Abstract

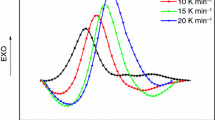

The influence of the curing conditions and dibutyl phthalate additions on the physicomechanical properties of cured polyepoxides based on ED-20 resin and 4,4'-diaminodiphenylmethane curing agent was examined. An increase in the curing temperature over 150°С does not noticeably influence the physicomechanical properties of the cured resin, and keeping of the reaction mixture at 180°С for 12 h leads to a considerable decrease in the glass transition temperature of the polymer. Addition of dibutyl phthalate in concentrations of up to 10 wt % decreases the glass transition teperature of the polymer by 44°C, but with increasing concentration of dibutyl phthalate the elastic modulus increases and the breaking strain slightly decreases. The dependence of the ultimate strength on the dibutyl phthalate concentration passes through a maximum at 3 wt % dibutyl phthalate.

Similar content being viewed by others

References

Badamshina, E.R., Gafurova, M.P., and Estrin, Y.I., Russ. Chem. Rev., 2010, vol. 79, no. 11, pp. 945–979.

Spitalsky, Z., Tasis, D., Papagelis, K., and Galiotis, C., Prog. Polym. Sci., 2010, vol. 35, no. 3, pp. 357–401.

Tasis, D., Tagmatarchis, N., Bianco, A., and Plato, M., Chem. Rev., 2006, vol. 106, no. 3, pp. 1105–1136.

Valenkov, A.M., Gofman, I.V., Nosov, K.S., et al., Russ. J. Appl. Chem., 2011, vol. 84, no. 5, pp. 735–750.

Wang, F., Yao, J., Sun, K., and Xing, B., Environ. Sci. Technol., 2010, vol. 44, no. 18, pp. 6985–6991.

Chang, S.-S., Polymer, 1992, vol. 33, no. 22, pp. 4768–4778.

Wisanrakkit, G., Gillham, J.K., and Enns, J.B., J. Appl. Polym. Sci., 1990, vol. 41, nos. 7–8 pp. 1895–1912.

Montserrat, S., J. Therm. Anal., 1991, vol. 37, pp. 1751–1758.

Sanz, G., Garmendia, J., Andres, M.A., and Mondragon, I., J. Appl. Polym. Sci., 1995, vol. 55, no. 1, pp. 75–87.

Chang, S.-S., in 37th Int. SAMPE Symp. and Exhibition “Mater. Work. for You 21st Century,” Anaheim, California, March 9–12, 1992. Covina, California, 1992. pp. 358–368.

Khozin, V.G., Usilenie epoksidnykh polimerov (Reinforcement of Epoxy Polymers), Kazan: Dom Pechati, 2004.

Garcia, F. and Soares, B., Polym. Test., 2003, vol. 22, no. 1, pp. 51–56.

Kenyon, A.S. and Nielsen, L.E., J. Macromol. Sci., Part A: Chemistry, 1969, vol. 3, no. 2, pp. 275–295.

Hata, N., Yamauchi, R., and Kumanotani, J., J. Appl. Polym. Sci., 1973, vol. 17, no. 7, pp. 2173–2181.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.E. Tarasov, G.V. Malkov, M.L. Bubnova, Ya.I. Estrin, E.R. Badamshina, 2015, published in Zhurnal Prikladnoi Khimii, 2015, Vol. 88, No. 12, pp. 1770–1775.

Rights and permissions

About this article

Cite this article

Tarasov, A.E., Malkov, G.V., Bubnova, M.L. et al. Influence of curing conditions and dibutyl phthalate concentration on the properties of cured epoxy resin. Russ J Appl Chem 88, 2015–2020 (2015). https://doi.org/10.1134/S10704272150120174

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S10704272150120174