Abstract

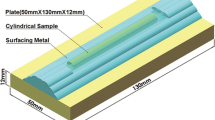

The present paper aims to characterize the welding residual stresses, microstructure, and mechanical properties of some AISI 410 plates welded with low-transformation temperature (LTT) fillers containing different Ni wt.%. The LTT fillers with 11 wt.% Cr and Ni content varying between 3 and 11 wt.% were produced using an arc melting furnace. Effect of Ni wt.% on Ms of LTT fillers was studied using a dilatometer. Five-millimeter-thick AISI 410 plates were welded by GTAW using LTT fillers mentioned above and ER410 conventional filler as a reference. Welding residual stresses were measured by using the hole drilling strain gage method (HDSG). Analyzing the effect of welding dilution on the chemical composition of weld metal was carried out using energy-dispersive X-ray spectroscopy (EDS) followed by a dilatometric test for the evaluation of weld metals Ms after welding. Microstructural examinations show that conventional filler leads to ferritic–martensitic weld metal while in the cases welded with LTT fillers, delta ferrite (δ-ferrite) is decreased when Ni increases. Also, by increasing Ni more than 9 wt.%, the retained austenite is detected in the weld metal. Furthermore, weld metal hardness rises with increasing Ni. Performing tensile and impact tests on welded joints endorse the successful use of LTT fillers for welding the AISI 410 plates.

Similar content being viewed by others

References

Cui C, Zhang Q, Bao Y, Bu Y, Luo Y (2019) Fatigue life evaluation of welded joints in steel bridge considering residual stress. J Constr Steel Res 153:509–518. https://doi.org/10.1016/j.jcsr.2018.11.003

Li L, Jia Q, Wan Z, Zhang Y, Qian P, Li J (2020) Experimental and numerical investigation of effects of residual stress and its release on fatigue strength of typical FPSO-unit welded joint. Ocean Eng 196:106858. https://doi.org/10.1016/j.oceaneng.2019.106858

Wang Y, Li KY, Scenini F, Jiao J, Qu SJ, Luo Q, Shen J (2016) The effect of residual stress on the electrochemical corrosion behavior of Fe-based amorphous coatings in chloride-containing solutions. Surf Coat Technol 302:27–38. https://doi.org/10.1016/j.surfcoat.2016.05.034

Li X, Xie F, Wang D, Xu Ch WM, Sun D, Qi J (2018) Effect of residual and external stress on corrosion behaviour of X80 pipeline steel in sulphate-reducing bacteria environment. Eng Fail Anal 91:275–290. https://doi.org/10.1016/j.engfailanal.2018.04.016

Ainsworth RA, Sharples JK, Smith SD (2000) Effects of residual stresses on fracture behaviour – experimental results and assessment methods. J Strain Anal Eng Des 35:307–316. https://doi.org/10.1243/0309324001514431

Coules HE, Horne GCM, Abburi Venkata K, Pirling T (2018) The effects of residual stress on elastic-plastic fracture propagation and stability. Mater Des 143:131–140. https://doi.org/10.1016/j.matdes.2018.01.064

Hurlston RG, Sharples JK, Sherry AH (2015) Understanding and accounting for the effects of residual stresses on cleavage fracture toughness measurements in the transition temperature regime. Int J Press Vessel Pip 128:69–83. https://doi.org/10.1016/j.ijpvp.2015.02.001

Scholtes B, Voehringer O (2004) Mechanical surface treatment. Encycl Mater Sci Technol:5253–5261. https://doi.org/10.1016/b0-08-043152-6/00916-5

Xie P, Zhao H, Wu B, Gong S (2015) Evaluation of residual stresses relaxation by post weld heat treatment using contour method and X-ray diffraction method. Exp Mech 55:1329–1337. https://doi.org/10.1007/s11340-015-0040-2

Abburi Venkata K, Khayatzadeh S, Achouri A, De Oliveira JA, Forsey AN, Gungor S, Bouchard PJ, Truman CE (2018) Examining stress relaxation in a dissimilar metal weld subjected to postweld heat treatment. Mater Perform Charact 7:675–692. https://doi.org/10.1520/mpc20180018

Smith DJ, Garwood SJ (1992) Influence of postweld heat treatment on the variation of residual stresses in 50 mm thick welded ferritic steel plates. Int J Press Vessel Pip 51:241–256. https://doi.org/10.1016/0308-0161(92)90083-R

Şedek P, Bŕozda J, Wang L, Withers PJ (2003) Residual stress relief in MAG welded joints of dissimilar steels. Int J Press Vessel Pip 80:705–713. https://doi.org/10.1016/j.ijpvp.2003.08.004

