Abstract

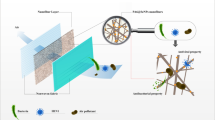

Air pollution is an increasing concern all over the world due to its adverse effects on human health. It claims thousands of lives every year. Hence, the demand for the ventilator, respirator, facemask, body protection, and hospital air filtration has been surging dramatically during the COVID-19 pandemic. Nanofiber membranes with optimal characteristics, such as a high specific surface area and porous microstructure with interconnected pores, can efficiently capture the fine particles (such as bacteria, fungi, virus, etc.). Recently, various types of polymers have been fabricated as electrospun fibrous membranes to be used as an anti-bacterial or anti-viral air filtration media. This review presents a brief overview of air filtration history and its main mechanisms and then the latest research about air filtration with antibacterial and antiviral properties will be reviewed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Outbreak of the infectious SARS-CoV2 disease has drastically affected health of the global population, causing long time effects on respiratory systems of the human body [1]. From another point of view, air, widespread with bioaerosols ranging from airborne viruses, bacteria, fungi, to pollens, ensues in various diseases including allergies when inhaled. Low settling velocity and minute size of the particles are the major reason for these particles to remain in the atmosphere for a longer duration than other aerosols [2–4]. In addition, nanoparticles are able to penetrate into the lower respiratory system due to their small size and cause undesired effects on lung tissue and other target organs that may cause allergies or respiratory infectious diseases, e.g., lung cancer, chronic obstructive pulmonary disease, or asthma [5]. So professional mask and indoor air filtration are a better choice to capture different air pollutants (such as bacteria, fungi, virus, etc.) [6]. The efficacy of an air filter depends on the type of air pollutant and can be tuned by the pollutant capturing mechanism [7]. Nowadays, researchers are trying to produce multifunctional filtering media for simultaneous removal of air contaminants. Nanofiber filter media provide the potential to produce multifunctional filter media because of their special properties [5]. The generated nanofibers have important characteristics such as large aspect ratio, high oxygen-permeable porosity, good mechanical properties and the possibility to incorporate active components on a nanoscale which can cover variety of applications such as filtration, tissue engineering, wound dressing, and functional materials [8–19]. Functional nanofibers are now recognized as efficient materials for the treatment of the environmental problems. The resulting product can be an excellent filter medium for air purification [20]. In the current review, we summarized the filtration mechanism and going to focus on the various types of the electrospun nanofibrous membranes for different contributions to remove pathogens by an overview to some recent research trends regarding modification of electrospun nanofibres for air filtration application. Finally, the conclusion about this review will be presented while addressing remaining problems and future challenges.

Nanotechnology in the Air Filtration Industry: History

The development of air filter media has been ongoing for two thousand years, and the history of fibrous filters has been elaborated in detail by Davies [21]. The development of nanofibre filter media for air filtration dates back to 1939 when Nathalie D. Rozenblum and Igor V. Petryanov-Sokolov developed the Petryanov filter (PF) in Russia [22]. They produced electrospun fiber mats that were used as filters in gas masks. They used cellulose acetate as the base material [23]. After the Second World War, the Russians set up five enterprises to manufacture these filters to capture radioactive aerosols in nuclear power plants. The first submicron fiber filtration media was commercialized in the USA by Donaldson Co. in the 1980s. In Europe, the commercial production of fibers by electroforming method started in 1990s by “Freudenberg” [24]. Since then, the technique has been adopted by many industries and research groups and has undergone massive improvements to suit different filtration markets [25].

Mechanism of Filtration Process

Air filtration media have been in use for a thousand years, but essential studies on filtration mechanisms were proposed only in the past century [26]. The mechanism of aerosol particle filtration mainly depends on fiber diameter, airflow velocity, and particle size [27]. Conventional filtering materials’ filtration mechanism is the result of various kinds of synthesized effects, such as the inertial effect, the diffusion effect, the interception effect, the electrostatic effect, gravity, the thermophoresis effect, etc., of which the first three are the predominantly govern filtration mechanisms [28].

Inertial impaction. Inertial impaction occurs when a particle is so large that it is unable to quickly adjust to the abrupt changes in streamline direction near a filter fiber [29]. For particles greater than about 0.5 μm diameter, inertial impaction is usually the primary collection mechanism [30]. Particles at a certain velocity tend to remain at velocity and travel in a continuous direction [31]. Figure 1 illustrates this mechanism.

Diffusion. When the particle size is very small (0.1 μm), Brownian motion of the particle plays a major role in increasing the collection efficiency by diffusion [32]. This mechanism due to Brownian motion do not follow the streamlines of the flow and may diffuse from the flow to the fibers and deposit (Fig. 2). The intensity of the Brownian motion increases for smaller particles and as a consequence so does the efficiency of removal [33].

Interception. Interception occurs when a particle follows the air stream line and makes a physical contact onto the media fiber [34]. Particles can be captured by the fibers due to Van der Waals’s attraction between the particles and the fibers. This mechanism is usually effective for 0.1 to 1 µm particles. Reducing the fiber size and increasing the specific surface of the fibers enhance the capturing efficiency of the particles (Fig. 3) [35].

