Abstract

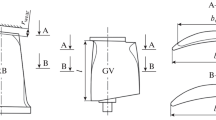

During operation, all components of a gas-turbine unit (GTU), including the blading of the axial compressor, are affected by the flow in the GTU flowpath, which results in the development of defects and deterioration of the main performance characteristics (efficiency, effective power, etc.). One of the most serious defects is erosive wear since it can cause destruction of one blade or all the blades in the compressor. This can lead to preliminary removal of a GTU from operation. Therefore, the erosion resistance of compressor blades is one of the main parameters controlling the service life of a gas-turbine unit. That is why studies of the erosive wear of axial compressors during operation of GTUs are urgent. This paper provides a review of the available publications on the erosive wear of blades and vanes in an axial compressor of gas-turbine units. The major erosion mechanisms classified by the type of particulates acting on blade material are examined. The geometric parameters of the compressor blading are found whose change due to erosive wear can disturb the flow aerodynamics and deteriorate the performance of individual elements and the overall GTU. The main three lines of erosive wear studies may be listed as follows: prediction of erosive wear, assessment and prediction of erosion consequences, and development of protective measures to control erosion during operation of a gas-turbine unit. The most frequently examined and promising subjects of erosion studies are outlined as applicable to gas turbine and compressor machine building. The state-of-the-art of studies in this field is analyzed.

Similar content being viewed by others

REFERENCES

D. Burnes and R. Kurz, “Performance degradation effects in modern industrial gas turbines,” in Proc. Zurich Global Power and Propulsion Forum, Zurich, Switzerland, Jan. 10–12, 2018 (Global Power and Propulsion Society, 2018), paper id. GPPS-2018-0019.

R. Kurz and K. Brun, “Degradation of gas turbine performance in natural gas service,” J. Nat. Gas Sci. Eng. 1 (3), 95–102 (2009). https://doi.org/10.1016/j.jngse.2009.03.007

C. Meher-Homji, A. F. Bromley, and J. P. Stalder, “Gas turbine performance deterioration and compressor washing,” in Proc. 2nd Middle East Turbomachiery Symp., Doha, Qatar, Mar. 17–20 2013, pp. 1–43.

K. M. Shpilev, Operation of Aircraft in a Mountainous–Desert Areas (Voen. Izd., Moscow, 1991) [in Russian].

I. S. Diakunchak, “Performance deterioration in industrial gas turbines,” J. Eng. Gas Turbines Power 114, 161–168 (1992). https://doi.org/10.1115/1.2906565

G. P. Sallee, Performance Deterioration Based on Existing (Historical) Data JT9D Jet Engine Diagnostics Program, Contractor Report CR-135448 (NASA Lewis Research Center, 1978).

S. M. Scala, M. Konrad, and R. B. Mason, “Predicting the performance of a gas turbine engine undergoing compressor blade erosion,” in Proc. 39th AIAA/ASME/SAE/ASEE Joint Propulsion Conf. and Exhibit, Huntsville, Ala., USA, July 20–23, 2003 (American Inst. of Aeronautics and Astronautics, Reston, Va., 2003), paper no. AIAA-2003-5259. https://doi.org/10.2514/6.2003-5259

J. Excell, “War machining,” Engineer 12, 64–70 (2003).

I. A. Krivosheev, R. F. Kamaeva, and S. A. Strugovets, “Specific features of the movement of dust particles in the flow path and changes in the geometry of compressor blades during the operation of gas turbine plants,” Vestn. UGATU, No. 3 (43), 18–24 (2011).

R. R. Myagi, Development of a Dust Abrasiveness Determination Method in Relation to the Rotors of Centrifugal Compressor Machines, Candidate’s Dissertation in Engineering (Tallinn Politechnic Univ., Tallinn, 1982).

A. Secareanu, D. Moroianu, A. Karlsson, and L. Fuchs, “Experimental and numerical study of ground vortex interaction in an air-intake,” in Proc. 43rd AIAA Aerospace Sciences Meeting and Exhibition, Reno, Nev., USA, Jan. 10–13, 2005 (American Inst. of Aeronautics and Astronautics, Reston, Va., 2005), paper no. AIAA-2005-1206. https://doi.org/10.2514/6.2005-1206

D. E. Glenny and N. G. T. E. Pyestock, Ingestion of Debris into Intakes by Vortex Action (Ministry of Technology, Aeronautical Research Council, London, 1970).

L. A. Robert and F. B. Garrett, Ingestion of Foreign Objects into Turbine Engines by Vortices, NACA Technical Note No. 3330 (National Advisory Committee for Aeronautics, Washington, DC, 1955).