Cherif A, Pyoun Y, Scholtes B (2010) Effects of ultrasonic nanocrystal surface modification (UNSM) on residual stress state and fatigue strength of AISI 304. J Mater Eng Perform 19:282–286. https://doi.org/10.1007/s11665-009-9445-3

Xiu L, Liu Z, Lv G, Ma J, Jin F, Dai H, Qiao Y (2018) Remove welding residual stress for CFETR vacuum vessel by trailing ultrasonic impact treatment. J Fusion Energ 37:193–199. https://doi.org/10.1007/s10894-018-0172-3

Munsi ASMY, Waddell AJ, Walker CA (2001) The effect of vibratory stress on the welding microstructure and residual stress distribution. Proc Inst Mech Eng L J Mater Des Appl 215:99–111. https://doi.org/10.1177/146442070121500204

Liu Z, Xiu L, Wu J, Lv G, Ma J (2019) Numerical simulation on residual stress eliminated by shot peening using SPH method. Fusion Eng Des 147:111231. https://doi.org/10.1016/j.fusengdes.2019.06.004

Hobbacher AF (2009) The new IIW recommendations for fatigue assessment of welded joints and components – a comprehensive code recently updated. Int J Fatigue 31:50–58. https://doi.org/10.1016/j.ijfatigue.2008.04.002

Sule J, Ganguly S, Coules H, Pirling T (2015) Application of local mechanical tensioning and laser processing to refine microstructure and modify residual stress state of a multi-pass 304L austenitic steels welds. J Manuf Process 18:141–150. https://doi.org/10.1016/J.JMAPRO.2015.03.003

Jiang W, Chen W, Woo W, Tu ST, Zhang XC, Em V (2018) Effects of low-temperature transformation and transformation-induced plasticity on weld residual stresses: numerical study and neutron diffraction measurement. Mater Des 147:65–79. https://doi.org/10.1016/j.matdes.2018.03.032

Ohta A, Suzuki N, Maeda Y (1997) Effect of residual stress on fatigue of weldment. In: IIW 5th Annual Assembly Conference International Conference, On Performance of Dynamically Loaded Welded Structures. Welding Research Council Inc, San Francisco, pp 108–122

Ohta A, Suzuki N, Maeda Y, Hiraoka K, Nakamura T (1999) Superior fatigue crack growth properties in newly developed weld metal. Int J Fatigue 21:S113–S118. https://doi.org/10.1016/S0142-1123(99)00062-6

Dixneit J, Kromm A, Boin M, Wimpory RC, Kannengiesser T, Gibmeier J, Schroepfer D (2017) Residual stresses of LTT welds in large-scale components. Weld World 61:1089–1097. https://doi.org/10.1007/s40194-017-0502-5

Wang H, Woo W, Kim DK, Em V, Lee SY (2018) Effect of chemical dilution and the number of weld layers on residual stresses in a multi-pass low-transformation-temperature weld. Mater Des 160:384–394. https://doi.org/10.1016/j.matdes.2018.09.016

Gadallah R, Tsutsumi S, Hiraoka K, Murakawa H (2015) Prediction of residual stresses induced by low transformation temperature weld wires and its validation using the contour method. Mar Struct 44:232–253. https://doi.org/10.1016/j.marstruc.2015.10.002

Moat RJ, Ooi S, Shirzadi AA, Dai H, Mark AF, Bhadeshia HKDH, Withers PJ (2018) Residual stress control of multipass welds using low transformation temperature fillers. Mater Sci Technol 34:519–528. https://doi.org/10.1080/02670836.2017.1410954

Wu S, Wang D, Zhang Z, Li C, Liu X, Zhou Z, Di X (2019) Effect of dilution on fatigue behaviour of welded joints produced by low-transformation-temperature fillers. Sci Technol Weld Join 24:601–608. https://doi.org/10.1080/13621718.2019.1576272

Dixneit J, Vollert F, Kromm A, Gibmeier J, Hannemann A, Fischer T, Kannengiesser T (2019) In situ analysis of the strain evolution during welding using low transformation temperature filler materials. Sci Technol Weld Join 24:243–255. https://doi.org/10.1080/13621718.2018.1525150

Harati E, Karlsson L, Svensson LE, Dalaei K (2017) Applicability of low transformation temperature welding consumables to increase fatigue strength of welded high strength steels. Int J Fatigue 97:39–47. https://doi.org/10.1016/j.ijfatigue.2016.12.007

