Abstract

Multiblock (segmented) copoly(urethane–imides) were prepared using as monomers toluene 2,4-diisocyanate-terminated aliphatic polyether and polyester [poly(propylene glycol), poly(1,6-hexanediol/neopentylene glycol-alt-adipic acid)], aromatic diamines [1,4-bis(4'-aminophenoxy)biphenyl sulfone or 4,4'-bis(4''-aminophenoxy)biphenyl in a mixture with 3,5-diaminobenzoic acid], and 1,3-bis(3',4-dicarboxyphenoxy)benzene dianhydride. Each of the polymers contains two structurally different soft polyether/polyester segments and two identical hard imide segments, into one of which the reactive carboxy group is introduced. The covalent cross-linking of the copolymers was performed by the reactions of the carboxy groups with aromatic diisocyanates (toluene 2,4-diisocyanate, biphenylmethane 4,4'-diisocyanate) and 1,2,5,6-diepoxycyclooctane. The cross-linked polymer systems obtained were studied by thermal gravimetric analysis, differential scanning calorimetry, and dynamic mechanical analysis. The kind of cross-linking agent influences the properties of cross-linked copoly(urethane–imides). Variation of the mechanical loss tangent tan δ and width of the temperature interval of the transition from glassy to rubber-elastic state in relation to the chemical structure of copoly(urethane–imides) was analyzed. For the polymers under consideration, the maximal tan δ values exceed 0.3, which indicates that these polymers exhibit the damping ability.

Similar content being viewed by others

REFERENCES

Gerkin, R.M. and Hilker, B.L., Encyclopedia of Materials: Science and Technology, Jürgen Buschow, K.H., Ed., Amsterdam: Elsevier, 2001. https://doi.org/10.1016/B0-08-043152-6/00140-6

Eisenbach, C.D. and Cronski, W., Chem. Rapid Commun., 1983, vol. 4, pp. 707–713. https://doi.org/10.1002/marc.1983.030041103

Didenko, A.L., Kuznetcov, D.A., Smirnova, V.E., Popova, E.N., Vaganov, G.V., Ivanov, A.G., Yudin, V.E., Svetlichnyi, V.M., and Kudryavtsev, V.V., Russ. Chem. Bull., 2020, vol. 69, no. 2, pp. 369–377. https://doi.org/10.1007/s11172-020-2769-8

Xiao, C., Bai, Y., Pu, Y., Luo, H., Xiao, S., and He, B., J. Appl. Polym. Sci., 2020, ID e49363. https://doi.org/10.1002/app.49363

Kuznetsov, D.A., Svetlichnyi, V.M., Didenko, A.L., Vaganov, G.V., Elokhovskii, V.Yu., Kudryavtsev, V.V., and Yudin, V.E., Russ. J. Appl. Chem., 2020, vol. 93, no. 10, pp. 1491–1497. https://doi.org/10.1134/S107042722010002X

Patent RU 2279452, Publ. 2006.

Vasnev, V.A. and Kuchanov, S.I., Russ. Chem. Rev., 1973, vol. 42, no. 12, pp. 1020–1033. https://doi.org/10.1070/RC1973v042n12ABEH002782

Didenko, A.L., Ivanov, A.G., Bogdanova, E.A., Smirnova, V.E., Vaganov, G.V., Popova, E.N., Kuznetsov, D.A., Kobykhno, I.A., Vasiliyeva, E.S., Tolochko, O.V., Svetlichniy, V.M., Yudin, V.E., and Kudryavtsev, V.V., Russ. Chem. Bull., 2021, vol. 70, pp. 1746–1756. https://doi.org/10.1007/s11172-021-3279-z

Didenko, A.L., Smirnova, V.E., Popova, E.N., Vaganov, G.V., Kuznetcov, D.A., Elokhovskiy, V.Y., Ivanov, A.G., Svetlichnyi, V.M., Yudin, V.E., and Kudryavtsev, V.V., Russ. J. Appl. Chem., 2020, vol. 93, no. 1, pp. 45–56. https://doi.org/10.1134/S107042722001005X

Thompson, J.M., Infrared Spectroscopy, Pan Stanford, 2018, p. 195.

Zimmer, B., Nies, С., Schmitt, C., and Possart, W., Polymer, 2017, vol. 11, pp. 77–95. https://doi.org/10.1016/j.polymer.2017.03.02

Rasa, A., Abstracts of Papers, Proc. Inter-Noise-2014, Melbourne, Nov. 16–19, 2014. https://www.acoustics.asn.au/conference_proceedings/INTERNOISE2014/papers/p426.pdf.