A. Vogel, A. J. Durant, M. Cassiani, R. Clarkson, M. Slaby, S. Diplas, and A. Stohl, “Simulation of volcanic ash ingestion into a large aero engine: Particle–fan interactions,” J. Turbomach. 141, 011010 (2019). https://doi.org/10.1115/1.4041464

A. J. Prata and A. Tupper, “Aviation hazards from volcanoes: The state of the science,” Nat. Hazards 51, 239–244 (2009).

T. J. Casadevall, “Volcanic ash and aviation safety,” in Proc. 1st Int. Symp. on Volcanic Ash and Aviation Safety, Seattle, Wash., USA, July 8–12, 1991; U. S. Geol. Surv. Bull., No. 2047 (1994). https://doi.org/10.3133/b2047

E. Syverud, O. Brekke, and L. E. Bakken, “Axial compressor deterioration caused by saltwater ingestion,” J. Turbomach. 129, 119–126 (2007). https://doi.org/10.1115/1.2219763

R. Kurz and K. Brun, “Fouling mechanism in axial compressors,” J. Eng. Gas Turbines Power 134, 935–946 (2011). https://doi.org/10.1115/GT2011-45012

T. Zaba, “Losses in gas turbines due to deposits on the blading,” Brown Boveri Rev. 67, 715–722 (1980).

A. Chiariotti, P. Venturi, D. Borello, S. Costagliola, and S. Gabriele, “Erosion prediction of gas turbine compressor blades subjected to water washing process,” in Proc. Asia Turbomachinery and Pump Symp. (ATPS-2018), Singapore, Mar. 12–15, 2018, pp. 1–10.

F. J. Heymann, “Erosion by liquids,” Mach. Des. 10, 118–124 (1970).

G. M. De Pratti, “Aerodynamical performance decay due to fouling and erosion in axial compressor for GT aeroengines,” in Proc. 75th Natl. ATI Congr., Rome, Italy, Sept. 15–16, 2020; E3S Web Conf. 197, 11002 (2020). https://doi.org/10.1051/e3sconf/202019711002

V. A. Grigor’ev and B. A. Ponomarev, Helicopter Gas Turbine Engines (Mashinostroenie, Moscow, 2007) [in Russian].

I. A. Krivosheev and R. F. Kamaeva, “Analysis of regularities of the effect of air dust content on the change in the geometry of the blades and the parameters of the stages of an axial compressor,” Mol. Uch., No. 3, 50–55 (2011).

A. V. Gumerov and R. G. Akmaletdinov, “Modeling of erosive wear of a compressor blade,” Aviats. Raketno-Kosm. Tekh., No. 3 (27), 233–239 (2011).

T. V. Khavlin, A. N. Mikhailov, and V. A. Mikhailov, “Analysis of the features of abrasive-erosive wear of the compressor blade airfoil elements of a helicopter gas turbine engine,” in Prospects of Development of the Means of Military Action, Theories and Practices of Modern Combat: Proc. Sci and Pract Conf., Donetsk, Feb. 18, 2021, pp. 248–253.

D. A. Mikhailov, “The main features of operation of compressor blades of a gas turbine engine and the classification of their operational functions,” Prog. Tekhnol. Sist. Mashinostr., No. 4(50), 126–131 (2014).

R. Z. Khamitov, A. A. Ryzhov, and V. S. D’yakonov, Development of a Testing and Industrial Example of a Compressed Air Generator of a Compressor Plant, VF VNIIST and NPO “Motor” Technical Report (Ufa, 1989).

J.-P. Immarigeon, D. Chow, V. R. Parameswaran, P. Au, H. Saari, and A. K. Koul, “Erosion testing of coatings for aero engine compressor components,” Adv. Perform. Mater. 4, 371–388 (1997).

W. Tabakoff, A. N. Lakshminarasimha, and M. Pasin, “Simulation of compressor performance deterioration due to erosion,” J. Turbomach. 112, 78–83 (1990). https://doi.org/10.1115/1.2927424

M. G. Dunn, C. Padova, J. E. Moller, and R. M. Adams, “Performance deterioration of a turbofan and a turbojet engine upon exposure to a dust environment,” J. Eng. Gas Turbines Power 109, 336–343 (1987).

Z. J. Przedpelski, “The T700-GE-700 engine experience in sand environment,” J. Am. Helicopter Soc. 29, 63–69 (1984). https://doi.org/10.4050/JAHS.29.63

N. A. Cumpsty, Compressor Aerodynamics (Longman Scientific and Technical, Harlow, 2004).

B. S. Revzin, Axial Compressors of Gas Turbine Gas Pumping Units, 2nd ed. (Ural. Gos. Tekh. Univ., Yekaterinburg, 2000) [in Russian].

