Abstract

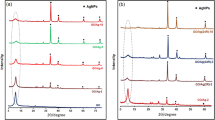

The invention represents a development of robust eco-friendly method use for water waste management and polluted water. The inadvertent role of peanut peels extract helps to simultaneously convert and form reduced graphene oxide gold nanocomposite (rGO@AuNCs) in single step. Fabricated nanocomposite was evaluated for its catalytic performance using reduction of 4-nitrophenol to 4-aminophenol as well as elimination of methylene blue (MB) and malachite green (MG) dyes from water. Graphene oxide (GO) and rGO@AuNCs, were synthesized using simplified approaches and preliminary characterization was done using UV–Vis spectrophotometer and Fourier transform infrared spectroscopy. Least concentration of rGO@AuNCs is required to eliminate MB and MG around 77 and 93%, respectively. Furthermore, surface morphology and elemental analysis of rGO@AuNCs confirm successful fabrication methods as well as X‑ray diffraction pattern confirms the crystalline behavior of nanocomposite. The study illustrates an environment-friendly and cost effective in situ fabrication rGO@AuNCs from industrial agro waste for an environmental remediation.

Similar content being viewed by others

REFERENCES

D. Chen, H. Feng and J. Li, Chem. Rev. 112, 6027 (2012).

B. Paulchamy, G. Arthi, and B. Lignesh, J. Nanomed. Nanotechnol. 6, 253 (2015).

P. H. C. Camargo, K. G. Satyanarayana, and F. Wypych, Mater. Res. 12, 1 (2009).

T. Wu, L. Zhang, J. Gao, Y. Liu, and C. Gao, J. Mater. Chem. A 1, 7384 (2013).

Z. Wang, C. Xu, G. Gao, and X. Li, RSC Adv. 4, 13644 (2014).

S. P. Lonkar and A. A. Abdala, J. Thermodyn. Catal. 5 (2), 1 (2014).

R. R. Mishra, R. Chandran, and S. S. Khan, RSC Adv. 4, 51787 (2014).

J. Pasupuleti, S. N. Nigam, M. K. Pandey, P. Nagesh, and R. K. Varshney, Front Plant Sci. 4, 23 (2013).

P. Bharthare, P. Shrivastava, P. Singh, and A. Ttiwari, Int. J. Adv. Res. 2, 1 (2014).

R. Radhakrishnan, S. B. Pae, B. K. Lee, and I. Y. Baek, Afr. J. Biotechnol. 12, 4477 (2013).

M. A. Usman, I. Momohjimoh, and A. S. Gimba, J. Miner. Mater. Charact. Eng. 4, 228 (2016).

D. Yan, H. Zhang, L. Chen, G. Zhu, Z. Wang, H. Xu, and A. Yuc, RSC Adv. 4, 23649 (2014).

M. K. Satapathy, P. Banerjee, and P. Das, Appl. Nanosci. 5, 1 (2015).

A. A. Bazrafshan, S. Hajati, and M. Ghaedi, RSC Adv. 5, 79119 (2015).

R. K. Upadhyay, N. Soin, and S. S. Roy, RSC Adv. 4, 3823 (2014).

P. O. Patil, P. V. Bhandari, P. K. Deshmukh, S. S. Mahale, A. G. Patil, H. R. Bafna, K. V. Patel, and S. B. Bari, Res. Chem. Intermediat. 43, 3757 (2017).

N. Burham, A. Mamdouh, and M. El-Sahat, Int. J. Adv. Res. 2, 755 (2014).

M. S. Gokhale and C. Kokate, Practical Pharmacognosy (Pragati Books, Mumbai, 2008).

M. K. Chuang, S. W. Lin, F. C. Chen, C. W. Chu, and C. S. Hsu, Nanoscale 6, 1573 (2014).

X. Weng, L. Huang, Z. Chen, M. Megharaj, and R. Naidu, Ind. Crop. Prod. 51, 342 (2013).

M. Li and G. Chen, Nanoscale 5, 11919 (2013).

K. J. Jeon and Z. Lee, Chem. Commun. 47, 3610 (2011).

M. Iliut, C. Leordean, V. Canpean, C. M. Teodorescu, and S. Astilean, J. Mater. Chem. C 1, 4094 (2013).

S. Bai and X. Shen, RSC Adv. 2, 64 (2012).

H. Zhang, D. Hines, and D. L. Akins, Dalton Trans. 43, 2670 (2014).

N. Karousis, N. Tagmatarchis, and D. Tasis, Chem. Rev. 110, 5366 (2010).

ACKNOWLEDGMENTS

Authors are thankful to Management, Principal, SES, H.R. Patel Institute of Pharmaceutical Education and Research, Shirpur for providing necessary facilities to do research work effectively. Authors are also thankful for North Maharashtra University, Jalgoan for their kind support in analytical facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Patil, P.O., Mahale, S.S., More, M.P. et al. Eco-Friendly In Situ Fabrication of Reduced Graphene Oxide Gold Nanocomposites for Catalysis and Dye Degradation. Russ. J. Phys. Chem. 92, 2750–2756 (2018). https://doi.org/10.1134/S003602441813023X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S003602441813023X