Abstract

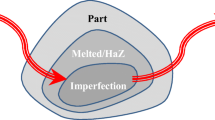

Possibilities, application domains, advantages, and limitations are considered for currently used physical methods of nondestructive testing of additive manufactured parts. The methods are classified according to the physical principle of operation.

Similar content being viewed by others

References

Aleshin, N.P., Grigor’ev, M.V., Shchipakov, N.A., Prilutskii, M.A., and Murashov, V.V., Using nondestructive testing methods for in-production quality control of additive manufactured parts, Russ. J. Nondestr. Test., 2016, vol. 52, no. 9, pp. 64–71.

Aleshin, N.P., Murashov, V.V., Evgenov, A.G., Grigor’ev, M.V., Shchipakov, N.A., Vasilenko, S.A., and Krasnov, I.S., The classification of flaws of metal materials synthesized by the selective laser melting method and the capabilities of nondestructive testing methods for their detection, Russ. J. Nondestr. Test., 2016, vol. 52, no. 1, pp. 38–43.

Aleshin, N.P., Murashov, V.V., Grigor’ev, M.V., Evgenov, A.G., Karachevtsev, F.N., Shchipakov, N.A., and Vasilenko, S.A., Flaws in heat resistant SLM-synthesized alloys, Materialovedenie, 2016, no.4.

Kalinina, N.E., Kavats, O.A., and Kalinin, V.T., Improving technological properties of casting aluminum alloys by modification with nano-dispersive particles, Aviats.-Kosm. Tekh. Tekhnol., 2010, no. 4 (71), pp. 17–20.

Peters, M. and Leyens, C., Aerospace and Space Materials, Oxford: UNESCO, 2003.

Louvis, E., Fox, P., and Sutcliffe, C.J., Selective laser melting of aluminium components, J. Mater. Process. Technol., 2011, vol. 211, no. 2, pp. 275–284.

Spierings, A., Schneider, M., and Eggenberger, R., Comparison of density measurement techniques for additive manufactured metallic parts, Rapid Prototyping J., 2011, vol.17.

Gong, H., Rafi, K., Gu, H., Starr, T., and Stucker, B., Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes, Addit. Manuf., 2014, vol. 1, pp. 87–98.

Kempen, K., Thijs, L., Yasa, E., Badrossamay, M., Verheecke, W., and Kruth, J., Process optimization and microstructural analysis for selective laser melting of AlSi10Mg, Phys. Procedia, 2012, vol. 39, pp. 439–446.

Spierings, A., Herres, N., and Levy, G., Influence of the particle size distribution on surface quality and mechanical properties in am steel parts, Rapid Prototyping J., 2011, vol. 17, pp. 195–202.

Vrancken, B., Wauthle, R., Kruth, J., and Humbeeck, V., Study of the Influence of Material Properties on Residual Stress in Selective Laser Melting, Paper presented at the 24th Solid Freeform Fabr. (SFF) Symp., Austin, TX, 2013.

Bael van, S., Kerckhofs, G., Moesen, M., Pyka, G., Schrooten, J., and Kruth, J.P., Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti–6Al–4V porous structures, Mater. Sci. Eng., 2011, vol. 528, pp. 7423–7431.

Löber, L., Schimansky, F.P., Kuhn, U., Pyczak, F., and Eckert, J., Selective laser melting of a beta-solidifying TNM-B1 titanium aluminide alloy, J. Mater. Process. Technol., 2014, vol. 214, pp. 1852–1860.

Ahsan, M.N., Bradley, R., and Pinkerton, A.J., Microcomputed tomography analysis of intralayer porosity generation in laser direct metal deposition and its causes, J. Laser Appl., 2011, vol.23.

Yu, J., Rombouts, M. and Maes, G., Cracking behavior and mechanical properties of austenitic stainless steel parts produced by laser metal deposition, Mater. Des., 2013, vol. 45, pp. 228–235.

Cerniglia, D., Scafidi, M., Pantano, A., and Santospirito, S.-P., Laser Ultrasonic Technique for Laser Powder Deposition Inspection, Paper presented at the 13th Int. Symp. Nondestr. Charact. Mater. (NDCMXIII), Le Mans, France, May 2013.

Rudlin, J., Cerniglia, D., Scafidi, M., and Schneider, C., Inspection of Laser Powder Deposited Layers, Paper presented at the 11th Eur. Conf. Non-Destr. Test. (ECNDT 2014), Prague, Czech Republic, October 2014.

Nilsson, P., Appelgren, A., Henrikson, P., and Runnemalm, A., Automatic Ultrasonic Testing for Metal Deposition, Paper presented at the 18th World Conf. Nondestr. Test., Durban, South Africa, April 2012.