K. V. Kholshchevnikov, Theory and Calculation of Aircraft Blade Machines (Mashinostroenie, Moscow, 1970) [in Russian].

Yu. B. Galerkin, Turbochargers. Workflow, Calculation and Design of the Flow Path (KKhT, Moscow, 2010) [in Russian].

A. P. Komarov, “Influence of the radial clearance in the blade rims on the characteristics of the compressor,” in Design and Adjustment of Aircraft Gas Turbine Engines: Interuniversity Collection (Kuibyshev. Aviats. Inst. Im. S. P. Koroleva, Kuybyshev, 1984), pp. 65–71 [in Russian].

C. Balan and W. Tabakoff, “Axial flow compressor performance deterioration,” in Proc. 20th Joint Propulsion Conf., Cincinnati, Oh., USA, June 11–13, 1984 (American Inst. of Aeronautics and Astronautics, Reston, Va., 1984). https://doi.org/10.2514/6.1984-1208

S. P. Izotov, V. V. Shashkin, and V. M. Kapralov, Aviation Gas Turbine Engines in Ground Plants (Mashinostroenie, Moscow, 1984) [in Russian].

F. M. White, Viscous Fluid Flow, 2nd ed. (McGraw-Hill, New York, 1991).

C. C. Koch and L. H. Smith, “Loss sources and magnitudes in axial flow compressors,” J. Eng. Gas Turbines Power 98, 411–424 (1976). https://doi.org/10.1115/1.3446202

H. Schlichting, Boundary Layer Theory, 4th ed. (McGraw-Hill, New York, 1960).

N. Aldi, M. Morini, M. Pinelli, P. R. Spina, A. Suman, and M. Venturini, “Numerical analysis of the effects of surface roughness localization on the performance of an axial compressor stage,” Energy Procedia 45, 1057–1066 (2014). https://doi.org/10.1016/j.egypro.2014.01.111

K. Walton, L. Blunt, L. Fleming, M. Goodhand, and H. Lung, “A real parametric characterisation of ex-service compressor blade leading edges,” Wear 321, 79–86 (2014). https://doi.org/10.1016/j.wear.2014.10.007

M. N. Goodhand and R. J. Miller, “Compressor leading edge spikes: A new performance criterion,” J. Turbomach. 133, 021006 (2011). https://doi.org/10.1115/1.4000567

H. Hertz, “On the vibration elastic bodies,” J. Reine Angew. Math. 92, 156–171 (1882).

H. Lamb, “I. On the propagation of tremors over the surface of an elastic solid,” Philos. Trans. R. Soc., A 203, 1–42 (1904). https://doi.org/10.1098/rsta.1904.0013

I. Finnie, “The mechanism of erosion of ductile metals,” in Proc. 3rd US Natl. Congr. on Applied Mechanics, Providence, R.I., June 11–14, 1958 (American Society of Mechanical Engineers, New York, 1958), pp. 527–532.

J. G. A. Bitter, “A study of erosion phenomena: Part I,” Wear 6, 5–21 (1963). J. G. A. Bitter, “A study of erosion phenomena: Part II,” Wear 6, 169–190 (1963). https://doi.org/10.1016/0043-1648(63)90073-510.1016/0043-1648(63)90073-5https://doi.org/10.1016/0043-1648(63)90003-6

J. H. Neilson and A. Gilchrist, “Erosion by a stream of solid particles,” Wear 11, 111–122 (1968). https://doi.org/10.1016/0043-1648(68)90591-7

G. L. Sheldon and A. Kanhere, “An investigation of impingement erosion using single particles,” Wear 21, 195–209 (1972). https://doi.org/10.1016/0043-1648(72)90257-8

G. P. Tilly, “A two-stage mechanism of ductile erosion,” Wear 23, 87–96 (1972). https://doi.org/10.1016/0043-1648(73)90044-6

W. H. Jennings, W. J. Head, and C. R. Manning, Jr., “A mechanistic model for the prediction of ductile erosion,” Wear 40, 93–112 (1976). https://doi.org/10.1016/0043-1648(76)90021-1

H. C. Meng and K. C. Ludema, “Wear model and prediction equations: Their form and content,” Wear 181–183, 443–457 (1995). https://doi.org/10.1016/0043-1648(95)90158-2

T. Deng, M. S. Bingley, and M. S. A. Bradley, “The influence of particle rotation on the solid particle erosion rate of metals,” Wear 256, 1037–1049 (2004). https://doi.org/10.1016/S0043-1648(03)00536-2

B. S. Chahar, S. Siddhartha, and A. K. Pun, “Erosion wear of ductile materials: A review,” ELK Asia Pac. J. - Spec. Issue (2018).

