Abstract

In the development of promising ULIS scaling technologies, one of the key roles is played by porous dielectrics with a low permittivity used to isolate interconnects in a metallization system. Condensation of gaseous products in the pores of such films makes it possible to solve the most important problem that prevents the integration of such films, to carry out low-damage plasma etching. However, methods for studying porosity are also based on the study of the adsorption isotherm during condensation in film pores. Therefore, the study of adsorption in pores is one of the most important practical problems arising in the creation of dielectrics with a low permittivity and the study of low-damaging methods for their structuring. The method of ellipsometric porosimetry is an easy-to-implement and accurate approach for obtaining an adsorption isotherm; however, its further analysis and determination of the pore size distribution are reduced to solving an integral equation and is an ill-posed problem. In this paper, we propose to apply Tikhonov’s regularization method to solve it. The method is verified on model data and used to study a low-k dielectric sample with an initial thickness of 202 nm and a permittivity of 2.3 based on organosilicate glass.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 INTRODUCTION

The continued scaling of transistors in integrated circuits places new demands on plating systems to reduce dielectric constant and reduce the conductor size. In relation to this, research is ongoing related to the optimization of the chemical composition in the development of new materials with a low dielectric constant to reduce RC delays and mutual effect (crosstalk) of integrated circuit interconnect systems [1]. At present, organosilicate glass (OSG) dielectrics with a low dielectric constant of about 2.5, which have a porosity of 30 to 40%, are common. These dielectrics are proposed for use in sub-10 nm technological routes, and therefore they are being intensively studied.

The relationship between the dielectric constant and the total polarization of a medium consisting of polarizable polar molecules is described by the Debye equation [2]:

where k is the permittivity, N is the number of dipoles, \({{{{\alpha }}}_{{\text{e}}}}\) is electronic polarization, \({{{{\alpha }}}_{{\text{d}}}}\) is ionic polarization, and \({{\mu }}\) is the orientation of the dipole in space. It can be seen from this equation that the dielectric constant directly depends on the total number of dipoles in the material and its density; thus, the partial replacement of the solid matrix of the material by a vacuum (\(k\,~ \approx ~\,1\)) reduces the dielectric constant. The possibilities of this approach range from a random uniform filling of the dielectric structure with pores with a characteristic size of less than 2 nm, which has been mastered in the implementation technology, to the creation of larger air-gaps localized between the conductors [3].

There are two ways to reduce the dielectric constant by pore embedding: plasma enhanced chemical vapor deposition (PECVD), which is suited to the currently used damascene integration technology and the spin-on film application method. When creating a film, sacrificial particles are introduced, after the removal of which voids are formed, which can be either connected between themselves and the surface (open porosity) or isolated (closed). There are five general requirements for successfully integrating low-k material: (1) the sample must be hydrophobic, since water has extremely polar O–H bonds and the value of a dielectric constant close to 80, and slight adsorption of atmospheric water leads to significant degradation of the dielectric; (2) the sample must be mechanically stable in order to withstand the mechanical processing steps; (3) the material must withstand a temperature of 400 to 450°C, at which the manufacture of interconnects takes place; (4) the material must be chemically and physically stable for the etching and cleaning steps; and (5) for compatibility with other materials, the low-k dielectric must have the appropriate parameters of the thermal expansion coefficient, barrier deposition, and adhesion.

Porosity determines the physical and chemical parameters of the film, and an increase in porosity leads to a deterioration in its mechanical properties, which makes it difficult to integrate porous dielectrics into metallization systems. Often the study of the pore size distribution and porosity structure helps optimize new materials [1].

Sample porosity, average pore radius, and pore size distribution are among the most important parameters that can be used to analyze both the created samples and those subjected to various physical processes. Methods based on filling pores with an adsorbate, such as ellipsometric porosimetry [4] and quartz microbalance in combination with adsorption [5], are not sensitive to closed pores, although they are widely used and are generally available. Total porosity can be measured by X-ray diffraction [6] and beam positron annihilation lifetime spectroscopy (PALS) [7]. The first method is based on the analysis of scattered rays as they pass through the sample. To analyze the data, it is necessary to build a model to determine the electron density \({{{{\rho }}}_{{\text{e}}}}\); therefore, the restoration of pore size distribution is a difficult task. In turn, PALS is a powerful method capable of studying the nanopores or defects in a wide range of sizes from 0.3 to 30 nm. In addition, beam-based PALS makes it possible to study samples layer-by-layer (from a few nanometers to a few microns thick). The disadvantage of this method is the complexity of the experimental implementation of the method.

