Abstract

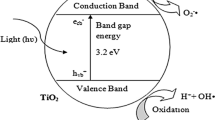

Leaf-like cupric oxide (CuO) with a high purity phase monoclinic structure was synthesized via a microwave method for use as a photocatalyst in the degradation of thiamethoxam insecticide. The synthesis process used copper nitrate and ammonia solution as precursors. The suspensions were treated via microwave irradiation at 600–800 W for 30 min, followed by a constant-temperature calcination process. The phase transitions, thermal stabilities, morphologies, chemical compositions, functional groups, and optical properties of the resulting leaf-like CuO powders were characterized via X-ray powder diffraction, TGA/DSC, SEM, particle size distribution analysis, EDS, FT-IR, UV-DRS, and PL. The experimental findings showed that increasing the microwave power resulted in favorable chemical and physical properties for the powders’ photocatalytic reactions, such as high purity phases, high crystallinity, high uniformity of the leaf-like shapes, smaller particle sizes, narrower size distributions, lower energy bandgaps, and lower rates of electron-hole pair recombination. The photocatalytic degradation of thiamethoxam insecticide using these leaf-like CuO powders under visible light illumination was studied. The concentration of thiamethoxam was analyzed using UV-Vis spectrophotometry. The highest thiamethoxam degradation efficiency was achieved by the CuO powder synthesized via microwave irradiation at 800 watts. Its efficiency was 48.65% in 60 min at a kinetic rate constant of 10.9 × 10−3 min−1.

Similar content being viewed by others

REFERENCES

P. Zhang, M. He, Y. Wei, et al., Crop. Prot. 90, 1 (2016). https://doi.org/10.1016/j.cropro.2016.07.028

D. Šojić, V. Despotović, D. Orčić, et al., J. Hydrol. 472–473, 314 (2012). https://doi.org/10.1016/j.jhydrol.2012.09.038

S. Kurwadkar, A. Evans, D. Dewine, et al., Environ. Toxicol. Chem. 35 (7), 1718 (2016). https://doi.org/10.1002/etc.3335

M. J. Hilton, S. N. Emburey, P. A. Edwards, et al., Pest. Manag. Sci. 75 (1), 63 (2019). https://doi.org/10.1002/ps.5168

M. Díaz-López, C. García, I. Garrido, et al., Geoderma 354, 113893 (2019). https://doi.org/10.1016/j.geoderma.2019.113893

N. A. Mir, A. Khan, M. Muneer, et al., Sci. Total Environ. 458–460, 388 (2013). https://doi.org/10.1016/j.scitotenv.2013.04.041

T. Lastovina, A. Budnyk, G. Khaishbashev, et al., J. Serb. Chem. Soc. 81 (7), 751 (2016). https://doi.org/10.2298/JSC151211036L

S. Dolai, R. Dey, S. Das, et al., J. Alloys Compd. 724, 456 (2017). https://doi.org/10.1016/j.jallcom.2017.07.061

J. Tan, M. Dun, L. Li, et al., Sens. Actuators, B 252, 1 (2017). https://doi.org/10.1016/j.snb.2017.05.107

X. Liu, Y. Yang, R. Liu, et al., J. Alloys Compd. 718, 304 (2017). https://doi.org/10.1016/j.jallcom.2017.05.201

A. Ulyankina, I. Leontyev, O. Maslova, et al., Mater. Sci. Semicon. Proc. 73, 111 (2018). https://doi.org/10.1016/j.mssp.2017.08.001

J. Huo, X. Liu, X. Li, et al., Int. J. Hydrogen Energ. 42, 15540 (2017). https://doi.org/10.1016/j.ijhydene.2017.05.033

K. Kumar, A. Priya, A. Arun, et al., Mater. Chem. Phys. 226, 106 (2019). https://doi.org/10.1016/j.matchemphys.2019.01.020

C. Karunakaran, G. Manikandan, and P. Gomathisankar, J. Alloys Compd. 580, 570 (2013). https://doi.org/10.1016/j.jallcom.2013.07.150

