Abstract

A study is performed of the catalytic properties of Cu–Zn catalysts on Al2O3 and SiO2 supports (Acros) in the reaction of CO2 hydrogenation to obtain methanol. A sample of 30Cu15Zn/Al2O3 displays great selectivity toward methanol. A sample of 30Cu15Zn/SiO2 has the highest methanol performance. The methanol performance of a sample of 10Cu5Zn/Al2O3 is doubled when the pressure is raised from 10 to 30 atm, and a 94% increase in selectivity is observed. A sample of catalyst 10Cu5Zn/SiO2 does not lose its activity after 10 h of a catalytic reaction, and its methanol performance grows with repeated use.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

Many works of the last two decades have been devoted to the hydrogenation of CO2, which proceeds with the formation of such chemical compounds as CO, methane [1], other hydrocarbons [2–12], and methanol [11, 13–20]. Methanol is widely used as a solvent and serves as a valuable chemical raw material for the production of formaldehyde [21, 22], olefins [23, 24], aromatic compounds [25, 26], and biodiesel fuel [27, 28]. Promising catalysts for obtaining methanol from CO2 are supported Cu–Zn catalytic systems, due to their efficiency and low cost [29–34]. Al2O3 and SiO2 supports are efficient in this process, due to their large surface areas, high mechanical stability, and accessibility [35]. Raising the pressure improves the reaction of CO2 hydrogenation for the production of methanol and prolongs the service life of the catalyst [31, 36]. When studying this reaction in [37], we used commercial supports from Saint Gobain (SG): Al2O3, Al2O3 with added SiO2, SiO2 with added Al2O3, and SiO2. All catalysts were shown to be efficient in the production of methanol. The greatest selectivity toward methanol was displayed by a sample on an Al2O3 support, and a sample on an Al2O3 support with added SiO2 had the highest methanol performance.

There is a wide variety of other commercially available Al2O3 and SiO2 adsorbents. The aim of this work was to synthesize catalysts based on copper and zinc, supported on widely used Acros (A) commercial adsorbents Al2O3 and SiO2, and to perform a comparative study of their catalytic properties at different pressures. Adsorbents Al2O3 (A) and SiO2 (A) are more available and less expensive than Al2O3 (SG) and SiO2 (SG). In addition, SiO2 (A) has more surface area than SiO2 (SG), but Al2O3 (A) has less surface area than Al2O3 (SG).

EXPERIMENTAL

Synthesizing Samples

Bimetallic Cu–Zn catalysts were prepared via impregnation from aqueous solutions of a mixture of copper and zinc nitrates. We used commercial granulated alumina Al2O3 (A) and silica gel SiO2 (A) as the support for preparing samples of the catalysts. Table 1 describes the textural characteristics of these media.

Supports (Al2O3 or SiO2) with a mass of 2 g and fractions of 0.25–0.5 mm were impregnated with 5 mL of a joint solution of metal precursors. Precursors of the active metals were copper(II) nitrate, Cu(NO)3)2⋅3H2O trihydrate (99%, Acros), and zinc nitrate hexahydrate Zn(NO3)2⋅6H2O (98% Acros). The resulting impregnated samples were dried in air with continuous stirring at a temperature of 50°C, then stirred for 10 h at 100°C, and finally calcined for 4 h at 450°C. The obtained bimetallic catalysts were 10, 20, 30 wt % copper and contained enough zinc for the molar ratio to be Cu : Zn = 2 : 1. We therefore obtained samples of catalysts 10Cu5Zn/Al2O3, 20Cu10Zn/Al2O3, and 30Cu15Zn/Al2O3 deposited on Al2O3 and 10Cu5Zn/SiO2, 20Cu10Zn/SiO2, and 30Cu15Zn/SiO2, deposited on SiO2.

Catalytic Tests

The hydrogenation of CO2 was done at pressures of 10, 20, 30 atm in the 170–210°C range of temperatures, using a flow catalytic setup with a steel reactor that had an inner diameter of 6 mm. The gas mixture was fed into the reactor in volume ratio H2 : CO2 = 3 : 1 at a flow rate of 80 mL/min. Before loading into the reactor, a 0.1 g sample of the catalyst was diluted to 1.4 mL with ~1.9 g of quartz. The products of the reaction were analyzed on a Chromatek-Krystal 5000 gas chromatograph with three thermal conductivity detectors and an FID. Our columns were an M ss316 NaX (80/100 mesh, 2 m × 2 mm), a HayeSep R (80/100 mesh, 1 m × 2 mm), an M ss316 HayeSep Q (80/100 mesh, 2 m × 2 mm), and a Zebron® ZBFFAP (50 m × 0.32 mm × 0.50 µm).

