Abstract

Normal and tangential contacts between a cylindrical steel indenter (wheel) and an elastomer possessing high adhesive properties have been investigated. Computer simulation of the indentation and detachment processes has been performed for the case of indentation in the normal direction, which demonstrated good agreement with experimental data. For the rolling-friction regime, the adhesive component of the friction force has been determined by analyzing the measured dependences of the tangential component of the contact force on wheel displacement. A case of sliding friction with blocked wheel rotation has been considered. In the presence of adhesion, the sliding-friction force is proportional to the contact area. In the absence of adhesion (the elastomer is completely coated with chalk dust), stick–slip friction is implemented. The frequency and amplitude of stick–slip transitions depend on the indentation depth in the elastomer.

Similar content being viewed by others

REFERENCES

Handbook of Adhesion Technology, Ed. by L. F. M. da Silva, A. Öchsner, and R. D. Adams, 2nd ed. (Springer, Berlin, 2018). https://doi.org/10.1007/978-3-319-55411-2

A. M. Krachler and K. Orth, Virulence 4 (4), 284 (2014). https://doi.org/10.4161/viru.24606

C. Berne, C. K. Ellison, A. Ducret, and Y. V. Brun, Nat. Rev. Microbiol. 16, 616 (2018). https://doi.org/10.1038/s41579-018-0057-5

Adhesion and Friction in Biological Systems, Ed. by S. Gorb (Springer, Berlin, 2012).

K. Autumn and N. Gravish, Philos. Trans. R. Soc. A 366 (1870), 1575 (2008). https://doi.org/10.1098/rsta.2007.2173

V. L. Popov, Q. Li, I. A. Lyashenko, and R. Pohrt, Friction 9 (6), 1688 (2021). https://doi.org/10.1007/s40544-020-0482-0

K. L. Johnson, K. Kendall, and A. D. Roberts, Proc. R. Soc. London A 324 (1558), 301 (1971). https://doi.org/10.1098/rspa.1971.0141

E. Popova and V. L. Popov, Phys. Mesomech. 21 (1), 1 (2018). https://doi.org/10.1134/S1029959918010010

B. V. Derjaguin, V. M. Muller, and Y. P. Toporov, J. Colloid Interface Sci. 53 (2), 314 (1975). https://doi.org/10.1016/0021-9797(75)90018-1

D. Maugis, J. Colloid Interface Sci. 150 (1), 243 (1992). https://doi.org/10.1016/0021-9797(92)90285-T

W. Deng and H. Kesari, Sci. Rep. 9, 1639 (2019). https://doi.org/10.1038/s41598-018-38212-z

S. Dalvi, A. Gujrati, S. R. Khanal, L. Pastewka, A. Dhinojwala, and T. D. B. Jacobs, Proc. Natl. Acad. Sci. U.S.A. 116 (51), 25484 (2019). https://doi.org/10.1073/pnas.1913126116

S. You and M. P. Wan, Langmuir 30 (23), 6808 (2014). https://doi.org/10.1021/la500360f

M. Ciavarella and A. Papangelo, Tribol. Lett. 68, 81 (2020). https://doi.org/10.1007/s11249-020-01318-5

H. Radhakrishnan and S. Akarapu, Sci. Rep. 10, 5402 (2020). https://doi.org/10.1038/s41598-020-61187-9

G. Violano and L. Afferrante, Tribol. Lett. 67, 119 (2019). https://doi.org/10.1007/s11249-019-1232-1

J. A. Greenwood, Tribol. Lett. 65, 159 (2017). https://doi.org/10.1007/s11249-017-0938-1

I. A. Lyashenko and V. L. Popov, Tech. Phys. Lett. 46 (11), 1092 (2020). https://doi.org/10.1134/S1063785020110097

I. A. Lyashenko and R. Pohrt, Front. Mech. Eng. 6, 49 (2020). https://doi.org/10.3389/fmech.2020.00049

I. A. Lyashenko and V. L. Popov, Tech. Phys. 66 (4), 672 (2021). https://doi.org/10.1134/S1063784221040113

Q. Li, R. Pohrt, I. A. Lyashenko, and V. L. Popov, Proc. Inst. Mech. Eng. J. 234 (1), 73 (2020). https://doi.org/10.1177/1350650119854250