Electrostatic attraction. If the particles in the air stream have the opposite charge of the fibers, they will be attracted by the fibers and deposit on them (Fig. 4) [35, 36]. Electret filters clearly perform better than mechanical filters and does not increase pressure drop across the filter medium [37]. Charge retention ability is reported to depend on the electrical properties of polymers such as conductivity and dielectric constants [34]. This filtration mechanism is widely used to capture particles having submicrometer diameters [26].

Gravitational effect. Particles will deviate from the streamline under the influence of gravity when they pass through fibrous layers, which means they will deposit on fiber surface by gravitational deposition [29]. However, the effect of the gravitational force seems to be the minimal among the above-mentioned effects since the particles are so tiny and the sedimentation can be thoroughly ignored when the particles are smaller than 0.5 μm (Fig. 5) [37].

Thermophoresis (thermal precipitation). One of the earliest techniques relied on the thermophoresis principle, in which bioaerosol particles are passed through a narrow channel with a temperature gradient perpendicular to the flow [38]. On entering the temperature gradient, the airborne particles tend to move away from the hot surface towards the cooler surface and depositing over it, a phenomenon known as thermophoretic motion. Although its collection efficiency for smaller particles (from b0.01 μm to 5 μm) is high yet its collection rate is very low in comparison to other samplers ranging from 7 cm3 min−1 to 1 L min−1 Thus this mechanism is not commonly used in industries (Fig. 6) [39].

Polymeric nanofiber-based filters. The main shortcoming of filters is the creation of a pressure drop that requires much energy to overcome this problem [40]. In addition, these fiber filters usually suffer from the disadvantages of large pore size and low porosity due to their microsized diameters [26]. Nanofilters have higher efficiency than conventional filters; with pores between 1 and 10 nm, can remove different kinds of bacteria, viruses, and organic contaminants effectively [40]. Hence while ambient microbial aerosol and droplets can be filtered by the particulate filtration mechanism, more research attention was drawn to develop antimicrobial [41–43] and antiviral [44–46]. Usually, three strategies have been applied to make antimicrobial filters: (1) Using polymers with inherent antimicrobial properties; (2) Introducing nanoparticles that have an antimicrobial effect on the membrane. This can be achieved by blending the nanoparticles to the polymer before making the filter or coating the polymeric membrane with the nanoparticles; (3) Coating the filter with the bio-antibacterial molecules [35]. The antimicrobial fibers are commonly based on the bactericidal effect of incorporated agents that disrupt the cell membrane. As antimicrobial agents, metals such as Ag, Au, and Cu, and photocatalytic metal oxides such as TiO2, ZnO, and MgO are commonly employed. When the metal type is used, the metal ions and the reactive oxygen species are released from the metal oxidation, and they cause cell death by damaging the proteins of membranes [34]. It should be noted that the filtration efficiency can be controlled by stacking the multiple layers of nanofiber from thicker to thinner one. For increasing the efficiency of the charged multilayer nanofiber filter without increasing the pressure drop, the suitable strategy used in this regard is to decrease the basis weight for each layer. Also, among the recent studies, Charging the nanofiber filter with electrostatic charge enhances the capture of nano-aerosols [47]. Examples of antiviral nanomaterials include but are not limited to silver nanomaterials, gold nanomaterials, copper nanomaterials, titanium oxide nanomaterials, zinc oxide nanomaterials, and carbon-based nanomaterials. Firstly, nanoparticles such as silver and copper nanoparticles can inactivate viruses by disrupting the invasion of viruses into cell receptors through interaction with surface proteins or envelopes of viruses, as shown in Fig. 7, owing to the hydrophobic and negatively charged surface of viruses, hydrophobic and electrostatic interaction is predominantly contributed to adsorption between viruses and other solid surfaces (Table 1) [48].

Scheme illustrating working principle of virucidal nanomaterial for inactivation of viruses. A mechanism of blocking the replication of virus by nanoparticles [48].

Antibacterial air filter. The pollutants in the air include not only particulate matter but also a large number of microorganisms that cannot be filtered by conventional air filtration membrane. Up to now, various types of polymers have been fabricated as electrospun nanofiber membranes to be used as an effective air filtration media. Here, we briefly explain some recent research trends regarding modification of electrospun nanofibers for this aim.

