Abstract

Nitrogen-doped graphene nanoflakes with a high nitrogen content (6.6 at %) and developed mesoporosity were synthesized via pyridine pyrolysis. They were tested in a supercapacitor with a non-aqueous electrolyte: a 1.2 M solution of ionic liquid Et4N+TFSI− in acetonitrile. It was found that incorporation of nitrogen into the graphene layers nearly tripled the specific capacitance of the electrode, compared to the undoped nanoflakes.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

INTRODUCTION

The development of microelectronics requires miniaturization of energy storing and converting devices. Unlike traditional storage batteries, supercapacitors (SCs) are compact, have high energy and power densities. The specific characteristics of an SC depend on the type of electrode material and the electrolyte [1–3]. Carbon nanomaterials (CNMs) are widely used as electrodes for supercapacitors, due to their high specific surface area, electrical conductivity, thermal and electrical stability. The specific energy of an SC depends on the capacitance and the operating voltage as E = (1/2)CV 2. In contrast to SCs with aqueous electrolytes, the operating voltage of which is limited by the electrochemical stability of water, ionic liquids (ILs) have higher electrochemical windows (up to 4–5 V [4]), allowing to achieve high specific energy of SC. Activated carbons (ACs) are widely used as the electrode material of SC. Depending on the activation method, specific surface areas of ACs can reach up to 3000 m2/g [5]. However, activation forms a large number of micropores in the material that hinder the access of IL ions and therefore prevent the effective accumulation of charge [6]. In addition, the conductivity of ACs is low. Unlike ACs, multiwalled carbon nanotubes (CNTs) have substantially higher electrical conductivity. However, CNTs can have closed ends, making the inner surface of the tube inaccessible for the formation of a electric double layer (EDL) during charge accumulation. In addition, the strong van der Waals interactions between the graphene planes can also hinder the access of electrolyte ions to the interlayer space.

One way of modifying the electronic structure of CNMs is to introduce heteroatoms (particularly nitrogen) that create active centers on the carbon surface [7, 8]. Graphitic nitrogen configuration is known to increase the electrical conductivity of the material, while pyridine and pyrrole nitrogen species improve capacitance due to reversible Faraday processes [9]. Unlike laser ablation and electric arc discharge, chemical vapor deposition (CVD) allows obtaining a homogeneous material by tuning and controlling the synthesis parameters (temperature, time, and type of precursor mixture) [10].

In this work, we propose a simple template synthesis that allows producing graphene nanoflakes (GNFs) with deformed edges that prevent their agglomeration. The synthesized GNFs were tested as electrodes of a SC based on a non-aqueous electrolyte: a 1.2 M solution of IL tetraethylammonium bis(trifluoromethanesulfonyl)imide Et4N+TFSI− in acetonitrile.

EXPERIMENTAL

Synthesis of GNFs

GNFs were synthesized according to the procedure in [11], using a quartz reactor (L = 1.5 m, d = 50 mm) placed in a Carbolite TZF 12/100/900 three-zone oven. During heating to a synthesis temperature of 900°C, a nitrogen flow (200 mL/min) was passed through the reactor to displace air and create an inert atmosphere. After reaching the required temperature, the N2 flow was increased to 1000 mL/min and bubbled through a Drechsel bottle with a precursor. The precursor vapors were decomposed on the MgO template (SBET = 140 m2/g) placed in the center of the reactor. Pyridine (>99.8%, Sigma Aldrich) was used as a nitrogen-containing precursor, ensuring the formation of nitrogen functional groups on the surface and in the bulk of GNFs. To vary the porous characteristics of the produced materials, the synthesis was carried out for 15 (N-GNF-15), 30 (N-GNF-30), and 90 min (N-GNF-90). To study the effect of nitrogen doping on the supercapacitor performance, undoped GNFs were also produced by CVD of hexane (99.9%, Reakhim) for 15 min at the same conditions (GNF‑15). Template was removed by refluxing the resulting materials in a solution of hydrochloric acid (10 wt %) for 8 h followed by washing to a neutral pH with distilled water and drying at 120°C.

