with their significant role in the new energy transition, lithium often being referred to as new gold or new oil. According to the data from the US Geological Survey, for the period from 2007 to 2022 (Fig. 1), lithium production increased from 25 thousand tons/year to 130 thousand tons/year. The share of lithium used in the production of batteries increased almost linearly from 20 to 80%. It is worth noting that a large demand for lithium is met with a limited supply, which is clearly demonstrated by the exchange commodity price of lithium carbonate (Fig. 2). 2022 became a real indicator of an acute shortage of lithium in the market, the price for it soaring from 33 thousand RMB (minimum 2020) to 600 thousand RMB per ton of Li2CO3. By the beginning of 2023, the price of lithium had adjusted to 160 thousand RMB and went on to a new active growth.

What is the reason for such high volatility of lithium prices despite the fact that lithium is a very common chemical element on Earth (the Clarke number of lithium is 3.2 × 10–3 wt %) and is not considered a rare element? The physicochemical properties of lithium compounds are both its advantage in practical applications and its disadvantage in mining processes. Lithium mining is a very difficult and non-trivial task for the following reasons:

— More than 90% of all lithium on Earth is in the world’s oceans and seawater currently unsuitable for lithium mining.

— The mining technologies are old, the lithium industry still being based on equipment and technologies of the last century.

— There is often a high content of elements similar in properties to lithium in raw materials, which is why the task of extracting lithium is like finding a needle in a haystack.

— A very limited selection of lithium-selective extractants and sorbents.

Problems in lithium mining, combined with high demand, are the cause of lithium shortage and allow, with some reservations, to discuss the problem of lithium mining on a par with the extraction of rare metals and with the separation processes of rare earth elements similar in properties.

The world’s lithium reserves amount to about 230 billion tons, while there are about 65 million tons in mineral resources, of which only 15 million tons are available for operation at the level of modern technologies and economic feasibility (Vikström H. et al., 2013). Lithium in hydromineral resources is estimated at 112 million tons, most of which consist of very poor raw materials bordering on seawater in their composition (Vikström H. et al., 2013).

In Russia, according to the US Geological Survey, there is at least 1 million tons of lithium, in equal shares in mineral and hydromineral resources (Jasinsk S.M., 2023) . Estimates of domestic researchers indicate significantly larger lithium resources in Russia (Boyarko G.Y. et al., 2022, Tolkushina et al., 2012). Proven mineral reserves amount to at least 1.65 million tons. Hydromineral lithium resources have been studied only up to their prediction. According to geophysical data only, lithium reserves at the Znamenskoye deposit alone should be about 4.2 million tons (with a brine volume of 9.8 million tons m3 and an average concentration of 0.42 g/L for lithium) (Tolkushina et al., 2012). Based on these estimates, Russia already ranks 5th among countries in lithium reserves, at the level of China (6.8 million tons) and Australia (7.9 million tons), which are among the top three in its production (Jasinsk S.M., 2023) . Mostly all lithium in Russia should be in hydromineral resources.

The paper (Boyarko G.Y. et al., 2022) presents the most detailed map of the currently explored Russian lithium deposits. Mineral lithium provinces are found on the Kola Peninsula, in the Southern Urals, in the Altai Territory, in the Kemerovo Region, in the Republic of Tyva, in the Eastern Sayan mountains region, the Trans-Baikal Territory and Yakutia, as well as on the border with China in the Jewish Autonomous Region, Khabarovsk and Primorsky Territories. Hydromineral deposits in most cases are groundwater (geothermal and technological brines) are represented by large Crimean-North Caucasian, Caspian and Angara-Lena lithium basins and a number of other individual deposits. Operating lithium mining enterprises are present in the Malyshev settlement (Sverdlovsk region) and at the Znamenskoye deposit. There is information in the media about the organization of production at the Kovykta field and on the Kola Peninsula. It is also worth noting that in the context of the development of lithium topics in Russia and favorable political and economic conditions, more than 100 new exploration projects are currently being actively implemented (Boyarko G.Y. et al., 2022).

