Abstract—

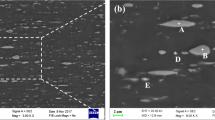

This article presents the results of investigating the microstructure, phase composition, parameters of the substructure and residual stresses of the surface layer of AK5M7 alloy after its electrospark treatment (EST) using a copper-phosphorus electrode. The main variable is the EST energy. The analyzed material is a multiphase system. The main phases are as follows: aluminum, Al2Cu, and Cu3Al. An increase in the energy of electrospark treatment is accompanied by an increase in the fractions of Al2Cu and Cu3Al, microscopic deformations and residual stresses, as well as a decrease in the sizes of subblocks. For the aluminum phase, the residual stresses are tensile, and for Al2Cu, the stresses are compressive. Analysis of the intensity of diffraction lines reveals possible texture in the treated layer. An increase in the energy of electrospark treatment results in the chaotic distribution of the orientation of grains of the generated crystallographic phases. The obtained results can be attributed to nonequilibrium processes in the surface layer at high mechanical and thermal impacts accompanied by micrometallurgical processes.

Similar content being viewed by others

REFERENCES

S. A. Velichko, P. V. Senin, and P. V. Chumakov, Increasing the Durability of Piston Hydraulic Cylinders Using Electrospark Technology (Mordov. Gos. Univ., Saransk, 2016) [in Russian].

N. E. Fomin, I. Kh. Khasan, and V. M. Kyashkin, Vestn. Donsk. Gos. Tekh. Univ. 19, 138 (2019). https://doi.org/10.23947/1992-5980-2019-19-2-138-142

D. A. Ignat’kov, Elektron. Obrab. Mater., No. 4, 9 (2001).

F. Kh. Burumkulov, V. P. Lyalyakin, I. A. Pushkin, and S. N. Frolov, Mekh. Elektrif. Sel’sk. Khoz., No. 4, 23 (2001).

S. I. Smagin, V. D. Vlasenko, and Yu. I. Mulin, Vychislit. Tekhnol., 14 (3), 79 (2009).

A. D. Verkhoturov, V. I. Ivanov, and L. A. Konevtsov, Tr. GOSNITI 107, 131 (2011).

V. D. Vlasenko and M. V. Kolisova, Contemporary Engineering Sci. 9, 249 (2016). https://doi.org/10.12988/ces.2016.611

E. V. Yurchenko and V. I. Ivanov, Tr. GOSNITI 117, 251 (2014).

S. Ya. Betsofen, L. M. Petrov, and A. A. Il’in, Poverkhn.: Rentgenovskie, Sinkhrotronnye Neitr. Issled., No. 1, 39 (2004).

S. Ya. Betsofen, A. A. Ashmarin, A. A. Lozovan, B. V. Ryabenko, A. N. Lutsenko, A. M. Mamonov, and D. E. Molostov, J. Surf. Invest.: X-ray, Synchrotron Neutron Tech. 10, 705 (2016). https://doi.org/10.1134/S1027451016040054

T. Gnaupel-Herold, J. Appl. Crystallogr. 45, 573 (2012). https://doi.org/10.1107/S0021889812014252

S. Wang and C. Fan, Metals 9, 1037 (2019). https://doi.org/10.3390/met9101037

H. Liu, I. Papadimitriou, F. X. Lin, and J. L. Lorca, Acta Mater. 167, 121 (2019). https://doi.org/10.1016/j.actamat.2019.01.024

Ya. S. Umanskii, Radiography of Metals (Metallurgiya, Moscow, 1967) [in Russian].

S. A. Pyachin, N. E. Ablesimov, and D. L. Yagodzinskii, Elektron. Obrab. Mater., No. 1, 19, (2003).

N. Ya. Parkanskii, M. S. Kats, M. G. Gol’diner, and A. E. Gitlevich, Elektron. Obrab. Mater., No. 3, 20 (1982).

N. Dolgopolov, A. Rodin, A. Simanov, and I. Contar’, Mater. Lett. 62, 4477 (2008). https://doi.org/10.3103/S1067821209020114

N. N. Goreslavets and A. O. Rodin, Phys. Met. Metallogr. 118, 1120 (2017). https://doi.org/10.1134/S0031918X17100064

J. Pelleg, L. Z. Zevin, S. Lungo, and N. Croitoru, Thin Solid Films 197, 117 (1991). https://doi.org/10.1016/0040-6090(91)90225-M

B. Rauschenbach and J. W. Gerlach, Cryst. Res. Technol. 35, 675 (2000). https://doi.org/10.1002/1521-4079(200007)35:6/7<675::AID-CRAT675>3.0.CO;2-7

J. P. Zhao, X. Wang, and Z. Y. Chen, J. Phys. D: Appl. Phys. 30, 5 (1997).

V. K. Afanas’ev, A. V. Gorshenin, M. A. Starostina, I. V. Degtyareva, and E. V. Pervakova, Metall. Mashinostr., No. 3, 30 (2010).

ACKNOWLEDGMENTS

We are grateful to Prof. N.E. Fomin, Head of the Chair of Solid State Physics, and V.M. Kyashkin, Assistant Professor of the Chair of Solid State Physics, Ogarev Mordovia State University, for performing the X-ray investigations and discussion of the experimental results.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by I. Moshkin

Rights and permissions

About this article

Cite this article

Hasan, I.K., Pan’kin, N.A. Microstructure, Phase Composition, Substructure and Residual Stress of AK5M7 Aluminum Alloy after its Electrospark Treatment. J. Surf. Investig. 15, 1080–1086 (2021). https://doi.org/10.1134/S1027451021050281

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1027451021050281