Characterization of GNFs

Micrographs of the GNFs were obtained on a JEOL JEM 2100 F UHR/Cs transmission electron microscope (TEM) equipped with an electron energy loss spectra (EELS) analyzer and a corrector of chromatic aberrations (CAs). The porosity characteristics of the GNFs were measured by low-temperature nitrogen porosimetry using an Autosorb-1C/MS/TPR surface analyzer. Prior to measurements, each sample was degassed for 3 h at 250°С. The specific surface areas were calculated according to the BET method. The pore size distributions were determined according to the BJH model. The surface composition and types of functional groups were characterized by X-ray photoelectron spectroscopy (XPS). XPS spectra were recorded on an Axis Ultra DLD spectrometer (Kratos Analytical, United Kingdom) using monochromatic AlKα (1486.6 eV) X-ray radiation.

Electrochemical Characterization

To prepare the electrode slurry, GNFs, Super C65 carbon black (Shandong GELON LIB) and polyvinylidene fluoride binder (Arkema) were mixed in a mass ratio of 8 : 1 : 1. The resulting mixture was thoroughly ground in a mortar, transferred to a weighing bottle, and mixed with N-methylpyrrolidone (chemically pure grade, Komponent-Reaktiv). After stirring with a magnetic stirrer for 24 h, the suspension was applied to a nickel foam (d = 10 mm), which was used as a current collector, and dried at 120°С for 72 h. After drying, to improve the contact between the current collector and the carbon material, the electrodes were pressed in rollers (Shandong GELON LIB). The SCs were assembled in a sealed SPEKS GB-02M glove box (CJSC Spectroscopic Systems) in an argon atmosphere. For this purpose, the electrodes were impregnated with an electrolyte, which was a 1.2 M solution of an ionic liquid tetraethylammonium bis(trifluoromethanesulfonyl)imide Et4N+TFSI– (≥99.0%, Sigma Aldrich) in acetonitrile (≥99.8%, Sigma Aldrich). This concentration provides the highest electrical conductivity of Et4N+TFSI– solution in CH3CN [12]. After impregnation, two symmetric electrodes were separated by a Whatman separator and sealed in a 2032 coin-cell using a hydraulic press.

The study of SCs was carried out by cyclic voltammetry (CV) and galvanostatic charge-discharge (GCD). The characteristics of SCs (specific capacity, energy, and power) were calculated as described in [3].

RESULTS AND DISCUSSION

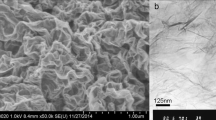

TEM images (Fig. 1) show the layered structures of GNFs consisting of several graphene layers replicating the shape of the template particles. The different curvatures on the edges of the graphene planes reduce the aggregation of GNF particles and thus improve the access of electrolyte ions to the inner surface of pores during charge accumulation. In contrast to carbon nanotubes, the doping of which with nitrogen atoms is usually accompanied by numerous constrictions inside their channels, incorporation of nitrogen doesn’t change morphology of GNFs [13, 14].

The surface composition of GNFs was analyzed by XPS. The pyrolysis of pyridine produces different nitrogen groups on the carbon surface. Lines of carbon (282 eV), nitrogen (402 eV), and oxygen (532 eV) are observed in survey XPS spectra (Fig. 2). The N1s spectrum of N-GNFs shows the contribution from pyridinic (398.1 eV; N6), pyrrolic (399.4 eV; N5), and graphitic (also called as quaternary) (401.1 eV; N-G) nitrogen species, along with oxidized pyridine N‑oxides (402.5 eV), R–ONO (403.8 eV), R–NO2 (405.5 eV), and R–ONO2 (407.4 eV) forms [15] (Table 1). The total nitrogen content (6.2–6.6 at %) is virtually independent of the synthesis time.