In [49] an ethanolic extract of Sophora flavescens, which exhibits great antibacterial activity against pathogens, were mixed with polymer solution for the electrospinning process. The HEI nanofibers had a smooth surface, smaller diameter, thermal stability, and better packing density than the control fibers. The electrical conductivity of the HEI polymer was higher than control polymer solution. The filtration efficiency and antimicrobial activity of the HEI nanofiber air filter were 99.9 and 99.5%, respectively, against S. epidermidis bioaerosols. The pressure drop across the HEI nanofiber air filter was 4.75 mmH2O at a face air velocity of 1.79 cm/s. They concluded that the herbal extract/polymer hybrid nanofiber in air filtration may have the potential to control indoor air quality against hazardous bioaerosols [49]. In another study Lubasová et al. synthetized soy protein isolate (SPI)/polyethylene-oxide (PEO) by electro-spinning process. The resulted nanofiber filter consisted of a single nanofiber layer grafted to the filter paper base. SEM result demonstrated SPI/PEO nanofiberous membrane has a structure without beads. They found out that bacterial filtration efficiency values were 100, 53, and 21% for filter paper covered by nanofibers, filter paper without nanofibers and commercial filter Energy Aire®, respectively. SEM images showed that the nanofiber-based filter was very effective in catching E. coli present in the air and most of the bacteria were attached to the fibers (Fig. 8) [50].

SEM of bacteria after filtration on: (a) commercial filter, (b) filter paper covered by nanofibers, (c) filter paper [50].

Also, Li et al. fabricated poly(lactic acid) (PLA)/chitosan composite air filter using the one-step electrospinning technique. According their result, when the chitosan concentration was 20% in the fiber, the chitosan nanoparticles were evenly inlaid on the surface of the fiber without agglomeration. Antibacterial test showed that when the mass ratio of chitosan to PLA was 2.5:8, the PLA/chitosan fibrous membrane exhibited an inhibition of 99.4 and 99.5% against E. coli and S. aureus, respectively and a relatively low pressure drop of 147.60 Pa. [51]. In another study, Selvam et al. prepared electrospun polyacrylonitrile (PAN) nanofibers by incorporating different weight percentages of silver (Ag) nanoparticles. According their results, pure PAN nanofiber had no inhibition zones against both S. aureus and E. coli. inhibition zone of different lengths in increasing order was observed for the PAN/Ag nanofiber with 5, 10, and 15 wt % of Ag. The change in the inhibition zone length in increasing order signifies the antibacterial activity due to increase in the amount of Ag nanoparticles in the nanofibers. The PAN/Ag-15 % nanofibers showed antibacterial efficiency of 66 and 78% for S. aureus and E. coli, respectively. Also, their result showed that PP spun bonded nonwoven of 50–55 gsm, electrospinning time of 2–2.5 h and Ag% of 10–12.5 it is possible to achieve 99% filtration efficiency with good antibacterial property against both gram positive and gram-negative bacteria [52]. Kharaghani et al. in other research designed and synthesized polyacrylonitrile/silver (PAN/AgNPs) nanofibers via an in-situ method. For this objective, the electrospun PAN nanofibers were stabilized via the heating method. Different amounts of AgNPs were loaded into the PAN nanofibers by using silver nitrate and sodium hydroxide solutions. Their results showed that the treated nanofibers with AgNPs have an effective antibacterial activity against Pseudomonas and Staphylococcus bacteria but it also shows that AgNPs presence in the nanofiber matrix has more effect against Pseudomonas than against Staphylococcus. They proved that PAN/AgNPs nanofibers, which were fabricated with one cycle loading AgNPs (2247 ppm/g nanofiber) made ideal membranes for the preparation of a washable antibacterial mask [53]. In another investigation, keratin was extracted from coarse wool and then, an Ag-doped keratin/Polyamide 6 (PA6) composite nanofiber membrane with enhanced filtration and antibacterial performance was prepared by shen et al. In this system, both keratin and doped AgNPs could change the viscosity and conductivity of the composite solution and can affect the diameter of nanofibers. The nanofiber membranes of Ag. 10%–Ker.30%/PA6 maintained a high level of antibacterial effectiveness, and the bacterial inhibition rate against S. aureus (E. coli) decreased from 99.62% (99.10%) to 96.7% (95.4%). It could be attributed to the antibacterial properties of doping silver ions decaying very slowly with the filter materials worn out. keratin as a dopant with polyamide-6 was found not only to improve air filtration efficiency but also to enhance water–vapor transmission. Bacterial filtration efficiency (BFE) of the composite membrane against S. aureus and E. coli were up to 96.8 and 95.6%, respectively [54]. In a study that performed by Swamidoss V. et al. Polyvinylidene fluoride (PVDF) nanofibers produced using electrospinning method blended with silver nanoparticles (AgNO3) of varying weight percentages of filler. Polypropylene (PP) non-woven substrate was used as base material for collecting the nanofibers and a barrier to protect the fibers. Zone of Inhibition test revealed that pure PVDF has minimum amount of antibacterial activity due to its inbuilt electrostatic property on both gram-positive and gram-negative bacteria. The bactericidal activity was found to increase with increase in silver nanoparticles concentration of the sample and 15 wt % of silver showed maximum antibacterial activity in the respective time period (Fig. 9). The results point out to the achievement of 99.86% of bacterial filtration efficiency by areal density of 60 GSM, electrospinning time of 3 h and silver nanoparticle concentration of 15 wt % [55].

