Abstract

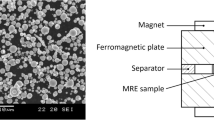

Viscoelastic properties of magnetoactive elastomers with spherical and plate-shaped filler have been studied. Four series of samples based on silicone elastomer and carbonyl iron microparticles have been prepared. A series of samples with a concentration of magnetic filler from 30 to 60 wt % which differed in the shape of filler particles (spherical and platelike) and in their distribution in the polymer matrix (isotropic and anisotropic). The magnetorheological properties of the obtained magnetoactive elastomers have been examined by dynamic mechanical analysis. Storage modulus values for samples of different compositions are in the range of 10–100 kPa. It has been shown that anisotropic materials are stiffer than the isotropic counterparts and demonstrate a higher magnetorheological effect: the increase in the elastic modulus of an anisotropic sample with the maximum filler content exceeds an order of magnitude in a magnetic field of 1 T. At the same filler concentrations, materials based on platelike iron are stiffer than those based on spherical iron. At low magnetic filler concentrations, the use of platelike iron makes it possible to achieve a higher magnetic response of the material; at high filler concentrations, the increase in the elastic modulus is greater for samples based on spherical particles. The anisotropic materials exhibit a more pronounced Payne effect.

Similar content being viewed by others

REFERENCES

S. B. Choi, W. Li, M. Yu, H. Du, J. Fu, and P. X. Do, Smart Mater. Struct. 25, 043001 (2016).

G. Filipcsei, I. Csetneki, A. Szilágyi, and M. Zrínyi, Adv. Polym. Sci. 206, 137 (2007).

Ubaidillah, J. Sutrisno, A. Purwanto, and S. A. Mazlan, Adv. Eng. Mater. 17, 563 (2015).

S. Odenbach, Arch. Appl. Mech. 86, 269 (2016).

M. T. Lopez-Lopez, J. D. G. Durán, L. Yu. Iskakova, and A. Yu. Zubarev, J. Nanofluids 5, 479 (2016).

A. K. Bastola, M. Paudel, L. Li, and W. Li, Smart Mater. Struct. 29, 123002 (2020).

N. Bira, P. Dhagat, and J. R. Davidson, Front. Rob. AI 7, 588391 (2020).

M. Schümann and S. Odenbach, J. Magn. Magn. Mater. 441, 88 (2017).

T. Gundermann and S. Odenbach, Smart. Mater. Struct. 23, 105013 (2014).

G. V. Stepanov, S. S. Abramchuk, D. A. Grishin, L. V. Nikitin, E. Y. Kramarenko, and A. R. Khokhlov, Polymer (Guildf) 48, 488 (2007).

G. V. Stepanov, D. A. Semerenko, A. V. Bakhtiiarov, and P. A. Storozhenko, J. Supercond. Novel Magn. 26, 1055 (2013).

I. A. Belyaeva, E. Y. Kramarenko, and M. Shamonin, Polymer (Guildf) 127, 119 (2017).

S. A. Kostrov, M. Shamonin, G. V. Stepanov, and E. Y. Kra-marenko, Int. J. Mol. Sci. 20, 2230 (2019).

D. Isaev, A. Semisalova, Y. Alekhina, L. Makarova, and N. Perov, Int. J. Mol. Sci. 20, 1457 (2019).

G. Glavan, P. Salamon, I. A. Belyaeva, M. Shamonin, and I. Drevenšek-Olenik, J. Appl. Polym. Sci. 135 (18), 46221 (2018).

V. V. Sorokin, B. O. Sokolov, G. V. Stepanov, and E. Yu. Kramarenko, J. Magn. Magn. Mater. 459, 268 (2018).

S. A. Kostrov, V. V. Gorodov, B. O. Sokolov, A. M. Mu-zafarov, and E. Yu. Kramarenko, Polym. Sci., Ser. A 62, 383 (2020).

E. Galipeau and P. Ponte Castañeda, Proc. R. Soc. London, Ser. A 469, 20130385 (2013).

D. V. Saveliev, I. A. Belyaeva, D. V. Chashin, L. Y. Fetisov, D. Romeis, W. Kettl, E. Yu. Kramarenko, M. Saphiannikova, G. V. Stepanov, and M. Shamonin, Materials 13, 3297 (2020).