A. Mirzaei and G. Neri, Sens. Actuators, B 237, 749 (2016). https://doi.org/10.1016/j.snb.2016.06.114

Y. Min, T. Wang, and Y. Chen, Appl. Surf. Sci. 257, 132 (2010). https://doi.org/10.1016/j.apsusc.2010.06.049

S. L. Wang, P. G. Li, H. W. Zhu, et al., Powder Technol. 230, 48 (2012). https://doi.org/10.1016/j.powtec.2012.06.051

X. Zhou, J. Zhang, Q. Su, et al., Electrochim. Acta 125, 615 (2014). https://doi.org/10.1016/j.electacta.2014.01.155

J. Sultana, S. Paul, A. Karmakar, et al., Appl. Surf. Sci. 418, 380 (2017). https://doi.org/10.1016/j.apsusc.2016.12.139

K. Kumar and A. Chowdhury, Ceram. Int. 43, 13943 (2017). https://doi.org/10.1016/j.ceramint.2017.07.125

H. Shi, Y. Zhao, N. Li, et al., Catal. Commun. 47, 7 (2014). https://doi.org/10.1016/j.catcom.2013.12.032

H. Wang, Q. Shen, X. Li, et al., Langmuir 25, 3152 (2009). https://doi.org/10.1021/la803276z

X. Zhou, J. Shi, Y. Liu, et al., J. Alloys Compd. 615, 390 (2014). https://doi.org/10.1016/j.jallcom.2014.07.013

T. S. Cam, A. E. Petrova, V. L. Ugolkov, et al., Russ. J. Inorg. Chem. 65, 725 (2020). https://doi.org/10.1134/S0036023620050046

L. Yang, D. Chu, and L. Wang, Powder Technol. 287, 346 (2016). https://doi.org/10.1016/j.powtec.2015.10.011

W. M. Rangel, R. A. A. B. Santa, and H. G. Riella, J. Mater. Res. Technol. 9 (1), 994 (2020). https://doi.org/10.1016/j.jmrt.2019.11.039

M. Verma, V. Kumar, and A. Katoch, Mater. Sci. Semicon. Proc. 76, 55 (2018). https://doi.org/10.1016/j.mssp.2017.12.018

B. Saravanakumar, C. Radhakrishnan, M. Ramasamy, et al., Results Phys. 13, 102185 (2019). https://doi.org/10.1016/j.rinp.2019.102185

S. Dagher, Y. Haik, A. I. Ayesh, et al., J. Lumin. 151, 149 (2014). https://doi.org/10.1016/j.jlumin.2014.02.015

J. Xia, H. Li, Z. Luo, et al., J. Phys. Chem. Solids 70, 1461 (2009). https://doi.org/10.1016/j.jpcs.2009.08.006

S. Sundar, G. Venkatachalam, and S. J. Kwon, Nanomaterials (Basel) 8, 823 (2018). https://doi.org/10.3390/nano8100823

A. V. Uschakov, I. V. Karpov, A. A. Lepeshev, et al., Vacuum 128, 123 (2016). https://doi.org/10.1016/j.vacuum.2016.03.025

R. Sathyamoorthy and K. Mageshwari, Physica E. 47, 157 (2013). https://doi.org/10.1016/j.physe.2012.10.019

K. Mageshwari, R. Sathyamoorthy, and J. Park, Powder. Technol. 278, 150 (2015). https://doi.org/10.1016/j.powtec.2015.03.004

M. Rabbani, R. Rahimi, M. Bozorgpour, et al., Mater. Lett. 119, 39 (2014). https://doi.org/10.1016/j.matlet.2013.12.095

S. Sonia, S. Poongodi, P. S. Kumar, et al., Mat. Sci. Semicon. Proc. 30, 585 (2015). https://doi.org/10.1016/j.mssp.2014.10.012