In this paper, we analyze the computational difficulties that arise in the interpretation of ellipsometric porosimetry data and propose the application of the Tikhonov regularization method to solve such problems. The proposed approach was verified by reconstructing the distribution of pores from the model data. The proposed approach is used to calculate the pore size distribution from the experimental data.

2 THEORETICAL FOUNDATIONS OF THE ELLIPSOMETRIC POROMETRY METHOD

The ellipsometry method is based on measuring the change in the polarization state of light upon reflection from the sample surface, which can be accurately determined [4, 8, 9]. From the Fresnel equations that relate the reflection coefficients for a wave with polarization in the plane of incidence Rp and and a wave perpendicular to it Rs, the fundamental equation of ellipsometry is obtained: \(\tan {\kern 1pt} {{\Psi }}{{e}^{{i{{\Delta }}}}} = \frac{{{{R}^{{\text{p}}}}}}{{{{R}^{{\text{s}}}}}}\). In the case where the sample consists of a thin optically transparent film on the silicon surface, the problem requires consideration of the rereflection of light at the upper and lower boundaries of the film and the interference between them. Parameters \({{\Psi }}\) and \({{\Delta }}\) can be calculated if the optical properties and film thickness are known. The inverse problem of calculating the optical properties and film thickness from parameters \({{\Psi }}\) and \({{\Delta }}\) is generally not possible. As a rule, the numerical solution of the inverse problem of ellipsometry is reduced to minimizing the discrepancy between the model and experimental values of parameters \({{\Psi }}\) and \({{\Delta }}\) (their spectral dependences). The method of spectral ellipsometry has been widely applied in microelectronics [10].

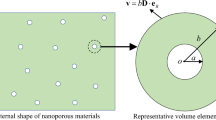

Ellipsometric porosimetry is used to measure porosity and the pore size distribution (PSD). The method is based on the ability of a porous film to adsorb gas vapors inside the pores to form a liquid. Porosity can be determined from the values of the refractive index of the film before and after gas adsorption. The connection between optical constants and properties of a multicomponent system is described by the Lorentz–Lorentz formula [11]:

where \(B\) is the effective polarization per unit volume, \(n\) is the effective refractive index of the multicomponent film, and \(N{\;\text{and}\; \alpha \;}\) are the number of molecules and molecular polarizability.

With an increase in the relative pressure of the adsorbate on the surface of the sample, pores with an increasing radius are filled, which leads to changes in the optical parameters. The dependences of the refractive index on the vapor pressure of the adsorbate are called adsorption and desorption isotherms. As a rule, these dependences are different; i.e., there is a hysteresis effect due to the presence of menisci in the pore structure, which lead to a delay in the release of pores during desorption.

The analysis of porosimetry data is based on the classification of Brunauer isotherms [12]. The characteristic pore size and shape play a decisive role [13].

Micro- and mesopores are characterized by different adsorption processes. Mesopores (pore radius greater than 2 nm) are characterized by polymolecular adsorption, which ends with capillary condensation with increasing pressure. This process is due to the manifestation of capillary forces. In the case of a flat surface, condensation occurs when the pressure becomes equal to the saturated vapor pressure, that is, when P/P0 = 1, and condensation over the concave surface in the pores occurs at P/P0 < 1, which leads to a change in the chemical potential and conditions of phase equilibrium in pores, where P0 is the pressure of saturated vapor above a flat surface. The relationship between the meniscus radius and relative pressure is described by the Kelvin–Thomson equation [14]:

where σ is the surface tension of the liquid, R is the gas constant, T is temperature, M is the molar mass, and \({{\rho }}\) is density. It is also worth noting that the processes of adsorption and desorption are different, since during adsorption the adsorbate is removed from the pore in its entire volume at the appropriate pressure. Therefore, the final radius during desorption is equal to the radius of the pore itself; at the same time, in adsorption processes, it is necessary to make the BET correction [15], which describes adsorption on the pore walls of the adsorbate layer until the pore itself is filled. It can be obtained from the Langmuir adsorption theory and has the form

where C is a constant describing the interaction of the adsorbent and adsorbate, K is the coefficient introduced to expand the application area of the BET equation [16], and \({{t}_{0}}~\) is the thickness of one monolayer. Hence, it turns out that the final pore radius during adsorption is \(r = {{r}_{{\text{m}}}} + t\).