In addition to mineral and hydromineral sources, a promising source of lithium is recycled raw materials formed mainly from spent lithium-ion batteries.

It can be calculated that batteries containing in total about 500 thousand tons of lithium have been produced so far. Most of this lithium will form a recycled raw material base, which will grow for some time until the consumer market is saturated and constantly replenished. By organizing the efficient collection and processing of spent lithium-ion batteries, it is possible to close the cycle, ensuring renewable lithium resources.

Mineral lithium raw materials are usually classified according to the content of certain rocks in them. Examples of lithium-containing minerals and their characteristics are presented in Table 1. Amblygonite, eucryptite, lepidolite, petalite, spodumene and zinnvaldite are pegmatites, while hectorite and jadarite are clay-like minerals. From an industrial point of view, the most profitable sources are deposits containing spodumene, which prevail in Russia. In fact, within one deposit there is a whole set of lithium minerals; for example, eucryptite, being formed during natural geological processes and being a byproduct for spodumene, is extremely rich in lithium.

The presented lithium content in each of the minerals corresponds to “pure” mineral, but deposits may obviously contain different amounts of certain minerals and the quality of the deposit depends on the proportion of waste rock, the presence of other valuable components or components that interfere with production, as well as transport accessibility and climatic conditions. Most of the Russian deposits are inferior in all these indicators, for example, to Australian mineral deposits. However, the depletion of the most profitable mineral deposits in other countries is one of the decisive factors in the switch to less profitable deposits typical of Russia.

The degree of lithium extraction from mineral raw materials by classic technologies is 60–70%, and the main production costs are associated with a large reagent and electricity consumption at all stages, including charging, leaching, concentration and carbonate deposition. In lithium mining processes, the issue of selectivity is rarely considered due to the low content of elements similar in properties to lithium. The attention is mainly focused on the stage of ore enrichment and the reduction of energy consumption in leaching processes.

The classification of hydromineral sources of raw materials or hydromineral raw materials (HRM) is more diverse due to their significant differences. Brines from salt lakes contain a large range of cations and anions. As a rule, these are chlorides, sulfates and carbonates of alkaline and alkaline earth metals. In the case of brines containing sulfates and carbonates, or regular washing of sulfate and carbonate rocks, the content of alkaline earth metals may be extremely low, in which case brines mainly contain lithium, sodium and potassium.

A fairly complete classification of HRM is given in (Ryabtsev, 2011). According to this classification, all hydromineral lithium-containing raw materials known in the world can be divided into two large groups: HRM lying in areas with a pronounced arid climate, and HRM lying in areas with a non-arid climate. Further, the author divides the brines into target (lithium content above 0.01 g/L) and non-target (less than 0.01 g/L), based on the possibility of industrial processing of these brines. The target brines are divided into brines with high lithium content (above 0.10 g/L) and brines with low lithium content (0.01–0.10 g/L). Based on the specific composition of each target HRM, it can be divided into raw materials concentrated by evaporation according to the halurgic method to a lithium content of more than 10 g/L (traditional HRM), slightly concentrated to a lithium content of no more than 1.5 g/L and not concentrated by lithium evaporation according to the halurgic method (non-traditional HRM).

In an arid climate, it is possible to organize the concentration of HRM in natural conditions (e.g. helioconcentration) with minimal energy consumption. According to the arid climate map within the Köppen-Geiger climate classification, there are no deposits in Russia that occur in areas with a pronounced arid climate.

Based on the classification considered and the data presented in the literature on the composition of a number of deposits of HRM of Russia (Table 1) it can be concluded that in Russia there is an HRM of sodium chloride and calcium chloride types, occurring in areas of non-arid climate, with lithium content of no more than 0.5 g/ L.