Zone of inhibition produced by PVDF + 0 wt % Ag and PVDF + Ag nanofibers (5, 10, 15 wt %) against Gram positive and negative bacteria for 24 h [55].

Fang et al. prepared a biodegradable and multifunctional air filtration membrane by electrospinning of soy protein isolate (SPI)/polyvinyl alcohol (PVA) system. The tensile strength of pure PVA nanofibers and the samples with low content of SPI was relatively high. But when the SPI content was elevated, the tensile strength of the nanofiber membranes showed a continuous declining trend due to the increase of brittleness and the local incompatibility of two kinds of polymer materials. There were a lot of polar functional groups on the surface of the SPI/PVA hybrid nanofibers, which were beneficial to high efficiency filtration of fine particles. The loading filtration efficiency of nanofiber membranes with optimized SPI/PVA proportion (2 : 1) can reach 99.99% after 30 min test for fine particles smaller than 2.5 mm while keeping a small pressure drop. Also, SPI/PVA (2 : 1) nanofibers showed an inhibiting effect on Escherichia coli bacteria, and bacteria inhibiting loop can be formed surrounding the circular membrane (Fig. 10) [56].

Antibacterial activity of (a) blank sample, (b) pure PVA nanofiber membrane and (c) SPI/PVA (2 : 1) nanofiber membrane against Escherichia coli [56].

In another study, Wang et al. synthetized bifunctional nanofiber mats consisting of chitosan (CS), poly(vinyl alcohol) (PVA), and silver nanocrystals (AgNCs) by electrospinning method. Their results indicated that CS/PVA nanofiber mats had the proper bactericidal properties, and CS/PVA nanofiber mats with 2, 4, and 8 wt % Ag NCs inactivated all of the bacteria at a concentration of 2 × 105 cfu mL–1 all of the AgNCs/CS/PVA nanofiber mats could prevent different levels of E. coli for initial colony densities at least up to 2 × 108 cfu mL–1. All of the AgNCs/CS/PVA nanofiber mats had outstanding antibacterial activity, because AgNCs are lethal to bacteria. Filtration results showed that with the filtration time increasing to 600 min, the color of the nanofiber mats gradually became tan in color (insets), and the suspended particulate matter (SPM) filtration efficiency was still greater than 98%, which was much more efficient than ordinary commercial dust masks (76%) [57]. Zhang et al. in an investigation synthesized A novel N-halamine biopolymer, P(ADMH-NVF), via a free-radical copolymerization of N-vinylformamide (NVF) and 3-allyl-5,5-dimethylhydantoin (ADMH), and combined with polyvinyl alcohol (PVA) as a middle layer [PVA/P(ADMH-NVF)]. Polyvinyl alcohol/chitosan electrospun membranes (PVA/CS) were then orderly assembled onto both sides of the (PVA/P(ADMH-NVF)) membranes to form multilayer membranes (Fig. 11). On the multilayer membrane, the intermediate layer is PVA/P(ADMH-NVF) membrane playing a leading role in antibacterial function, while the membranes on both sides are PVA/CS membranes as the enhancement and auxiliary antibacterial layers. the multilayer membranes with a basis weight of 2.1 g/m2 could reach a standard and high filtration efficiency of 99.3% for NaCl and 99.4% for DEHS particles, while holding a relatively low pressure drop of 183 Pa for NaCl and 238 Pa for DEHS particles. Furthermore, antibacterial assays suggest that chlorinated multilayer membranes have antibacterial ability against E. coli and S. aureus [58].

Schematic illustration of fabrication of the multilayer membranes and application on the antibacterial air filtration [58].

Son et al. produced activated carbon (AC)/poly-urethane (PU) nanofibers containing cinnamon oil (CO) via electrospinning. Antibacterial activity was investigated with different contain of activated carbon and cinnamon oil (1 : 3, 1 : 4) in AC/CO/PU nanofibrous by inhibition zone test. In order to increase the amount of essential oil contained in nanofibers, it was adsorbed on activated carbon and then mixed with PU solution for electrospinning. The results of nanofibers containing 10 and 15 wt % of cinnamon oil in the PU solution are shown in Figs. 12a, 12c. Antibacterial activity started to appear from 15 wt % of cinnamon oil. According to the filtration efficiency results, the filter efficiencies were increased to 61.9, 68.16, and 68.23%, respectively, as the contain of activated carbon increased. Also, the pressure drop was 13.56, 12.7, and 8.8 Pa, and it decreased with increasing the amount of activated carbon [59].

Zones of inhibition of (a, b) E. coli and (d, e) S. aureus and zone of inhibition diameter graph (c, f) [59].

Also, in another research, Victor et al. electrospun polyvinylidene fluoride (PVDF) blended with varying concentrations of titanium nanotubes (TNT) to result in ananocomposite filter media. Antibacterial and zone of inhibition studies revealed that the prepared filter media was highly efficient against both Escherichia coli and Staphylococcus aureus. In this study, it was found that 15 wt % of the filler proved for the highest bacterial filter efficiency of 99.88% [60].