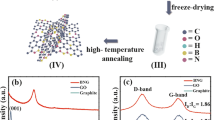

GNFs/N-GNFs were tested in the two-electrode coin-cell to study the effect of nitrogen doping on the SC performance. The CV curves (Fig. 3a) are nearly rectangular, indicating that the mechanism of charge accumulation is based on the electrostatic adsorption of electrolyte ions in the porous structure of electrodes. The small reversible peaks in the potential range of 2.5–2.8 V correspond to the redox processes involving nitrogen groups and contributing to pseudocapacitance. Pyridinic and pyrrolic nitrogen species can improve pseudocapacitance due to redox processes, while graphitic nitrogen enhances the electrical conductivity of the material and its wettability with the electrolyte [16]. Nitrogen doping of GNF leads to a notable increase in the specific capacitance. The highest specific capacitance values, calculated at a scan rate of 5 mV/s are 123 (N-GNF-15), 93 (N-GNF-30), and 82 F/g (N-GNF-90), which are much higher than the capacitance of undoped GNF-15 (41 F/g). The decrease in capacitance with increasing the scan rate was attributed to the shorter charge time that reduced the proportion of pores participating in the formation of an EDL. The specific capacitances calculated via GCD are consistent with the CV data and reach 36 (GNF-15), 117 (N-GNF-15), 88 (N-GNF-30), and 77 F/g (N-GNF-90) at a current density of 0.5 A/g (Fig. 3b). XPS showed that the distribution of nitrogen groups on the surface of N-GNF was almost independent of the synthesis time. Thus, the capacitance of N‑GNFs is determined mainly by their textural characteristics. As it was shown in [17], the specific capacitance of a double-layer SC is proportional to the dielectric constant ε of the electrolyte and specific surface area S of the electrode at the electrode/electrolyte interface as C = εS/d, where d is the effective thickness of the EDL. It was found that the increase in synthesis duration led to the reduction of specific surface area SBET from 910 (N-GNF-15) to 700 (N‑GNF-30) and 560 m2/g (N-GNF-90). Indeed, TEM showed that prolonged pyrolysis enlarges GNF particles and increases the number of graphene layers, reducing the specific surface area. There is also an increase in the average pore size, and thus a reduction in the surface available for charge accumulation. Though the specific surface area of GNF-15 (590 m2/g) is higher than that of N-GNF-90, the specific capacitance of the former is much lower. This shows that incorporation of nitrogen atoms into graphene layers leads to the formation of active nitrogen centers and has a determinative effect on the capacitive characteristics of the electrode material.

The Ragone plots are presented in Fig. 3c. In contrast to undoped GNFs, the nitrogen-doped materials show higher specific energies of 36.2 (N-GNF-15), 27.0 (N-GNF-30) and 23.7 (N-GNF-90) W h/kg at a current density of 0.5 A/g, while that for GNF-15 did not exceed 11.1 W h/kg. The specific energies calculated in this work are comparable to those for SCs based on N‑carbon nanofoam (26.6–63.4 W h/kg [18]), N‑graphene (36 W h/kg [19]), ACs (19.2 W h/kg [20]), carbon nanosheet (45.5 W h/kg [21]) electrodes in IL electrolytes. In addition, SCs based on GNFs and N‑GNFs retained high electrochemical stability over 1000 cycles (Fig. 3d).

CONCLUSIONS

It was shown that the pyrolysis of pyridine on the MgO template produced graphene nanoflakes with the developed mesoporosity and high nitrogen content (6.6 at %). The obtained materials tested as electrodes of the SC with a non-aqueous electrolyte: a 1.2 M solution of IL Et4N+TFSI− in acetonitrile. It was found that the specific capacitance of the electrode depended on the content of nitrogen and specific surface area. In contrast to undoped GNFs, the incorporation of nitrogen significantly increased the specific capacitance of the material and resulted in high energy density of the supercapacitor, due to a combination of two effects.