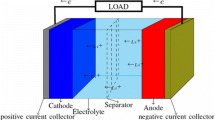

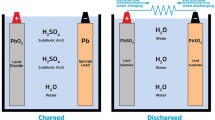

In the case of lithium current sources, the classification of secondary raw materials is much simpler. Batteries are artificial products, and each of them has a known composition (Table 2). According to the principle of their operation, the more common lithium-ion batteries and least common lithium-metal and lithium-air ones can be distinguished. For a long time there were no clear standards and external attributes for lithium batteries, which made them difficult to collect, sort and further recycle. Recently, manufacturers have been striving to produce uniform batteries with a color code that characterizes their qualitative composition. There is a publicly available database created by enthusiasts containing information about cylindrical batteries (Cell Database).

Currently, most of the spent lithium-ion batteries are batteries produced in the period from the 2000s to the 2020s, and they are difficult to sort, so they are usually divided into flat (from mobile phones and some laptops), cylindrical (from electric cars, electronic cigarettes, tools and portable external power sources), as well as laptop batteries. Manual pre-sorting does not always allow you to separate lithium batteries from Ni–Cd batteries, which were previously often used in portable equipment. In the near future, when non-standard batteries are completely out of circulation, their sorting and direct disassembly can be carried out automatically with the secondary use of components and minimal environmental impact.

Thus, there are only 3 sources of lithium: natural and technological brines, mineral or ore deposits, and spent lithium-ion batteries. The technologies of extracting lithium from solid sources include various pyrometallurgical and hydrometallurgical processes. The lithium-containing solutions obtained in this way can be categorized as technological lithium-containing brine. Further recovery of lithium, with some reservations, can be considered in parallel with the recovery of lithium from natural brines.

Where does Russia stand in the lithium issue and what are the prospects? As already mentioned, Russia has large deposits of lithium comparable to the world’s lithium giants. However, in the process of deep structural transformations of the 1990s, the lithium industry stopped in its development. Despite this, the current economic and political conditions contribute to the revival of the Russian lithium industry.

To date, a number of promising projects are known: Rosatom together with Nornickel are planning to create enterprises for extracting lithium from mineral sources of raw materials on the Kola Peninsula, Gazprom together with the Irkutsk Oil Company (INC) are planning lithium production at the Kovykta gas condensate field, and projects for processing spent lithium-ion batteries are also being formed. However, domestic lithium mining technologies, which were actively used during the USSR era, are not currently applicable and might bring small profits. Moreover, no foreign company will sell licenses for truly revolutionary or highly efficient technologies. Also, available foreign technologies can only temporarily satisfy the need for lithium and bring insignificant profits without prospects for development. A solution can be found only in the development of new domestic technologies.

Now there are two lines of development of Russian lithium extraction technologies: sorption and extraction. In particular, one of the relevant solutions offered by Russian specialists is a technology based on aluminum-containing sorbents created in cooperation with Siberian scientists under the supervision of Dr. Natalya Kotsupalo from the Institute of Solid State Chemistry and Mechanochemistry of the Siberian Branch of RAS (ISSCM SB RAS) (Menzheres et al., 2004; Kotsupalo et al., 2013; Ryabtsev et al., 2020). This technology has been actively developing in recent years independently of each other in Ecostar-Nautech LLC and ISSCM SB RAS.

From the point of view of large-scale production, the most promising is the development of lithium extraction processes, since they significantly exceed sorption processes in their productivity. The uniqueness of the extraction method also lies in the fact that it can be used to create a unified lithium extraction technology with a minimum number of processing stages.