Antiviral air filter. Many types of filters with nano-coating have been used for inactivating the viruses. But compared to nanofiber antibacterial air filters, very little number of studies has been done in order to fabricate anti-viral nanofiber air filtration with the ability to capture and inactivate virus particles. In recent years, after the corona epidemic, anti-viral filtration has become one of the most essential challenges we face. In the following, we will evaluation latest research in this regard.

In [29] poly(ε-caprolactone) (PCL)/zein/Ag nanoparticle (AgNP) fibrous membranes were prepared by ultrasonication-assisted electrospinning using different ultrasonication times and AgNP loadings. E. coli phage was used as a double-stranded DNA virus model to investigate the antiviral activities of PCL/zein/1%Ag-30 and PCL/zein membranes. The results demonstrated that the above-mentioned membrane exhibited a 97.1 ± 2.1% virus removal efficiency after 60 min. The high performance of this bead-on-string membrane for air filtration was ascribed to the low packing density due to the presence of open interconnected beaded airflow channels and small beads. According their results, this membrane showed >97% filtration capacity for particles with the sizes of 0.3, 0.5, and 1.0 mm [61]. Wang et al. fabricated an air filtration system by electrospinning a polyvinylidene fluoride (PVDF, 15 wt %) solution onto a layer of polypropylene fabrics (PP, basic protection face mask). A three-layer non-woven surgical mask, a three-layer woven cotton mask, and a one-layer woven polyester neck gaiter were selected as representative commercial face masks because of their wide availability, extensive use, and distinct properties. The fabricated electrospun air filters were designated as PVDF20 and PVDF30, respectively. To increase the binding between coronavirus and air filters by electrostatic attraction and promote virus removal efficiency, a positive or negative charged polyelectrolyte, i.e., poly(ethyleneimine) (PEI) or poly(vinyl phosphonic acid) (PVPA), was coated onto PVDF20, and the fabricated filters were denoted as PVDF20/PEI and PVDF20/PVPA, respectively. They reported that increase of electrospinning duration and thickness of the air filters enhanced coronavirus aerosol removal (99.9% and 99.1% for PVDF30 and PVDF20, respectively), though there was a marginal decrease of the pore size of PVDF30 compared to PVDF20. Polyelectrolyte coating did not promote electrospun air filters for removing coronavirus aerosols, and the average filtration efficiency for PVDF20/PEI and PVDF20/PVPA was 99.1% and 95.7%, respectively [62]. Also, Shen et al. a homogeneous electrospinning dope solution containing of polyvinylidene difluoride (PVDF) and a dye photosensitizer in N,N-dimethylformamide/acetone was electrospun onto one layer of polypropylene (PP) fabrics (basic protection face mask). The filtration efficiency for murine hepatitis virus A59 (MHV-A59) aerosols was on par with that for removing NaCl aerosols (99.1%, p > 0.05), and it was much higher compared with filtration efficiency of MHV-A59 aerosols by commercial masks, including a surgical mask (98.2%), a cotton mask (73.3%), and a neck gaiter (44.9%). The excellent aerosol filtration efficiency was resulted from the ultrafine nanofibers and the small pore size of the electrospun membrane. Also, Photosensitized electrospun membranes showed excellent performance for capturing and killing coronavirus aerosols, i.e., they removed 99.2% of MHV-A59 aerosols, and inactivated 98.9% of MHV-A59 droplets only after 15 min of desk lamp irradiation [63]. Buluş et al. in another study, 1, 5, and 8% activated charcoal (AC) reinforced polylactic acid (PLA) nanofiber membranes produced by electrospinning technique (Fig. 13). According to the tensile test values of the membranes, 10% PLA-8% AC was the highest strength value. The most important reason for this is that it has the thinnest nanofiber structure and the orientation of the fibers. It has been determined that it is above ≥98 in terms of filtration efficiency. When the results of the study are evaluated, PLA-AC composites have ideal material properties that can be preferred in an ideal filtration membrane for long-term use for the use of the whole society, especially healthcare workers, as protective equipment, especially in the COVID-19 pandemic [64].

Process steps of the production of composites with electrospinning technique [64].

CONCLUSIONS

Wherever filtration is required, the nanofiber has a significant role to play. Using finer fibers to create greater breathability or use less energy is an appealing factor. We have discussed the properties that can influence nanofibers’ bactericidal effects, such as its (1) morphology including size, diameter and porosity, (2) the surface charge of the nanofibers, and (3) surface wettability. However, it has been proven that nanofibers are not able to fight bacteria alone. The addition of antimicrobial agents and surface modification via functionalized groups is strongly required to enhance the antibacterial or antiviral activity of nanofibers and create filters with enhanced filtration efficiencies and the selective adsorption of particles. This study contributes to the development of effective nanofiber filtration materials and for this purpose, it was essential to understand the filtration mechanisms and nanofiber air filtration advantages in order to provide a basis. Then, we summarize recent studies about antibacterial and antiviral air filters based on electrospun nanofibers and their unique characteristics to increase filtration performance, which can support the other research groups in this field. In terms of environmental pollution, more efforts are needed to develop reusable filters and preferably from biopolymers of renewable raw materials and biowaste. The use of bio- and biodegradable polymers helps to protect the environment, because the resources on earth are limited. Also, the next phase of growth could be in functional, “intelligent” filters that selectively capture pollutants of challenge (VOCs, microbes and viruses, heavy metals, etc.) using active ingredients. They also solve the growing problem of overloading and biofouling of filters by extending the life of the filter and improving energy efficiency.

