Abstract

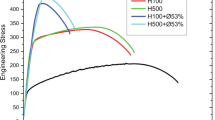

T8 treatment includes solution treatment, cold working and artificial aging treatment. T8 treatment can greatly improve the hardness and strength of 2024 aluminum alloy without reducing the corrosion resistance. The effect of 0, 1, 2, 3, and 4% cold-drawing deformation on the microstructures of the alloy was observed by transmission electron microscopy, and properties of the alloy was investigated by hardness tests, tensile tests and electrochemical corrosion tests. The results show that the mechanical properties and corrosion resistance of cold-drawing deformed 2024 aluminum alloy are better than those of non-deformed alloy. Compared with AA2024-T6, AA2024-T8 with 2% cold-drawing deformation has a higher hardness by 11.3%, and a higher tensile strength by 10.8%. The improvement of the properties of AA2024-T8 is mainly due to the interaction between dislocations and precipitates. With the increase in cold-drawing deformation, the nucleation points of precipitates in AA2024-T8 gradually increase, and precipitates are gradually coarsened under the same artificial aging treatment.

Similar content being viewed by others

REFERENCES

C. Fan, L. Ou, Z. Hu, J. Yang, and X. Chen, “Re-dissolution and re-precipitation behavior of nano-precipitated phase in Al−Cu−Mg alloy subjected to rapid cold stamping,” Trans. Nonferrous Met. Soc. China 29, 2455–2462 (2019). https://doi.org/10.1016/s1003-6326(19)65153-8

Y. Liu, F. Teng, F. H. Cao, Z. X. Yin, Y. Jiang, S. B. Wang, and P. K. Shen, “Defective GP-zones and their evolution in an Al–Cu–Mg alloy during high-temperature aging,” J. Alloys Compd. 774, 988–996 (2019). https://doi.org/10.1016/j.jallcom.2018.10.061

M. H. Ghoncheh, S. G. Shabestari, A. Asgari, and M. Karimzadeh, “Nonmechanical criteria proposed for prediction of hot tearing sensitivity in 2024 aluminum alloy,” Trans. Nonferrous Met. Soc. China 28, 848–857 (2018). https://doi.org/10.1016/s1003-6326(18)64718-1

M.-L. De Bonfils-Lahovary, L. Laffont, and C. Blanc, “Characterization of intergranular corrosion defects in a 2024 T351 aluminium alloy,” Corros. Sci. 119, 60–67 (2017). https://doi.org/10.1016/j.corsci.2017.02.020

F. M. Queiroz, M. Terada, A. F. S. Bugarin, H. G. De Melo, and I. Costa, “Comparison of corrosion resistance of the AA2524-T3 and the AA2024-T3,” Metals 11, 980 (2021). https://doi.org/10.3390/met11060980

F. Z. Lemmadi, A. Chala, O. Belahssen, and S. Benramache, “Effect of heat treatments on structural, microstructural and mechanical properties of Al 2017 alloy,” Phys. Met. Metallogr. 117, 83–88 (2016). https://doi.org/10.1134/s0031918x16010099

C. Rockenhäuser, C. Rowolt, B. Milkereit, R. Darvishi Kamachali, O. Kessler, and B. Skrotzki, “On the long-term aging of S-phase in aluminum alloy 2618A,” J. Mater. Sci. 56, 8704–8716 (2021). https://doi.org/10.1007/s10853-020-05740-x

S. Sun, Yi. Fang, L. Zhang, C. Li, and S. Hu, “Effects of aging treatment and peripheral coarse grain on the exfoliation corrosion behaviour of 2024 aluminium alloy using SR-CT,” J. Mater. Res. Technol. 9, 3219–3229 (2020). https://doi.org/10.1016/j.jmrt.2020.01.069

W. Shi, H. Zhou, and X. Zhang, “High-strength and anti-corrosion of Al–Cu–Mg alloy by controlled ageing process,” Philos. Mag. Lett. 99, 235–242 (2019). https://doi.org/10.1080/09500839.2019.1662960

Y. C. Lin, G. Liu, M.-S. Chen, J.-L. Zhang, Zh.-G. Chen, Yu-Q. Jiang, and J. Li, “Corrosion resistance of a two-stage stress-aged Al–Cu–Mg alloy: Effects of external stress,” J. Alloys Compd. 661, 221–230 (2016). https://doi.org/10.1016/j.jallcom.2015.11.173