W. B. Clevenger and W. Tabakoff, “Dust particle trajectories in aircraft radial turbines,” J. Aircr. 13, 786–791 (1976). https://doi.org/10.2514/3.58711

G. Grant and W. Tabakoff, “Erosion prediction in turbomachinery resulting from environmental solid particles,” J. Aircr. 12, 471–478 (1975). https://doi.org/10.2514/3.59826

G. Grant and W. Tabakoff, “Erosion prediction in turbomachinery due to environmental solid particles,” in Proc. 12th Aerospace Sci. Meeting, Washington, DC, Jan. 30 – Feb. 1, 1974 (American Inst. of Aeronautics and Astronautics, Washington, DC, 1974). https://doi.org/10.2514/6.1974-16

M. F. Hussein and W. Tabakoff, Calculation of Particle Trajectories in a Stationary Two Dimensional Cascade, Project Themis Report No. 72-27 (Univ. of Cincinnati, Cincinnati, Oh., 1972).

W. Tabakoff, “Compressor erosion and performance deterioration,” J. Fluids Eng. 109, 297–306 (1987). https://doi.org/10.1115/1.3242664

A. Ghenaiet, S. C. Tan, and R. L. Elder, “Prediction of an axial turbomachine performance degradation due to sand ingestion,” Proc. Inst. Mech. Eng., Part A 219, 273–287 (2005). https://doi.org/10.1243/095765005X7592

A. Ghenaiet, S. C. Tan, and R. L. Elder, “Study of erosion effects on an axial fan global range of operation,” in Proc. ASME Turbo Expo 2004: Power for Land, Sea and Air, Vienna, Austria, June 14–17, 2004 (American Society of Mechanical Engineers, New York, 2004), Vol. 2, pp. 283–293. https://doi.org/10.1115/GT2004-54169

A. Ghenaiet, S. C. Tan, and R. L. Elder, “Particles trajectories through an axial fan and performance degradation due to sand ingestion,” in Proc. ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, La., USA, June 4–7, 2001 (American Society of Mechanical Engineers, New York, 2001), Vol. 1, paper id. 2001-GT-0497. https://doi.org/10.1115/2001-GT-0497

M. Junkar, B. Jurisevic, M. Fajdiga, and M. Grah, “Finite element analysis of single-particle impact in abrasive water jet machining,” Int. J. Impact Eng. 32, 1095–1112 (2006). https://doi.org/10.1016/j.ijimpeng.2004.09.006

S. Y. Ahmadi-Brooghani, H. Hassanzadeh, and P. Kahhal, “Modeling of single-particle impact in abrasive water jet machining,” Int. J. Mech., Aerosp., Ind., Mechatron., Manuf. Eng. 1, 723–728 (2007).

J. Alqallaf, A. Naser, J. A. Teixeira, and A. Addali, “Solid particle erosion behaviour and protective coatings for gas turbine compressor blades: A review,” Processes 8, 984–1025 (2020). https://doi.org/10.3390/pr8080984

M. B. Abdel’vakhid, A. N. Cherkasov, R. M. Fedorov, and K. S. Fedechkin, “Computational study of the influence of erosive wear on the altitude-speed characteristics of turbofan engines,” Vestn. UGATU, No. 3 (64), 16–22 (2014).

B. M. Galitseiskii and V. Yu. Shustrova, “Two-phase turbulent jet flows with phase transformations,” Mat. Model. 17 (7), 79–93 (2005).

A. Farokhipour, Z. Mansoori, M. Saffar-Avval, and G. Ahmadi, “Numerical modelling of sand particle erosion at return bends in gas-particle twophase flow,” Sci. Iran., Trans. B 25, 3231–3242 (2018). https://doi.org/10.24200/SCI.2018.50801.1871

A. Mansouri, A Combined CFD-Experimental Method for Developing an Erosion Equation for Both Gas-Sand and Liquid-Sand Flows, PhD Thesis (Department of Mechanical Engineering, Univ. of Tulsa, Tulsa, Okla., 2016).

D. Anielli, D. Borello, F. Rispoli, A. Salvagni, and P. Venturini, “Prediction of particle erosion in the internal cooling channels of a turbine blade,” in Proc. 11th Eur. Conf. on Turbomachinery Fluid Dynamics and Thermodynamics, Madrid, Spain, Mar. 23–27, 2015, paper no. ETC2015-184.