RESULTS AND DISCUSSION

The main products of carbon dioxide hydrogenation were methanol and water. Competing reactions produced such reaction by-products as carbon monoxide, methane, and dimethyl ether. Note that since the yield of dimethyl ether was less than 1% throughout the range of temperatures, its contribution to the overall selectivity was not considered when calculating the selectivities of the reaction products.

Hydrogenation of CO2 on Bimetallic Cu–Zn/Al2O3 Catalysts

Figure 1 shows the dependence of methanol selectivity on the temperature of the reaction for a series of CuZn/Al2O3 catalysts. At temperatures of 170–190°C, the selectivity toward target product methanol on all synthesized catalysts was 92–95%, slightly lower (by 3–4%) than on similar catalysts based on SG commercial supports [37]. The selectivity toward methane for the obtained samples in the same range of temperatures was 2–6%, and the selectivity toward CO was 1–4%. In the 170–180°C range of temperatures, the higher the content of copper and zinc, the greater the selectivity toward methanol and the lower the selectivity toward methane. When the temperature was raised to 200°C, all catalyst samples displayed a drop in selectivity toward methanol and methane: the higher the content of metal, the larger the drop.

Figure 2 shows the selectivity toward methanol as a function of pressure. From the sample of 10Cu5Zn/Al2O3, we can see there was a nonlinear increase in selectivity when the pressure was raised.

Figure 3 shows methanol capacity (η) as a function of temperature. For all synthesized samples of catalysts based on Al2O3 (A), there was an increase in productivity as the temperature of the reaction rose. The 30Cu15Zn/Al2O3 catalyst displayed the best performance with regard to methanol. It roughly doubled for the worst of the three catalysts in Fig. 3 (10Cu5Zn/Al2O3) when the pressure was raised by ~2 times from 10 to 30 atm (Fig. 4). It should also be noted that the methanol capacity of the catalysts based on the Al2O3 (A) support was ⁓25% lower than those of catalysts based on Al2O3 (SG).

Hydrogenation of CO2 on Bimetallic Cu–Zn/SiO2 Catalysts

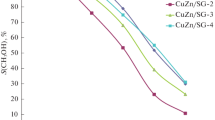

Figure 5 shows the dependence of the selectivity toward methanol on the temperature of the reaction for a series of CuZn/SiO2 catalysts. All of the synthesized catalysts display a methanol selectivity of 87–93% at temperatures of 170–190°C, which is slightly lower than that of catalysts on Al2O3 (A) and SiO2 (SG) supports. In the same range of temperatures, the selectivity toward methane is 1–4%, and the selectivity toward CO is 4–11%. In the 170–180°C range of temperatures, the higher the contents of copper and zinc, the higher the selectivity toward methanol and the lower the selectivity toward methane. As the temperature rose to 210°C, all catalyst samples displayed a notable drop in selectivity toward methanol and methane: the higher the content of metal, the greater the drop.

Figure 6 shows the temperature dependence of the methanol performance of catalysts based on SiO2. The performance of catalysts based on SiO2, and of catalysts based on Al2O3, grows along with temperature. The best performance is observed for the 30Cu15Zn/SiO2 catalyst. The methanol performance for catalysts based on an SiO2 (A) support is lower than for catalysts based on SiO2 (SG).

Figure 7 shows the temperature dependence of methanol performance when a sample of 10Cu5Zn/SiO2 was used twice in the hydrogenation of CO2 to obtain methanol. Using the 10Cu5Zn/SiO2 sample as an example, it was shown there was no drop in catalytic activity after 10 h of using the catalyst in the hydrogenation of CO2 to produce methanol. A rise in methanol performance was observed when the sample was used twice in the 170–190°C range of temperatures.

CONCLUSIONS

Compared to catalysts based on Al2O3 and SiO2 (SG) supports, bimetallic Cu–Zn catalysts synthesized on Al2O3 and SiO2 (A) supports are just as efficient in the hydrogenation of CO2 in terms of the selectivity toward methanol and less efficient in terms of the methanol performance of catalysts. The highest selectivity toward methanol was obtained using a sample of 30Cu15Zn/Al2O3. In the 170–190°C range of temperatures, the selectivity toward methanol for this catalyst was 92–95%. The highest methanol performance was obtained for a sample of 30Cu15Zn/SiO2 at a reaction temperature of 210°C. The methanol performance of a sample of 10Cu5Zn/Al2O3 doubled when the pressure was raised from 10 to 30 atm, and its selectivity rose slightly to 94%. There was no drop in the catalytic activity of a sample of 10Cu5Zn/SiO2 catalyst after it was used for 20 h in the hydrogenation of CO2 to produce methanol. Its methanol performance rose when it was used a second time.