Altenkirch J, Gibmeier J, Kromm A, Kannengiesser T, Nitschke-Pagel T, Hofmann M (2011) In situ study of structural integrity of low transformation temperature (LTT)-welds. Mater Sci Eng A 528:5566–5575. https://doi.org/10.1016/j.msea.2011.03.091

Camilleri D, McPherson N, Gray TGF (2013) The applicability of using low transformation temperature welding wire to minimize unwanted residual stresses and distortions. Int J Press Vessel Pip 110:2–8. https://doi.org/10.1016/j.ijpvp.2013.04.014

Deng D, Murakawa H (2013) Influence of transformation induced plasticity on simulated results of welding residual stress in low temperature transformation steel. Comput Mater Sci 78:55–62. https://doi.org/10.1016/j.commatsci.2013.05.023

Moat RJ, Stone HJ, Shirzadi AA, Francis JA, Kundu S, Mark AF, Bhadeshia HKDH, Karlsson L, Withers PJ (2011) Design of weld fillers for mitigation of residual stresses in ferritic and austenitic steel welds. Sci Technol Weld Join 16:279–284. https://doi.org/10.1179/1362171811y.0000000003

Vamsi Krishna B, Bandyopadhyay A (2009) Surface modification of AISI 410 stainless steel using laser engineered net shaping (LENSTM). Mater Des 30:1490–1496. https://doi.org/10.1016/j.matdes.2008.08.003

Hejripour F, Aidun DK (2017) Consumable selection for arc welding between stainless steel 410 and Inconel 718. J Mater Process Technol 245:287–299. https://doi.org/10.1016/j.jmatprotec.2017.02.013

Tsai MC, Chiou CS, Du JS, Yang JR (2002) Phase transformation in AISI 410 stainless steel. Mater Sci Eng A 332:1–10. https://doi.org/10.1016/S0921-5093(01)01710-5

Hosseini SA, Gheisari K, Moshayedi H, Warchomicka F, Enzinger N (2020) Basic alloy development of low-transformation-temperature fillers for AISI 410 martensitic stainless steel. Sci Technol Weld Join 25:243–250. https://doi.org/10.1080/13621718.2019.1681159

ASTM-E837 (2008) Determining residual stresses by the hole-drilling strain-gage method

Schajer GS (2013) Practical residual stress measurement methods. Wiley, Vancouver, pp 42–47

ASTM E92-17 (2017) Standard test methods for Vickers hardness and Knoop hardness of metallic materials. ASTM International, West Conshohocken

ASTM E8 (2010) ASTM E8/E8M standard test methods for tension testing of metallic materials 1. Annu B ASTM Stand 4:1–27

ASTM E 23-12c (2013) Standard test methods for notched bar impact testing of metallic materials. Standards i:1–25

Hsu TY (1985) An approximate approach for the calculation of Ms in iron-base alloys. J Mater Sci 20:23–31. https://doi.org/10.1007/BF00555894

Wu S, Wang D, Zhang Z, Li C, Liu X, Meng X, Feng Z, Di X (2019) Mechanical properties of low-transformation-temperature weld metals after low-temperature postweld heat treatment. Sci Technol Weld Join 24:112–120. https://doi.org/10.1080/13621718.2018.1492776

Barsoum Z, Gustafsson M (2009) Fatigue of high strength steel joints welded with low temperature transformation consumables. Eng Fail Anal 16:2186–2194. https://doi.org/10.1016/j.engfailanal.2009.02.013

Thibault D, Bocher P, Thomas M (2009) Residual stress and microstructure in welds of 13%Cr–4%Ni martensitic stainless steel. J Mater Process Technol 209:2195–2202. https://doi.org/10.1016/J.JMATPROTEC.2008.05.005

Xiong J, Tan MY, Forsyth M (2013) The corrosion behaviors of stainless steel weldments in sodium chloride solution observed using a novel electrochemical measurement approach. Desalination 327:39–45. https://doi.org/10.1016/J.DESAL.2013.08.006

Zhou T, Yu H, Wang S (2016) Effect of microstructural types on toughness and microstructural optimization of ultra-heavy steel plate: EBSD analysis and microscopic fracture mechanism. Mater Sci Eng A 658:150–158. https://doi.org/10.1016/J.MSEA.2016.02.001

Rout M, Ranjan R, Pal SK, Singh SB (2018) EBSD study of microstructure evolution during axisymmetric hot compression of 304LN stainless steel. Mater Sci Eng A 711:378–388. https://doi.org/10.1016/J.MSEA.2017.11.059