The adsorption isotherm is described by the integral of the function \(z\left( r \right)\)representing the pore size distribution:

In micropores (radius less than 2 nm), the fields of surface forces overlap and act in the entire volume of micropores. To describe adsorption in micropores, Dubinin developed the theory of volumetric filling of micropores (MVFT) [17], which describes the filling of a pore instantly in the entire volume in the relative pressure range from 0.001 to 0.1. The main thermodynamic function of this theory is the differential maximum molar work of adsorption A, equal with a minus sign to the change in the Gibbs free energy of adsorption \(\Delta G\): \(A = RT{\text{ln}}\left( {P{\text{/}}{{P}_{0}}} \right) = - \Delta G\), where \(p\) is the equilibrium vapor pressure at temperature \(T\). If adsorption is expressed in dimensionless units, then it is advisable to express the differential molar work of adsorption in a way similar in form to the dimensionless ratio \(A{\text{/}}E\), where \(E\) is the characteristic free energy of adsorption. Then the thermal adsorption equation can be represented in the general form: \(\theta \) \( = f\left( {\frac{A}{E},n} \right),~\) where n is a parameter depending on the adsorbent, \(\theta \) is the degree of filling of pores, equal to the ratio of filling \(W\) to maximum pore filling \({{W}_{0}}\). The last equation expresses the distribution of micropore filling depending on the differential molar work of adsorption A, while the distribution parameters E and n do not depend on temperature. From temperature invariance and based on the Weibull distribution, Dubinin and Astakhov obtained the thermal adsorption equation in analytical form, which is expressed as follows [17]:

It can be seen (with p/p0 = 1) that F(A) expresses the proportion of the unfilled pore volume; therefore, \(\theta \) describes the proportion of the volume filled with the condensate:

Figure 1a schematically shows adsorption isotherms for microporous and mesoporous samples. According to Brunauer’s classification, these isotherms belong to the first and fifth types of isotherms. If the distance between opposite pore walls becomes too large, then the surface force fields no longer overlap (Fig. 1b), and the theory of volume filling ceases to work, and further adsorption is described by capillary condensation [18, 19]. Therefore, the sum of two isotherms for micro- and mesopores is observed in the experiments.

In the article [20], using the data of small-angle X‑ray scattering on carbon-containing adsorbents [21], which provided information on the linear characteristics of micropores, an empirical relation was obtained relating the radius of gyration of a slit-like pore x and the free energy of adsorption E:

Here parameter \(k\) is the proportionality factor and is usually taken equal to 12.

Hence the Dubinin–Astakhov equation (DA) (with n = 2 Dubinin–Radushkevich) takes the form [17]:

where \(\beta \) is the similarity coefficient reflecting the nature of the adsorbed substance. This equation describes adsorption for a sample having pores of the same size. The pore size is found by linearizing the equation in coordinates \(\left( {{\text{log}}\left( W \right),~{{A}^{2}}} \right).\)

An approach is possible in which the parameters of the pore size distribution are determined from the family of such distributions, for example, described by the Gaussian [22]. The disadvantage of this approach is that the distribution form is not determined when solving the problem, but is set a priori.

To determine the distribution of pores \(z\left( B \right)\), where \(B = {{r}^{2}}{\text{/}}{{k}^{2}}\), it is necessary to solve the integral equation that describes the process of adsorption in micropores:

Problems (5) and (10) belong to the class of ill-posed problems. As a rule, their solution by numerical methods is related to the appearance of instabilities and artifacts that lead to significant errors. In this paper, it is proposed to implement the solution by the Tikhonov regularization method [22]. The choice of the method is due to the fact that it ensures that problems of this class are solve efficiently. Tikhonov’s method, like any regularization method, is based on the use of a priori information about the class of functions on which the solution of the problem is sought.