REFERENCES

N. D. Evdokimenko, A. L. Kustov, K. O. Kim, et al., Mendeleev Commun. 28, 147 (2018).

Y. A. Pokusaeva, A. E. Koklin, V. V. Lunin, et al., Mendeleev Commun. 29, 382 (2019).

N. D. Evdokimenko, A. L. Kustov, K. O. Kim, et al., Funct. Mater. Lett. 2040004, 1 (2020).

S. A. Chernyak, A. S. Ivanov, D. N. Stolbov, et al., Carbon 168, 475 (2020).

V. I. Bogdan, A. E. Koklin, A. L. Kustov, et al., Molecules 26, 2883 (2021).

A. S. Konopatsky, K. L. Firestein, N. D. Evdokimenko, et al., J. Catal. 402, 130 (2021).

A. M. Kovalskii, I. N. Volkov, N. D. Evdokimenko, et al., Appl. Catal. B 303, 120891 (2022).

N. D. Evdokimenko, G. I. Kapustin, O. P. Tkachenko, et al., Molecules 27, 1065 (2022).

Zeolites and Zeolite-like Materials, Ed. by B. F. Sels and L. M. Kustov (Elsevier, Amsterdam, 2016).

O. Tursunov, L. Kustov, and Z. Tilyabaev, J. Pet. Sci. Eng. 180, 773 (2019).

O. Tursunov, L. Kustov, and A. Kustov, Oil Gas Sci. Technol. 72 (5), 30 (2017).

O. Tursunov, L. Kustov, and Z. Tilyabaev, J. Taiwan Inst. Chem. Eng. 78, 416 (2017).

M. Kurtz, Catal. Lett. 86, 77 (2003).

M. Saito, Catal. Surv. Asia 8, 285 (2004).

J. Ma, N. N. Sun, X. L. Zhang, et al., Catal. Today 148, 221 (2009).

W. Wang, S. Wang, X. Ma, et al., Chem. Soc. Rev. 40, 3703 (2011).

Y. Jiang, J. CO2 Util. 26, 642 (2018).

V. D. B. C. Dasireddy and B. Likozar, Renew. Energy 140, 452 (2019).

N. Meunier, R. Chauvy, S. Mouhoubi, et al., Renew. Energy 146, 1192 (2020).

X. Fang, Y. Xi, H. Jia, et al., J. Ind. Eng. Chem. 88, 268 (2020).

T. Kropp, J. Paier, and J. Sauer, J. Catal. 352, 382 (2017).

A. Gribovskii, E. Ovchinnikova, N. Vernikovskaya, et al., Chem. Eng. J. 308, 135 (2017).

P. Losch, A. B. Pinar, M. G. Willinger, et al., J. Catal. 345, 11 (2017).

X. Wang, R. Li, S. Bakhtiar, et al., Catal. Commun. 108, 64 (2018).

X. Niu, J. Gao, K. Wang, et al., Fuel Process Technol. 157, 99 (2017).

L. Yang, Z. Liu, Z. Liu, et al., Chin. J. Catal. 38, 683 (2017).

C. Pirola, F. Galli, C. L. Bianchi, et al., Energy Fuels 28, 5236 (2014).

D. C. Boffito, F. Galli, P. R. Martinez, et al., Chem. Eng. Trans. 43, 427 (2014).

Q. Sun, J. Catal. 167, 92 (1997).

P. Mierczynski, Catal. Today 176, 21 (2011).

V. I. Bogdan and L. M. Kustov, Mendeleev Commun. 25, 446 (2015).

H. Ren, J. Ind. Eng. Chem. 28, 261 (2015).

M. Bukhtiyarova, Catal. Lett. 147, 416 (2017).

C. Zhang, J. CO2 Util. 17, 263 (2017).

J. Sloczynski, R. Grabowski, A. Kozlowska, et al., Appl. Catal., A 278, 11 (2004).

N. D. Evdokimenko, K. O. Kim, G. I. Kapustin, et al., Catal. Ind. 10, 288 (2018).

K. O. Kim, N. D. Evdokimenko, P. V. Pribytkov, et al., Russ. J. Phys. Chem. A 95, 2422 (2021).

Funding

This work in the part related to catalytic research was supported by the Russian Science Foundation, project no. 20-73-10106. This work in the part related to the preparation of catalysts was carried out within the framework of the state budget theme “Fundamentals of the creation of metal and composite materials,” CITIS: AAAAA-A21-121011590083-9.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kim, K.O., Shesterkina, A.A., Tedeeva, M.A. et al. Obtaining Methanol from CO2 on Cu–Zn/Al2O3 and Cu–Zn/SiO2 Catalysts: Effect of the Support and Conditions of the Reaction. Russ. J. Phys. Chem. 97, 582–586 (2023). https://doi.org/10.1134/S0036024423040167

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024423040167