Abstract

Tungsten inert gas (TIG) welding had been applied to produce four double-V butt welded joints performed on thick plates made from 6082-T6 aluminum alloy. The thicknesses of the plates are 18, 45, 60, and 80 mm. This type of aluminum alloy is very sensitive to heat due to its high conductivity and high thermal expansion coefficient. Heat from TIG welding reduces the strength of the cited welded plates in the welding zone and in the heat affected zone (HAZ) and favorites the formation of porosities and solidification cracks in the welded joints. Porosities and solidification cracks are the most frequent imperfection that appear in this type of welded joints and they are often the reason which prevent them to comply with the requirements of the BS EN ISO 10675-2: 2017 Non destructive testing of welds: Acceptance levels for radiography testing—Aluminium and its alloys, and of the BS EN ISO 23277: 2015 penetrant testing of welds—Acceptance levels. This article represents the type of the filler metal that used and the welding parameters that applied to perform TIG welding of the cited thick plates in order to get welded joints that are free from porosities and solidification cracks as confirmed by X-ray radiography and by red dye penetrant testing of these welded joints.

Similar content being viewed by others

REFERENCES

Mathers, G., The Welding of Aluminum and its Alloys, Cambridge: Woodhead Publishing, 2002.

Totten, G.E. and Mackenzie, D.S., Handbook of Aluminium: Volume 2: Alloy Production and Materials Manufacturing, Boca Raton: CRC Press, 2003. 1st ed.

Mukhopadhyay, P., Alloy designation, processing, and use of AA6XXX series aluminium alloys, Int. Scholarly Res. Network, 2012, vol. 2012.

Kolarik, L., Kovanda, K., Valova, M., Vondrous, P., and Dunovsky, J., Weldability test of precipitation hardenable aluminum alloy EN AW 6082-T6, Mod. Mach. Sci. J., 2011.

Stojanovic, B., Bukivic, M., and Epler, I., Application of aluminium and aluminium alloys in engineering, Appl. Eng. Lett., 2018, vol. 3, no. 2, pp. 52–62.

Md. Tanwir Alam and Akhter Husain Ansari, Review on aluminium and its alloys for automotive applications, Int. J. Adv. Technol. Eng. Sci., 2017, vol. 5.

AWS D1.2/D1.2M2008. Structural welding code—aluminium, Am. Weld. Soc., 2008.

ASTM B209M-14. Standard specification for aluminium and aluminium alloys sheet and plates, West Conshohocken, PA: ASTM Int., 2014.

Missori, S. and Sili, A., Mechanical behavior of 6082-T6 aluminium alloy welds, Metal. Sci. Technol., 2000, vol. 18, no. 1.

El-Shennawy, M., Abdel-Aziz, Kh., and Omar, A. A., Metallurgical and mechanical properties of heat treatable aluminum alloy AA6082 welds, Int. J. Appl. Eng. Res., vol. 12, No. 11(2017), pp. 2832–2839.

BS-EN-ISO-18273. Welding consumables. Wire electrodes, wires and rods for welding of aluminium and aluminium alloys. Classification. 2015.

Ellis, M., Gittos, M., and Hadley, I., Significance of liquation cracks in thick section welds in AL-MG-SI plate, 7th Int. Conf. Joints Aluminium (Abington, 1998).

Frank Armao, Aluminum Workshop: Cleaning Aluminum Before Welding, 2014.

Clinton Aluminum, The Best Aluminum Alloys for Welding. https://www.clintonaluminum.com/the-best-aluminum-alloys-for-welding/. Accessed April 2017.

BS EN 1011-4. Welding—Recommendations for welding of metallic materials. Arc welding of aluminium and aluminium alloys, 2000.

Prakash Mohan, Study of the effects of welding parameters on tig welding of aluminium plate, Master Thesis, Rourkela: Natl. Inst. Technol. Rourkela, 2014.

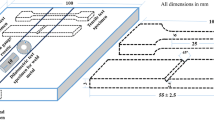

BS EN ISO 9692-3. Welding and allied processes—types of joint preparation. Metal inert gas welding and tungsten inert gas welding of aluminium and its alloys, 2016.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wafik Harara Evaluation of the 6082-T6 Aluminum Thick Plates Welded Joints Performance for High Stress Industrial Application According to European Standards. Russ J Nondestruct Test 57, 337–342 (2021). https://doi.org/10.1134/S1061830921040069

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830921040069