Abstract

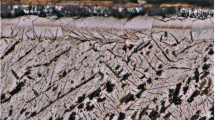

Diffusion boronizing, as a method of thermochemical treatment, significantly improves the wear resistance and corrosion resistance of hardened products. The main disadvantage of boride coatings, which limits their application, is high fragility. This problem can be solved by applying multicomponent boron–based coatings using boron chromizing, boron titanizing, and boron–chromium–titanizing. Samples of sintered VK8 W–Co ceramics 12 mm in diameter and 10 mm in length were coated by a titanium daub (titanium powder with a particle size of 40 µm diluted in ethyl silicate). Simultaneous diffusion saturation with boron, chromium, and titanium was carried out in a chamber furnace equipped with a PID controller from a self-shielding powder. The temperature and time of saturation were equal to 1050°С and 1.5 h, respectively. After saturation, the samples were removed from the container and subjected to oil quenching starting directly from the saturation temperature. The hardness of the basic material on VK8 samples was 1740 ± 180 HV0.1. The maximal microhardness of diffusion coatings, 4600 HV0.1, was observed on samples precoated by a titanium daub and subjected to simultaneous saturation with boron, chromium, and titanium. For coatings obtained by simultaneous boron–chromium–titanium saturation without precoating, the maximal microhardness did not exceed 3500 HV0.1. The thickness of the diffusion layer on samples hardened using precoating by the titanium daub was 10 µm, and that of the diffusion coating simultaneously saturated wirth boron, chromium, and titanium was 12 µm. According to production test data for cast steel milling, the durability of removable titanium-daub-precoated VK8 cutting plates hardened by the simultaneous diffusion of boron, chromium, and titanium turned out to be 3.2–3.5 times higher than that of unhardened cutting plates and 1.5 times higher than the durability of cutting plates simultaneously saturated with boron, chromium, and titanium without titanium daub.

Similar content being viewed by others

REFERENCES

A. S. Vereshchaka, A. V. Dacheva, and A. I. Anikeev, Processing of hard-to-process materials with a tool made of a hard alloy with a Re–Co-bundle of increased heat resistance and a nano-structured wear-resistant coating, in Proc. Int. Sci. Tech. Conf. “Automobile and Tractor Construction in Russia: Development Priorities and Personnel Training” Dedicated to the 145th Anniversary of MSTU “MAMI,” 2010, p. 39 [in Russian].

D. Kassel, W. D. Hans, K. Dreyer, K. Rodider, W. Lengauer, and M. Lovonyak, FRG Patent No. 10225521 (December 18, 2003).

A. B. Korshunov et al., RF Patent No. 2181643 (April 27, 2002).

L. I. Aleksandrova, V. P. Bondarenko, T. V. Nayuk, et al., Sverkhtverd. Mater., No. 2, 3 (2006).

V. G. Khizhnyak, V. Yu. Dolgikh, V. I. Korol’, et al., Nauchn. Vesti Nats. Tekh. Univ. “Kievsk. Politekh. Inst.”, No. 1, 74 (2002).

L. Shourong, H. Jianmin, C. Lianging, and S. Junting, J. Chin. Rare Earth Soc. 20 (1), 26 (2002).

E. I. Bel’skii, M. V. Sitkevich, E. I. Ponkratin, and V. A. Stefanovich, Chemical and Thermal Treatment of Tool Materials (Nauka i Tehnika, Minsk, 1986) [in Russian].

A. M. Gur’ev, Yu. P. Kharaev, O. A. Gur’eva, and B. D. Lygdenov, Sovr. Probl. Nauki Obraz., No. 3, 65 (2006).

M. A. Gur’ev, A. M. Gur’ev, A. G. Ivanov, and S. G. Ivanov, Mezhdunarod. Zh. Prikl. Fund. Issled., No. 5, 155 (2010).

A. M. Gur’ev, E. V. Kozlov, A. I. Krymskikh, L. N. Ignatenko, and N. A. Popova, Izv. Vyssh. Uchebn. Zaved., Fiz. 43 (11), 60 (2000).

B. D. Lygdenov and A. M. Gur’ev, Izv. Vyssh. Uchebn. Zaved., Fiz. 43 (11), 269 (2000).

A. M. Gur’ev, É. V. Kozlov, A. I. Zhdanov, et al., Russ. Phys. J. 44, 183 (2001). https://doi.org/10.1023/A:1011326004528

A. M. Gur’ev, S. G. Ivanov, M. A. Gur’ev, A. G. Ivanov, B. D. Lygdenov, S. A. Zemlyakov, and A. A. Dolgorov, Fund. Probl. Sovr. Materialoved. 7 (1), 27 (2010).

