Abstract

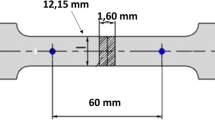

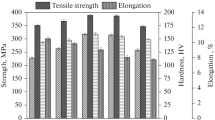

AA2024 was developed to investigate how heat treatment might affect its mechanical and corrosion characteristics. The samples underwent different heat treatment processes: three solution heat treatments at 495 °C for 2 h followed by natural aging for 5 days, and two artificial aging treatments, one at 190 °C for 2.5 h and the other at 130 °C for 6 h. After the heat treatments, all samples were immersed in a 3% Nacl salt solution for a total of 2880 h. The metallurgical characterization of the samples was performed using optical microscopy, and scanning electron microscopy. The observations revealed the formation of corrosion product nodules on some samples, while others showed pitting corrosion, and one sample (T6) experienced intergranular corrosion. Moreover, the microstructural analysis indicated an evolution of dimples in the AA2024 T4 alloy, along with the development of fine grains compared to the non-heat-treated samples. Mechanical characterization was carried out using a Vickers hardness tester and a tensile testing machine. The Vickers hardness test showed that the AA2024 T4 sample exhibited the highest hardness value (Hv = 145) compared to the other samples. However, the tensile strength of the AA2024 alloy decreased from 512.20 MPa to 411.02 MPa after the T4 heat treatment. The yield strength (YS) and elongation properties also experienced changes after the heat treatments.

Similar content being viewed by others

References

Read « Aging of U.S. Air Force Aircraft: Final Report » at NAP.edu. https://doi.org/10.17226/5917

Yumpu.com, Success Stories: Air Force: Material Substitution and New Sealing ..., yumpu.com. https://www.yumpu.com/en/document/view/43390696/success-stories-air-force-material-substitution-and-new-sealing-/3. Accessed 16 Aug 2023

Aluminum: Properties and Physical Metallurgy - ASM International | ASM International. https://www.asminternational.org/home/-/journal_content/56/10192/06236G/PUBLICATION/. Accessed 16 Aug 2023

Metallurgical factors affecting fracture toughness of aluminum alloys | SpringerLink. https://link.springer.com/article/10.1007/BF02672285. Accessed 16 Aug 2023

Luo C, Zhou X, Thompson GE, Hughes AE et al (2012) Observations of intergranular corrosion in AA2024-T351: The influence of grain stored energy. Corros Sci 61:35–44. https://doi.org/10.1016/j.corsci.2012.04.005

The effect of solution treatment on aging behavior and mechanical properties of AA2024-TiB2 composite synthesized by semi-solid casting | SpringerLink. https://link.springer.com/article/10.1007/s42452-019-1531-z. consulté le 11 avril 2023

Foundations of Materials Science and Engineering 3RD EDITION

GORE® SKYFLEX® Aerospace Materials for Civil & Military Applications, Gore. https://www.gore.com/SKYFLEX-Aerospace-Materials. consulté le 11 avril 2023

Dilmeç M, Arikan H et al (2014) Effect of Solution Heat Treatment Conditions on the Mechanical Properties and Formability for AA 2024 Alloy. Appl Mech Mater 686:3–9. https://doi.org/10.4028/www.scientific.net/AMM.686.3

Hutchinson CR, Ringer SP et al (2000) Precipitation processes in Al-Cu-Mg alloys microalloyed with Si. Metall Mater Trans A 31(11):2721–2733. https://doi.org/10.1007/BF02830331

Elgallad E, Shen P, Zhang Z, Chen X-G et al (2014) Effects of heat treatment on the microstructure and mechanical properties of AA2618 DC cast alloy. Mater Des 61:133–140. https://doi.org/10.1016/j.matdes.2014.04.045

Siqueira M, Silva A, Melo MDL, Rodrigues G et al (2019) Mechanical properties analysis of Al2024 alloy submitted to different aging time and different cold plastic deformation degree. Mater Res 22. https://doi.org/10.1590/1980-5373-mr-2018-0598

Alodan MA, Smyrl WH et al (1998) Detection of localized corrosion of aluminum alloys using fluorescence microscopy. J Electrochem Soc 145(5):1571. https://doi.org/10.1149/1.1838520