Slotwinski, J.A., Garboczi, E.J., and Hebenstreit, K.M., Porosity measurements and analysis for metal additive manufacturing process control, J. Res. Natl. Inst. Stand. Technol., 2014, vol. 119, pp. 494–528.

Karthik, N.V., Gu, H., Pal, D., Starr, T., and Stucker, B., High Frequency Ultrasonic Non Destructive Evaluation of Additively Manufactured Components, Paper presented at the 24th Annual Int. Solid Freeform Fabr. (SFF) Symp., Austin, TX, 2013.

Wong, B.S. and Ong, M.Y., Non-Destructive Testing of Metallic 3D Printed Specimens, Saarbrucken: LAP LAMBERT Academic, 2015.

Smith, R.J., Li, W.Q., Coulson, J., Clark, M., Somekh, M.G., and Sharples, S.D., Spatially resolved acoustic spectroscopy for rapid imaging of material microstructure and grain orientation, Meas. Sci. Technol., vol. 25, 2014. doi 10.1364/OE.14.010435

Caiazzo, F., Cardaropoli, F., Alfieri, V., Sergi, V., and Cuccaro, L., Experimental analysis of Selective Laser Melting process for Ti–6Al–4V turbine blade manufacturing, Proc. XIX Int. Symp. High-Power Laser Syst. Appl., 2012, vol. 8677. doi 10.1117/12.201057710.1117/12.2010577

Rometsch, P.A., Pelliccia, D., Tomus, D., and Wu, X., Evaluation of polychromatic X-ray radiography defect detection limits in a sample fabricated from Hastelloy X by selective laser melting, NDT & E Int., 2014, vol. 62, pp. 184–192.

Ziolkowski, G., Chlebus, E., Szymczyk, P., and Kurza, J., Application of X-ray CT method for discontinuity and porosity detection in 316L stainless steel parts produced with SLM technology, Arch. Civ. Mech. Eng., 2014, vol.13.

Leonard, F., Tammas-Williams, S., Prangnell, P.B., Todd, I., and Withers, P.J., Assessment by X-Ray CTof the Effects of Geometry and Build Direction on Defects in Titanium ALM Parts, Paper presented at the Conf. Ind. Comput. Tomogr. (ICT), Wels, Austria, 2012.

Tammas-William, S., Zhao, H., Leonard, F., Derguti, F., Todd, I., and Prangnell, P.B., XCT analysis of the influence of melt strategies on defect population in Ti-6Al-4V components manufactured by selective electron beam melting, Mater. Charact., 2015, vol. 102, pp. 47–61.

Raguvarun, K., Balasubramaniam, K., and Rajagopal, P., A Study of Internal Structure in Components Made by Additive Manufacturing Process Using 3D X-Ray Tomography, Paper presented at the QNDE Rev. Prog. Quant. Nondestr. Eval., Boise, ID, 2014.

Slotwinski, J.A. and Garboczi, E.J., Porosity of Additive Manufacturing Parts for Process Monitoring, Paper presented at AIP Conf. Proc., Baltimore, MD,2013.

Plessis du, A., le Roux, S.G., Els, J., Booysen, G., and Blaine, D.C., Application of microCT to the nondestructive testing of an additive manufactured titanium component, Case Stud. Nondestr. Test. Eval., 2015, vol. 4, pp. 1–7.

Ye, N. and Jian, F., Effect of voxel size and partial volume effect on accuracy of tooth volumetric measurements with cone beam CT, Dentomaxillofac Radiol., 2013, vol. 42, no.5.

Sezgin, M. and Sankur, B., Survey over image thresholding techniques and quantitative performance evaluation, Electron. Imaging, 2004, vol. 13, p.146.

Pal, N.R. and Pal, S.K., A review on image segmentation techniques, Pattern Recognit., 1993, vol. 26, p. 1277.

Rajagopalan, S., Lu, L.C., Yaszemski, M.J., and Robb, R.A., Optimal segmentation of microcomputed tomographic images of porous tissue-engineering scaffolds, J. Biomed. Mater. Res., 2005, vol. 75, p. 877.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © N.P. Aleshin, M.V. Grigor’ev, N.A. Shchipakov, M.A. Prilutskii, V.V. Murashov, 2016, published in Defektoskopiya, 2016, No. 10, pp. 63–75.

Rights and permissions

About this article

Cite this article

Aleshin, N.P., Grigor’ev, M.V., Shchipakov, N.A. et al. Applying nondestructive testing to quality control of additive manufactured parts. Russ J Nondestruct Test 52, 600–609 (2016). https://doi.org/10.1134/S1061830916100028

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1061830916100028