Abstract

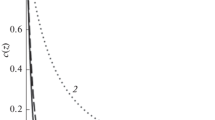

To perform the oxygen reduction reaction effectively, the active layer of the lithium–oxygen battery positive electrode must have developed surface possessing a complicated pore structure. During discharge (the oxygen reaction cathodic component), the electrode accumulates lithium peroxide, a final product of electrochemical and chemical reactions (resulting in the conjunction of lithium ions, oxygen molecules. and electrons); the latter undergoes oxidation (the oxygen reaction anodic component) during the lithium–oxygen battery charging. The lithium peroxide is a water-insoluble compound that has no electronic conduction; when depositing on the electrode surface it seals openings of narrow pores and prevents oxygen penetration therein. To obtain more lithium peroxide via oxygen reduction in the presence of lithium ions, a cluster of large pores, practically unsealed with the lithium peroxide, is produced in the active layer; the pores supply oxygen deep into the active layer. The Li2O2 accumulation occurs in a cluster of lesser pores with developed surface. In the creating of the lithium–oxygen battery positive electrode active layer optimal structure, the difficulty is that some key quantities are unknown in advance. They are the large-scale and lesser pore average size and their volume fractions in the active layer. To solve the problem, the regular biporous model of the pore structure can be used. In the model, the pore radii are strictly fixed. This opens a relatively easy way for the interconnecting, by calculations, of parameters and the lithium–oxygen battery dimensioning specifications during its discharge. This work aimed at the proposing of the positive electrode active layer regular biporous model and developing of a procedure for the calculating of the lithium–oxygen battery dimensioning specifications during the discharge. it is shown, in a specific context, how the varying of the positive electrode active layer structure and the oxygen consumption constant k can control the Li2O2 accumulation.

Similar content being viewed by others

Notes

For convenience, in what follows we shall designate the positive electrode in the discharging mode as cathode.

REFERENCES

Toni, J.E.A., McDonald, G.D., and Elliott, W.E., Lithium–Moist Air Battery, Fort Belvoir, Virginia, 1966.

Abraham, K.M. and Jiang, Z., A polymer electrolyte-based rechargeable lithium/oxygen battery, J. Electrochem. Soc., 1996, vol. 143, p. 1.

Ogasawara, T., Débart, A., Holzapfel, M., Novák, P., and Bruceet, P.G., Rechargeable Li2O2 Electrode for Lithium Batteries, J. Am. Chem. Soc., 2006, vol. 128, p. 1390.

Christensen, J., Albertus, P., Sanchez-Carrera, R.S., Lohmann, T., Kozinsky, B., Litdike, R., Jasim, A., and Kojic, A., A critical review of Li/air batteries, J. Electrochem. Soc., 2011, vol. 159(2), p. R1.

Luntz, A. and Bryan D., Nonaqueous Li-air batteries: a status report, Chem. Rev., 2014, vol. 114(23), p. 11721.

Imanishi, N., Luntz, A., and Druce, P., The Lithium–Air Battery: Fundamentals, Berlin: Springer, 2014.

Bruce, P., Freuriberger, S., Hardwick, L., and Tarascon, J., Li–O2 and Li–S batteries with high energy storage, Nat. Mater., 2012, vol. 11, p. 19.

Yang, X., He, P., and Xia, Y., Preparation of mesocellular carbon foam and its application for Lithium/Air Battery, Electrochem. Commun., 2009, vol. 11(6), p. 1127.

Tran, C., Yang, X., and Qu, D., Investigation of the gas-diffusion-electrode used as lithium/air cathode in non-aqueous electrolyte and the importance of carbon material porosity, J. Power Sources., 2010, vol. 195(7), p. 2057.

Laoire, C., Mukerjee, S., Abraham, K., Plichta, E., and Hendrickson, M., Elucidating the mechanism of oxygen reduction for lithium-air battery applications, J. Phys. Chem. C, 2009, vol. 113(46), p. 20127.

Laoire, C., Mukerjee, S., Abraham, K., Plichta, E., and Hendrickson, M., Influence of nonaqueous solvents on the electrochemistry of oxygen in the rechargeable lithium–air battery, J. Phys. Chem. C, 2010, vol. 114(19), p. 9178.

Jones, R., Gittleson, F., Templeton, J., and Ward, D., A simple model for interpreting the reaction-diffusion characteristics of L-air batteries, J. Electrochem. Soc., 2017, vol. 164(1), p. A6422.

Chen, X., Bevara, V., Andrei, P., Hendrickson, M., Plichta, E., and Zheng, J., Combined effects of oxygen diffusion and electronic resistance in Li-air batteries with carbon nanofiber cathodes, J. Electrochem. Soc., 2014, vol. 161(12), p. A1877.

Xue, K., Nguyen, T., and Franco, A., Impact of the cathode microstructure on the discharge performance of lithium air batteries: a multiscale model, J. Electrochem. Soc., 2014, vol. 161(8), p. E3028.

Sandhu, S., Fellner, J., and Brutchen, G., Diffusion-limited model for a lithium/air battery with an organic electrolyte, J. Power Sources, 2007, vol. 164(1), p. 365.

Petru, A., Zheng, J., Hendrickson, M., and Plichta, E., Some possible approaches for improving the energy density of Li–air batteries, J. Electrochem. Soc., 2010, vol. 157(12), p. A1287.

Albertus, P., Girishkumar, G., VcCloskey, B., Sanchez-Carrera, R., Kozinsky, B., Cristensen, J., and Luntz, A., Identifying capacity limitations in the Li/oxygen battery using experiments and modeling, J. Electrochem. Soc., 2011, vol. 158, no. 3, p. A343.