A. M. Guriev, S. G. Ivanov, and M. A. Guriev, Pis’ma Mater. 4 (4 (16)), 257 (2014).

M. A. Gur’ev, S. G. Ivanov, D. L. Alontseva, T. G. Ivanova, and A. M. Gur’ev, Pis’ma Mater. 4 (3 (15)), 179 (2014).

Biplab Sarma, Doctoral Dissertation of Philosophy (Univ. Utah, 2011).

ASM Handbook, Vol. 4: Heat Treating (ASM Int., USA, 1991).

M. Matsushita, Materials 4, 1309 (2011).

F. E. Şeşen and Ö. S. Özgen, Sigma 32, 334 (2014).

S. G. Ivanov, A. M. Guriev, M. D. Starostenkov, T. G. Ivanova, and A. A. Levchenko, Russ. Phys. J. 57, 266 (2014). https://doi.org/10.1007/s11182-014-0234-6

S. G. Ivanov, A. M. Gur’ev, E. V. Chernykh, M. A. Gur’ev, T. G. Ivanova, I. A. Garmaeva, V. V. Zobnev, and V. Gong, Fund. Probl. Sovr. Materialoved. 11 (1), 13 (2014).

ASM Handbook, Vol. 9: Metallography and Microstructures (ASM Int., 2004), pp. 493–512.

A. A. Kazakov, S. V. Ryaboshuk, D. A. Lyubochko, and L. S. Chigintsev, Microsc. Microanal. 21 (3), 1755 (2015).

G. Vander Voort, O. Pakhomova, and A. Kazakov, Mater. Perform. Charact. 5 (5), 521 (2016).

A. A. Kazakov and D. Kiselev, Metallogr., Microstruct., Anal. 5, 294 (2016).

G. F. Vander Voort, Mater. Charact. 27 (4), 241 (1991).

A. A. Kazakov and D. Kiselev, Microsc. Microanal. 21 (3), 457 (2015).

A. Kazakov, P. Kovalev, and S. Ryaboshuk, CIS Iron Steel Rev., Nos. 1–2, 7 (2007).

A. A. Kazakov, D. V. Kiselev, O. V. Sych, and E. I. Khlusova, CIS Iron Steel Rev. 20, 41 (2020).

A. A. Kazakov, A. I. Zhitenev, P. A. Ishpaev, O. V. Fomina, and P. V. Melnikov, CIS Iron Steel Rev. 19, 48 (2020).

A. A. Kazakov, A. I. Zhitenev, A. S. Fedorov, and O. V. Fomina, Izv. Ferrous Metall. 63 (3–4), 254 (2020).

S. G. Ivanov, A. M. Gur’ev, S. A. Zemlyakov, M. A. Gur’ev, and V. V. Romanenko, Polzunovsk. Vestn., No. 2, 165 (2020).

A. M. Gur’ev, M. A. Gur’ev, S. A. Zemlyakov, and S. G. Ivanov, Identification of features of morphology and phase composition of steels by methods of special metallographic etching, in Proc. 16th Int. School-Seminar “Evolution of Defective Structures in Condensed Media”, 2020, p. 83 [in Russian].

S. G. Ivanov, A. M. Gur’ev, S. A. Zemlyakov, and M. A. Gur’ev, Polzunovsk. Vestn., No. 3, 102 (2020).

. M. Gur’ev, S. A. Zemlyakov, M. A. Gur’ev, E. A. Kosheleva, and S. G. Ivanov, Polzunovsk. Al’manakh, No. 3, 3 (2020)

M. A. Gur’ev, S. G. Ivanov, A. M. Gur’ev, E. A. Kosheleva, and E. V. Chernykh, Polzunovsk. Al’manakh, No. 3, 19 (2020).

S. G. Ivanov, M. A. Gur’ev, A. M. Gur’ev, and V. V. Romanenko, Fund. Probl. Sovr. Materialoved. 17 (1), 74 (2020).

A. M. Gur’ev, M. A. Gur’ev, S. G. Ivanov, and Sh. Mei, Mezhdunarod. Zh. Prikl. Fund. Issled., No. 10, 16 (2018).

M. A. Gur’ev and S. G. Ivanov, Increasing the service life of a carbide tool by complex saturation with boron, chromium and titanium, in Abstr. 15th Int. School-Seminar “Evolution of Defective Structures in Condensed Media”, 2018, p. 108 [in Russian].

ACKNOWLEDGEMENTS

The study was carried out in the Center for Collective Use at the Polzunov Sate Technical University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Isaakyan

Rights and permissions

About this article

Cite this article

Gur’ev, A.M., Gur’ev, M.A., Ivanov, S.G. et al. Diffusion Hardening of Sintered Ceramic W–Co Materials by Simultaneous Diffusion Saturation with Boron, Chromium, and Titanium. Tech. Phys. 67, 692–695 (2022). https://doi.org/10.1134/S1063784222100024

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063784222100024