3 TIKHONOV REGULARIZATION METHOD

We consider an equation of the first kind

where Z and U are finite-dimensional functional spaces, with operator \(A{\kern 1pt} :Z \to U\). Problems of this type are often encountered in physics during various studies and experiments, and due to the presence of noise in the initial data, the solution is unstable, that is, an ill-posed problem. According to J. Hadamard’s definition of a correctly posed problem, \(Z,~U\) are metric spaces and \(A~{\kern 1pt} :Z \to U\) is a continuous operator, then the problem of finding \(z\) is a correctly posed problem if all of the following conditions are met:

(1) Eq. (11) is solvable for \(\forall \,\,u \in U\) ;

(2) the solution is unique;

(3) the solution is stable.

We will assume that Eq. (11) is solvable in the classical way and we will select the minimal solution among all solutions in the norm of space \(Z\). Thus, the defined normal solution exists and is unique, and the main task will be the problem of finding a solution to the problem (with index 0):

where \(Z,~U~\) are Hilbert spaces, \({{A}^{0}}{\kern 1pt} :Z \to U\) is a linear continuous operator, and \({{u}^{0}} \in U\) is some given element. Through \({{z}^{0}}\) we denote the normal solution of Eq. (12). Operator \({{A}^{0}}\) and right-hand side \({{u}^{0}}~\), respectively, are the exact operator and the exact right part; however, they are not exactly known, and only their approximations are known: the linear continuous operator \({{A}^{h}}{\kern 1pt} :Z \to U\) and the right side \({{u}^{\delta }} \in U\), together with estimates of their deviation from \({{A}^{0}}\) and \({{u}^{0}}\), respectively:

where \(h{{\;}} \in {{\;}}\left( {0,{{\;}}{{h}_{0}}} \right)\), \({{\delta \;}} \in {{\;}}\left( {0,{{\;}}{{{{\delta }}}_{0}}} \right),\) \({{h}_{0}},{{\;}}{{{{\delta }}}_{0}}\) are some fixed positive numbers.

According to optimization theory, if (11) is solvable, then it has a unique normal, i.e., minimal by the norm, solution. This normal solution is the solution to the minimization problem:

In other words, the problem of solving Eq. (12) is equivalent to the minimization problem

Often the set of minimum points of any given function \(f\left( z \right)\) on the set \(D\) is denoted as follows:

It turns out, however, that it is possible to manipulate problem (12) in such a way, by replacing it with a whole family depending on the numerical parameter (regularization parameter) \(\alpha \) > 0 of minimization problems, that, first, the solution of each of the problems of this family will no longer have the indicated effect of instability, and, second, when parameter \(\alpha \) tends to zero, these solutions will converge in the norm Z to the solution \({{z}^{0}}~\) of the original problem (12). In other words, refusing to directly solve problem (12), we can nevertheless obtain its approximate solution with any predetermined accuracy. This method is called the Tikhonov regularization method, which shows that the solution of the problem of finding z can be considered the problem of minimizing the Tikhonov functional:

and as before, the operator \({{A}^{h}}\) and element \({{u}^{\delta }}\) are approximations, respectively, of the operator \({{A}^{0}}\) and \({{u}^{0}}\). The main property of this functional \({{M}^{\alpha }}\) is that its minimum value on the entire Hilbert space Z is achieved for any triple \({{A}^{h}}\), \({{u}^{\delta }}\), and \(\eta \); and, moreover, at a single point \(z_{\eta }^{\alpha }\) for which the estimate is valid:

This element is used to approximate the exact solution \({{z}^{0}}\) and the main idea is the consistent tendency to zero errors of the given operator \(h\), the right side \(\delta \), and the regularization parameter \(\alpha \). Therefore, if, at \(\alpha \left( \eta \right) \to 0{\text{ at }}\eta \to 0\), the matching condition \(\left( {{{h}^{2}} + {{\delta }^{2}}} \right){\text{/}}\alpha \left( \eta \right) \to 0\) is met, then

where \({{z}^{0}}\) is the normal solution of Eq. (12).

Based on this, we can define the regularizing operator:

The regularization process considered above, when the space of solutions Z was taken as space L2(a,b) (a priori information), is called a zero-order regularization because it does not use information about the derivatives of the exact solution.

