Abstract

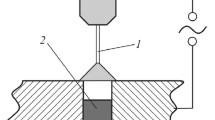

The structure, the mechanical properties, and the electrical conductivity of the Cu–0.7% Cr–0.9% Hf alloy subjected to equal-channel angular pressing (ECAP) followed by aging are studied. The treatment that consists of ECAP and aging at 450°C for 2.5 h is shown to result in a high strength (σu = 605 MPa) and a high electrical conductivity (78% IACS) of the alloy. This combination of properties increases the resistance of the contact welding electrodes made of an ultrafine-grained Cu–0.7% Cr–0.9% Hf alloy as compared to its initial coarse-grained state.

Similar content being viewed by others

REFERENCES

A. K. Nikolaev and V. M. Rozenberg, Alloys for Contact Welding Electrodes (Metallurgiya, Moscow, 1978).

N. Bochvar, “Cr–Cu–Zr (chromium–copper–zirconium),” in Non-Ferrous Metal Systems. Pt. 2: Selected Cooper Systems, Ed. by G. Effenberg and S. Ilyenko (Springer, Berlin, 2007), Vol. 11C2, pp. 228–242.

C. Watanabe, R. Monzen, and K. Tazaki, “Mechanical properties of Cu–Cr system alloys with and without Zr and Ag,” J. Mater. Sci. 43, 813–819 (2008).

D. V. Shangina, N. R. Bochvar, M. V. Gorshenkov, H. Yanar, G. Purcek, and S. V. Dobatkin, “Influence of microalloying with zirconium on the structure and properties of Cu–Cr alloy after high pressure torsion,” Mater. Sci. Eng. A 650, 63–66 (2016).

R. K. Islamgaliev, K. M. Nesterov, J. Bourgon, Y. Champion, and R. Z. Valiev, “Nanostructured Cu–Cr alloy with high strength and electrical conductivity,” J. Appl. Phys. 115, article no. 194301 (2014).

V. I. Zel’dovich, I. V. Khomskaya, N. Yu. Frolova, A. E. Kheifets, E. V. Shorokhov, and P. A. Nasonov, “Structure of chromium–zirconium bronze subjected to dynamic channel-angular pressing and aging,” Phys. Met. Metallogr. 114 (5) 411–418 (2013).

A. Vinogradov, V. Patlan, Y. Suzuki, K. Kitagawa, and V. I. Kopylov, “Structure and properties of ultra-fine grain Cu–Cr–Zr alloy produced by equal-channel angular pressing,” Acta Mater. 50, 1639–1651 (2002).

A. Vinogradov, T. Ishida, K. Kitagawa, and V. I. Kopylov, “Effect of strain path on structure and mechanical behavior of ultrafine grain Cu–Cr alloy produced by equal-channel angular pressing,” Acta Mater. 53, 2181–2192 (2005).

Q. J. Wang, C. Z. Xu, M. S. Zheng, J. W. Zhu, and Z. Z. Du, “Fatigue crack initiation life prediction of ultra-fine grain chromium–bronze prepared by equal-channel angular pressing,” Mater. Sci. Eng. A 496, 434–438 (2008).

K. V. Valdés León, M. A. Munoz-Morris, and D. G. Morris, “Optimization of strength and ductility of Cu–Cr–Zr by combining severe plastic deformation and precipitation,” Mater. Sci. Eng. A 536, 181–189 (2012).

G. Purcek, H. Yanar, O. Saray, I. Karaman, and H. J. Maier, “Effect of precipitation on mechanical and wear properties of ultrafine-grained Cu–Cr–Zr alloy,” Wear 311, 149–158 (2014).

J. Li, J. Wongsa-Ngam, J. Xu, D. Shan, B. Guo, and T. G. Langdon, “Wear resistance of an ultrafine-grained Cu–Zr alloy processed by equal-channel angular pressing,” Wear 326–327, 10–19 (2015).

A. P. Zhilyaev, I. Shakhova, A. Morozova, A. Belyakov, and R. Kaibyshev, “Grain refinement kinetics and strengthening mechanisms in Cu–0.3Cr–0.5Zr alloy subjected to intense plastic deformation,” Mater. Sci. Eng. A 654, 131–142 (2016).

G. Purcek, H. Yanar, M. Demirtas, Y. Alemdag, D. V. Shangina, and S. V. Dobatkin, “Optimization of strength, ductility and electrical conductivity of Cu–Cr–Zr alloy by combining multi-route ECAP and aging,” Mater. Sci. Eng. A 649, 114–122 (2016).

R. K. Islamgaliev, K. M. Nesterov, and R. Z. Valiev, “Structure, strength, and electrical conductivity of a Cu–Cr copper-based alloy subjected to severe plastic deformation,” Phys. Met. Metallogr. 116 (2) 209–218 (2015).

M. E. Drits, N. R. Bochvar, L. S. Guzei, E. V. Lysova, E. M. Padezhnova, L. L. Rokhlin, and N. I. Turkina, Copper-Based Binary and Multicomponent Systems (Nauka, Moscow, 1979).

ACKNOWLEDGMENTS

We thank M.N. Putintseva for her help in performing the experiments and helpful discussions.

This work was performed according to state task no. 007-00129-18-00.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Shan’gina, D.V., Ivanov, N.I., Bochvar, N.R. et al. Resistance of the Contact Welding Electrodes Made of a Cu–0.7% Cr–0.9% Hf Alloy with an Ultrafine-Grained Structure. Russ. Metall. 2018, 815–819 (2018). https://doi.org/10.1134/S0036029518090112

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029518090112