Abstract

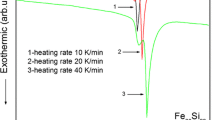

In order to determine the mechanism of plastic deformation, the hardness and local plasticity of amorphous Fe78P20Si2 alloy are compared at different stages of its crystallization activated by thermal treatment at 300–750°C or short-term photon treatment with a radiation dose coming to the sample of 10–60 J/cm2. The phase composition and structure were investigated by X-ray diffractometry and high-resolution transmission electron microscopy. With the same sequence of structural changes, the crystallization rate under photon treatment is more than two orders of magnitude higher than that under thermal treatment, which indicates the effect of a high rate of input of the process activation energy. The nonmonotonic dependence of the hardness, elastic modulus, and the proportion of plastic strain in the indentation work is found, depending on the annealing temperature or radiation dose received by the sample, as a result of structural changes in the alloy. The local plasticity of the initial alloy and fully crystallized alloy are close in magnitude. Based on the features of the crystal structure of the Fe3P phase (the impossibility of the dislocation mechanism of plastic deformation) and assuming that the structural unit (tetrahedral Fe3P cluster) of the crystallized and amorphous alloy is identical, a conclusion was formulated about the cluster mechanism of plastic deformation of the amorphous alloy.

Similar content being viewed by others

Notes

Within the scope of the article, it should be noted that both fused quartz and sodium silicate glass have a significant proportion of the plastic component in the nanoindentation deformation work [9].

Weak translational symmetry of crystalline hydroxyapatite eliminates the formation of dislocations of deformation origin.

REFERENCES

C. A. Schuh, T. C. Hufnagel, and U. Ramamurty, Acta Mater. 55, 4067 (2007).

A. S. Argon and H. Y. Kuo, Mater. Sci. Eng. A 39, 101 (1979).

D. Srolovitz, V. Vitek, and T. Egami, Acta Met. 31, 335 (1983).

J. S. Langer, Scr. Mater. 54, 375 (2005).

M. H. Cohen and D. Turnbull, J. Chem. Phys. 31, 1164 (1959).

F. Spaepen, Acta Met. 25, 407 (1977).

A. S. Bakai, Policluster Amorphous Bodies (Energoatomizdat, Moscow, 1987) [in Russian].

Institute of Silicate Chemistry of RAS – 80 Years. Historical Essays, Ed. by V. Ya. Shevchenko (Art-Ekspress, St. Petersburg, 2016) [in Russian].

Yu. I. Golovin, Nanoindentation and its Capabilities (Mashinostroenie, Moscow, 2009) [in Russian].

A. V. Evteev, A. T. Kosilov, and E. V. Levchenko, in Proceedings of the Conference on Amorphous Precision Alloys (Moscow, 2000), p. 62.

V. M. Ievlev, A. V. Kostyuchenko, B. M. Darinskii, and S. M. Barinov, Phys. Solid State 56, 321 (2014).

V. M. Ievlev, S. M. Barinov, V. S. Komlev, A. Y. Fedotov, and A. V. Kostyuchenko, Ceram. Int. 41, 10526 (2015).

https://materials.springer.com/isp/crystallographic/docs/sd_0452183.

S. Huang, Structure and Structure Analysis of Amorphous Materials (Clarendon, Oxford, 1984).

G. E. Abrosimova, A. S. Aronin, and N. N. Kholstin, Phys. Solid State 52, 445 (2010).

W. C. Oliver and G. M. Pharr, J. Mater. Res. 7, 1564 (1992).

M. C. Antonova, E. K. Belonogov, A. V. Boryak, V. V. Vavilova, V. M. Ievlev, S. V. Kannykin, and N. A. Palii, Inorg. Mater. 51, 283 (2015).

A. M. Glezer, Melt-Hardened Nanocrystals (Fizmatlit, Moscow, 2012) [in Russian].

ACKNOWLEDGMENTS

The authors are grateful to G.V. Afonin (Voronezh State Pedagogical University) for his assistance in conducting the study.

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 1703-01140 A. The scientific equipment of the Center for Collective Use of the Voronezh State University was used.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by O. Zhukova

Rights and permissions

About this article

Cite this article

Ievlev, V.M., Kannykin, S.V., Il’inova, T.N. et al. Microplasticity of Amorphous and Crystallized Fe78P20Si2 Alloy. Phys. Solid State 61, 1231–1238 (2019). https://doi.org/10.1134/S1063783419070114

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063783419070114