Yurkin, Yu.V., Mansurova, I.A., Belozerov, V.S., and Zlobina, A., Mater. Plast., 2018, vol. 55, no. 4, pp. 469–473. https://doi.org/10.37358/MP.18.4.5055

Volotskoi, A.N., Yurkin, Yu.V., and Avdonin, V.V., Elektron. Nauchn. Zh. Inzh. Vestn. Dona, 2019, no. 8. http://www.ivdon.ru/uploads/article/pdf/IVD_77__7y2019_volotsoy_yurkin_avdonin_2.pdf_df6a067d49.pdf.

Kobykhno, I.I., Honcharenko, D., Didenko, A.L., Kudryavtsev, V.V., Vasilyeva, E., and Tolochko, O., Mater. Today: Proc., 2020, vol. 30, pp. 393–397. https://doi.org/10.1016/j.matpr.2019.12.383

Author information

Authors and Affiliations

Contributions

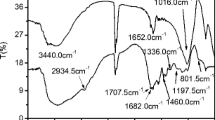

A.L. Didenko: participation in setting the tasks of the research and interpreting its results, general planning of the research and coordination of the work of all the participants, suggestion and trials of modified procedures for preparing the polymers and forming polymer film samples in accordance with the preset polymer architecture, and principal participation in writing the manuscript. A.G. Ivanov: instrumental study of the chemical structure of the synthesized polymers by IR spectroscopy, interpretation of the results, and preparation of the corresponding part of the paper. E.G. Bogdanova: synthesis of covalently cross-linked polymers, preparation of polymer film samples for studies by physical methods, instrumental study of the temperature dependence of the mechanical loss coefficient of film samples, interpretation of the results obtained, and participation in writing the corresponding part of the paper. V.E. Smirnova: instrumental study of the mechanical properties of the polymers under the conditions of dynamic tests, interpretation of the results obtained, and participation in writing the corresponding part of the paper. G.V. Vaganov: instrumental study of the mechanical properties of polymers under the conditions of dynamic tests, interpretation of the results obtained, participation in writing the corresponding part of the paper. E.N. Popova: instrumental study of the heat resistance of the polymers by thermal gravimetric analysis and differential scanning calorimetry, interpretation of the results obtained, and participation in writing the corresponding part of the paper. D.A. Kuznetsov: synthesis of physically cross-linked polymers, preparation of polymer film samples for study by physical methods, identification of the chemical structure of all the synthesized polymers by NMR, determination of the intrinsic viscosity of the physically cross-linked polymers, and preparation of the Experimental section of the paper. I.A. Kobykhno: participation in setting the tasks of the study, evaluation of the performance of the polymers as vibration-damping materials based on the results of mechanical loss studies, and participation in writing the paper. E.S. Vasil’eva: analysis of variation of the mechanical loss tangent in relation to the polymer structure (architecture), participation in writing the paper. O.V. Tolochko: setting of the task of preparing polymers combining enhanced heat resistance with high values of the mechanical loss coefficient, implemented in the study, and participation in writing the paper. V.M. Svetlichnyi: consulting of synthetic chemists in the field of nontrivial polycondensation synthesis involving two comonomers and two intermonomers, used in the study, and participation in setting the tasks and writing the paper. V.E. Yudin: adjustment of procedures for studying the physical properties of the newly synthesized polymers, taking into account specific features of their structure (architecture), summation of the results obtained by the research participants to ensure the study integrity, and participation in setting the tasks and writing the paper. V.V. Kudryavtsev: substantiation of the research concept, participation in setting the objective and tasks of the study and in interpretation of results in all the steps of the study, analysis and summation of relevant published data, and participation in writing the paper. All the coauthors actively participated in discussion of the results obtained and in formulation of the conclusions.

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated from Zhurnal Prikladnoi Khimii, No. 9, pp. 1164–1185, January, 2021 https://doi.org/10.31857/S0044461821090073

Rights and permissions

About this article

Cite this article

Didenko, A.L., Ivanov, A.G., Bogdanova, E.A. et al. Synthesis, Heat Resistance, and Mechanical Properties of Cross-Linked Urethane–Imide Copolymers Containing Blocks of Two Structurally Different Aliphatic Fragments (Polyether and Polyester) in the Backbone. Russ J Appl Chem 94, 1240–1258 (2021). https://doi.org/10.1134/S107042722109007X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S107042722109007X