REFERENCES

Patil, N.A., Gore, P.M., Prakash, N.J., Govindaraj, P., Yadav, R., Verma, V., Shanmugarajan, D., Patil, S., Kore, A., and Kandasubramanian, B., Chem. Eng. J., 2021, p. 416. https://doi.org/10.1016/j.cej.2021.129152

Victor, F.S., Kugarajah, V., Bangaru, M., Ranjan, S., and Dharmalingam, S., Environ. Sci. Pollut. Res., 2021, vol. 28, p. 28. https://doi.org/10.1007/s11356-021-13202-3

Zhu, M., Han, J, Wang, F., Shao, W., Xiong, R., Zhang, Q., and Huang, C., Macromol. Mater. Eng., 2017, vol. 302, no. 1. https://doi.org/10.1002/mame.201600353

Leung, V. and Ko, F., Polym. Adv. Technol., 2011, vol. 22, no. 3, pp. 681–694. https://doi.org/10.1002/pat.1813

Mohraz, M.H., Golbabaei, F., Yu, I.J., Mansournia, M.A., Zadeh, A.S., and Dehghan, S.F., Int. J. Environ. Sci. Technol., 2019, vol. 16, no. 2. https://doi.org/10.1007/s13762-018-1649-3

Wang, C.S. and Otani, Y., Ind. Eng. Chem. Prod. Res., 2013, vol. 52, no. 1, pp. 5–17. https://doi.org/10.1021/ie300574m

Kadam, V.V., Wang, L., and Padhye, R.J., Ind. Text., 2018, vol. 47, no. 8, pp. 2253–2280. https://doi.org/10.1177/1528083716676812

Habibi, S. and Hajinasrollah, K., Russ. J. Appl. Chem., 2018, vol. 91, no. 5, pp. 877–881. https://doi.org/10.1134/S1070427218050191

Koosha, K., Habibi, S., and Talebian, A., Russ. J. Appl. Chem, 2017, vol. 90, no. 10, pp. 1640–1647. https://doi.org/10.1134/S1070427217010135

Elhami, M., and Habibi, S., J. Vinyl Add. Tech., 2021, vol. 27, no. 1, pp. 89–96. https://doi.org/10.1002/vnl.21786

Hajinasrollah, K., Habibi, S., and Nazockdast, H., J. Eng. Fibers Fabr. 2019, vol. 14. https://doi.org/10.1177/1558925019881142

Habibi, S., Saket, M., Nazockdast, H., and Hajinasrollah, K., J. Text. Inst., 2019, vol. 110, no. 11. https://doi.org/10.1080/00405000.2019.1613029

Ghajarieh, A., Habibi, S., and Talebian, A., Russ. J. Appl. Chem., 2021, vol. 94, no. 7, pp. 847–872. https://doi.org/10.1134/S1070427221070016

Wahab, J.A. and Al Mamun, S., Mater. Res. Express, 2020, vol. 7, no. 1. https://doi.org/10.1088/2053-1591/ab6c26

Lim, C.T., Prog. Polym. Sci., 2017, vol. 70, pp. 1–17. https://doi.org/10.1016/j.progpolymsci.2017.03.002

Islam, M.S., Ang, B.C., Andriyana, A., and Afifi, A.M., SN Appl. Sci., 2019, vol. 1, no. 10, pp. 1–16. https://doi.org/10.1007/s42452-019-1288-4

Nadaf, A., Gupta, A., Hasan, N., Ahmad, S., Kesharwani, P., and Ahmad, F.J., RSC Adv., 2022, vol. 12, no. 37, pp. 23808–23828. https://doi.org/10.1039/D2RA02864F

Bansal, P. and Purwar, R., Fibers Polym., 2021, vol. 22, no. 10, pp. 2726–2737. https://doi.org/10.1007/s12221-021-0914-0

Yu, J., Tian, X., Xin, B., and Xu, J., Fibers Polym., 2021, vol. 22, no. 9, pp. 2413–2423. https://doi.org/10.1007/s12221-021-1123-6

Wang, L., Zhang, C., Gao, F., and Pan, G., RSC Adv., 2016, vol. 6, no. 107, pp. 105988–105995. https://doi.org/10.1039/C6RA24557A

Davies, C.N., Air Filtration, New York: Academic Press, 1973.

