Abstract

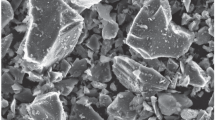

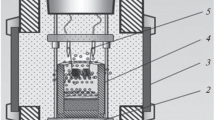

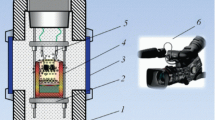

Using the method of self-propagating high-temperature synthesis (SHS metallurgy), cast composite materials were produced in the Cr–Ti–B system. The experiments were carried out in universal SHS reactors with an initial argon pressure of Рin = 5 MPa. Mixtures of CaCrO4, TiO2, Al, and B powders were used as batch. It was shown that by varying the mass ratio α of CaCrO4/2Al/2B and 3TiO2/4Al/6B mixtures in a batch, it is possible to significantly affect the synthesis patterns, phase composition, and microstructure of the target products. The initial mixtures are capable of burning in the range of α 0–20%. The phase separation limit occurs at α = 15%. The introduction of a highly exothermic CaO2 + Al additive into the mixture made it possible to expand the phase separation limit to α = 20%. As α increases, the amount of titanium boride in the final product increases. The resulting composite material consists of titanium-chromium boride distributed in a matrix of chromium boride. The synthesized materials were characterized by X-ray and local microstructural analysis. The structural phase states of the target products produced under various conditions were studied.

Similar content being viewed by others

REFERENCES

Momozawa, A. and Telle, R., Vacuum, 2019, vol. 167, pp. 577–585. https://doi.org/10.1016/j.vacuum.2018.06.036

Jordan, L.R., Betts, A.J., Dahm, K.L., Dearnley, P.A., and Wright, G.A., Corrosion Sci., 2005, vol. 47, no. 5, pp. 1085–1096. https://doi.org/10.1016/j.corsci.2003.10.018

Samsonov, G.V., Serebryakova, T.I., and Neronov, V.A., Boridy (Borides). Moscow: Atomizdat, 1975.

Iizumi, K., Kudaka, K., Maezawa, D., Sasaki, T., J. Ceram. Soc. Japan, 1999, vol. 107, no. 1245, pp. 491–493. https://doi.org/10.2109/jcersj.107.491

Evtushok, T.M., Grigor’ev, O.N., Kostenko, A.D., Zhunkovskii, G.L., Kotenko, V.A., and Mazur, P.V., Powder Metallurgy Metal Ceram., 2005, vol. 44, no. 7–8, pp. 353–357. https://doi.org/10.1007/s11106-005-0102-6

Murthy, T.S.R.Ch., Sonber, J.K., Sairam, K., Bedse, R.D., and Chakarvartty, J.K., Mater. Today: Proceedings, 2016, vol. 3, no. 9, pp. 3104–3113. https:// doi.org/10.1016/j.matpr.2016.09.026 .

Arestov, O.V. and Ruzhitskaya, E.V., Vestnik inzhenernoi shkoly DVFU, 2012, no. 4(13), pp. 20–26.

Gorshkov, V.A. and Yukhvid, V.I., Abstract of Papers, 3-ya Mezhdunar. konf. “Materialy i pokrytiya v ekstremal’nykh usloviyakh: issledovaniya, primenenie, ekologicheskie chistye tekhnologii proizvodstva i utilizatsii izdelii” (Int. Conf. “Materials and Coatings in Extreme Conditions: Research, Application, Environmentally Friendly Technologies for the Production and Disposal of Products”), Katsiveli-Ponizovka, 2004.

Shcherbakov, V.A., Gryadunov, A.N., Sachkova, N.V., and Samokhin, A.V., Lett. Mater., 2015, vol. 5, no. 1, pp. 20–23. https://doi.org/10.22226/2410-3535-2015-1-20-23

Ziemnicka-Sylwester, M., Ceram. Mater. Energy Applications IV, 2014, vol. 35, no. 7, pp. 127–138. https://doi.org/10.1002/9781119040323.ch12

Xu, Q., Zhang, X.H., Han, J.C., and He, X.D., Key Eng. Mater., 2007, vol. 280–283, pp. 1441–1444. https://doi.org/10.4028/www.scientific.net/KEM.280-283.1441

Andreev, D.E, Sanin, V.N., Yukhvid, V.I., and Kovalev, D.Yu., Combustion, Explosion, and Shock Waves, 2011, vol. 47, no. 6, pp. 671–676. https://doi.org/10.1134/S0010508211060074

Levashov, E.A., Rogachev, A.S., Kurbatkina, V.V., Maksimov, Yu.M., and Yukhvid, V.I., Perspektivnye materialy i tekhnologii samorasprostranyayushchegosya vysokotemperaturnogo sinteza (Promising Materials and Technologies for Self-Propagating High-Temperature Synthesis), Moscow: Izd. Dom MISiS, 2011.

Salnikow, K. and Zhitkovich, A., Chem. Res. Toxicol., 2008, vol. 21, pp. 28–44. https://doi.org/10.1021/tx700198a

Miloserdov, P.A., Yukhvid, V.I., Gorshkov, V.A., Ignat’eva, T.I., Semenova, V.N., and Shchukin, A.S., Combustion, Explosion, and Shock Waves, 2017, vol. 53, no. 6, pp. 665–668. https://doi.org/10.1134/S0010508217060065

Miloserdov, P.A., Yukhvid, V.I., Gorshkov, V.A., Kovalev, I.D., and Miloserdova, O.M., Int. J. Self-Propagating High-Temperature Synthesis, 2018, vol. 27, no. 2, pp. 123–126. https://doi.org/10.3103/S1061386218020139

Shiryaev, A.A., Int. J. Self-Propagating High-Temperature Synthesis, 1995, vol. 4, no. 4, pp. 351–362.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

ACKNOWLEDGMENTS

To perform the research, the equipment of the ISMAN Distributed Center for Collective Use was involved.

FUNDING

This work was financially supported by the grant of the Russian Foundation for Basic Research no. 18-08-00804.

CONFLICT OF INTERESTS

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Miloserdov, P.A., Gorshkov, V.A., Sachkova, N.V. et al. Synthesis of Composite Materials in the System Cr–Ti–B by the Self-Propagating High-Temperature Synthesis from Mixtures CaCrO4/TiO2/Al/B. Russ J Appl Chem 93, 362–368 (2020). https://doi.org/10.1134/S1070427220030076

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1070427220030076