Abstract

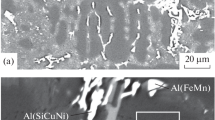

The microstructure, the phase composition, the component distribution, and the grain structure of the commercial eutectic Al–12.2 Si–0.2 Fe (at %) silumins formed at cooling rates of 102 and 105 K/s are studied. Three phases are detected in the alloy after solidification at both cooling rates: α-aluminum, silicon, and an iron-containing phase. The bulk samples have a heterogeneous dendritic structure with large dendrites of an aluminum-based solid solution, and a eutectic lamellar mixture of aluminum and silicon filling the interdendritic space. The melt-quenched foils are characterized by a homogeneous microstructure over the thickness; however, they have a layered structure. The rapidly solidified foils also have a homogeneous granular structure through the thickness and no pronounced texture. The mechanisms of solidification and microstructure formation are proposed for both the bulk samples and the melt-quenched foils.

Similar content being viewed by others

REFERENCES

Y. Haizhi, “An overview of the development of Al–Si alloy based material for engine applications,” J. Mater. Eng. Perform. 12, 288–297 (2003).

R. Hernandez, C. Francisco, H. Ramirez, J. Martin, and R. Mackay, Al–Si Alloys Automotive, Aeronautical, and Aerospace Applications (Springer, 2017).

O. Gusakova, V. Shepelevich, and L. Scherbachenko, “Effect of melt cooling rate on microstructure of Sn–Bi and Sn–Pb eutectic alloys,” Adv. Mater. Res. 856, 236–240 (2014).

C. T. Rios, S. Santos, W. J. Botta, and C. Bolfarini “Microstructural characterization of as-quenched and heat treated Al–Si–Mg melt-spun ribbons,” J. Metastable Nanocryst. Mater. 22, 103–108 (2004).

O. Gusakova, V. Shepelevich, and L. Scherbachenko, “Aging of rapidly solidified eutectic Sn–Bi, Sn–Pb, Bi–Cd alloys,” Perspekt. Mater. 5, 25–32 (2016).

O. Uzun, T. Karaaslan, and M. Keskin, “Production and structure of rapidly solidified Al–Si,” Turk. J. Phys. 25, 455–466 (2001).

A. Bendijk, R. Delhez, L. Katgerman, Th. H. De Keijser, E. J. Mittemeijer, and N. M. Van Der Pers, “Characterization of Al–Si–alloys rapidly quenched from the melt,” Mater. Sci. 15, 2803–2810 (1980).

D. Herlach, P. Galenko, and D. Holland-Moritz, Metastable Solids from Undercooled Melts, (Elsevier, Amsterdam, 2007).

D. V. Alexandrov, D. A. Danilov, and P. K. Galenko, “Selection criterion of a stable dendrite growth in rapid solidification,” Int. J. Heat Mass Transfer 101, 789–799 (2016).

P. K. Galenko, D. A. Danilov, K. Reuther, D. V. Alexandrov, M. Rettenmayr, and D. M. Herlach, “Effect of convective flow on stable dendritic growth in rapid solidification of a binary alloy,” J. Cryst. Growth. 457, 349–355 (2017).

D. V. Alexandrov and P. K. Galenko, “Selected mode for rapidly growing needle-like dendrite controlled by heat and mass transport,” Acta Mater. 137, 64–70 (2017).

Q. Liu, M. Liu, C. Xu, W. Xiao, H. Yamagata, S. Xie, and C. Ma, “Effects of Sr, Ce and P on the microstructure and mechanical properties of rapidly solidified Al–7Si alloys,” Mater. Charact. 140, 290–298 (2018).

N. A. Belov, S. V. Savchenko, and A. V. Khvan, “Phase composition and structure of silumins,” (MISiS, Moscow, 2007).

Funding

This work was supported by the Belarusian Republican Foundation for Fundamental Research (project no. F18R-195) and the Russian Foundation for Basic Research (project no. 18-58-00034).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Gusakova, O.V., Shepelevich, V.G., Alexandrov, D.V. et al. Structure Formation in the Melt-Quenched Al–12.2Si–0.2Fe Alloys. Russ. Metall. 2020, 885–892 (2020). https://doi.org/10.1134/S0036029520080054

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520080054