Xianglin, I. and Faghri, A., Optimization of the cathode structure of Lithium-air batteries based on a two-dimensional, transient, non-isothermal model, J. Electrochem. Soc., 2012, vol. 159(10), p. A1747.

Dabrowski, T., Struck, A., Fenske, D., Maaß, P., and Colombi Ciacchi, L., Optimization of Catalytically Active Sites Positioning in Porous Cathodes of Lithium/Air Batteries Filled with Different Electrolytes, J. Electrochem. Soc., 2015, vol. 162(14), p. A2796.

Wang, Y., Wang, Z., Yuan, H., and Li, T., Discharge oxide storage capacity and voltage loss in Li–air battery, Electrochim. Acta, 2015, vol. 180, p. 382.

Younesi, R., Urbonaite, S., Bjorefors, F., and Edstrom, K., Influence of the cathode porosity on the discharge performance of the lithium-oxygen batatery, J. Power Sources, 2011, vol. 196, p. 9835.

Meini, S., Piana, M., Beyer, H., Schwammlein, J., and Gasteiger, H., Effect of carbon surface area on first discharge capacity of Li–O2 cathodes and cycle-life behavior in ether–based electrolytes, J. Electrochem. Soc., 2012, vol. 159, p. A2135.

Ma, S., Lee, D., Roev, V., Im, D., and Doo, S., Effect of porosity on electrochemical properties of carbon materials as cathode foe lithium-oxygen battery. J. Power Sources, 2013, vol. 244, p. 494.

Zhang, Y., Zhang, H., Li, J., Wang, M., Nie, H., and Zhang, F., The use of mixed carbon materials with improved oxygen transport in a lithium-air battery, J. Power Sources, 2013, vol. 240, p. 390.

Lin, X., Zhou, L., Huang, T., and Yu, A., Hierarchically porous honeycomb-like carbon as a lithium-oxygen electrode, J. Mater. Chem., A, 2013, vol. 1, p. 1239.

Olivares-Marin, M., Palomino, P., Enciso, E., and Tonti, D., Simple method to relate experimental pore size distribution and discharge capacity in cathodes for Li–O2 batteries, J. Phys. Chem. C, 2014, vol. 118, p. 20772.

Ma, Z., Yuan, X., Li, L., Ma, Z., Wilkinson, D., Zhang, L., and Zhang, J., A review of cathode materials and structures for rechargeable lithium-air batteries. Energy Environ. Sci., 2015, vol. 8, p. 2144.

Li, X., Huang, J., and Faghri, A., A critical review of macroscopic modeling studies on Li–O and Li–air batteries using organic electrolyte: Challenges and opportunities, J. Power Sources, 2016, vol. 332, p. 420.

Wang, Y., Modeling discharge deposit formation and its effect on lithium–air battery performance, Electrochim. Acta, 2012, vol. 75, p. 239.

Bevara, V. and Andrei, P., Changing the cathode microstructure to improve the capacity of Li–air batteries: Theoretical predictions, J. Electrochem. Soc., 2014, vol. 161(14), p.12.

Andersen, C., Hu, H., Qiu, G., Kalra, V., and Sun, Y., Pore-scale transport resolved model incorporating cathode microstructure and peroxide growth in lithium-air batteries, J. Electrochem. Soc., 2015, vol. 162(7), p. A1135.

Bao, J., Hu, W., Bhattacharya, P., Stewart, M., Zhang, J., and Pan, W., Discharge performance of Li–O2 batteries using a multiscale modeling approach, J. Phys. Chem. C., 2015, vol. 119(27), p. 14851.

Pan, W., Yang, X., Bao, J., and Wang, M., Optimizing discharge capacity of Li–O2 Batteries dy design of air-electrode porous structure: Multifidelity modeling and optimization, J. Electrochem. Soc., 2017, vol. 164(11), p. E3499.

Tarasevich, Yu.Yu., Percolation: Theory, Applications, Algorithms (in Russian), Moscow: Editorial URSS.

Chirkov, Yu.G., Theory of porous electrodes: percolation, calculations of percolation lines, Russ. J. Electrochem., 1999, vol. 35, p. 1281.

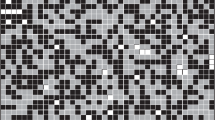

Chirkov, Yu.G., Rostokin, V.I., and Skundin, A.M., Digital simulation of the positive electrode in the lithium-ion batteries, Russ. J. Electrochem., 2011, vol. 47, p. 71.

LaBolle, E., Quastel, J., and Fogg, G., Diffusion theory for transport in porous media: Transition-probability densities of diffusion processes corresponding to advection-dispersion equations, Water Resources Res., 1998, vol. 416(7), p. 1685.

Petersen, E., Diffusion in a pore of varying cross section, AIChE Journal, 1958, vol. 4(3), p. 343.

Edwards, C.H. and Penney, D.E., Differential Equations and Boundary Value Problems : Computing and Modeling using Mathematica, Maple and MATLAB, 3rd Ed., Kiev: Dialektika-Williams, 2007, ISBN 978-5-8459-1166-7.

Goloskokov, D.P., Equations of Mathematical Physics. Solving of Problems in Maple System, St. Petersburg: Piter, 2004.

Funding

This work was supported by the Ministry of Science and Higher Education of the Russian Federation.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflict of interest.

Additional information

Translated by Yu. Pleskov

Rights and permissions

About this article

Cite this article

Chirkov, Y.G., Andreev, V.N., Rostokin, V.I. et al. Regular Biporous Model of Active Layer of the Lithium–Oxygen Battery Positive Electrode. Russ J Electrochem 55, 860–870 (2019). https://doi.org/10.1134/S1023193519090052

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1023193519090052