Abstract

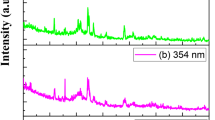

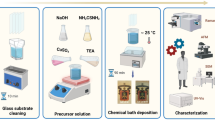

In this study, the effect of deposition time on physical properties of tin monosulphide films capped by polyvinyl alcohol was investigated. Chemical bath deposition technique was used to deposit Polyvinyl alcohol capped SnS films on cleaned glass substrates and the deposition was carried out at four different times varying from 45 to 90 min. The X-ray diffraction study revealed that the deposited layers were polycrystalline in nature with (040) as the preferred plane. Single phase SnS was observed in the layers grown at a deposition time of 90 min while the other layers had secondary phases of Sn and S. The XRD data was also used to determine various parameters such as crystallite size, dislocation density, lattice strain, stacking faults and inter planar spacing. Raman measurements exhibited same structural phases, consistent with the XRD observations. The surface morphology of the layers was initially uneven and become uniform at 90 min deposition time. Fourier transform infrared spectra, confirmed the presence of SnS and PVA in the films. Optical studies revealed high optical absorption coefficient for all the films with a shift in optical band gap value compared with the bulk value.

Similar content being viewed by others

REFERENCES

Y. Kawano, J. Chantana, and T. Minemoto, Curr. Appl. Phys. 15, 897 (2015).

J. A. Andrade-Arvizu, M. Courel-Piedrahital, and O. Vigil-Galan, J. Mater. Sci.: Mater. Electron. 26, 4541 (2015).

K. T. Ramakrishna Reddy, N. Koteswsara Reddy, and R. W. Miles, Sol. Energy Mater Sol. Cells 90, 3041 (2006).

E. Guneri, F. Gode, C. Ulutas, F. Kirmigigul, and G. Altindemir, Chalcogenide Lett. 7, 685 (2010).

J. J. L. Hmar, T. Majumder, and S. P. Mondal, Thin Solid Films 598, 243 (2016).

U. Baishya and D. Sarkar, Bull. Mater. Sci. 34, 1285 (2011).

P. K. Khanna, N. Singh, and S. Charan, Mater. Lett. 61, 4725 (2007).

I. S. Elashmawi, A. M. Abdelghany, and N. A. Hakeema, J. Mater. Sci. Mater. Electron. 24, 2956 (2014).

S. C. Ezugwu, F. I. Ezema, R. U. Asogwa, B. A. Ezekoye, A. B. C. Ekwealor, C. Chigbo, M. Anasuya, and M. Mahaboob Beevi, Optoelectron. Adv. Mater. 3, 528 (2009).

M. Sudha, S. Senthilkumar, R. Hariharan, A. Suganthi, and M. Rajarajan, J. Sol-Gel Sci. Technol. 61, 14 (2012).

S. K. M. Begum, G. Nirmala, K. Ravindranadh, T. A. Swini, M. C. Rao, P. Sambasiva Rao, and R. V. S. S. N. Ravikumar, J. Mol. Struct. 1006, 344 (2011).

Donglin Xia, X. Jun, Wenqing Shi, Pan Lei, and Xiujian Zhao, Key Eng. Mater. 509, 333 (2012).

M. Safonova, P. K. Nair, E. Mellikov, A. R. Garcia, K. Kerm, N. Revathi, T. Romann, V. Mikli, and O. Volobujeva, J. Mater. Sci.: Mater. Electron. 25, 3160 (2014).

T. H. Sajeesh, A. S. Cherian, C. Sudha Kartha, and K. P. Vijayakumar, Energy Proc. 15, 325 (2012).

A. Basaka, A. Hati, A. Mondala, U. P. Singh, and S. K. Taheruddinc, Thin Solid Films 645, 97 (2018).

A. Ceylan, Mater. Lett. 201, 194 (2017).

S. Jana, R. Thapa, R. Maity, and K. K. Chattopadhyay, Phys. E (Amsterdam, Neth.) 40, 3121 (2008).

E. Guneri, C. Ultas, F. Kirmizigul, G. Altindemir, F. Gode, and C. Gumus, Appl. Surf. Sci. 25, 1189 (2010).

T. H. Patel, Open Surf. Sci. J. 4, 6 (2012).

G. H. Yue, D. L. Peng, P. X. Yan, and L. S. Wang, J. Alloy Compd. 468, 254 (2009).

K. Sarmah, R. Sarma, and H. L. Das, Chalcogenide Lett. 5, 153 (2008).

A. Purohit, S. Chander, S. P. Nehra and M. S. Dhaka, Phys. E (Amsterdam, Neth.) 69, 342 (2015).

T. Sreenivasulu Reddy, G. Phaneendra Reddy, and K. T. Ramakrishna Reddy, Appl. Surf. Sci. 458, 333 (2018).

B. H. Baby, V. M. Vaisakh, and D. B. Mohan, Mater. Today Proc. 3, 2077 (2016).

T. Sall, B. M. Soucase, M. Mollar, and J. A. Sans, J. Electron. Mater. 46, 1714 (2017).

A. M. S. Arulanantham, S. Valanarasu, K. Jeyadheepan, V. Ganesh, and M. Shkir, J. Mol. Struct. 1152, 137 (2018).

A. Voznyi, V. Kosak, L. Grase, J. Vecstaudza, P. Onufrijevs, Yu. Yeromenko, A. Medvid, and A. Opanasyak, Mater. Sci. Semicond. Process 79, 32 (2018).

D. Das and R. Kumar Dutta, J. Colloid Interface Sci. 457, 339 (2015).

G. Sreedevi, M. Vasudeva Reddy, C. Park, J. Chan-Wook, and K. T. Ramakrishna Reddy, Opt. Mater. 42, 468 (2015).

G. Phaneendra Reddy, G. Sreedevi, and K. T. R. Reddy, Mater. Sci. Semicond. Process 86, 164 (2018).

J. Osuntokun and P. A. Ajibade, Phys. B (Amsterdam, Neth.) 496, 106 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Devi, P.M., Reddy, G.P. & Reddy, K.T. Effect of Deposition Time on Structural, Morphological and Optical Properties of PVA Capped SnS Films Grown by CBD Process. Semiconductors 53, 1745–1750 (2019). https://doi.org/10.1134/S1063782619130062

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063782619130062