The extraction direction is actively developing at the Frumkin Institute of Physical Chemistry and Electrochemistry (IPCE RAS), where a number of new lithium-selective extractants have been developed (Ivanova et al., 2019; Solov’ev et al., 2021; Tsivadze et al., 2022; Bezdomnikov et al., 2023; Kireeva et al., 2023), which, in comparison with existing analogues, have better extraction characteristics and lower cost. On the basis of new lithium-selective extractants, methods have been developed for the selective extraction of lithium from lithium-sodium and lithium-calcium brines, which make up hydromineral lithium sources of raw materials, and are also formed in the processing of mineral raw materials. Thus, the developments of the IPCE RAS allow us to create a wholly extractive technology for lithium extraction from brines (products of leaching of mineral raw materials and spent lithium-ion batteries, associated waters, grouting brines) and natural brines (geothermal waters, salt lakes). The technology has the following advantages:

— High speed, productivity and continuity of the process;

— Significant savings in energy and resources during the concentration and deposition stages;

— Environmental safety and repetitive use of the extractants;

— The possibility of organizing waste-free production;

— High quality (battery grade) of the lithium products obtained;

— Low reagent consumption in comparison with carbonate and sorption processes.

In general, in recent years, more and more scientific groups and organizations have begun to contribute to the development of Russian lithium-related issues, not only in the development of new lithium-selective extractants and methods of lithium extraction (Garipova et al., 2018; Kalmykov et al., 2021; Milevskii et al., 2022; Nesterov and Zakurdaeva, 2022) , but also in the development of lithium electric current sources (Kornev et al., 2022; Kulova et al., 2022; Chirkov et al., 2022a, 2022b). At the same time, the production of electric and self-driving vehicles is actively developing. All these processes lead to an increase in domestic demand and supply of lithium products and open up great prospects for the development of the lithium industry in Russia. The tasks of the State should include increasing support for these initiatives and creating favorable conditions for the development of domestic technologies, science and industry. However, at present, based on the available literature data, it is impossible to conduct a qualitative and quantitative analysis of the technical and economic indicators of the proposed solutions in terms of productivity, manufacturability, cost-effectiveness and environmental friendliness. The time has come to urgently conduct an examination of all proposed solutions at the level of the Russian Academy of Sciences on the basis of developed clear criteria for evaluating the necessary indicators.

REFERENCES

Bezdomnikov, A.A., et al., Liquid extraction of lithium using a mixture of alkyl salicylate and tri-n-octylphosphine oxide, Sep. Purif. Technol, 2023, vol. 320, p. 124137.

Boyarko, G.Y., Khatkov, V.Y., and Tkacheva, E.V., Lithium raw potential in Russia, Bull. Tomsk Polytech. Univ. Geo Assets Eng., 2022, vol. 333, no. 12, pp. 7–16.

Cell Database. https://secondlifestorage.com/index.php?pages/cell-database/.

Chirkov, Yu.G., et al., Galvanostatic discharge of lithium–oxygen battery: the influence of the active layer thickness on the positive electrode characteristics, Russ. J. Electrochem., 2022a, vol. 58, no. 1, pp. 50–59.

Chirkov, Yu.G., Rostokin, V.I., Andreev, V.N., et al., Lithium-air battery: on the possibility of improving the discharge characteristics, Russ. J. Phys. Chem., 2022b, vol. 96, no. 5, pp. 1085–1092.

Garipova, A.R., Kamkina, A.G., Urazgalieva, A.A., et al., Membrane extraction of lithium and sodium ions with 2-ethylhexyl hydrogen [bis(2-ethylhexyl)amino]methylphosphonate acid, Russ. J. General Chem., 2018, vol. 88, no. 1, pp. 120–123.

Ivanova, I.S., et al., 2,4,6-tris[2-(diphenylphosphoryl)-4-ethylphenoxy]-1,3,5-triazine: a new ligand for lithium binding, Inorganica Chim. Acta. Elsevier, 2019, vol. 497, p. 119095.

Jasinsk, S.M., Mineral Commodity Summaries, 2023.

Kalmykov, D., et al., Operation of three-stage process of lithium recovery from geothermal brine: simulation, Membranes (Basel), 2021, vol. 11, no. 3, pp. 1–21.

