Abstract

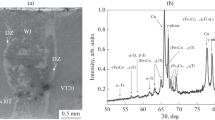

The microstructure, the chemical and the phase compositions, and the mechanical properties of the welded-joint metal of sheet (hot-rolled) and as-cast austenitic 0.05% C–(21–23)% Cr–8% Ni–15% Mn–(1–2)% Mo–(0.2–0.5)% N steels butt welded with a laser beam have been studied. Welding is carried out without a welding additive using a fiber ytterbium laser developed by IPG IRE–Polus. It is shown that defect-free welds from 350 to 1200 μm wide without δ-ferrite and σ phase can be formed over the entire welding regime range. Laser welding is found to affect the manganese and nitrogen contents in the weld metal. The mechanical properties of the weld metal are estimated. In welding the hot-rolled and the as-cast steels, the ultimate strength of the weld metal is shown to be almost the same as that of the base metal, which correlates with the microhardness measured in the base metal and the weld metal, and to be higher than the ultimate strength of traditional corrosion-resistant nitrogen-free steels.

Similar content being viewed by others

Notes

Hereafter, the element contents are given in wt %.

In [18], >70 inches/min (1 inch = 25.4 mm).

REFERENCES

V. G. Gavriljuk and H. Berns, High Nitrogen Steels: Structure, Properties, Manufacture, Applications (Springer, Berlin, 1999).

M. O. Shpaidel’, “New nitrogen-containing austenitic stainless steels with high strength and ductility,” Metalloved. Term. Obrab. Met., No. 11, 9–13 (2005).

K. H. Lo, C. H. Chek, and J. K. L. Lai, “Recent developments in stainless steels,” Mater. Sci. Eng. R 65, 39–104 (2009).

I. V. Gorynin, V. A. Malyshevskii, G. Yu. Kalinin, S. Yu. Mushnikova, O. A. Bannykh, V. M. Blinov, and M. V. Kostina, “Corrosion-resistant high-strength nitrogen steels,” Vopr. Materialoved., No. 3 (59), 7–15 (2009).

H. J. Grabke, “The role of nitrogen in the corrosion of iron and steels,” Iron and Steel Inst. Japan Int. 36 (7), 777–786 (1996).

T. I. Tabatchikova, A. D. Nosov, S. N. Goncharov, N. Z. Gudnev, S. Yu. Del’gado Reina, and I. L. Yakovleva, “Structure and ductility of the heat-affected zone of welded joints of a high-strength steel,” Phys. Met. Metallogr. 115 (12), 1241–1248 (2014).

A. G. Ignatov, V. I. Krivorotov, and V. A. Mirgorodskii, “Laser welded joints of corrosion-resistant steels,” Fotonika, No. 2, 18–21 (2010).

A. V. Perestoronin and A. I. Misyurov, “Laser welding of Cryogenic Steels,” Molodezh. Naych.-Techn. Vestn., No. 7 (2014).

Lin Zhao, Zhiling Tian, and Yun Peng, “Porosity and nitrogen content of weld metal in laser welding of high nitrogen austenitic stainless steel,” ISIJ Intern 47 (12), 1772–1775 (2007).

A. I. Balitskii, I. F. Kostyuk, and O. A. Krokhmalnyi, “Physicomechanical inhomogeneity of welded joints of high nitrogen chromium-manganese steels and their corrosion resistance,” Avtomat. Svarka, No. 2, 28–31 (2003).

L. G. Rigina, M. V. Kostina, O. A. Bannykh, V. M. Blinov, and T. N. Zvereva, “Effect of alloying on the composition-stable nitrogen content and phase composition of corrosion-resistant Fe–Cr–Mn–Ni–Mo–V–Nb alloys after solidification,” in Proceedings of the 9th International Conference High Nitrogen Steels (Moscow, July 2009).

M. Okatomo and T. J. Naito, Iron Steel Inst. Jap. 49 (13), 1915 (1963).

O. A. Bannykh, V. M. Blinov, M. V. Kostina, E. V. Blinov, and T. N. Zvereva, “Weldability of corrosion-resistant high nitrogen austenitic Kh22AG16N8M-type steels,” Rus. Met. (Metally), No. 5, 348–354 (2007).

S. D. Voronchuk, V. I. Krivorotov, L. V. Shamova, M. V. Kostina, S. O. Muradjan, E. V. Blinov, and Yu. Petrov, “Performance assessment of full strength and tension of laser welds of nitrogen content, austenitic and martensitic steels,” in Proceedings of the 16th International Conference Laser Optics 2014, (St. Petersburg, 2014), p. 55.

B. Acherjee, “Hybrid laser arc welding: state-of-art review,” Optics Laser Technol. 99, 60–71 (2018).

M. Harzenmoser, “Welding of high nitrogen steels,” Mater. Manufact. Proc. 19 (1), 75–86 (2004). https://doi.org/10.1081/AMP-120027503.

J. T. Norris, C. V. Robino, D. A. Hirschfeld, and M. J. Perricone, “Effects of laser parameters on porosity formation: Investigating millimeter scale continuous wave Nd : YAG laser welds,” Welding J. 90, 198–203 (2011).

S. B. Tate, “Laser weldability of type 21Cr–6Ni–9Mn stainless steel,” Colorado School of Mines, 2007-Mines Theses & Dissertations. http://dsapce.library.colosate.edu/handle/11124/17065.

P. A. A. Khan, T. DebRoy, and S. A. David, “Laser welding of high-manganese stainless steels: examination of alloying element loss and microstructural changes,” Weld. J. 67 (1), 1s–7s (1988).

T. Iambjliev, A. Zumbilev, L. Kalev, S. Christov, V. Ianev, and R.G. Stang, “Laser welding of high-nitrogen-containing austenitic stainless steel,” Weld. J. 78 (7), 245s–252s (1999).

ACKNOWLEDGMENTS

This work was performed according by state assignment no. 45.3.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by Yu. Ryzhkov

Rights and permissions

About this article

Cite this article

Kostina, V.S., Kostina, M.V., Voronchuk, S.D. et al. Structure and Properties of the Metal in the Laser Welding Joints of an Austenitic Steel Containing ~0.5% N in the As-Cast and Deformed States. Russ. Metall. 2018, 795–802 (2018). https://doi.org/10.1134/S0036029518090094

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029518090094