S. Peng, Q. Chen, C. Shan, and D. Wang, “Numerical analysis of particle erosion in the rectifying plate system during shale gas extraction,” Energy Sci. Eng. 7, 1838–1851 (2019). https://doi.org/10.1002/ese3.395

H. Arabnejad, Development of Erosion Equations for Solid Particle and Liquid Droplet Impact, PhD Thesis (Department of Mechanical Engineering, Univ. of Tulsa, Tulsa, Okla., 2015).

K. Sun, L. Lu, and H. Jin, “Modeling and numerical analysis of the solid particle erosion in curved ducts,” Abstr. Appl. Anal. 4, 245074 (2013). https://doi.org/10.1155/2013/245074

M. Grazia de Giorgi, S. Campilongo, A. Ficarella, M. Coltelli, V. Pfister, and F. Sepe, “Experimental and numerical study of particle ingestion in aircraft engine,” in Proc. ASME Turbo Expo: Turbine Tech. Conf. and Exposition, San Antonio, Tex., USA, June 3–7, 2013 (American Society of Mechanical Engineers, New York, 2013). https://doi.org/10.1115/GT2013-95662

A. Hamed, R. Rivir, P. Arora, and K. Das, “Turbine blade surface deterioration by erosion,” J. Turbomach. 127, 445–452 (2004). https://doi.org/10.1115/1.1860376

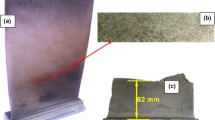

E. Poursaeidi, H. Tafrishi, and H. Amani, “Experimental-numerical investigation for predicting erosion in the first stage of an axial compressor,” Powder Technol. 306, 80–87 (2017). https://doi.org/10.1016/j.powtec.2016.10.057

D. Borello, L. Cardillo, A. Corsini, G. Delibra, F. Rispoli, A. Salvagni, and P. Venturini, “Modelling of particle transport, erosion and deposition in power plant gas paths,” in Proc. ASME Turbo Expo: Power for Land, Sea and Air, Seoul, South Korea, Sept. 20, 2016 (American Society of Mechanical Engineers, New York, 2016), paper id. GT2016-57984. https://doi.org/10.1115/GT2016-57984

H. Yang and J. G. Boulanger, “The whole annulus computations of particulate flow and erosion in an axial fan,” J. Turbomach. 135, 11040 (2013). https://doi.org/10.1115/1.4006564

A. Corsini, A. Marchegiani, F. Rispoli, and P. Venturini, “Predicting blade leading edge erosion in an axial induced draft fan,” J. Eng. Gas Turbines Power 134, 042601 (2012). https://doi.org/10.1115/1.4004724

M. Suzuki and M. Yamamoto, “Numerical simulation of sand erosion in a transonic compressor rotor,” in Proc. ASME Turbo Expo 2010, Glasgow, Scotland, June 14–18, 2010 (American Society of Mechanical Engineers, New York, 2010), Vol. 7, pp. 1011–1018. https://doi.org/10.1115/GT2010-23593

M. Suzuki, K. Inaba, and M. Yamamoto, “Numerical simulation of sand erosion phenomena in rotor/stator interaction of compressor,” J. Therm. Sci. 17, 125–133 (2006). https://doi.org/10.1007/s11630-008-0125-7

E. A. Strokach, G. D. Kozhevnikov, and A. A. Pozhidaev, “Numerical simulation of solid particle erosion in a gaseous flow (review),” Vestn. PNIPU, Aerokosm. Tekh., No. 67, 56–69 (2021). https://doi.org/10.15593/2224-9982/2021.67.06

X. Chen, B. S. McLaury, and S. A. Shirazi, “Application and experimental validation of a computational fluid dynamics (CFD)-based erosion prediction model in elbows and plugged tees,” Comp. Fluids 33, 1251–1272 (2004). https://doi.org/10.1016/j.compfluid.2004.02.003

H. Hadziahmetovic, N. Hodzic, D. Kahrimanovic, and E. Dzaferovic, “Computational fluid dynamics (CFD) based erosion prediction model in elbows,” Teh. Vjesn. – Tech. Gaz. 21, 275–282 (2014).

A. Mansouri, H. Arabnejad, S. Karimi, S. A. Shirazi, and B. S. McLaury, “Improved CFD modeling and validation of erosion damage due to fine sand particles,” Wear 338–339, 339–350 (2015). https://doi.org/10.1016/j.wear.2015.07.011

D. A. Pandya, Development of Computational Fluid Dynamics (CFD) Based Erosion Models for Oil and Gas Industry Applications, PhD Thesis (Univ. of Texas, Arlington, Tex., 2013).