Thus, an algorithm that allows us to find an approximate solution to ill-posed operator problems of the form \(Az = u\) is based on the application of the Tikhonov functional and the solution of the problem of its minimization (17).

4 APPLICATION OF THE TIKHONOV METHOD FOR ELLIPSOMETRIC POROMETRY

It is easy to see that in the case of problems of ellipsometric porosimetry, integral equations (5) and (10) are the Fredholm equations of the first kind. In this paper, we propose to use a numerical method following the Tikhonov methodology, which reduces the solution of problems (5) and (10) to an operator problem:

Under the integral, there is the kernel and the desired function. A partition is introduced

where n and m can be any number. Then it is easy to replace the integral by the sum using the trapezoid method.

where \({{r}_{j}}\) is the distance between adjacent points in the split along the abscissa axis. Thus, the integral is replaced by the SLAE with respect to the unknown functions. The regularization operator \(A\) is made up of \({{a}_{{ij}}} = {{r}_{j}}{{K}_{{ij}}}\).

First, consider the solution of problem (5) for mesopores \(W\left( P \right) = \int_0^{ + \infty } {z\left( r \right)dr} \). In this case, the kernel of the integral equation is equal to unity, but since the Fredholm equation is given on a rectangular finite region, it is necessary to change the limits along the \(x\) axis, corresponding to the pore radius \(x \in \left[ {0,d} \right]\). Also, with an increase in pressure, pores of increasing size are filled; thus, it is necessary to limit the area in which the pores are filled (Fig. 2a). The limited area is calculated according to the Kelvin equation (3). It is necessary to switch to a new kernel:

Restriction of the area of the regularization matrix by (a) the theoretical data calculated from the Kelvin equation (3) and (b) experimental data from the linearization of the Dubinin equation (9).

Then the solution of the Fredholm integral equation is reduced to the solution of the system of linear equations:

For noise reduction and finding eigenvalues, it is proposed to use the SVD [24] singular value decomposition method and apply it to the matrix \(A\): \({{\left[ A \right]}_{{mn}}} = {{\;}}{{\left[ U \right]}_{{mm}}}{\text{diag}}{{\left( {{{{\left[ S \right]}}_{{mn}}}} \right)}_{{{\text{m}}1}}}{{\left[ V \right]}_{{nn}}}\). After that, the solution to the minimization of the Tikhonov functional has the form

For micropores, the Fredholm equation describing Dubinin’s integral equation looks like this:

where \(y = {{\left\{ {\frac{T}{{{\beta }}}{\text{log}}\left( {{{P}_{0}}{\text{/}}P} \right)} \right\}}^{2}}\), \(A = RT{\text{ln}}\left( {{{P}_{0}}{\text{/}}P} \right)\), \(B = \frac{{{{r}^{2}}}}{{{{k}^{2}}}}\), and \(m = \frac{1}{{{{{\left( {{{\beta }}k} \right)}}^{2}}}}\);

It can be seen that the kernel of the integral equation has the form \(K\left( {r,P{\text{/}}{{P}_{0}}} \right) = \exp \left( { - m{{r}^{2}}A{{{\left( {P{\text{/}}{{P}_{0}}} \right)}}^{2}}} \right)\) in the area

In this case, to solve this integral equation, a transition is made to a region limited in radius, according to physical considerations, since the Dubinin equation is applicable for pores with a radius of up to two nanometers. It is also necessary to take into account the Dubinin algorithm for determining the pore size at the given pressure. Thus, for each pressure in the experiment, we determine the radius and maximum porosity \({{W}_{0}}\), from which we later construct a solution to the Dubinin integral equation using the Tikhonov regularization method. The regularization operator is calculated over all possible sets of pressures and radii, and we need to choose points \({{r}_{{{\delta }}}}\) on the grid, lying close to \({{r}_{0}}\), which we obtained from the experiment using formula (8) (Fig. 2b). Since the method is applicable in the pressure range from 0 to 0.1, this also limits the area. Therefore, a transition is made to a new integral kernel and solution area:

Then, similarly to the previous problem, the following system of linear equations is solved using a singular value decomposition, after which the solution to minimizing the Tikhonov functional has the form similar to equation (23):

The regularization parameter is determined by finding the minimum of the generalized cross-validation GCV function [25].