Knight SP, Salagaras M, Wythe AM, De Carlo F, Davenport AJ, Trueman AR et al (2010) In situ X-ray tomography of intergranular corrosion of 2024 and 7050 aluminium alloys. Corros Sci 52(12):3855–3860. https://doi.org/10.1016/j.corsci.2010.08.026

Sehgal A, Frankel GS, Zoofan B, Rokhlin S et al (2000) Pit growth study in Al alloys by the foil penetration technique. J Electrochem Soc 147(1):140. https://doi.org/10.1149/1.1393167

Robinson MJ, Jackson NC et al (1999) The influence of grain structure and intergranularcorrosion rate on exfoliation and stress corrosion crackingof high strength Al–Cu–Mg alloys. Corros Sci 41(5):1013–1028. https://doi.org/10.1016/S0010-938X[98)00171-1

Liu X, Frankel GS, Zoofan B, Rokhlin SI et al (2004) Effect of applied tensile stress on intergranular corrosion of AA2024-T3. Corros Sci 46(2):405–425. https://doi.org/10.1016/S0010-938X[03)00149-5

Liu X, Frankel G et al (2006) Effects of compressive stress on localized corrosion in AA2024-T3. Corros Sci 48:3309–3329. https://doi.org/10.1016/j.corsci.2005.12.003

Transition from Intergranular Corrosion to Intergranular Stress Corrosion Cracking in AA2024-T3 - IOPscience. https://iopscience.iop.org/article/10.1149/1.2142288/meta. Accessed 16 Aug 2023

Empirical Propagation Laws of Intergranular Corrosion Defects Affecting 2024 T351 Alloy in Chloride Solutions | Request PDF. https://www.researchgate.net/publication/277678917_Empirical_Propagation_Laws_of_Intergranular_Corrosion_Defects_Affecting_2024_T351_Alloy_in_Chloride_Solutions. Accessed 16 Aug 2023

Larignon C, Alexis J, Andrieu E, Blanc C, Odemer G, Salabura J-C et al (2011) Corrosion damages induced by cyclic exposure of 2024 aluminum alloy in chloride-containing environments. J Electrochem Soc 158:C284–C295. https://doi.org/10.1149/1.3610401

Liao C-M, Wei RP (1999) Galvanic coupling of model alloys to aluminum—a foundation for understanding particle-induced pitting in aluminum alloys. Electrochim Acta 45:881–888

Buchheit RG, Grant RP, Hlava PF, Mckenzie B, Zender GL (1997) Local dissolution phenomena associated with S phase (Al2CuMg) particles in aluminum alloy 2024–T3. J Electrochem Soc 144:2621

Boag A, Hughes AE, Glenn AM, Muster TH, McCulloch D (2011) Corrosion of AA2024-T3 Part I: Localised corrosion of isolated IM particles. Corros Sci 53:17–26

Deng YHG, Deng Yanjun HG et al (2018) Effect of pre-deformation on the second phase precipitation and mechanical properties of Al-Cu-Li-Mn-Zr alloys. Mater Guide 32(4):569–573. https://doi.org/10.11896/j.issn.1005-023X.2018.04.012

Garchani FEE, Kabiri MR et al (2023) The study on characteristics of heat treatment of the AA2024 aluminum alloys. J Multidiscip Appl Nat Sci 3(2). https://doi.org/10.47352/jmans.2774-3047.166

Shimizu K, Brown GM, Kobayashi K, Skeldon P, Thompson GE, Wood GC et al (1998) Ultramicrotomy—a route towards the enhanced understanding of the corrosion and filming behaviour of aluminium and its alloys. Corros Sci 40(7):1049–1072. https://doi.org/10.1016/S0010-938X[98)00006-7

Corrosion Behaviour of Different Tempers of AA7075 Aluminium Alloy | Request PDF. https://www.researchgate.net/publication/223725147_Corrosion_Behaviour_of_Different_Tempers_of_AA7075_Aluminium_Alloy. consulté le 22 juillet 2022

(1999) Galvanic coupling of model alloys to aluminum — a foundation for understanding particle-induced pitting in aluminum alloys. Electrochimica Acta 45(6): 881-888. https://doi.org/10.1016/S0013-4686[99)00299-6