H. Sommerfeld, C. Koch, A. Schwarz, and A. Beck, “High velocity measurements of particle rebound characteristics under erosive conditions of high-pressure compressors,” Wear 470–471, 203626 (2021). https://doi.org/10.1016/j.wear.2021.203626

E. Poursaeidi, A. M. Niaei, M. Arablu, and A. Salarvand, “Experimental investigation on erosion performance and wear factors of custom 450 steel as the first-row blade material of an axial compressor,” Int. J. Surf. Sci. Eng. 11, 85–99 (2017). https://doi.org/10.1504/IJSURFSE.2017.084663

C. J. Reagle, Technique for Measuring the Coefficient of Restitution for Microparticle sand Impacts at High Temperature for Turbomachinery Applications, PhD Thesis (Virginia Polytechnic Inst. and State Univ., Blacksburg, Va., 2012).

W. Tabakoff, “Investigation of coatings at high temperature for use in turbomachinery,” Surf. Coat. Technol. 39–40, 97–115 (1989). https://doi.org/10.1016/0257-8972(89)90045-5

W. Tabakoff, R. H. Kotwal, and A. Hamed, “Erosion study of different materials affected by coal ash particles,” Wear 52, 161–173 (1979). https://doi.org/10.1016/0043-1648(79)90206-0

G. Grant, W. Tabakoff, and R. Ball, An Experimental Study of Certain Aerodynamic Effects on Erosion (Univ. of Cincinnati, Cincinnati, Oh., 1972). https://doi.org/10.2514/6.1974-639

A. Ghenaiet, S. C. Tan, and R. L. Eder, “Experimental investigation of axial fan erosion and performance degradation,” Proc. Inst. Mech. Eng., Part A 218, 437–450 (2004). https://doi.org/10.1243/0957650041761900

D. V. Pavlenko and Ya. V. Dvirnik, “Patterns of wear of the rotor blades of the compressor of helicopter engines operating in a dusty atmosphere,” Vestn. Dvigatelestr., No. 1, 42–51 (2016).

J. P. Van der Walt and N. Alan, “Erosion of dust-filtered helicopter turbine engines. Part I: Basic theoretical considerations,” J. Aircr. 32, 106–111 (1995). https://doi.org/10.2514/3.56919

A. Hamed and W. Tabakoff, “Aerodynamic effects on erosion in turbomachinery,” in Proc. Joint Gas Turbine Congr., Tokyo, Japan, May 22–27, 1977 (Gas Turbine Society of Japan, Tokyo, 1977), Vol. 70.

K. Ratkovska and M. Hocko, “Dust impact on the geometrical characteristics of an axial compressor,” AIP Conf. Proc. 1889, 020031 (2017). https://doi.org/10.1063/1.5004365

P. F. Batcho, J. C. Moller, C. Padova, and M. G. Dunn, “Interpretation of gas turbine response due to dust ingestion,” J. Eng. Gas Turbines Power 109, 344–352 (1987). https://doi.org/10.1115/1.3240046

A. S. Vinogradov, The Design of RD-33 Turbofan Engine: Textbook (Minist. Obrazov. Nauki RF / Samar. Gos. Aerokosm. Univ. im. S. P. Koroleva, Samara, 2013) [in Russian].

Ya. V. Dvirnik and D. V. Pavlenko, “Influence of blades dust erosion on the axial compressor gasdynamic characteristics of gas turbine engine,” Vestn. Dvigatelestr., No. 1, 56–66 (2017).

M. Suzuki and M. Yamamoto, “Numerical simulation of sand erosion phenomena in single stage axial compressor,” Trans. Jpn. Soc. Mech. Eng., Part B 76, 795–803 (2010).

V. A. Kostyshev, Yu. I. Klimnyuk, N. S. Regov, S. A. Kosyrev, and L. A. Anipchenko, “Bench test of the flow part of the compressor of the ‘NK-16ST’ gas turbine power drive for erosive wear,” in Proc. Int. Sci. and Tech. Conf. on Problems and Prospects for the Development of Engine Building, 2003 (Samar. Gos. Aerokosm. Inst., Samara, 2003), Vol. 1, pp. 44–49.

S. A. Strugovets, I. A. Krivosheev, R. I. Galiulin, R. F. Kamaeva, and K. E. Rozhkov, “Development of a method for parametric diagnostics of the technical condition of a gas turbine engine based on the analysis of blade erosion and regularities in the flow of compressor characteristics,” Vestn. UGATU 14 (4), 3–10 (2010).

G. G. Enikeev, “Complex protection of a gas turbine engine operating in a dusty atmosphere and marine environment,” Vestn. UGATU 17 (3), 41–48 (2013).