5 VERIFICATION OF VERIFICATION

For the calculations, the MATLAB development environment was chosen, in which a program was written for solving problems (5) and (10) using the Tikhonov regularization method. The method was verified by solving simulated problems with a known solution. For the Kelvin equation (3), problems were modeled in which various features (bimodality) were present in order to prove the sensitivity of the method to them. First, according to the given parameters, the distribution density is constructed by the sum of two gausses, which has the meaning of the pore size distribution. It is easy to obtain from it a distribution function that has the meaning of an adsorption isotherm, to which the generated noise must be added. Next, the adsorption isotherm is run through an algorithm based on solving the ill-posed problem (5) by the Tikhonov regularization method, after which the obtained graphs are compared with the simulated ones.

When imposing graphs 6a on 6b and 6c, there is a similarity between the simulated pore size distribution and the adsorption isotherm (red line), with the graphs obtained by solving the ill-posed problem.

Verification of the solution to problem (10) of the Dubinin integral equation is a nontrivial task, since there is no single-valued transition from the pressure to the radius, as in solving problem (5). For verification, the direct operator problem (26) was considered. The generated Weibull distribution function (Fig. 3a), which describes adsorption in micropores, was used as the input data. To restore the original distribution function, the resulting pore size distribution (Fig. 3b) was substituted into (26) (Fig. 3c).

6 MEASURING EQUIPMENT

The measuring method is based on the change in the optical parameters of porous films in the process of adsorbate adsorption in them, which can be seen from the Lorentz–Lorentz formula (2). In our case, isopropyl alcohol acts as an adsorbate (C3H8O), and the change in optical parameters is measured using the M-2000X ellipsometer from J.A. Woollam Co.

The adsorbate vapor supply system is shown in Fig. 4 and includes two gas flow controllers (mass flow controller (MFC) with a flow rate of 200 st. cm3/min, which are controlled by the L-card E14-440 DAC/ADC module. Dry nitrogen is supplied through one of them, and saturated vapors of isopropyl alcohol are supplied through the second one. The ratio of their flows determines the relative pressure of the adsorbate over the sample. Due to the design features of this MFC, with a relative flow below 1.5%, their readings are unreliable; therefore, in the future, a pressure range of [1.5%, 100%] of the saturated vapor pressure. The system of K1–K2 valves prevents a sharp jump in pressure in the tank with liquid isopropyl alcohol.

The time interval between the establishment of the required gas flows and the beginning of the ellipsometric measurement procedure should exceed the time for establishing the equilibrium filling of the film with the adsorbate, which is 5 s, as was found experimentally. The fineness of the step in the pressure of the adsorbate must be sufficiently small so as not to lose the features of the distribution when solving the inverse problem [26].

When analyzing a sample, the processes of filling pores with an adsorbate (adsorption) and its subsequent removal from pores (desorption) are of primary interest. By measuring the dependence of pore filling (W) on pressure (P), it is possible to obtain adsorption and desorption isotherms, a preliminary analysis of which can tell which type according to the Brunauer classification they belong to and what type of porosity prevails in the sample. Further, by solving problems (5) or (10) for the obtained isotherm, the pore size distribution and the average radius can be found.

7 DEFINITION OF BET PARAMETERS

In the presence of a gaseous adsorbate with pressure P in the atmosphere above the surface of a smooth sample, an adsorbate layer is formed with thickness t(P), which is determined by the BET equation (4). An assessment of the dependence of the thickness of this layer on pressure is required for correct measurements by porosimetry. In this study, an experiment to determine the BET parameters was carried out by varying the adsorbate pressure over the silicon oxide surface. The thickness of the adsorbed layer was measured ellipsometrically (Fig. 5). Nonlinear fitting of the experimental data makes it possible to determine the parameters of Eq. (4). It is also possible to determine the thickness of the first monolayer t0 whose value lies at the beginning of the linear section of the isotherm and is 0.28 nm.

To determine parameter C, it is necessary to construct a linear adsorption isotherm. With coefficient \(K = 0.5\) for the given sample, the applicability of the BET equation lies in the range from 0.05P0 up to 0.9P0. Differences at high pressures do not play a role, since, the operating pressure range lies below the saturated vapor pressure. The value of the \(C = 148\) was also estimated. The quality of the fit is shown in Fig. 5.

