Abstract

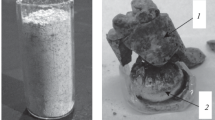

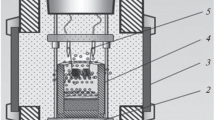

High-temperature synthesis of cast composite materials in the Cr–Mn–Al–C system with various ratios between the Cr2AlC MAX phase and chromium and manganese aluminides and carbides was studied. Experiments were performed in a universal 3-L reactor under argon pressure Р = 5 MPa. Mixtures of powders of chromium(III) and manganese(II, IV) oxides and calcium peroxide with aluminum (ASD-I) and carbon were used as a charge. The synthesis features and the phase composition and microstructure of the target products are significantly influenced by the reactant ratio in the charge. At the stoichiometric ratio of the components corresponding to the Cr2AlC phase, a cast composite material consisting of the Cr2AlC MAX phase, chromium carbides Cr7C3 and Cr3C2, and chromium aluminide Cr5Al8 is formed. In the course of combustion of the charge with the component ratio corresponding to the Mn2AlC phase, a cast composite material consisting of manganese carbides (Mn3AlC, Mn0.545Al0.42C0.035) and aluminide (MnAl) is formed. When these compositions are combined in an 0.75 : 0.25 ratio, the final product is a composite material consisting of a solid solution based on the Cr2AlC MAX phase, manganese carbides (Mn3AlC), and chromium aluminides (Cr2Al). When these compositions are combined in an 0.5 : 0.5 ratio, the final product is a composite material consisting of the manganese-doped Cr2AlC MAX phase and of manganese (Mn14Al86, Mn22.5Al77.5) and chromium (Cr5Al8) aluminides. The final products were characterized by X-ray diffraction and local microstructural analysis.

Similar content being viewed by others

REFERENCES

Kieffer, R. and Benezovsky, F., Hartmetalle, Vienna: Springer, 1965.

Guilemagy, J.M., Espallargas, N., Suegama, P.H., and Benedetti, A.V., Corr. Sci., 2006, vol. 48, no. 10, pp. 2998–3013. https://doi.org/10.1016/j.corsci.2005.10.016

Burkhanov, G.S., Milyaev, I.M., and Yusupov, V.S., Perspekt. Mater., 2011, no. 11, pp. 208–215.

Barsoum, M.W., Prog. Solid State Chem., 2000, vol. 28, pp. 201–281. https://doi.org/10.1016/S0079-6786(00)00006-6

Hettinger, J.D., Lofland, S.E., Finkel, P., Meehan, T., Palma, J., Harrell, K., Gupta, S., Ganguly, A., El-Raghy, T., and Barsoum, M.W., Phys. Rev. B, 2005, vol. 72, ID 115120. https://doi.org/10.1103/PhysRevB.72.115120

Tian, W.B., Wang, P.L., Zhang, G., Kan, Y., Li, Y., and Yan, D., Scripta Mater., 2006, vol. 54, pp. 841–846. https://doi.org/10.1016/j.scriptamat.2005.11.009

Lin, Z., Zhou, Y., and Li, M., J. Mater. Sci. Technol., 2007, vol. 23, no. 6, pp. 721–746.

Schneider, J.M., Sun, Z., Mertens, R., Uestel, F., and Ahuja, R., Solid State Commun., 2004, vol. 130, no. 7, pp. 445–449. https://doi.org/10.1016/j.ssc.2004.02.047

Tian, W., Vanmeensel, K., Wang, P., Zhang, G., Li, Y., Vleugels, J., and Van der Biest, O., Mater. Lett., 2007, vol. 61, no. 22, pp. 4442–4445. https://doi.org/10.1016/j.matlet.2007.02.023

Xiao, Li.O., Li, S.B., Song, G., and Sloof, W.G., J. Eur. Ceram. Soc., 2011, vol. 31, no. 8, pp. 1497–1502. https://doi.org/10.1016/j.jeurceramsoc.2011.01.009

Panigrahi, B.B., Chu, M.C., Kim, Y.I., Cho, S.J., and Gracio, J.J., J. Am. Ceram. Soc., 2010, vol. 93, no. 6, pp. 1530–1533. https://doi.org/10.1111/j.1551-2916.2009.03560.x

Xiao, D., Zhu, J., Wang, F., and Tang, Y., J. Nanosci. Nanotech., 2015, vol. 15, pp. 7341–7345. https://doi.org/10.1166/jnn.2015.10590

Duan, X., Shen, L., Jia, D., Zhou, Y., Zwaag, S., and Sloof, W.G., J. Eur. Ceram. Soc., 2015, vol. 35, no. 5, pp. 1393–1400. https://doi.org/10.1016/j.jeurceramsoc.2014.11.008

Tian, W.B., Sun, Z.M., Du, Y., and Hashimoot, H., Mater. Lett., 2008, vol. 62, no. 23, pp. 3852–3855. https://doi.org/10.1016/j.matlet.2008.05.001

Jaouen, M., Bugnet, M., Jaouen, N., Ohresser, P., Mauchamp, V., Cabioćh, T., and Rogalev, A., J. Phys.: Condens. Matter, 2014, vol. 26, ID 176002. https://doi.org/10.1088/0953-8984/26/17/176002

Lin, S., Huang, Y., Zu, L., Kan, X., Lin, J., Song, W., Tong, P., Zhu, X., and Sun, Y., J. Alloys Compd., 2016, vol. 680, pp. 452–461. https://doi.org/10.1016/j.jallcom.2016.04.197

Hamm, C.M., Bocarsly, J.D., Seward, G., Kramm, U.I., and Birke, C.S., J. Mater. Chem. C, 2017, vol. 5, no. 23, pp. 5700–5708. https://doi.org/10.1039/C7TC00112F

Merzhanov, A.G., J. Mater. Chem., 2004, vol. 14, no. 12, pp. 1779–1786. https://doi.org/10.1039/B401358C

Levashov, E.A., Mukasyan, A.S., Rogachev, A.S., and Shtansky, D.V., Int. Mater. Rev., 2016, vol. 62, no. 4, pp. 203–239. https://doi.org/10.1080/09506608.2016.1243291

Gorshkov, V.A., Miloserdov, P.A., Luginina, M.A., Sachkova, N.V., and Belikova, A.F., Inorg. Mater., 2017, vol. 53, no. 3, pp. 271–277. https://doi.org/10.1134/S0020168517030062

Gorshkov, V.A., Miloserdov, P.A., Sachkova, N.V., Luginina, M.A., and Yukhvid, V.I., Russ. J. Non-Ferrous Met., 2018, vol. 59, no. 5, pp. 570–575. https://doi.org/10.3103/S106782121805005X

Funding

The study was financially supported by the Russian Foundation for Basic Research (project no. 19-08-00053).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated from Zhurnal Prikladnoi Khimii, No. 1, pp. 13–20, January, 2021 https://doi.org/10.31857/S0044461821010023

Rights and permissions

About this article

Cite this article

Gorshkov, V.A., Miloserdov, P.A., Khomenko, N.Y. et al. High-Temperature Synthesis of Composite Materials Based on MAX Phases in the Cr–Mn–Al–C System. Russ J Appl Chem 94, 9–16 (2021). https://doi.org/10.1134/S107042722101002X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S107042722101002X