Di X, Geng D, Wu S, Wang D, Zhang Z, Li C (2019) Solidification behaviour and microstructure of welding transition zone using low-transformation-temperature welding consumables. Sci Technol Weld Join 24:148–155. https://doi.org/10.1080/13621718.2018.1494403

Kangazian J, Shamanian M (2019) Micro-texture and corrosion behavior of dissimilar joints of UNS S32750 stainless steel/UNS N08825 Ni-based superalloy. Mater Charact 155:109802. https://doi.org/10.1016/J.MATCHAR.2019.109802

Fu Z, Li T, Shan M, Gou G, Zhu Z, Ma C, Gao W, Hu Y (2019) Hydrogen atoms on the SCC behavior of SUS301L-MT stainless steel laser-arc hybrid welded joints. Corros Sci 148:272–280. https://doi.org/10.1016/J.CORSCI.2018.12.023

Kubin L, Mortensen A (2003) Geometrically necessary dislocations and strain-gradient plasticity: a few critical issues. Scr Mater 48:119–125. https://doi.org/10.1016/S1359-6462(02)00335-4

Calcagnotto M, Ponge D, Demir E, Raabe D (2010) Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater Sci Eng A 527:2738–2746. https://doi.org/10.1016/J.MSEA.2010.01.004

Carrouge D (2002) Phase transformations in welded supermartensitic stainless steels. Dissertation, University of Cambridge, pp 28–30

Wang P, Lu SP, Xiao NM, Li DZ, Li YY (2010) Effect of delta ferrite on impact properties of low carbon 13Cr–4Ni martensitic stainless steel. Mater Sci Eng A 527:3210–3216. https://doi.org/10.1016/J.MSEA.2010.01.085

Carrouge D, Bhadeshia HKDH, Woollin P (2004) Effect of δ-ferrite on impact properties of supermartensitic stainless steel heat affected zones. Sci Technol Weld Join 9:377–389. https://doi.org/10.1179/136217104225021823

Das CR, Albert SK, Bhaduri AK, Srinivasan G, Ramasubbu V (2008) Effect of minor change in composition on toughness of weldmetal for repair of turbine blades made of martensitic stainless steel. Sci Technol Weld Join 13:159–166. https://doi.org/10.1179/174329308X271814

Yan Sh PJ, Chi B, Jian L (2010) Estimation of driving force for martensitic transformation in (Ni52.5Mn23.5Ga24)100-xCox alloys. J Alloys Compd 507:331–334. https://doi.org/10.1016/j.jallcom.2010.07.194

Durand-Charre M (2004) Microstructure of steels and cast irons, 1st edn. Springer, Berlin

Muthupandi V, Bala Srinivasan P, Seshadri SK, Sundaresan S (2003) Effect of weld metal chemistry and heat input on the structure and properties of duplex stainless steel welds. Mater Sci Eng A 358:9–16. https://doi.org/10.1016/S0921-5093(03)00077-7

Ooi SW, Garnham JE, Ramjaun TI (2014) Review: Low transformation temperature weld filler for tensile residual stress reduction. Mater Des 56:773–781. https://doi.org/10.1016/j.matdes.2013.11.050

Li J, Cheng L, Zhang P, Wang L, Li H (2019) Effect of delta ferrites on the anisotropy of impact toughness in martensitic heat-resistant steel. J Mater Res Technol 8:1781–1788. https://doi.org/10.1016/j.jmrt.2018.12.008

Li J, Zhang C, Jiang B, Zhou L, Liu Y (2016) Effect of large-size M23C6-type carbides on the low-temperature toughness of martensitic heat-resistant steels. J Alloys Compd 685:248–257. https://doi.org/10.1016/j.jallcom.2016.05.294

Kim S-J, Gil Lee C, Lee T-H, Oh C-S (2003) Effect of Cu, Cr and Ni on mechanical properties of 0.15 wt.% C TRIP-aided cold rolled steels. Scr Mater 48:539–544. https://doi.org/10.1016/S1359-6462(02)00477-3

Acknowledgments

Financial support provided by the Shahid Chamran University of Ahvaz through the grant number SCU.EM98.222 is gratefully appreciated. The authors wish to express their thanks to Mr. Florian Pixner and Mr. Andreas Hütter for all the technical help.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

About this article

Cite this article

Hosseini, S.A., Gheisari, K., Moshayedi, H. et al. Assessment of the chemical composition of LTT fillers on residual stresses, microstructure, and mechanical properties of 410 AISI welded joints. Weld World 65, 807–823 (2021). https://doi.org/10.1007/s40194-020-01064-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-01064-1