F. C. Da Silva, M. Grinet, and A. R. Silva, “A machine learning approach to forecasting turbofan engine health using real flight data,” in Proc. AIAA SCITECH 2022 Forum, San Diego, Calif., USA, Jan. 3–7, 2022 (American Inst. of Aeronautics and Astronautics, Reston, Va., 2022), paper id. AIAA 2022-0491. https://doi.org/10.2514/6.2022-0491

M. Tahan, M. Muhammad, and Z. A. Abdul Karim, “A multi-nets ANN model for real-time performance-based automatic fault diagnosis of industrial gas turbine engines,” J. Braz. Soc. Mech. Sci. Eng. 39, 2865–2876 (2017). https://doi.org/10.1007/s40430-017-0742-8

J. V. Taylor, B. Conduit, A. Dickens, C. Hall, M. Hillel, and R. J. Miller, “Predicting the operability of damaged compressors using machine learning,” in Proc. ASME Turbo Expo 2019: Turbomachinery Tech. Conf. and Exposition, Phoenix, Ariz., USA, June 17–21, 2019 (American Society of Mechanical Engineers, New York, 2019), Vol. 2A: Turbomachinery, paper id. GT2019-91339. https://doi.org/10.1115/GT2019-91339

P. Voigt, M. Voigt, R. Mailach, D. Münzinger, K. Abu-Taa, and A. Lange, “A novel methodology for detecting foreign object damage on compressor blading,” in Proc. ASME Turbo Expo 2019: Turbomachinery Tech. Conf. and Exposition, Phoenix, Ariz., USA, June 17–21, 2019 (American Society of Mechanical Engineers, New York, 2019), Vol. 2D: Turbomachinery, paper id. V02DT46A005.

V. L. Blinov, I. S. Zubkov, O. V. Belyaev, E. Yu. Iskortsev, and P. I. Plishkin, “Special aspects of numerical simulation of a two-stage axial-flow compressor with defective blades,” Vestn. Samar. Univ., Aerokosm. Tekh., Tekhnol. Mashinostr. 20 (4), 7–19 (2021). https://doi.org/10.18287/2541-7533-2021-20-4-7-19

K. Brun, R. Kurz, J. Thorp, and B. Winkelmann, “Gas turbine packaging options and features,” in Proc. 45th Turbomachinery and 32nd Pump Symp., Houston, Tex., USA, Sept. 12–15, 2016 (Turbomachinery Laboratory, Texas A&M Engineering Experiment Station, College Station, Tex., 2016).

C. B. Meher-Homji and G. A. Gabriles, “Gas turbine blade failure-causes, avoidance and troubleshooting,” in Proc. 27th Turbomachinery Symp. and 27th International Pump Users Symp., Houston, Tex., Sept. 22–24, 1998 (Turbomachinery Laboratory, College Station, Tex., 1998).

M. A. Wilcox and R. Kurz, “Successful selection an operation of gas turbine inlet filtration systems,” in Proc. 40th Turbomachinery Symp., Houston, Tex., 2011 (Turbomachinery Laboratory, Texas A&M Univ., College Station, Tex., 2011).

M. A. Wilcox and N. W. Poerner, “Gas turbine filter efficiency test procedure: liquid and solid particles,” in Proc. Gas Machinery Research Council Conf., Dallas, Tex., 2011.

D. Orhon, R. Kurz, S. D. Hiner, and J. Benson, “Gas turbine air filtration systems for offshore applications,” in Proc. 44th Turbomachinery and 31st Pump Symp., Houston, Tex., Sept. 14–17, 2015 (Turbomachinery Laboratory at Texas A&M Engineering Experiment Station, College Station, Tex., 2015).

P. T. McGuigan, “Salt in the marine environment and the creation of a standard input for gas turbine air intake filtration systems,” in Proc. ASME Turbo Expo: Power for Land, Sea, and Air, Vienna, Austria, June 14–17, 2004 (American Society of Mechanical Engineers, New York, 2004), pp. 767–775, paper id. GT2004-53113. https://doi.org/10.1115/GT2004-53113

N. K. Galantsev, “Development of integrated air cleaning units (ACUs) for marine applications based on air filters and AAF International technologies,” in Proc. 11th Int. Conf. and Exposition on Development of Oil and Gas of Russian Arctic and the Continental Shelf of CIS Countries (RAO / CIS Offshore 2013), St. Petersburg, Russia, 2013, pp. 172–175.

A. S. Gishvarov, R. R. Aitov, and A. M. Aitumbetov, “Study of the effectiveness of dust protection devices for helicopter gas turbine engines,” Vestn. UGATU 19 (2), 100–110 (2015).