Buchheit R, Grant RP, Hlava P, McKenzie B, Zender G et al (1997) Local Dissolution Phenomena Associated with S Phase [Al2CuMg) Particles in Aluminum Alloy 2024‐T3. https://doi.org/10.1149/1.1837874

El Garchani FE et al (2023) Effects of heat treatment on the corrosion behavior and mechanical properties of aluminum alloy 2024. J Mater Res Technol 25:1355–1363. https://doi.org/10.1016/j.jmrt.2023.05.278

Ge F, Zhang L, Tian H, Yu M, Liang J, Wang X et al (2020) Stress corrosion cracking behavior of 2024 and 7075 high-strength aluminum alloys in a simulated marine atmosphere contaminated with SO2. J Mater Eng Perform 29(1):410–422. https://doi.org/10.1007/s11665-019-04537-7

[PDF) Local Hydrogen Enrichment Induced by Corrosion in a 2024 Aluminum Alloy. https://www.researchgate.net/publication/233852819_Local_Hydrogen_Enrichment_Induced_by_Corrosion_in_a_2024_Aluminum_Alloy. Accessed 16 Aug 2023

Zhang X, Song R, Sun B et al (2018) Effects of aging treatment on intergranular corrosion and stress corrosion cracking behavior of AA7003. J Wuhan Univ Technol-Mat Sci Edit 33(5):1198–1204. https://doi.org/10.1007/s11595-018-1953-2

Dwivedi SP, Ashok Kumar MV, Mishra R (2019) Effect of MgO addition on physico-chemical, mechanical and thermal behaviour of Al/Si3N4 composite material developed via hybrid casting technique. J Ceram Process Res 20(6):632–642

Ilevbare GO, Schneider O, Kelly RG, Scully JR (2004) In Situ Confocal Laser Scanning Microscopy of AA 2024-T3 Corrosion Metrology: I. Localized Corrosion of Particles. J Electrochem Soc 151:B453. https://doi.org/10.1149/1.1764780

Blanc C, Freulon A, Lafont M-C, Kihn Y, Mankowski G (2006) Modelling the corrosion behaviour of Al2CuMg coarse particles in copper-rich aluminium alloys. Corros Sci 48:3838–3851. https://doi.org/10.1016/j.corsci.2006.01.012

Lacroix L, Ressier L, Blanc C, Mankowski G (2008) Combination of AFM, SKPFM, and SIMS to Study the Corrosion Behavior of S-phase particles in AA2024-T351. J Electrochem Soc 155:C131. https://doi.org/10.1149/1.2833315

Hughes AE, Parvizi R, Forsyth M (2015) Microstructure and corrosion of AA2024. Corros Rev 33:1–30. https://doi.org/10.1515/corrrev-2014-0039

Zhang W, Frankel G et al (2003) Transitions between pitting and intergranular corrosion in AA2024. Electrochimica Acta 48:1193–1210. https://doi.org/10.1016/S0013-4686[02)00828-9

Localized corrosion of 2024 T351 aluminium alloy in chloride media | Semantic Scholar. https://www.semanticscholar.org/paper/Localized-corrosion-of-2024-T351-aluminium-alloy-in-Guillaumin-Mankowski/834c060adfd3f00dfa34e108718899537de49981. consulté le 11 avril 2023

Blanc C, Lavelle B, Mankowski G et al (1997) The role of precipitates enriched with copper on the susceptibility to pitting corrosion of the 2024 aluminium alloy. Corros Sci 39(3):495–510. https://doi.org/10.1016/S0010-938X[97)86099-4

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Sample statement

“All authors contributed to the design and development of the study. The preparation of the material, data collection, and analysis were carried out by Fatima Ezzohra El Garchani, and Moulay Rachid Kabiri. The first draft of the manuscript was written by Fatima Ezzohra El Garchani and all authors commented on the previous versions of the manuscript. All authors have read and approved the final manuscript.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

El Garchani, F., Kabiri, M.R. Intergranular corrosion and mechanical property evolution in AA2024 alloy through heat treatment. Int J Adv Manuf Technol 128, 3273–3282 (2023). https://doi.org/10.1007/s00170-023-12161-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12161-y