D. A. Lockner, B. D. Kilgore, N. M. Beeler, and D. E. Moore, in Fault Zone Dynamic Processes: Evolution of Fault Properties During Seismic Rupture, Ed. by M. Y. Thomas, T. M. Mitchell, and H. S. Bhat (Am. Geophys. Union, 2017), Chap. 6, pp. 105–131. https://doi.org/10.1002/9781119156895.ch6

C. Dong, C. Yuan, A. Xu, X. Bai, and Y. Tian, Langmuir 35 (7), 2878 (2019). https://doi.org/10.1021/acs.langmuir.8b04068

J. F. Waters and P.R. Guduru, Proc. R. Soc. A 466, 1303 (2010). https://doi.org/10.1098/rspa.2009.0461

H. J. Hertz, J. Angew. Math. 92, 156 (1882). https://doi.org/10.1515/crll.1882.92.156

Funding

This study was supported in part by the Deutsche Forschungsgemeinschaft (project no. PO 810/55-3) and performed within the framework of a state order to the Institute of Strength Physics and Materials Science of the Siberian Branch of the Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by A. Sin’kov

APPENDIX

APPENDIX

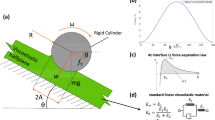

This paper presents experimental results obtained using the setup shown in Fig. 1. In all performed experiments, we measured contact forces and took (every second) photographs of the contact region. For some of the described experiments, we created videos demonstrating evolution of the contact forces and the contact shape. These video files make a valuable addition to the study, because they allow one to trace the dynamics of experiments. The files are placed on constant links using the ResearchGate site, which makes it possible to assign a DOI classifier to digital objects. Here, we present links to these video files with their descriptions.

(i) https://doi.org/10.13140/RG.2.2.20690.07363

Video demonstrating experimental results on normal indentation of a rigid cylindrical indenter with radius R = 80 mm and width H = 11 mm into an elastic sheet of TARNAC CRG N3005 transparent rubber with thickness h = 5 mm. The configuration of the contact region and real time t (in seconds) passed from the indentation onset are given on the left-hand panel. Dependences of normal force F (middle panel) and contact area A (right-hand panel) on indentation depth d are shown in the video. The video presents results of three successive indentation cycles. The video file corresponds to Fig. 2.

(ii) https://doi.org/10.13140/RG.2.2.34111.84644

Video demonstrating experimental results on rolling friction of a rigid cylindrical indenter with radius R = 80 mm and width H = 11 mm impressed into an elastic sheet of TARNAC CRG N3005 transparent rubber with thickness h = 5 mm for depth d = 0.2 mm. The configuration of the contact region and values of the indentation depth d and tangential displacement x are given on the upper panel. The video presents the dependences of normal force FN and tangential (shear) force Fx on time t (in minutes) and the dependence of tangential force Fx on indenter displacement x. Two experiments are shown successively. Direct contact between the indenter surface and the rubber (adhesive case) is implemented in the first one. In the second experiment, the rubber surface is coated with a thin chalk dust layer (nonadhesive case). The video file corresponds to Fig. 3.

(iii) https://doi.org/10.13140/RG.2.2.25723.23840

The description of the video file coincides with that in paragraph (ii), with the only difference being that, in this experiment, the wheel (indenter) was rigidly mounted on the axis and could not rotate. Therefore, the experiment shown in the video corresponds to sliding friction.

Rights and permissions

About this article

Cite this article

Lyashenko, I.A., Popov, V.L. The Influence of Adhesion on Rolling and Sliding Friction: an Experiment. Tech. Phys. 67, 203–214 (2022). https://doi.org/10.1134/S106378422204003X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S106378422204003X