V. A. Danilov, Helicopter Mi-8 (Assembly and Maintenance) (Transport, Moscow, 1988) [in Russian].

N. E. Ginzburg and E. I. Nikitin, “Study of dusty air near Mi-1 and Mi-4 helicopters in operational conditions,” in Helicopter Gas Turbine Engines: Compilation of Papers (Mashinostroenie, Moscow, 1966), pp. 145–165 [in Russian].

V. S. Efanov, A. N. Prokopenko, A. V. Ovchinnikov, and Yu. N. Vnukov, “Erosion resistance of helicopter GTE compressor blades protected by various types of coatings,” Vestn. Dvigatelestr., No. 1, 120–123 (2017).

S. A. Muboyadzhyan, D. A. Aleksandrov, D. S. Gorlov, L. P. Egorova, and E. E. Bulavintseva, “Protective and hardening ion-plasma coatings for blades and other critical parts of the gas turbine engine compressor,” Aviats. Mater. Tekhnol., No. 6, 72–81 (2012).

S. A. Muboyadzhyan, D. A. Aleksandrov, and D. S. Gorlov, “Nanolayer hardening coatings for the protection of steel and titanium blades of a gas turbine engine compressor,” Aviats. Mater. Tekhnol., No. 3 (20), 3–8 (2011).

E. N. Kablov, S. A. Muboyadzhyan, S. A. Budinovskii, and Ya. A. Pomelov, “Ion-plasma protective coatings for gas turbine engine blades,” Konvers. Mashinostr., No. 2, 42–47 (1999).

N. V. Belan, V. V. Omel’chenko, and A. N. Prokopenko, “Increasing the erosion resistance of working blades of a gas turbine engine compressor,” Aviats. Prom-st., No. 10, 19–20 (1986).

R. Rajendran, “Gas turbine coatings: An overview,” Eng. Failure Anal. 26, 355–369 (2012). https://doi.org/10.1016/j.engfailanal.2012.07.007

E. N. Kablov and S. A. Muboyadzhyan, “Erosion-resistant coatings for gas turbine engine compressor blades,” Russ. Metall. (Engl. Transl.) 2017, 494–504 (2017). https://doi.org/10.1134/S0036029517060118

L. Swadzba, B. Formanek, H. Gabriel, P. Liberski, and P. Podolski, “Erosion- and corrosion-resistant coatings for aircraft compressor blades,” Surf. Coat. Technol. 62, 486–492 (1993). https://doi.org/10.1016/0257-8972(93)90288-y

V. Bonu, M. Jeevitha, V. P. Kumar, G. Srinivas, and H. C. Barshilia, “Solid particle erosion and corrosion resistance performance of nanolayered multilayered Ti/TiN and TiAl/TiAlN coatings deposited on Ti6Al4V substrates,” Surf. Coat. Technol. 387, 125531 (2020). https://doi.org/10.1016/j.surfcoat.2020.125531

S. A. Budinovskii, D. A. Chubarov, and P. V. Matveev, “State of the art methods for applying thermal coatings on gas turbine engine blades (review),” Aviats. Mater. Tekhnol., No. S5, 38–44 (2014). https://doi.org/10.18577/2071-9140-2014-0-s5-38-44

J. M. Drexler, K. Shinoda, A. L. Ortiz, D. Li, A. L. Vasiliev, A. D. Gledhill, S. Sampath, and N. Padture, “Air-plasma-sprayed thermal barrier coatings that are resistant to high-temperature attack by glassy deposits,” Acta Mater. 58, 6835–6844 (2010). https://doi.org/10.1016/j.actamat.2010.09.013

D. S. de Almeida, C. R. M. da Silva, M. do Carmo A. Nono, and C. A. A. Cairo, “NiAl alloy coating deposition by electron beam physical vapour deposition,” in Proc. 17th Brazilian Congr. of Engineering and Materials Science, Paraná, Brazil, Nov. 15–19, 2006, pp. 15–19.

T. N. Rhys-Jones, “The use of thermally sprayed coatings for compressor and turbine applications in aero engines,” Surf. Coat. Technol. 42, 1–11 (1990). https://doi.org/10.1016/0257-8972(90)90109-P

Funding

The study was funded by the Russian Science Foundation (grant no. 22-79-00169).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Krasnoshchekova

Rights and permissions

About this article

Cite this article

Blinov, V.L., Zubkov, I.S., Bogdanets, S.V. et al. Studies of Erosive Wear of the Blading in Axial Compressors of Gas Turbines (Review). Therm. Eng. 70, 430–442 (2023). https://doi.org/10.1134/S0040601523060022

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040601523060022