G. V. Stepanov, E. Y. Kramarenko, and D. A. Semerenko, J. Phys.: Conf. Ser. 412, 012031 (2013).

W. H. Li, Y. Zhou, and T. F. Tian, Rheol. Acta 49, 733 (2010).

A. Stoll, M. Mayer, G. J. Monkman, and M. Shamonin, J. Appl. Polym. Sci. 131, 131 (2014).

M. Cvek, M. Mrlik, J. Sevcik, and M. Sedlacik, Polymers (Basel) 10, 1411 (2018).

R. Moucka, M. Sedlacik, and M. Cvek, Appl. Phys. Lett. 112, 122901 (2018).

T. Tian and M. Nakano, J. Intell. Mater. Syst. Struct. 29, 151 (2018).

M. M. Schmauch, S. R. Mishra, B. A. Evans, O. D. Velev, and J. B. Tracy, ACS Appl. Mater. Interfaces 9, 11895 (2017).

L. Ding, J. Zhang, Q. Shu, S. Liu, S. Xuan, X. Gong, and D. Zhang, ACS Appl. Mater. Interfaces 13, 13724 (2021).

D. Lin, F. Yang, D. Gong, Z. Lin, R. Li, W. Qian, C. Li, S. Jia, and H. Chen, ACS Appl. Mater. Interfaces 13, 34935 (2021).

H. Lu, M. Zhang, Y. Yang, Q. Huang, T. Fukuda, Z. Wang, and Y. Shen, Nat. Commun. 9, 3944 (2018).

M. Farshad and A. Benine, Polym. Test. 23, 347 (2004).

S. A. Kostrov, V. V. Gorodov, A. M. Muzafarov, and E. Yu. Kramarenko, Polym. Sci., Ser. B 64, 888 (2022).

M. A. Khanouki, R. Sedaghati, and M. Hemmatian, Composites, Part B 176, 107311 (2019).

J. Kaleta, M. Królewicz, and D. Lewandowski, Smart Mater. Struct. 20, 085006 (2011).

J. Wu, X. Gong, Y. Fan, and H. Xia, Smart Mater. Struct. 19, 105007 (2010).

S. Chougale, D. Romeis, and M. Saphiannikova, Materials 15, 645 (2022).

J. G. Puente- Córdova, M. E. Reyes-Melo, L. M. Palacios-Pineda, I. A. Martínez-Perales, O. Martínez-Romero, and A. Elías-Zúñiga, Polymers (Basel) 10, 1343 (2018).

G. B. Sohoni and J. E. Mark, J. Appl. Polym. Sci. 34, 2853 (1987).

T. H. Nam, I. Petríková, and B. Marvalová, Polym. Test. 81, 106272 (2020).

E. Coquelle, G. Bossis, D. Szabo, and F. Giulieri, J. Mater. Sci. 41, 5941 (2006).

R. Chokkalingam, R. S. Pandi, and M. Mahendran, J. Compos. Mater. 45, 1545 (2011).

A. Boczkowska, S. F. Awietjan, and R. Wroblewski, Smart Mater. Struct. 16, 1924 (2007).

T. A. Nadzharyan, O. V. Stolbov, Y. L. Raikher, and E. Yu. Kramarenko, Soft Matter 15, 9507 (2019).

G. V. Stepanov, S. I. Kirichenko, E. E. Makhaeva, and E. Yu. Kramarenko, Polym. Sci., Ser. A 65, 157 (2023).

A. Yu. Grossberg and A. R. Khokhlov, Statistical Physics of Macromolecules (Nauka, Moscow, 1989; Am. Inst. Phys., New York, 1994).

S. Abramchuk, E. Kramarenko, G. Stepanov, L. V. Nikitin, G. Filipcsei, A. R. Khokhlov, and M. Zrínyi, Polym. Adv. Technol. 18, 883 (2007).

A. R. Payne, J. Appl. Polym. Sci. 9, 3245 (1965).

S. Richter, M. Saphiannikova, K. W. Stöckelhuber, and G. Heinrich, Macromol. Symp. 291–292, 193 (2010).

R. Hentschke, Express Polym. Lett. 11, 278—292 (2017).

V. V. Sorokin, E. Ecker, G. V. Stepanov, M. Shamonin, G. J. Monkman, E. Yu. Kramarenko, and A. R. Kho-khlov, Soft Matter 10, 8765 (2014).

Funding

NMR and GPC studies were carried out at the Shared-Use Center “Polymer Research Center” of the Enikolopov Institute of Synthetic Polymer Materials of the Russian Academy of Sciences with the support of the Ministry of Science and Higher Education of the Russian Federation, topic no. 0071-2021-0004.

The work was supported by the Russian Science Foundation, project no. 19-13-00340-П.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflict of interest.

Additional information

Translated by S. Zatonsky

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

About this article

Cite this article

Kostrov, S.A., Razakov, V.S., Stepanov, G.V. et al. Influence of Distribution Anisotropy and Particle Shape on Magnetorheological Properties of Magnetoactive Elastomers. Polym. Sci. Ser. A 65, 822–830 (2023). https://doi.org/10.1134/S0965545X23600655

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0965545X23600655