C. Yang, X. Su, J. Wang, et al., Sens. Actuators, B 185, 159 (2013). https://doi.org/10.1016/j.snb.2013.04.100

C. Saovakon and P. Jansanthea, J. Aust. Ceram. Soc. Early Access (2020). https://doi.org/10.1007/s41779-020-00488-8

A. Mahmood, F. Tezcan, and G. Kardas, Int. J. Hydrogen. Energ. 42, 23268 (2017). https://doi.org/10.1016/j.ijhydene.2017.06.003

P. Chand, Manisha, and P. Kumar, Optik 156, 743 (2018). https://doi.org/10.1016/j.ijleo.2017.12.029

C. Zhang, Y. Li, J. Li, et al., Chem. Eng. J. 392, 123687 (2020). https://doi.org/10.1016/j.cej.2019.123687

R. Žabar, T. Komel, J. Fabjan, et al., Chemosphere 89, 293 (2013). https://doi.org/10.1016/j.chemosphere.2012.04.039

A. Sadollahkhani, Z. H. Ibupoto, S. Elhag, et al., Ceram. Int. 40, 11311 (2014). https://doi.org/10.1016/j.ceramint.2014.03.132

S. Mosleh, M. R. Rahimi, M. Ghaedi, et al., Ultrason. Sonochem. 40, 601 (2018). https://doi.org/10.1016/j.ultsonch.2017.08.007

H. Yang, H. Liu, Z. Hub, et al., Chem. Eng. J. 245, 24 (2014). https://doi.org/10.1016/j.cej.2014.02.016

M. F. N. Taufique, A. Haque, P. Karnati, et al., J. Electron. Mater. 47 (11), 6731 (2018). https://doi.org/10.1007/s11664-018-6582-1

S. H. Kim, A. Umar, R. Kumar, et al., Mater. Lett. 156, 138 (2015). https://doi.org/10.1016/j.matlet.2015.05.014

G. Chen, H. Zhou, W. Ma, et al., Solid State Sci. 13, 2137 (2011). https://doi.org/10.1016/j.solidstatesciences.2011.08.013

L. Guo, F. Tong, H. Liu, et al., Mater. Lett. 71, 32 (2012). https://doi.org/10.1016/j.matlet.2011.11.105

K. Yao, S. Liu, Y.-Y. Dong, et al., Mater. Des. 90, 129 (2016). https://doi.org/10.1016/j.matdes.2015.10.121

L. Yang, D. Chu, and L. Wang, Mater. Lett. 160, 246 (2015). https://doi.org/10.1016/j.matlet.2015.07.133

F. Wang, A. Kalam, L. Chang, et al., Mater. Lett. 92, 96 (2013). https://doi.org/10.1016/j.matlet.2012.10.058

M. P. Rao, J. J. Wu, A. M. Asiri, et al., J. Environ. Sci. (China) 69, 115 (2018). https://doi.org/10.1016/j.jes.2017.05.005

K. Sahu, S. Choudhary, S. A. Khan, et al., Nano-Struct. Nano-Objects 17, 92 (2019). https://doi.org/10.1016/j.nanoso.2018.12.005

L. Arfaoui, F. Janene, S. Kouass, et al., Russ. J. Inorg. Chem. 64, 1687 (2019). https://doi.org/10.1134/S0036023619130060

ACKNOWLEDGMENTS

The authors thank the Program in Chemistry, Faculty of Science and Technology, Uttaradit Rajabhat University, Uttaradit, Thailand, for the use of its research equipment.

Funding

The authors acknowledged the National Research Council of Thailand (NRCT) for its financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare no conflicts of interest.

Rights and permissions

About this article

Cite this article

Jansanthea, P., Saovakon, C., Chomkitichai, W. et al. Thiamethoxam Insecticide Degradation with a Leaf-Like Cupric Oxide Monoclinic Structure Synthesized via the Microwave Method. Russ. J. Inorg. Chem. 66, 667–678 (2021). https://doi.org/10.1134/S0036023621050089

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036023621050089