H. He, Yo. Yi, S. Huang, W. Guo, and Yu. Zhang, “Effects of thermomechanical treatment on grain refinement, second-phase particle dissolution, and mechanical properties of 2219 Al alloy,” J. Mater. Process. Technol. 278, 116506 (2020). https://doi.org/10.1016/j.jmatprotec.2019.116506

H. Li, W. Xu, Z. Wang, B. Fang, R. Song, and Z. Zheng, “Effects of re-ageing treatment on microstructure and tensile properties of solution treated and cold-rolled Al–Cu–Mg alloys,” Mater. Sci. Eng., A 650, 254–263 (2016). https://doi.org/10.1016/j.msea.2015.10.051

Y. J. Huang, Z. G. Chen, and Z. Q. Zheng, “A conventional thermo-mechanical process of Al–Cu–Mg alloy for increasing ductility while maintaining high strength,” Scr. Mater. 64, 382–385 (2011). https://doi.org/10.1016/j.scriptamat.2010.10.037

X.-Ya. Liu, Zh.-P. Wang, Q.-Sh. Li, X.-L. Zhang, H.‑X. Cui, and X.-L. Zhang, “Effects of pre-deformation on microstructure and properties of Al–Cu–Mg–Ag heat-resistant alloy,” J. Cent. S. Univ. 24, 1027–1033 (2017). https://doi.org/10.1007/s11771-017-3505-x

H. Wang, Yo. Yi, and S. Huang, “Influence of pre-deformation and subsequent ageing on the hardening behavior and microstructure of 2219 aluminum alloy forgings,” J. Alloys Compd. 685, 941–948 (2016). https://doi.org/10.1016/j.jallcom.2016.06.111

X. Li, K. Lei, P. Song, X. Liu, F. Zhang, J. Li, and J. Chen, “Strengthening of aluminum alloy 2219 by thermo-mechanical treatment,” J. Mater. Eng. Perform. 24, 3905–3911 (2015). https://doi.org/10.1007/s11665-015-1665-0

T. S. Parel, S. C. Wang, and M. J. Starink, “Hardening of an Al–Cu–Mg alloy containing Types I and II S phase precipitates,” Mater. Des. 31, S2–S5 (2010). https://doi.org/10.1016/j.matdes.2009.12.048

A. Balbo, A. Frignani, V. Grassi, and F. Zucchi, “Electrochemical behaviour of AA2198 and AA2139 in neutral solutions,” Mater. Corros. 66, 796–802 (2015). https://doi.org/10.1002/maco.201408059

L. Huang, K. Chen, and S. Li, “Influence of grain-boundary pre-precipitation and corrosion characteristics of inter-granular phases on corrosion behaviors of an Al–Zn–Mg–Cu alloy,” Mater. Sci. Eng., B 177, 862–868 (2012). https://doi.org/10.1016/j.mseb.2012.04.008

K. S. Ghosh and K. Tripati, “Microstructural characterization and electrochemical behavior of AA2014 Al-Cu–Mg–Si alloy of various tempers,” J. Mater. Eng. Perform. 27, 5926–5937 (2018). https://doi.org/10.1007/s11665-018-3694-y

U. Donatus, R. M. da Silva, J. V. de Sousa Araujo, M. X. Milagre, C. P. de Abreu, C. de Souza Carvalho Machado, and I. Costa, “Macro and microgalvanic interactions in friction stir weldment of AA2198-T851 alloy,” J. Mater. Res. Technol. 8, 6209–6222 (2019). https://doi.org/10.1016/j.jmrt.2019.10.015

S. Chen, K. Chen, G. Peng, L. Jia, and P. Dong, “Effect of heat treatment on strength, exfoliation corrosion and electrochemical behavior of 7085 aluminum alloy,” Mater. Des. 35, 93–98 (2012). https://doi.org/10.1016/j.matdes.2011.09.033

L. Wen, Ya. Wang, Yu. Zhou, J. Ouyang, L. Guo, and D. Jia, “Corrosion evaluation of microarc oxidation coatings formed on 2024 aluminium alloy,” Corros. Sci. 52, 2687–2696 (2010). https://doi.org/10.1016/j.corsci.2010.04.022