Nascimento, M.L.F., Araujo, E.S, Cordeiro, E.R., HP de Oliveira, A., and P de Oliveira, H., Recent Pat. Nanotechnol., 2015, vol. 9, no. 2, pp. 76–85.

Tabe, S., J. Membr. Sci. Res., 2017, vol. 3, no. 3, pp. 228–239. https://dx.doi.org/10.22079/jmsr.2017.56718.1124

Barhate, R.S. and Ramakrishna, S., J. Membr. Sci., 2007, vol. 296, no. 1–2, pp. 1–8. https://doi.org/10.1016/j.memsci.2007.03.038

Poudyal, A., Beckermann, G.W., Chand , N.A., Hosie, I.C., Blake, A, and Kannan, B., Electrospun Nanofibre Filter Media: New Emergent Technologies and Market Perspectives, Filtering Media by Electrospinning, Springer, Cham, 2018. https://doi.org/10.1007/978-3-319-78163-1_9

Zhang, S., Rind, N., Tang, A.N., Liu, H., Yin, X., Yu, J., and Ding, B., Electrospun Nanofibers for Air Filtration, In Electrospinning: Nanofabrication and Applications, Amsterdam: William Andrew Publishing, 2019. https://doi.org/10.1016/B978-0-323-51270-1.00012-1

Lu, T., Cui, J., Qu, Q., Wang, Y., Zhang, J., Xiong, R., and Huang, C., ACS Appl. Mater. Interfaces, 2021, vol. 13, no. 20, pp. 23293–23313. https://doi.org/10.1021/acsami.1c06520

Liu, G., Xiao, M., Zhang, X., Gal, C., Chen, X., Liu, L., Pan, S., Wu, J., Tang, L. and Clements-Croome, D., Sustainable Cities Soc., 2017, vol. 32, pp. 375–396. https://doi.org/10.1016/j.scs.2017.04.011

Xu, Z., Filtration Mechanism of Fine Particle, Fundamentals of Air Cleaning Technology and Its Application in Clean Rooms, Berlin: Springer, 2014. https://doi.org/10.1007/978-3-642-39374-7_3

Miller, B., Sustainable Cities Soc., 2017.

Gaurav, K., Mittal, G., and Karn, A., Abstracts of Papers, International Conference on Advances in the Field of Health, Safety, Fire, Environment and Allied Sciences, 2020, pp.179–196. https://doi.org/10.1007/978-981-16-8270-4_13

Oh, Y.W., Jeon, K.J., Jung, A.I., and Jung, Y.W., Aerosol Sci. Technol., 36, no. 5, 2002, pp. 573–582. https://doi.org/10.1080/02786820252883810

Dunnett, S., Aerosol Sci. Technol. Appl., 2013, pp. 89–117. https://doi.org/10.1002/9781118682555.ch5

Jung, S. and Kim, J., Polym., 12, no. 8, 2020, p. 1714. https://doi.org/10.3390/polym12081714

Borojeni, I.A., Gajewski, G., and Riahi, R.A., Fibers, 2022, vol. 10, no. 2, p. 15. https://doi.org/10.3390/fib10020015

Rubenstein, D.I., and Koehl, M.A., Am. Nat., 1977, vol. 111, no. 981, pp. 981–994.

Lv, D., Zhu, M., Jiang, Z., Jiang, S., Zhang, Q., Xiong, R., and Huang, C., Macromol. Mater. Eng., 2018, vol. 303, no. 12. https://doi.org/10.1002/mame.201800336

Gollakota, A.R., Gautam, S., Santosh, M., Sudan, H.A., Gandhi, R., Jebadurai, V.S., and Shu, C.M., Gondwana Res., 2021, vol. 99, pp. 178–203.

Ghosh, B., Lal, H., and Srivastava, A., Environ. Int., 2015, vol. 85, pp. 254–272. https://doi.org/10.1016/j.envint.2015.09.018

Taran, M., Safaei, M., Karimi, N., and Almasi, A., Biointerface Res. Appl. Chem., 2021, vol. 11, no. 1, pp. 7860–7870. https://doi.org/10.33263/BRIAC111.78607870

Zhang, H., Jia, L., Li, P., Yu, L., Liu, Y., Zhao, W., Wang, H., and Li, B., Appl. Polym. Mater., 2022, vol. 4, no. 3, pp. 2081–2090. https://doi.org/10.1021/acsapm.1c01916

Xiao, Y., Wang, Y., Zhu, W., Yao, J., Sun, C., Militky, J., Venkataraman, M., and Zhu, G., Sep. Purif. Technol., 2021, vol. 259. https://doi.org/10.1016/j.seppur.2020.118135

Kumar, S., Jang, J., Oh, H., Jung, B.J., Lee, Y., Park, H., Yang, K.H., Chang Seong, Y., and Lee, J.S., ACS Appl. Nano Mater., 2020, vol. 4, no. 3, pp. 2375–2385. https://doi.org/10.1021/acsanm.0c02366