8 RESULTS AND DISCUSSION

To determine the pore size distribution by the proposed method, industrial samples of a low-k dielectric with an initial thickness of 202 nm and a dielectric constant of 2.3 based on organosilicate glass were used. Before the measurement, the film samples were annealed for 30 min at a temperature of 400 deg to remove the adsorbed atmospheric moisture. The adsorption and desorption isotherms obtained in the adsorption–desorption cycle are shown in Fig. 6.

By the form of the isotherm, we can say that at a relative pressure of less than \(P{\text{/}}{{P}_{0}}~ < 0.1\), there is a sharp increase in adsorption, which may also indicate the presence of a certain amount of micropores in the sample. Also at \(P{\text{/}}{{P}_{0}} = 0.13\) we can see a change in the slope of the adsorption isotherm, which may indicate the presence of mesopores in the sample. The inverse problem for micropores and mesopores was solved using the algorithm presented in the previous sections, which made it possible to obtain the pore size distribution (Fig. 7).

To determine the statistical characteristics of these distributions, the distribution moments were also found: the first initial moment, (average pore radius \(\bar {x}\)), the second central moment, or the dispersion D which can be used to calculate the standard deviation σ, the third central moment, from which the skewness coefficient S is obtained, and the fourth one, showing the coefficient of kurtosis ε [27]. The results are given in the Table 1.

9 CONCLUSIONS

In this paper, it is proposed to apply the Tikhonov regularization method to solve the problem of ellipsometric porosimetry. The expediency of using the regularization method is explained by the fact that the problem of ellipsometric porosimetry is ill-posed and a priori information is required to obtain its stable solution. In this case [27], this is information about the smoothness of the size distribution function, which follows from general considerations. The proposed method includes separate approaches for micro- and mesopores, as well as taking into account surface adsorption (the BET theory). To determine the BET parameters, ellipsometric measurements of the thickness of the adsorbed layer on silicon oxide were taken. The method for determining the pore size distribution using the Tikhonov regularization method was verified on model distributions. In this study, an industrial sample of a low-k dielectric with the initial thickness of 202 nm and a dielectric constant of 2.3 based on organosilicate glass were studied. Their pore size distributions and their statistical characteristics are obtained. It is shown that it is necessary to use a combined approach that takes into account the presence of micropores and mesopores in the sample structure.

Change history

08 September 2022

An Erratum to this paper has been published: https://doi.org/10.1134/S1063739722550017

REFERENCES

Rasadujjaman, M., Wang, Y., Zhang, L., et al., A detailed ellipsometric porosimetry and positron annihilation spectroscopy study of porous organosilicate-glass films with various ratios of methyl terminal and ethylene bridging groups, Microporous Mesoporous Mater., 2020, vol. 306, p. 110434.

Kittel, Ch., Introduction to Solid State Physics, New York: Wiley, 1978.

Zahedmanesh, H., Besser, P.R., Wilson, C.J., and Croes, K., Airgaps in nano-interconnects: Mechanics and impact on electromigration, J. Appl. Phys., 2016, vol. 120, no. 9, p. 095103.

Tompkins, H.G., A User’s Guide to Ellipsometry, New York: Academic, 1993.

Rouessac, V., Lee, A., Bosc, F., Durand, J., and Ayral, A., Three characterization techniques coupled with adsorption for studying the nanoporosity of supported films and membranes, Microporous Mesoporous Mater., 2008, vol. 111, nos. 1–3, pp. 417–428.

Tao Li, Andrew, J.S., and Lee, B., Small angle X-ray scattering for nanoparticle research, Chem. Rev., 2016, vol. 116, no. 18, p. 11128–11180.

Gidley, D.W., Peng, H.-G., and Vallery, R.S., Positron annihilation as a method to characterize porous materials, Ann. Rev. Mater. Res., 2006, vol. 36, no. 1, pp. 49–79.

Miakonkikh, A.V., Smirnova, E.A., and Clemente, I.E., Application of the spectral ellipsometry method to study the processes of atomic layer deposition, Russ. Microelectron., 2021, vol. 50, no. 4, pp. 230–238.

