Abstract

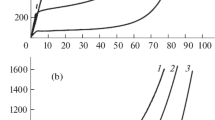

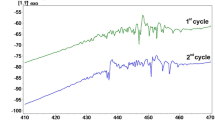

We studied the ability of Cu 82.5 wt %–Al 13.5 wt %–Ni 4.0 wt % martensitic single crystals to perform work by moving a load with an impact during the shape-memory-strain recovery of reverse martensitic transformation. The dependence of this work on preload is studied. The transition to the impact mode occurs after the precompression of the crystal until the complete deformation of the shape memory (~9%) when the load exceeds the martensite detwinning stress by more than a factor of 2. Differential scanning calorimetry showed that, after such compression of the crystal to 200–250 MPa and more, the temperature range of the reverse martensitic transformation sharply narrows.

Similar content being viewed by others

REFERENCES

V. I. Nikolaev, P. N. Yakushev, G. A. Malygin, and S. A. Pul’nev, Tech. Phys. Lett. 36, 914 (2010). https://doi.org/10.1134/S1063785010100123

V. I. Nikolaev, P. N. Yakushev, G. A. Malygin, A. I. Averkin, A. V. Chikiryaka, and S. A. Pulnev, Tech. Phys. Lett. 40, 123 (2014). https://doi.org/10.1134/S1063785014020126

A. I. Averkin, P. N. Yakushev, E. V. Trofimova, G. P. Zograf, R. B. Timashov, S. A. Pulnev, S. B. Kustov, and V. I. Nikolaev, Fiz. Mekh. Mater. 22, 64 (2015). https://mpm.spbstu.ru/en/article/2015.38.9/.

S. Yang, T. Omori, C. Wang, Y. Liu, M. Nagasako, J. Ruan, R. Kainuma, K. Ishida, and X. Liu, Sci. Rep. 6, 21754 (2016). https://doi.org/10.1038/srep21754

X. Huang, K. Kumar, M. K. Jawed, A. M. Nasab, Z. Ye, W. Shan, and C. Majidi, Adv. Mater. Technol. 4, 1800540 (2019). https://doi.org/10.1002/admt.201800540

V. I. Nikolaev, R. B. Timashov, S. A. Pulnev, L. I. Guzilova, P. N. Butenko, and S. I. Stepanov, Mater. Phys. Mech. 47, 59 (2021)

C. Picornell, J. Pons, and E. Cesari, Acta Mater. 49, 4221 (2001). https://doi.org/10.1016/S1359-6454(01)00308-1

E. Cingolani, J. van Humbeeck, and M. Ahlers, Metall. Mater. Trans. A 30, 493 (1999). https://doi.org/10.1007/s11661-999-0041-9

L. A. Matlakhova, E. C. Pereira, S. A. Pulnev, et al., Metals 10, 219 (2020). https://doi.org/10.3390/met10020219

C. Picornell, J. Pons, A. Paulsen, J. Frenzel, V. Kaminskii, K. Sapozhnikov, J. van Humbeeck, and S. Kustov, Scr. Mater. 180, 23 (2020). https://doi.org/10.1016/j.scriptamat.2020.01.018

E. S. Machlin and M. Cohen, Trans. AIME 191, 746 (1951).

A. R. Entwistle, Metall. Trans. 2, 2395 (1971).

O. B. Naimark, L. V. Filimonova, V. A. Barannikov, V. F. Leont’ev, and S. V. Uvarov, Phys. Mesomech. 4 (5), 13 (2001).

B. S. Kerner and V. V. Osipov, Sov. Phys. Usp. 32, 101 (1989).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by O. Zhukova

Rights and permissions

About this article

Cite this article

Timashov, R.B., Yakushev, P.N., Pul’nev, S.A. et al. The Effect of Compressive Preload on the Work Produced by Cu–Al–Ni Single Crystals in the Course of Burstlike Recovery of Shape-Memory Strain. Tech. Phys. Lett. 48, 86–89 (2022). https://doi.org/10.1134/S1063785022030099

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063785022030099