Kireeva, N., Baulin, V.E., and Tsivadze, A.Y., A machine learning-based study of Li+ and Na+ metal complexation with phosphoryl-containing ligands for the selective extraction of Li+ from brine, Chem. Eng., 2023, vol. 7, no. 3, p. 41.

Kornev, P.V., Kulova, T.L., Kuz’mina, A.A., et al., Europium-doped lithium titanate as a material for the anodes of lithium-ion batteries, Russ. J. Phys. Chem., 2022, vol. 96, no. 2, pp. 437–443.

Kotsupalo, N.P., Ryabtsev, A.D., Poroshina, I.A., et al., Effect of structure on the sorption properties of chlorine-containing form of double aluminum hydroxide, Russ. J. Appl. Chem., 2013, vol. 86, no. 4, pp. 482–487.

Kulova, T.L., Skundin, A.M., Gavrilin, I.M., et al., Binder-free Ge–Co–P anode material for lithium-ion and sodium-ion batteries, Batteries, 2022, vol. 8, no. 8, p. 98.

Menzheres, L.T., Ryabtsev, A.D., Mamylova, E.V., Selective sorbent for lithium extraction from highly mineralized brines, Izv. Tomsk. Politekhn. Univ., 2004, vol. 307, no. 7, pp. 76–80.

Milevskii, N.A., Zinovieva, I.V., Zakhodyaeva, Yu.A., and Voshkin, A.A., Separation of Li(I), Co(II), Ni(II), Mn(II), and Fe(III) from hydrochloric acid solution using a menthol-based hydrophobic deep eutectic solvent, Hydrometallurgy, 2022, vol. 207, p. 105777.

Nesterov, S.V. and Zakurdaeva, O.A., Targeted preparation of highly efficient lithium extractants based on 14-membered crown ethers, Mendeleev Commun., 2022, vol. 32, no. 5, pp. 670–671.

Ryabtsev, A.D., Pererabotka litienosnogo polikomponentnogo gidromineral’nogo syr’ya na osnove ego obogashcheniya po litiyu (Processing of Lithium-Bearing Polycomponent Hydromineral Raw Material Based on Lithium Enrichment), Novosibirsk, 2011.

Ryabtsev, A.D., et al., Scientific principles of production of sorbent selective to lithium and industrial technology of extraction of lithium chloride from hydromineral polycomponent raw material, Tekhnol. Inorg. Veshch. Mater., 2020, no. 8, pp. 338–352.

Solov’ev, V., Baulin, D., and Tsivadze, A., Design of phosphoryl containing podands with Li+/Na+ selectivity using machine learning, SAR QSAR Environ. Res., 2021, vol. 32, no. 7, pp. 521–539.

Tolkushina, E.A., Torikova, M.V., Komin, M.F., Mineral-raw lithium base: problems of development and application, Geologorazved. Syr’ev. Baza, 2012, vol. 2, p. 7.

Tsivadze, A.Yu., Bezdomnikov, A.A., Baulin, V.E., et al., A new extraction system based on isopropyl salicylate and trioctylphosphine oxide for separating alkali metals, Molecules, 2022, vol. 27, no. 10, p. 3051.

Vikström, H., Davidsson, S., and Hook, M., Lithium availability and future production outlooks, Appl. Energy. Elsevier Ltd, 2013, vol. 110, pp. 252–266.

Wang, X., Gaustad, G., Babbitt C.W., et al., Economic and environmental characterization of an evolving li-ion battery waste stream, J. Environ. Manag., 2014, vol. 135, pp. 126–134.

Funding

This work was supported by the Ministry of Science and Higher Education of Russian Federation (grant no. 122011300052-1).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tsivadze, A.Y., Bezdomnikov, A.A. & Kostikova, G.V. The Lithium Boom: Lithium Sources and Prospects for the Russian Lithium Industry. Geol. Ore Deposits 65, 463–468 (2023). https://doi.org/10.1134/S1075701523050094

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1075701523050094