Dedkova, A.A., Nikiforov, M.O., Mitko, S.V., and Kireev, V.Yu., Investigation of gallium nitride island films on sapphire substrates via scanning electron microscopy and spectral ellipsometry, Nanotechnol. Russ., 2019, vol. 14, nos. 3–4, pp. 176–183.

Orlikovskii, A.A. and Rudenko, K.V., In situ diagnostics of plasma processes in microelectronics: The current status and immediate prospect, Part III, Russ. Microelectron., 2001, vol. 30, pp. 275–294.

Lorenz, L. Experimentale og theoretiske undersøgelser over Legemernes Brydningsforhold, Vidensk. Selsk. Skr., 1869, vol. 8, p. 203..

Brunauer, S., Deming, L.S., Deming, W.E., and Teller, E., On a theory of the van der Waals adsorption of gases, J. Am. Chem. Soc., 1940, vol. 62, no. 7, pp. 1723–1732.

De Boer, J., Structure and Properties of Porous Materials, London: Butterworths, 1958, p. 68.

Thomson, W.T., On the equilibrium of vapour at a curved surface of liquid, Philos. Mag., 1871, vol. 42, pp. 448–452.

Brunauer, S., Emmett, P.H., and Teller, E., Adsorption of gases in multimolecular layers, J. Am. Chem. Soc., 1938, vol. 60, pp. 309–319.

Brunauer, S., Skalny, J., and Bodor, E.E., Adsorption on nonporous solids, J. Colloid Interface Sci., 1969, vol. 30, pp. 546–552.

Dubinin, M.M., The potential theory of adsorption of gases and vapors for adsorbents with energetically nonuniform surfaces, Chem. Rev., 1960, vol. 60, no. 2, pp. 235–241.

Dubinin, M.M. and Zaverina, E.D., Zh. Fiz. Khim., 1949, vol. 23, p. 1129.

Everett, D.H. and John, C.P., Adsorption in slit-like and cylindrical micropores in the Henry’s law region. A model for the microporosity of carbons, J. Chem. Soc., Faraday Trans., 1976, vol. 72, pp. 619–636.

Dubinin, M.M. and Stoeckli, H.F., Homogeneous and heterogeneous micropore structures, J. Colloid Interface Sci., 1980, vol. 75, no. 1, pp. 34–42.

Plavnik, G.M. and Dubinin, M.M., Investigation of the porous structure of activated charcoals from sucrose by method of adsorption and small-angle scattering of X-rays, Russ. Chem. Bull., 1966, vol. 15, pp. 597–605.

Dubinin, M.M., Inhomogeneous microporous structures of carbonaceous adsorbents, Carbon, 1981, vol. 19, no. 4, pp. 321–324.

Tikhonov, A.N. and Arsenin, V.Y., Solution of Ill-Posed Problems, Washington: Winston & Sons, 1977.

Golub, G. and Kahan, W., Calculating the singular values and pseudo-inverse of a matrix, J. Soc. Ind. Appl. Math., Ser. B: Numer. Anal., 1965, vol. 2, no. 2, рр. 205–224.

Bottegal, G. and Pillonetto, G., The generalized cross validation filter, Automatica, 2018, vol. 90, pp. 130–137.

Liu, C., Qi, Q., Seregin, D.S., Vishnevskiy, A.S., et al., Effect of terminal methyl groups concentration on properties of organosilicate glass low dielectric constant films, Jpn. J. Appl. Phys., 2018, vol. 57, no. 7S2, p. 07MC01.

Chebyshev, P.L., Polnoe sobranie sochinenii P.L. Chebysheva (The Complete Works of P.L. Chebyshev), Moscow: Akad. Nauk SSSR, 1944–1951.

Funding

This study was carried out as part of a state task of the Valiev Institute of Physics and Technology, Russian Academy of Sciences, Ministry of Education and Science of the Russian Federation on topic no. FFNN-2022-0019, and it was partially supported by the Russian Foundation for Basic Research, grant no. 18-29-27025 MK.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gaidukasov, R.A., Myakon’kikh, A.V. & Rudenko, K.V. Application of the Tikhonov Regularization Method in Problems of Ellipsometic Porometry of Low-K Dielectrics. Russ Microelectron 51, 199–209 (2022). https://doi.org/10.1134/S1063739722040060

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1063739722040060