(1) Doping graphene layers with N atoms produces active nitrogen centers on the carbon surface that not only contribute to the formation of pseudocapacitance but also increase the electrical conductivity of the material and improve wetting of the electrode surface with the electrolyte solution.

(2) The developed mesoporosity of N-GNFs improves the transport of electrolyte ions to the inner surfaces of pores and ensures efficient charge accumulation during the formation of EDL.

Change history

15 July 2021

An Erratum to this paper has been published: https://doi.org/10.1134/S0036024421310022

REFERENCES

V. V. Chernyavina, A. G. Berezhnaya, and E. A. Zhikhareva, Elektrokhim. Energet. 18, 192 (2018).

S. A. Baskakov, Yu. V. Baskakova, N. V. Lyskov, et al., Zh. Fiz. Khim. 91, 1748 (2017).

E. A. Arkhipova, A. S. Ivanov, K. I. Maslakov, et al., Microporous Mesoporous Mater. 294, 109851 (2020).

S. P. Ong, O. Andreussi, Y. Wu, et al., Chem. Mater. 23, 2979 (2011).

K. Mensah-Darkwa, C. Zequine, P. Kahol, and R. Gupta, Sustainability 11, 414 (2019).

M. Inagaki, H. Konno, and O. Tanaike, J. Power Sources 195, 7880 (2010).

R. L. McCreery, Chem. Rev. 108, 2646 (2008).

M. Terrones, P. M. Ajayan, F. Banhart, et al., Appl. Phys. A 74, 355 (2002).

D. Hulicova-Jurcakova, M. Seredych, G. Q. Lu, and T. J. Bandosz, Adv. Funct. Mater. 19, 438 (2009).

K. A. Shah and B. A. Tali, Mater. Sci. Semicond. Process. 41, 67 (2016).

S. V. Savilov, E. A. Arkhipova, A. S. Ivanov, et al., Mater. Res. Bull. 69, 7 (2015).

E. A. Arkhipova, A. S. Ivanov, K. I. Maslakov, et al., Electrochim. Acta 297, 842 (2019).

E. A. Arkhipova, A. S. Ivanov, N. E. Strokova, et al., Carbon 125, 20 (2017).

H. Liu, Y. Zhang, R. Li, X. Sun, et al., Carbon 48, 1498 (2010).

E. A. Arkhipova, A. S. Ivanov, K. I. Maslakov, and S. V. Savilov, Electrochim. Acta 353, 136463 (2020).

L. Sun, C. Tian, Y. Fu, et al., Chem. – Eur. J. 20, 564 (2014).

E. Frackowiak, Phys. Chem. Chem. Phys. 9, 1774 (2007).

P. Ramakrishnan and S. Shanmugam, J. Power Sources 16, 60 (2016).

S. Suresh Balaji, M. Karnan, and M. Sathish, Int. J. Hydrogen Energy 43, 4044 (2018).

A. Krause and A. Balducci, Electrochem. Commun. 13, 814 (2011).

D. Zhou, H. Wang, N. Mao, et al., Microporous Mesoporous Mater. 241, 202 (2017).

Funding

This work was financially supported by the Russian Foundation for Basic Research, project no. 19-03-00713A.

Author information

Authors and Affiliations

Corresponding author

Additional information

The original online version of this article was revised due to a retrospective Open Access order.

Rights and permissions

Open Access. This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Arkhipova, E.A., Ivanov, A.S., Maslakov, K.I. et al. Nitrogen Heterosubstitution in Graphene Nanoflakes: An Effective Approach to Improving Performance of Supercapacitors with Ionic Liquid Electrolyte. Russ. J. Phys. Chem. 95, 565–569 (2021). https://doi.org/10.1134/S0036024421030031

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036024421030031