K. Wang, R. Su, T. Liu, Yi. Qu, and R. Li, “Electrochemical assessment of laser heat treatment of an Al–Zn–Mg–Cu alloy,” Mater. Corros. 71, 374–381 (2020). https://doi.org/10.1002/maco.201911154

S. Wang and M. Starink, “Precipitates and intermetallic phases in precipitation hardening Al–Cu–Mg–(Li) based alloys,” Int. Mater. Rev. 50, 193–215 (2005). https://doi.org/10.1179/174328005x14357

H.-Zh. Li, R.-M. Liu, X.-P. Liang, M. Deng, H.-J. Liao, and L. Huang, “Effect of pre-deformation on microstructures and mechanical properties of high purity Al–Cu–Mg alloy,” Trans. Nonferrous Met. Soc. China 26, 1482–1490 (2016). https://doi.org/10.1016/s1003-6326(16)64253-x

S. C. Wang and M. J. Starink, “Two types of S phase precipitates in Al–Cu–Mg alloys,” Acta Mater. 55, 933–941 (2007). https://doi.org/10.1016/j.actamat.2006.09.015

R. Oltra, B. Vuillemin, F. Rechou, and C. Henon, “Effect of aeration on the microelectrochemical characterization of Al2Cu intermetallic phases,” Electrochem. Solid-State Lett. 12, C29–C31 (2009). https://doi.org/10.1149/1.3224876

M. Araghchi, H. Mansouri, R. Vafaei, and Yi. Guo, “A novel cryogenic treatment for reduction of residual stresses in 2024 aluminum alloy,” Mater. Sci. Eng., A 689, 48–52 (2017). https://doi.org/10.1016/j.msea.2017.01.095

R. K. W. Marceau, G. Sha, R. N. Lumley, and S. P. Ringer, “Evolution of solute clustering in Al–Cu–Mg alloys during secondary ageing,” Acta Mater. 58, 1795–1805 (2010). https://doi.org/10.1016/j.actamat.2009.11.021

R. K. W. Marceau, G. Sha, R. Ferragut, A. Dupasquier, and S. P. Ringer, “Solute clustering in Al–Cu–Mg alloys during the early stages of elevated temperature ageing,” Acta Mater. 58, 4923–4939 (2010). https://doi.org/10.1016/j.actamat.2010.05.020

S. C. Wang, M. J. Starink, and N. Gao, “Precipitation hardening in Al–Cu–Mg alloys revisited,” Scr. Mater. 54, 287–291 (2006). https://doi.org/10.1016/j.scriptamat.2005.09.010

M. J. Starink and S. C. Wang, “The thermodynamics of and strengthening due to co-clusters: General theory and application to the case of Al–Cu–Mg alloys,” Acta Mater. 57, 2376–2389 (2009). https://doi.org/10.1016/j.actamat.2009.01.021

L. C. Abodi, J. A. DeRose, S. Van Damme, A. Demeter, T. Suter, and J. Deconinck, “Modeling localized aluminum alloy corrosion in chloride solutions under non-equilibrium conditions: Steps toward understanding pitting initiation,” Electrochim. Acta 63, 169–178 (2012). https://doi.org/10.1016/j.electacta.2011.12.074

R. Su, S. Ma, K. Wang, G. Li, Yi. Qu, and R. Li, “Effect of cyclic deep cryogenic treatment on corrosion resistance of 7075 alloy,” Met. Mater. Int. 28, 862–870 (2022). https://doi.org/10.1007/s12540-021-00975-y

Funding

This research was financially supported by the Liaoning Natural Science Foundation (2021-MS-235), the Science and Technology Program of Liaoning Provincial Department of Education (LJGD2020010) and the National Nature Science Foundation of China (51775353).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors of this work declare that they have no conflicts of interest.

Additional information

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jia, Y.X., Su, R.M., Zhang, W.J. et al. Effect of Cold-Drawing Deformation on the Microstructure and Properties of AA2024-T8. Phys. Metals Metallogr. 124, 1501–1508 (2023). https://doi.org/10.1134/S0031918X22100362

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0031918X22100362