Ju, Y., Han, T., Yin, J., Li, Q., Chen, Z., Wei, Z., Zhang, Y., and Dong, L., Bumpy. Sci. Total Environ., 2021, vol. 777. https://doi.org/10.1016/j.scitotenv.2021.145768

Joe, Y.H., Woo, K., and Hwang, J., J. Hazard. Mater., 2014, vol. 280, pp. 356–363. https://doi.org/10.1016/j.jhazmat.2014.08.013

Tian, C., Wu, F., Jiao, W., Liu, X., Yin, X., Si, Y., Yu, J., and Ding, B., Compos. Commun., 2021, vol. 24. https://doi.org/10.1016/j.coco.2021.100668

Jazie, A.A., Albaaji, A.J., and Abed, S.A., Air Qual. Atmos. Health, 2021 , vol. 14, no. 11, pp. 1811–1824. https://doi.org/10.1007/s11869-021-01055-1

Alayande, A.B., Kang, Y., Jang, J., Jee, H., Lee, Y.G., Kim, I.S., and Yang, E., Membranes, 2021, vol. 11, no. 7, p. 458. https://doi.org/10.3390/membranes11070458

Choi, J., Yang, B.J., Bae, G.N., and Jung, J.H., ACS Appl. Mater. Interfaces, 2015, vol. 7, no. 45, pp. 25313–25320. https://doi.org/10.1021/acsami.5b07441

Lubasová, D., Netravali, A., Parker, J., and Ingel, B., 4th International Nanoconference, 2012.

Li, H., Wang, Z., Zhang, H., and Pan, Z., Polymers, 2018, vol. 10, no. 10, p. 1085. https://doi.org/10.3390/polym10101085

Selvam, A.K. and Nallathambi, G., Fibers Polym., 2015, vol.16, no. 6, pp. 1327–1335. https://doi.org/10.1007/s12221-015-1327-8

Kharaghani, D., Khan, M.Q., Shahzad, A., Inoue, Y., Yamamoto, T., Rozet, S., Tamada, Y., and Kim, I.S., J. Nanomater., 2018, vol. 8, no. 7, p. 461. https://doi.org/10.3390/nano8070461

Shen, B., Zhang, D., Wei, Y., Zhao, Z., Ma, X., Zhao, X., Wang, S., and Yang, W., Polymers, 2019, vol. 11, no. 9, p. 1511. https://doi.org/10.3390/polym11091511

Swamidoss, V. Felix, Bangaru, M., Nalathambi, G., Sangeetha, D., and Selvam, A.K., Aerosol Sci. Technol., 2019, vol. 53, no. 2, pp. 196–206. https://doi.org/10.1080/02786826.2018.1554892

Fang, Q., Zhu, M., Yu, S., Sui, G., and Yang, X., Mater. Sci. Eng., B, 2016, vol. 214, pp. 1–10. https://doi.org/10.1016/j.mseb.2016.08.004

Wang, D., Lu, Q., Wei, M., and Guo, E., Appl. Polym. Sci., 2018, vol. 135, no. 28. https://doi.org/10.1002/app.46504

Zhang, L., Li, L., Wang, L., Nie, J., and Ma, G., Appl. Surf. Sci., 2020, vol. 515. https://doi.org/10.1016/j.apsusc.2020.145962

Son, B.C., Park, C.H., and Kim, C.S., J. Nanosci. Nanotechnol., 2020, vol. 20, no. 7, pp. 4376–4380. https://doi.org/10.1166/jnn.2020.17597

Victor, F.S., Kugarajah, V., Bangaru, M., Ranjan, S., and Dharmalingam, S., Environ. Sci. Pollut. Res., 2021, pp. 1–14. https://doi.org/10.1007/s11356-021-13202-3

Liu, Y., Li, S., Lan, W., Hossen, M.A., Qin, W., and Lee, K., Mater. Today Adv., 2021, vol. 12. https://doi.org/10.1016/j.mtadv.2021.100173

He, Y., Zhang, W., Ma, J., Xia, Q., Song, Z., Zhu, L., Zhang, C., Liu, J., Ye, Y., Fu, P.P., and Zhuge, Y., Environ. Sci. Technol. Lett., 2021, vol. 8, no. 7, pp. 551–557. https://doi.org/10.1021/acs.estlett.1c00359

Shen, H., Zhou, Z., Wang, H., Chen, J., Zhang, M., Han, M., Shen, Y., and Shuai, D., Environ. Sci. Technol., 2022, vol. 56, no. 7, pp. 4295–4304. https://doi.org/10.1021/acs.est.2c00885

Buluş, E., Buluş, G.S., and Yakuphanoglu, F., J. Mater. Electron. Device, 2020, vol. 4, no. 1, pp. 21–26.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Habibi, S., Ghajarieh, A. Application of Nanofibers in Virus and Bacteria Filtration. Russ J Appl Chem 95, 486–498 (2022). https://doi.org/10.1134/S1070427222040036

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427222040036